A film sticking device

A film sticking device and film sticking technology, applied in packaging and other directions, can solve problems such as poor lamination between film and workpiece, achieve uninterrupted and continuous film sticking, reduce film defect rate, and enhance film strength.

Active Publication Date: 2017-04-05

JIANGSU BVM INTELLIGENT TECH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for workpieces whose film surface is not flat, common film laminating devices will have quality problems such as poor lamination of the film and the workpiece.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

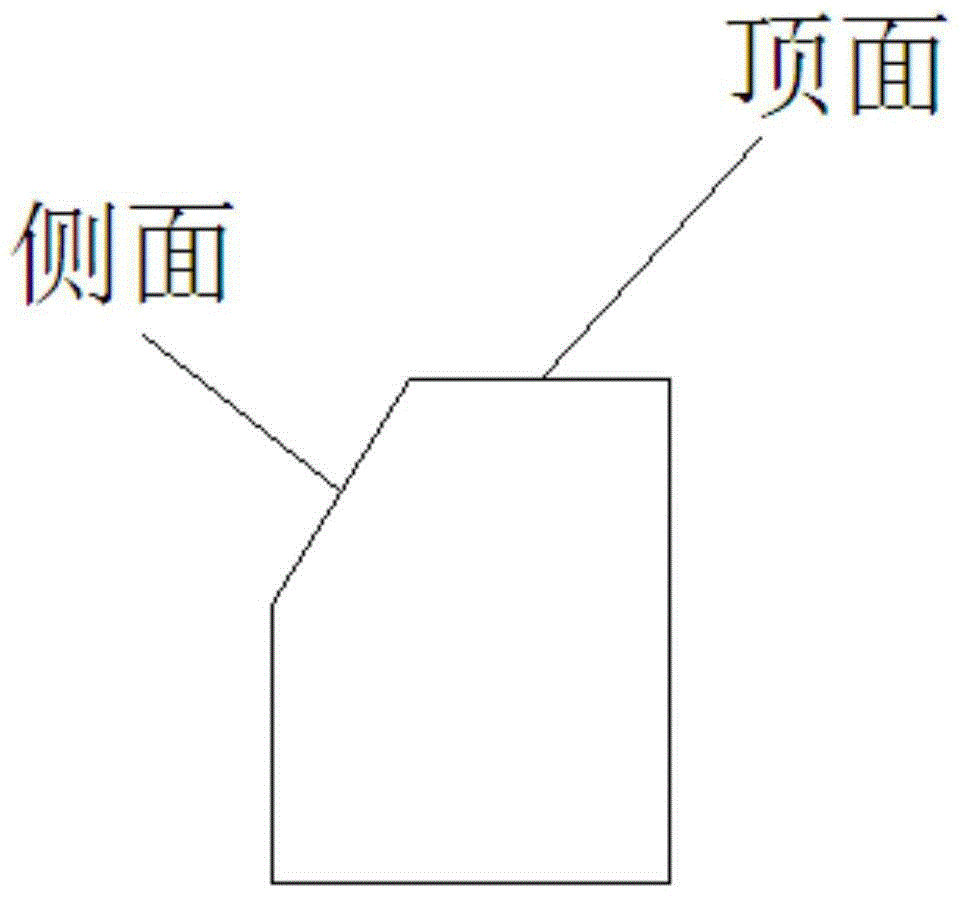

[0016] Specific embodiment: The first filming station and the second filming station of the transposition mechanism are moved back and forth, and the film is applied alternately under the film stripping mechanism station. Each filming station moves to the right to complete the pressing of the top and side surfaces of the workpiece The process, then receiving and loading, and so on.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

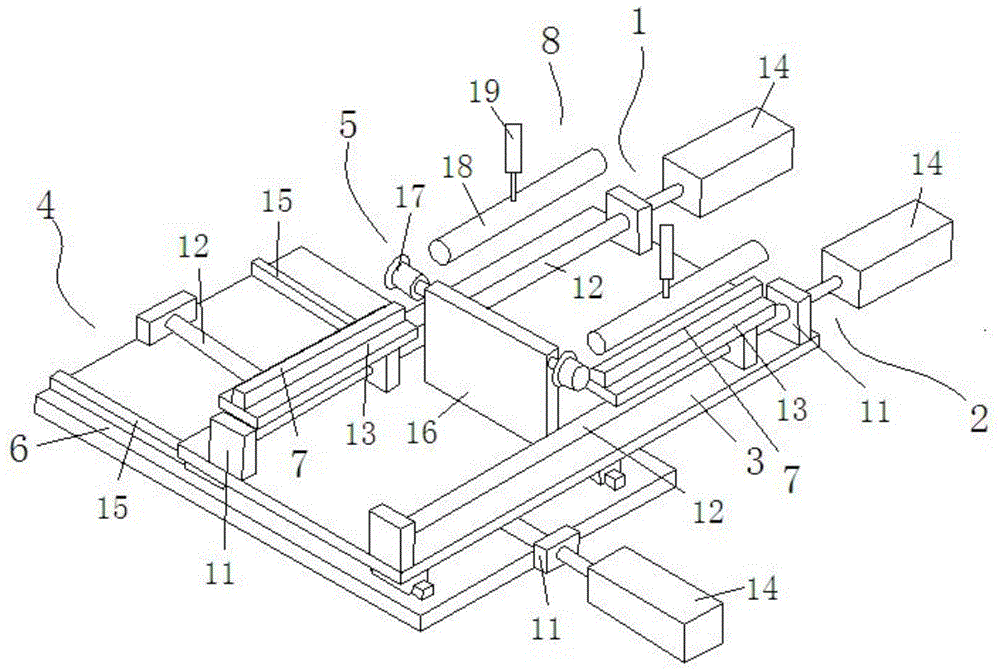

The invention discloses a pad pasting apparatus comprising a first pad pasting work position, a second pad pasting work position, a first base plate, an inversion mechanism and a pad pressing mechanism. The first pad pasting work position and the second pad pasting work position are arranged on the front end and the back end of the first base plate; the first pad pasting work position and the second pad pasting work position both comprises a fixing plate, a lead screw, a work plate and a motor; each work plate can move left to right on the lead screw; the inversion mechanism is formed by a second base plate, a guide rail, a fixing plate, a lead screw and a motor; the bottom surface of the first base plate can move back and forth along the guide rail; and the pad pressing mechanism consists of a positioning plate and a pad pressing roller. With two pad pasting work positions aligned to a pad peeling mechanism, pads can be continuously passed, so pad pasting speed can be improved; besides, with the addition of the pad pressing roller and the side pressing roller, pad pasting speed is enhanced and performance for adaptability to different pressing surfaces is improved; and reject ratio is lowered.

Description

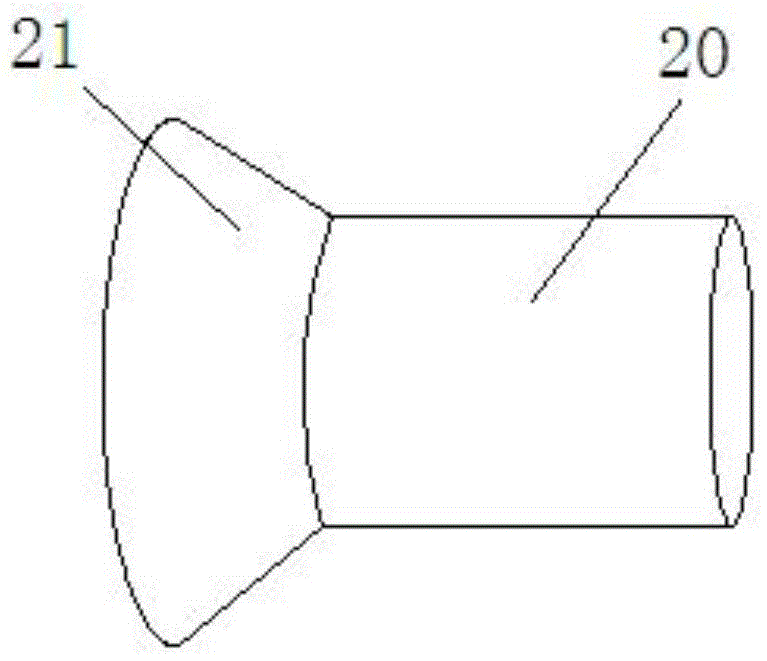

Technical field [0001] The invention relates to a film sticking device, belonging to the technical field of automatic film sticking equipment. Background technique [0002] At present, the workpiece film is the most common process. However, for workpieces whose film surface is not flat, common film application devices will have quality problems that the film and the workpiece are not well pressed. In addition, how to improve the utilization rate of the film stripping machine, in a station, can make the film stripping device to stick the film on the workpiece on the film sticking device without stopping is a problem that this industry needs to solve urgently. Summary of the invention [0003] Purpose: In order to overcome the deficiencies in the prior art, the present invention provides a film sticking device. [0004] Technical solution: In order to solve the above technical problems, the technical solution adopted by the present invention is: [0005] A film sticking device includ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B33/02

CPCB65B33/02

Inventor 李相鹏牛福洲杨浩谢明杨李伟马玮城宦智杰

Owner JIANGSU BVM INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com