Car B-pillar exterior trim panel surface laminating machine

A technology for exterior trim panels and laminating machines, applied in packaging and other directions, can solve the problem of no special equipment, etc., and achieve the effects of convenient operation, liberation of manpower, and reduction of labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

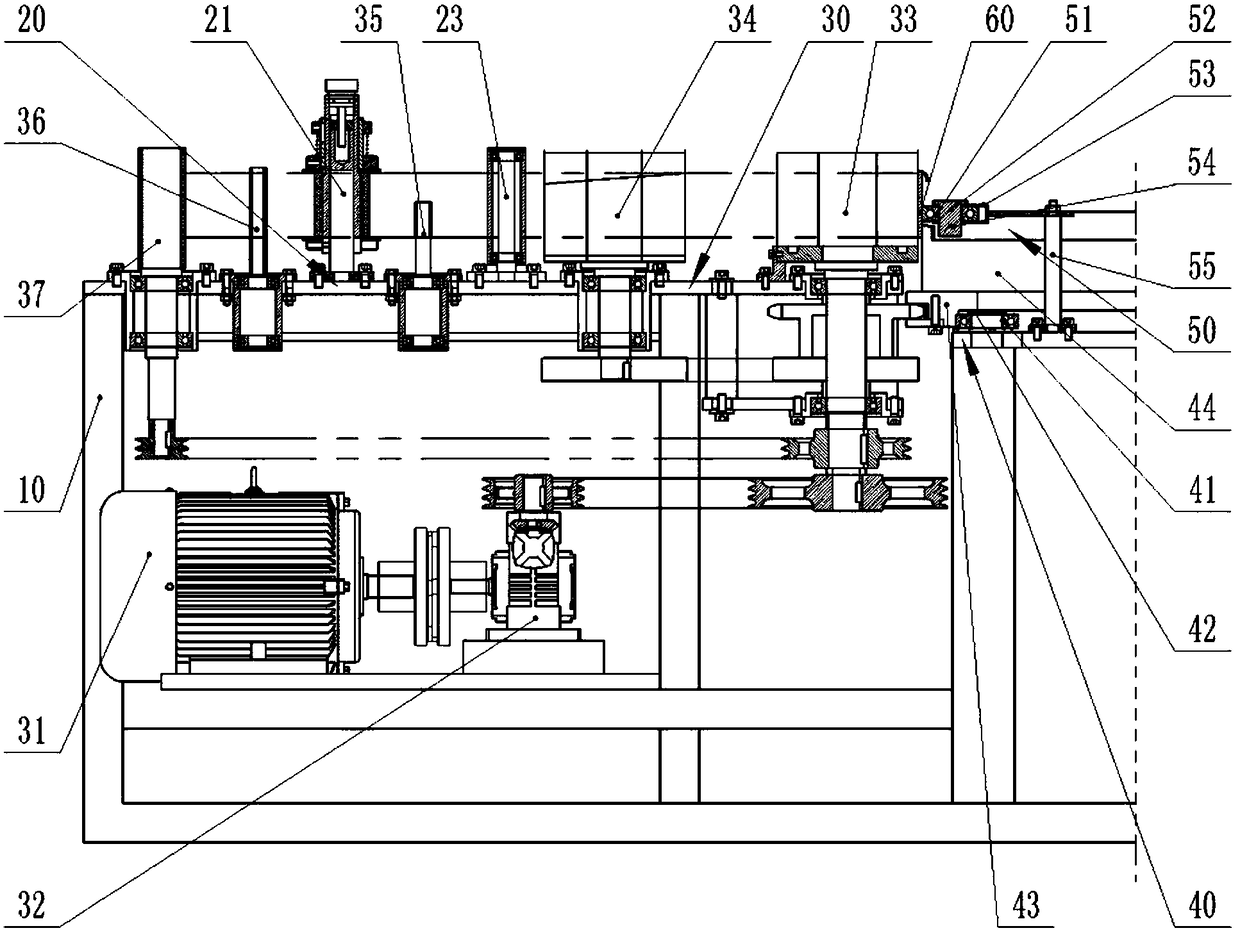

[0041]In the present embodiment, the number of film supply wheels in the feed module 20 described in the automobile B-pillar exterior trim panel surface laminating machine is 2, that is, the first film supply wheel 21 and the second film supply wheel 22; the number of guide wheels is 4, namely the first guide wheel 23, the second guide wheel 24, the third guide wheel 25 and the fourth guide wheel 26; the first film supply wheel 21 and the second film supply wheel 22 are installed side by side on the frame 10 on the left side, the interval between the two is greater than the diameter of the film roll (the film used in this embodiment is in a roll shape and is sleeved on the first film supply wheel 21 and the second film supply wheel 22, and two film supply wheels are arranged For the convenience of changing film rolls without shutting down); the second film supply wheel 22 is positioned at the first film supply wheel 21 rear; the first guide wheel 23, the second guide wheel 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com