Patents

Literature

41results about How to "Improve the accuracy of film application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

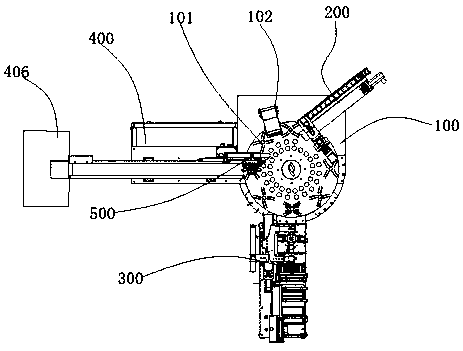

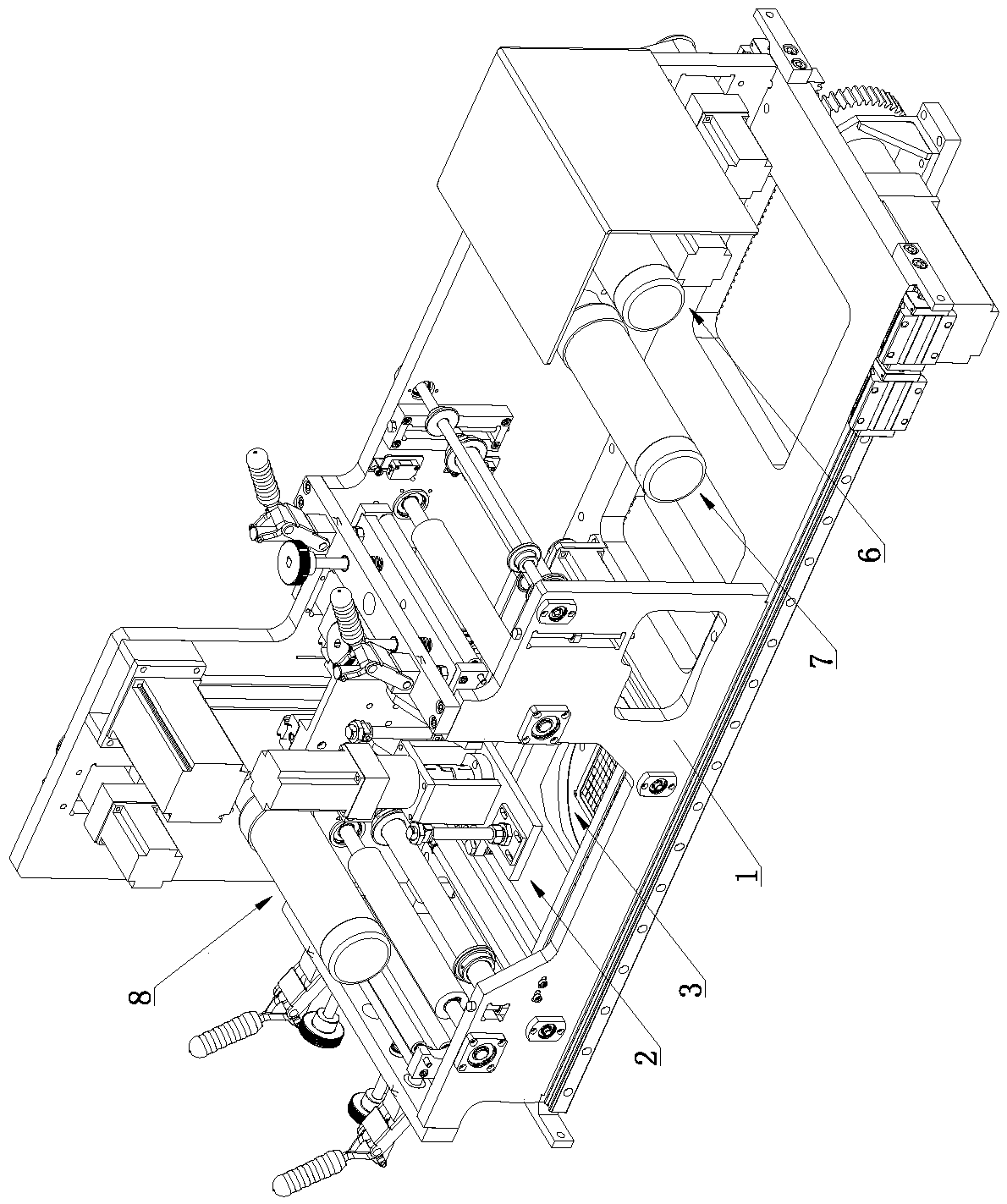

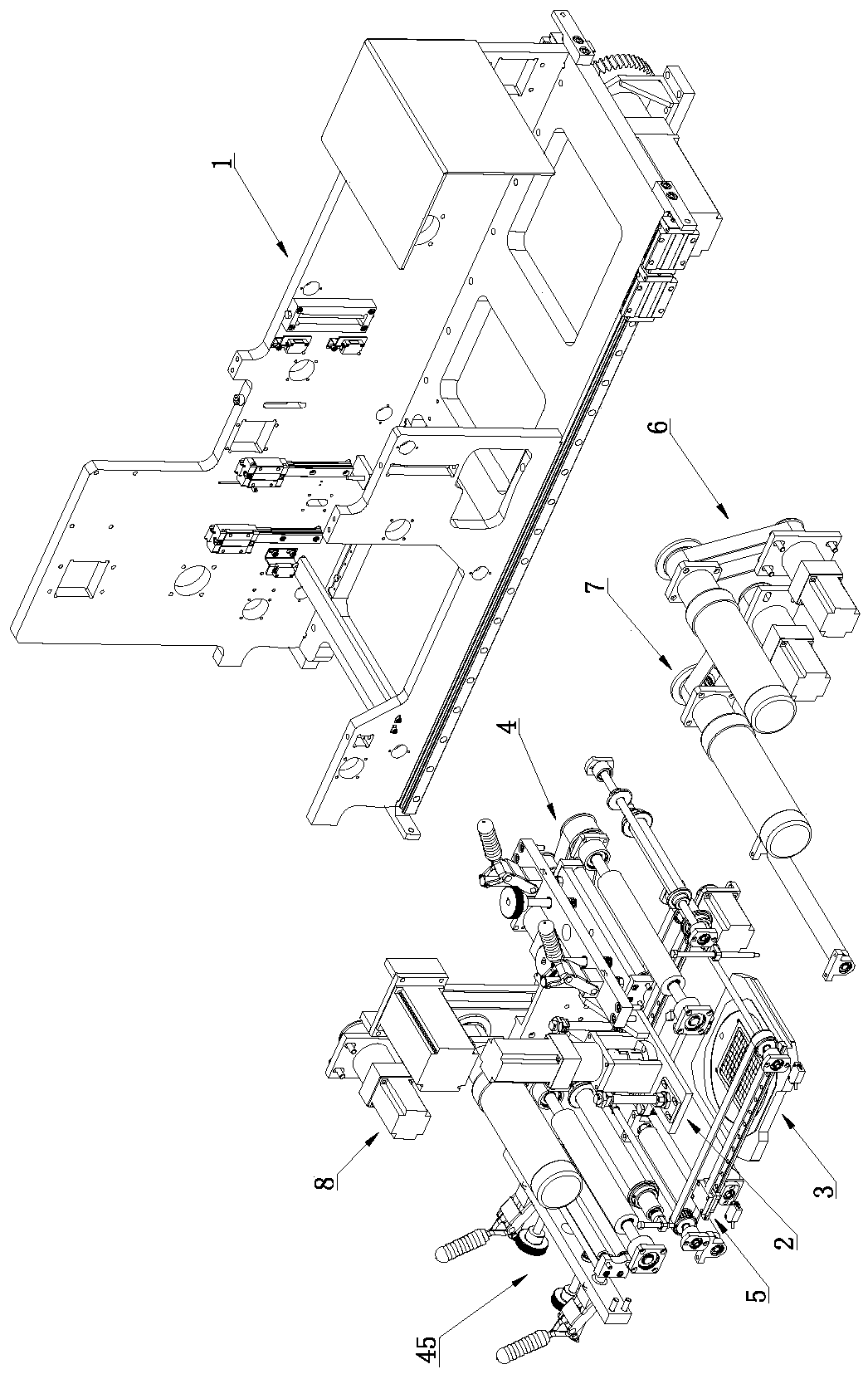

Semi-automatic pad pasting machine

InactiveCN104828283AReduce labor costsImprove film quality and film precisionPackagingManipulatorOne-time pad

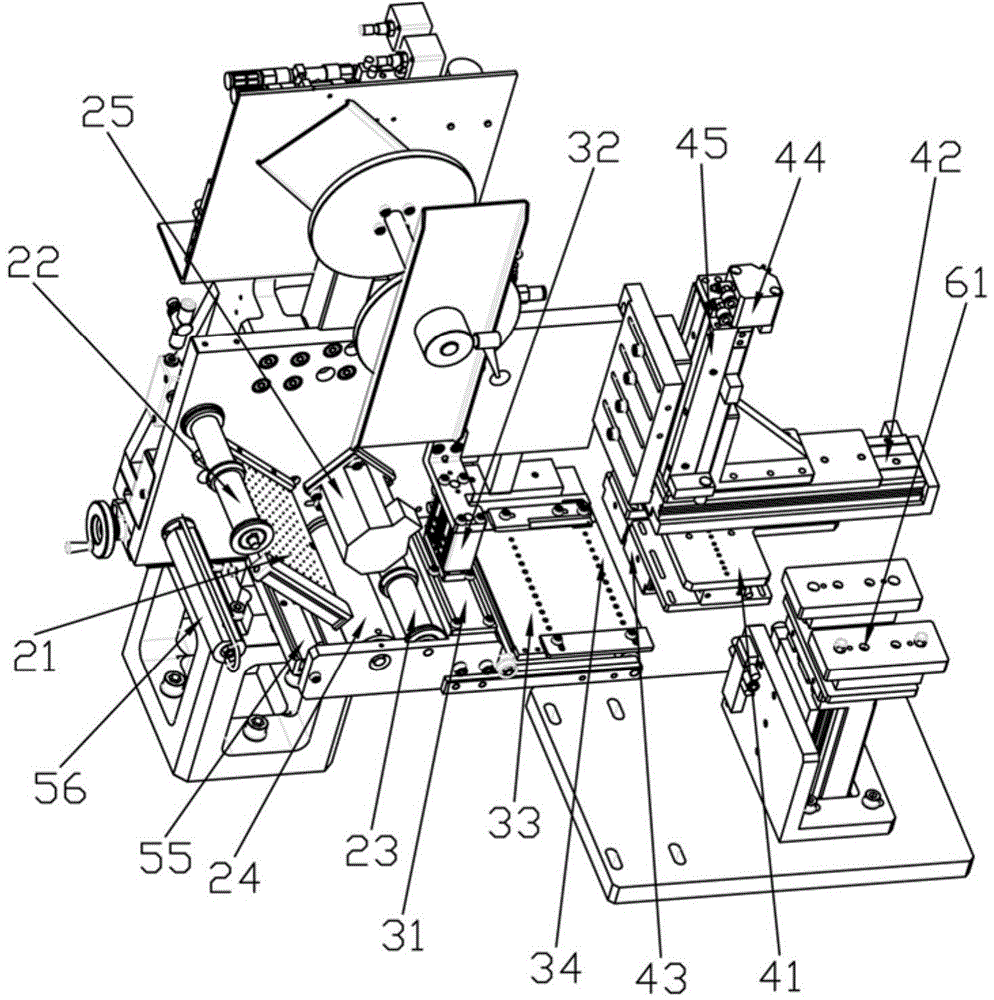

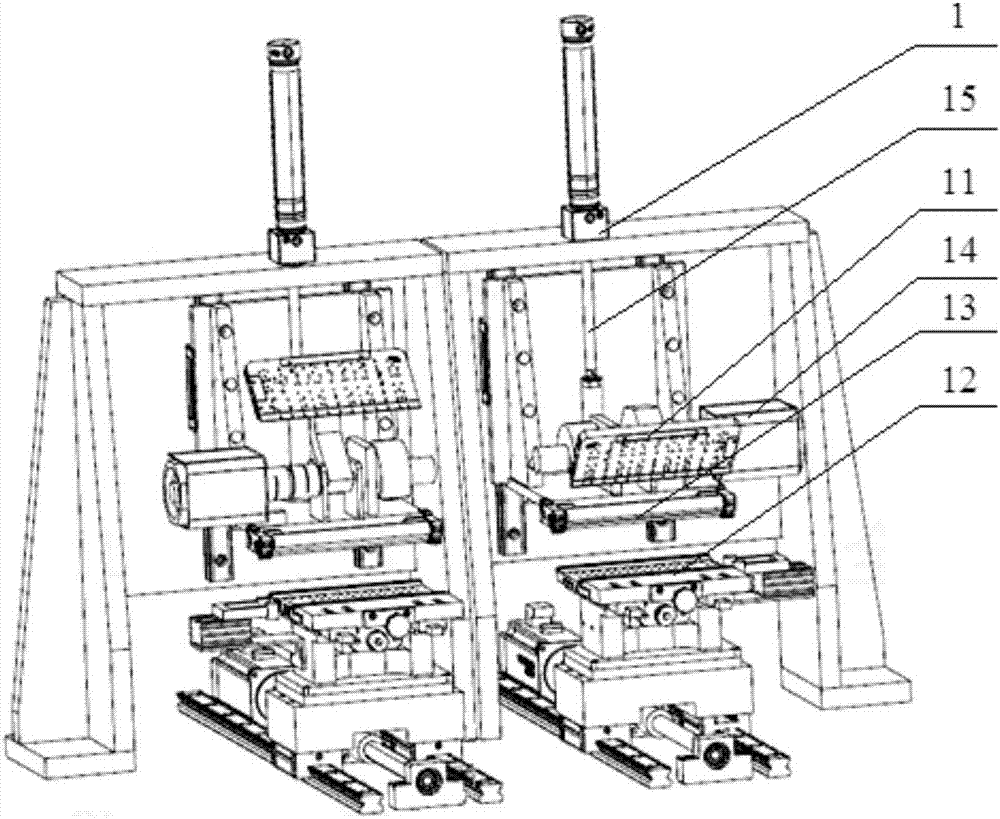

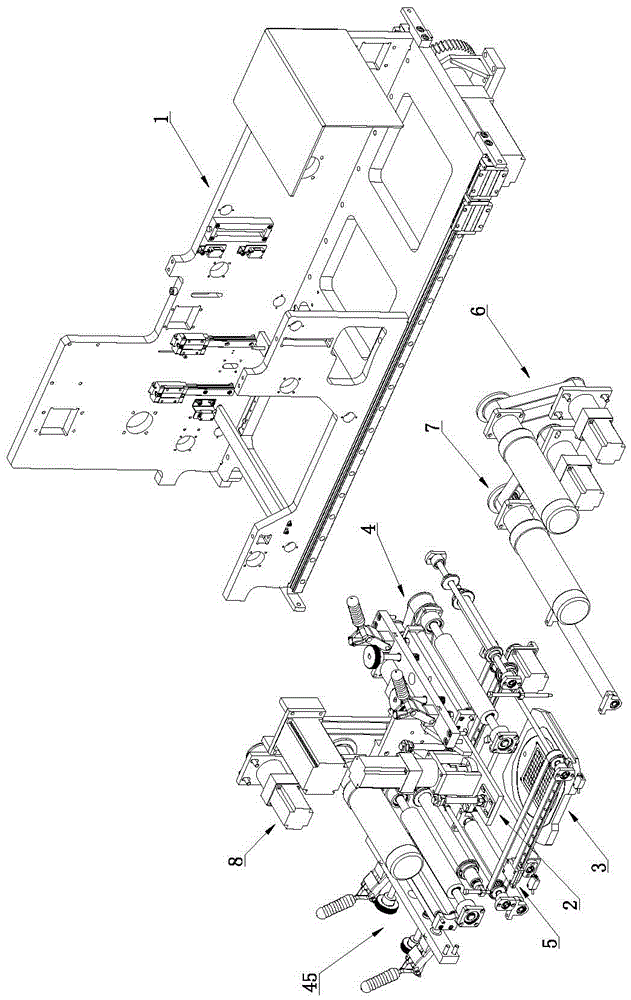

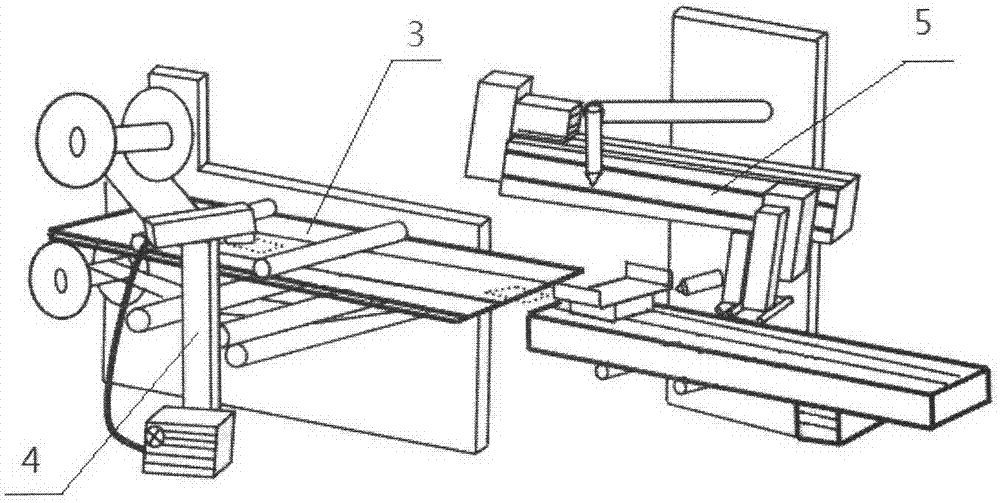

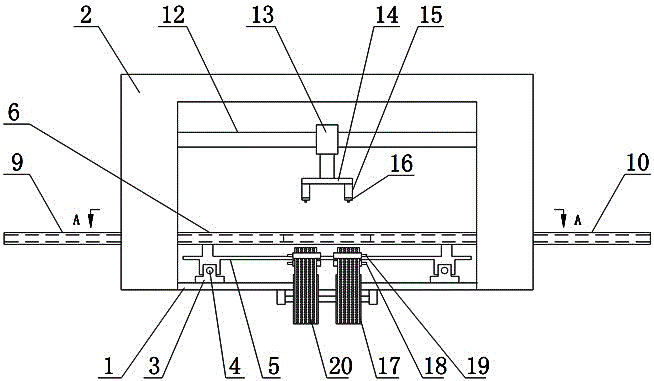

The invention relates to the field of pad pasting, in particular to a semi-automatic pad pasting machine. The semi-automatic pad pasting machine comprises a frame. A feeding mechanism is arranged on the frame. A stripping mechanism is arranged at the portion, located at the output end of the feeding mechanism, of the frame. A waste recycling mechanism is further arranged at the portion, located at the output end of the stripping mechanism, of the frame. A mechanical arm mechanism is arranged at the portion, located at the output end of the stripping mechanism, of the frame and comprises a suction cup assembly used for sucking a to-be-pasted pad, an unfolding assembly used for unfolding the to-be-pasted pad during pad pasting and a bubble removing assembly used for removing bubbles generated during pad pasting, wherein the suction cup assembly, the unfolding assembly and the bubble removing assembly are arranged at the bottom of the mechanical arm mechanism. A pad pasting station is further arranged on the frame and located on the transferring path of the mechanical arm mechanism. According to the semi-automatic pad pasting machine, as the feeding mechanism, the stripping mechanism and the mechanical arm mechanism are arranged to be matched, a user only needs to hang the pad on a hanging roller, the to-be-pasted pad is transferred and pasted through the mechanical arm mechanism, then the waste recycling mechanism carries out assisting to recycle waste, a one-time pad pasting process is completed, and the pad pasting quality and the pad pasting accuracy can be improved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

Film pasting device for 3D glass with two opposite edges as curved edges and film pasting method

ActiveCN107323726AGuaranteed non-interferenceEasy accessPackagingGlass productionEngineeringMechanical engineering

Owner:LENS TECH CHANGSHA

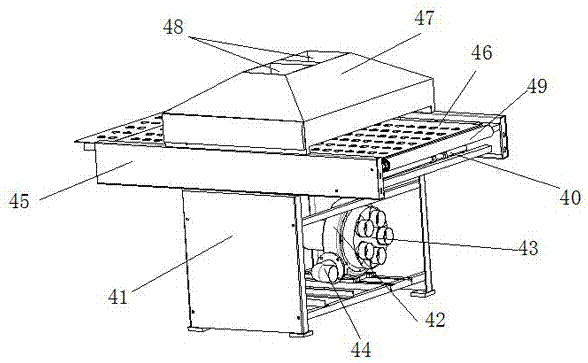

Automatic film covering machine

ActiveCN106379593AAvoid wastingAvoid contaminationWrapping material feeding apparatusMechanical engineeringEngineering

The invention relates to the technical field of film covering, in particular to an automatic film covering machine which comprises a rack, a film cutting device arranged on the rack, a film feeding mechanism used for conveying a film to the lower side of the film cutting device and a film covering device used for pressing a film sheet cut by the film cutting device on the surface of a product; and the film cutting device is composed of a film cutting lifting seat, a cutter mounting plate arranged on the film cutting lifting seat, cutter components arranged on the cutter mounting plate, a film cutting lifting drive mechanism used for driving the film cutting lifting seat to lift up and down and a film cutting rotary drive mechanism used for driving the cutter mounting plate to rotationally cut the film. According to the automatic film covering machine, feeding and rotary cutting of the film are automatically carried out, film covering is carried out on the cut film sheet, and the size of the cut film can be regulated online according to the size of the product, thus the film sheet is prevented from wasting, the film is cut when being adhered, the time of transferring the film sheet is shortened, the film sheet is also prevented from being polluted, the film adhering accuracy and the production efficiency are improved, and the rate of a good product is increased.

Owner:东莞市豪斯特热冲压技术有限公司

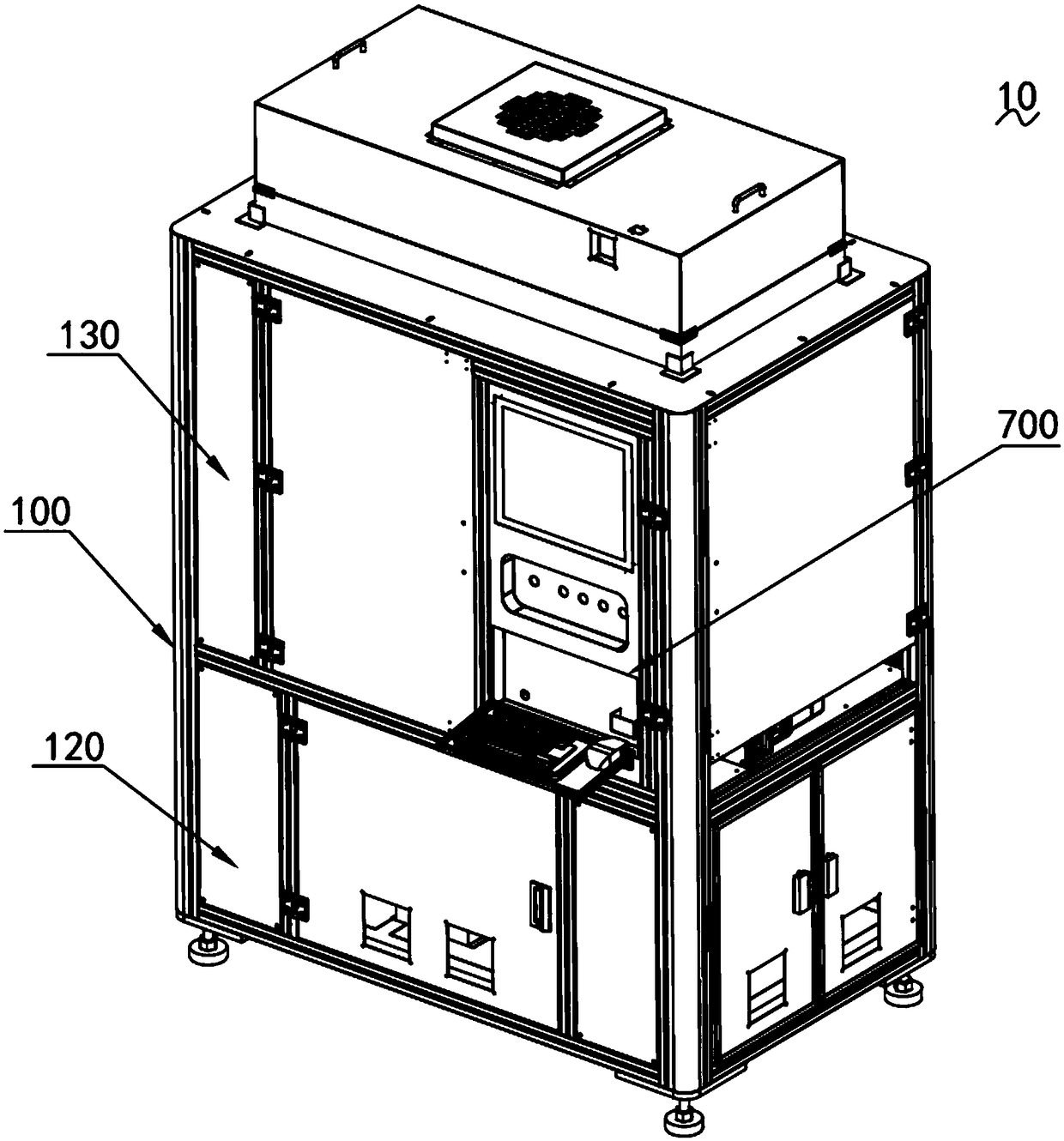

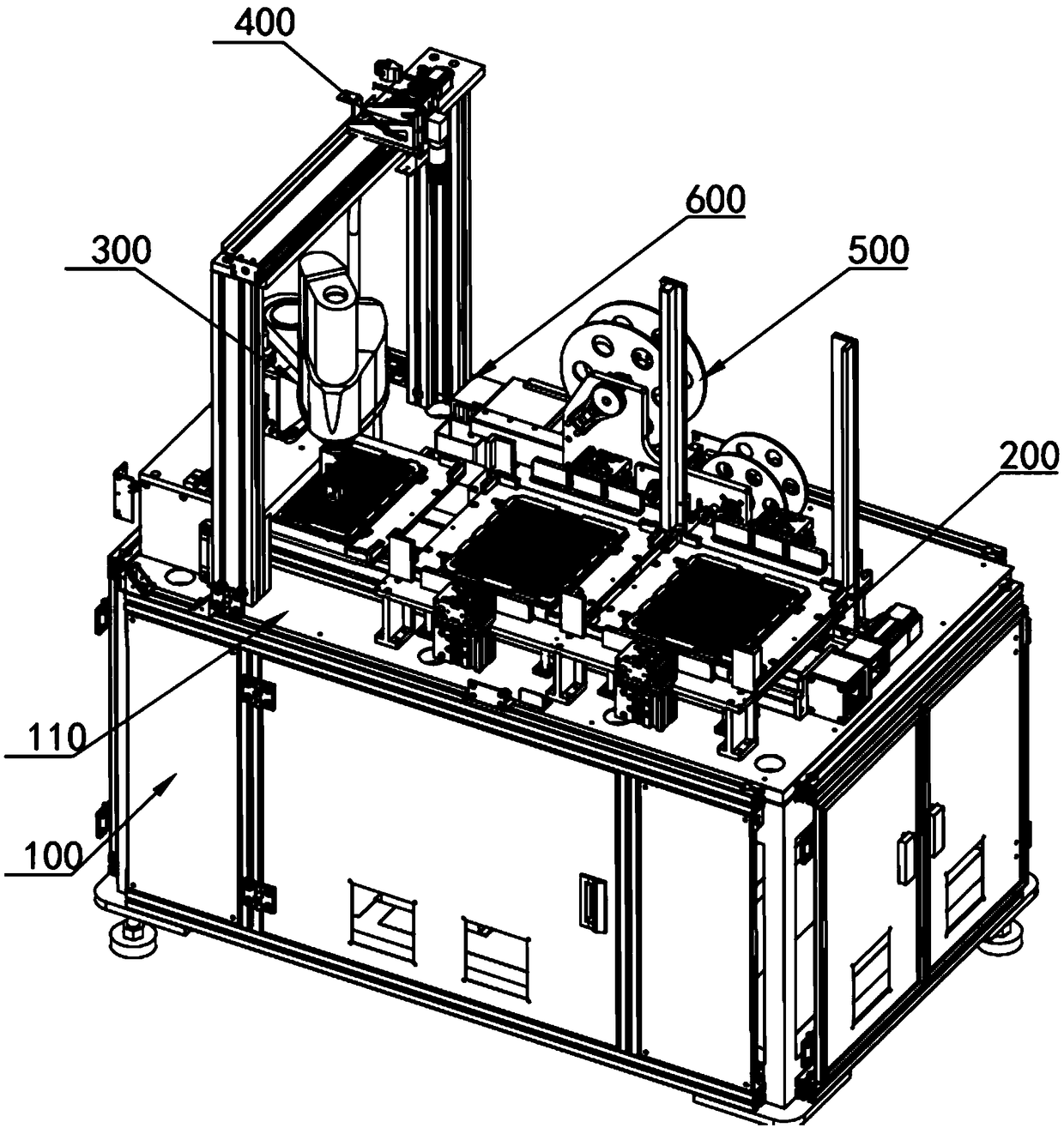

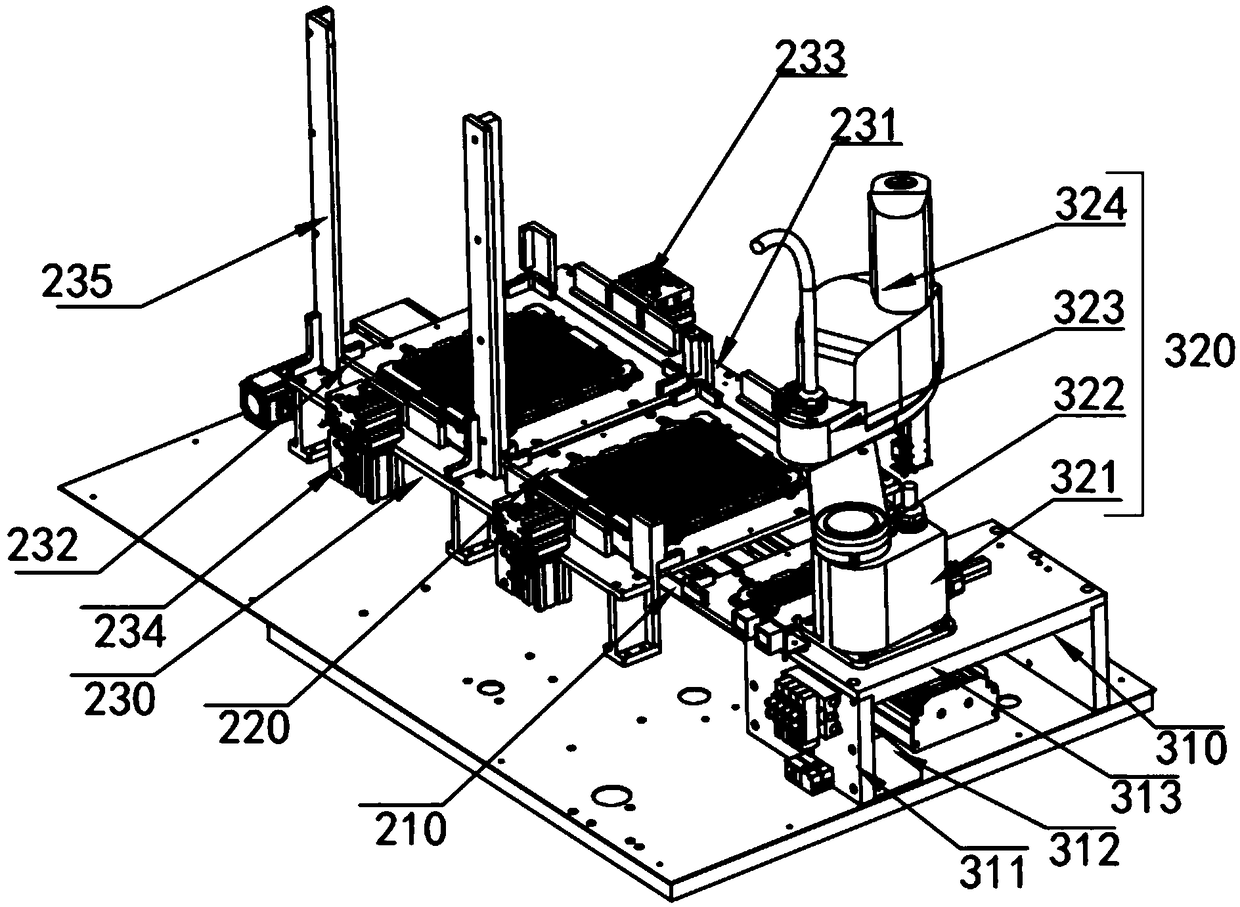

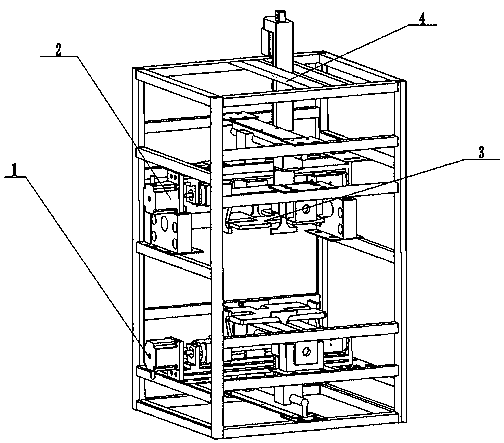

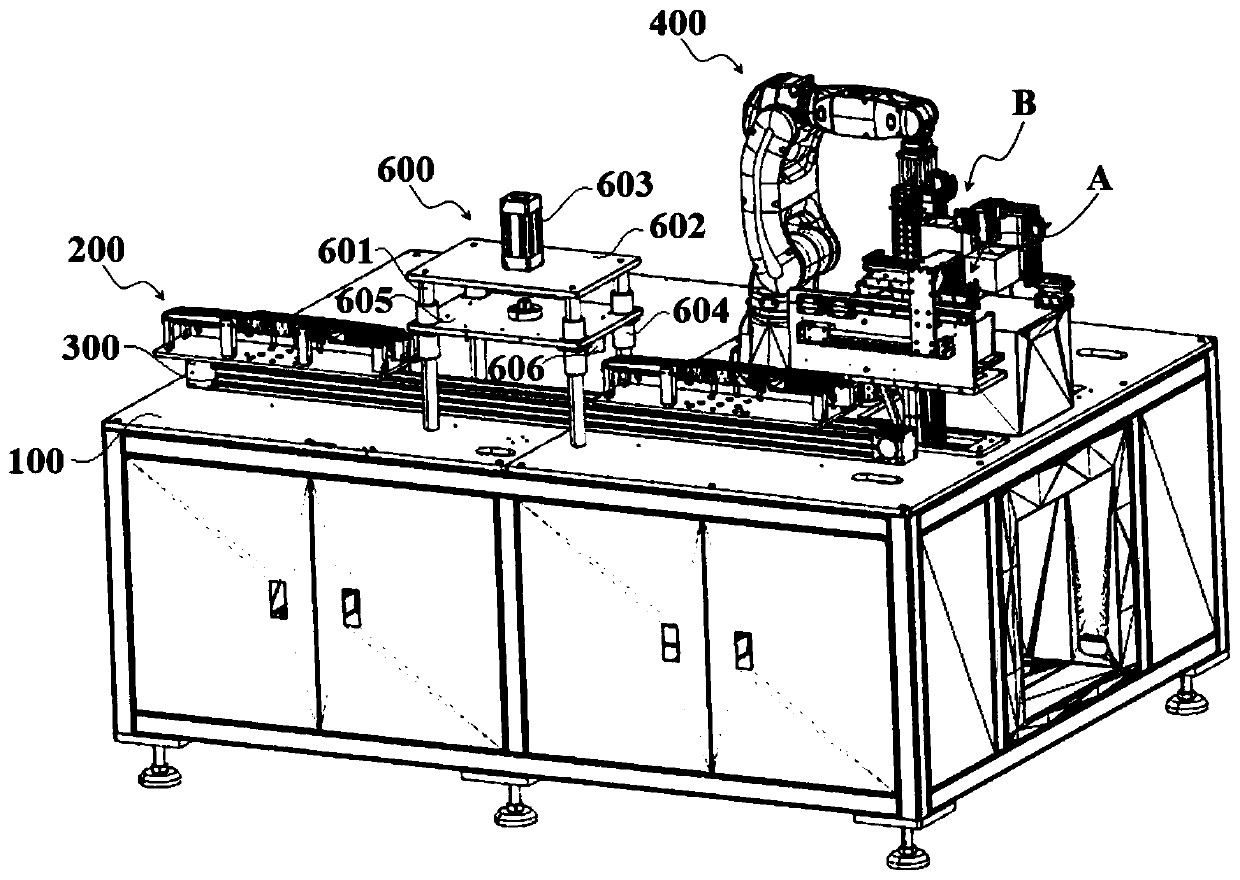

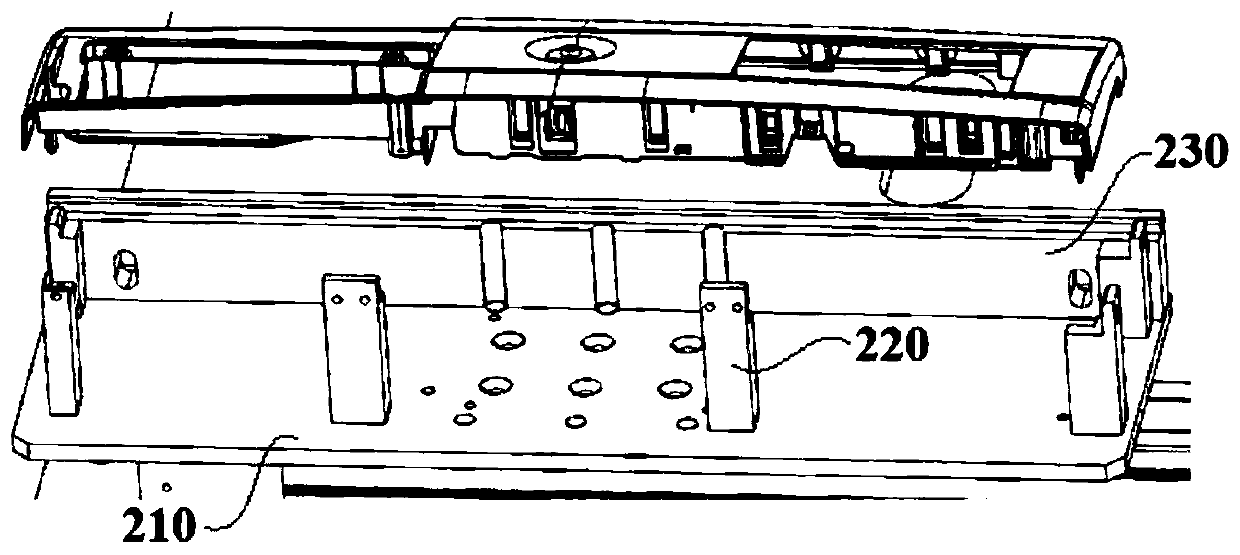

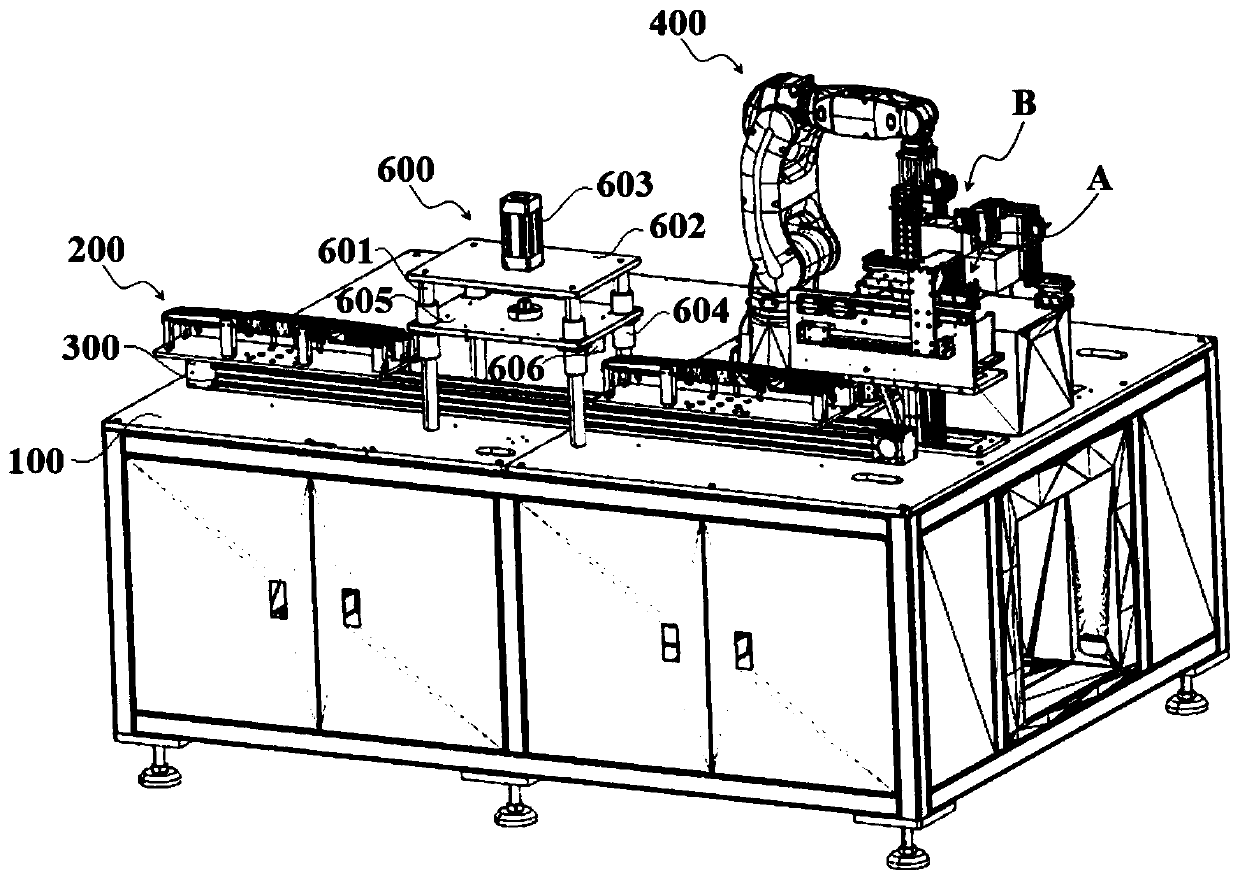

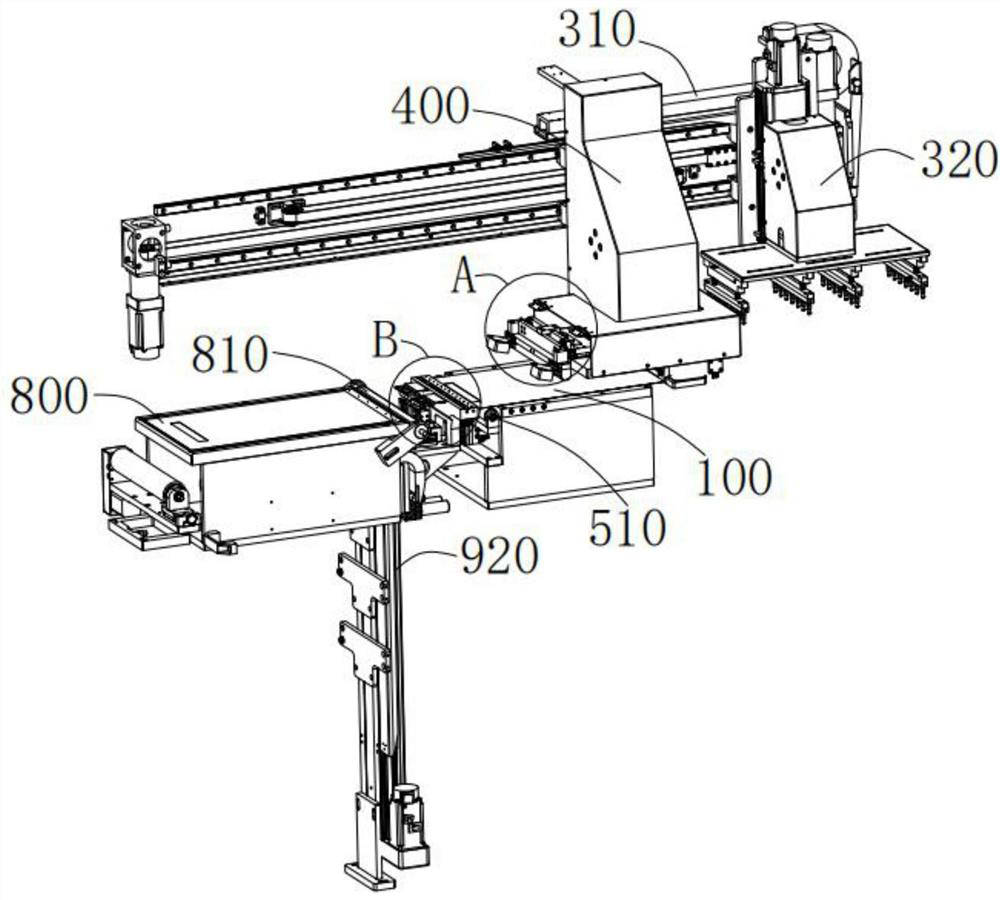

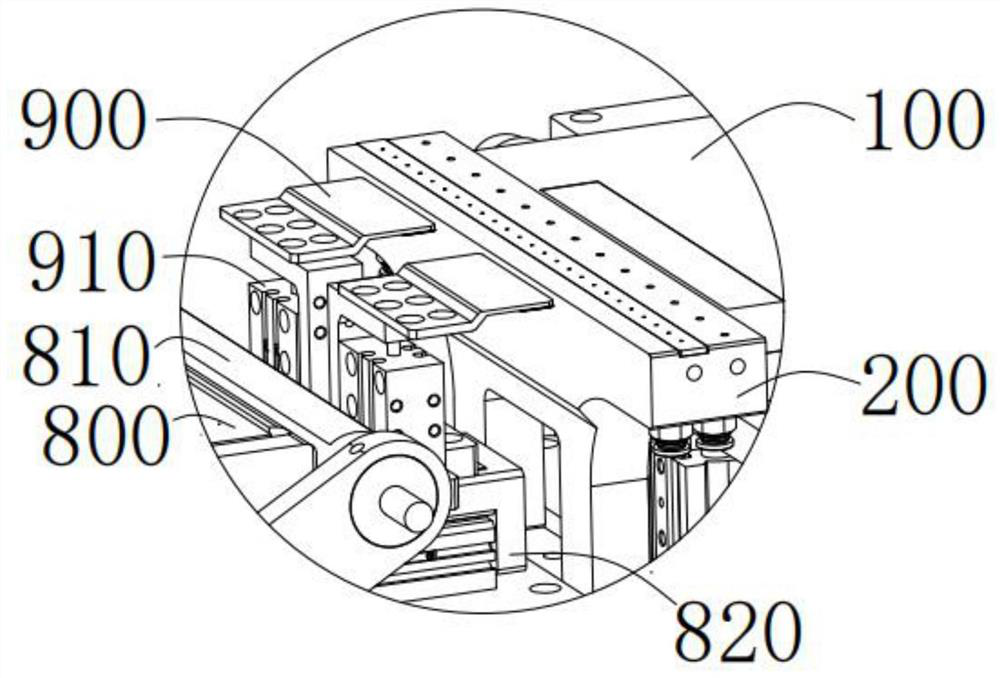

Automatic film sticking machine and film sticking method based on automatic film sticking machine

ActiveCN109968650AImprove the accuracy of film applicationImprove film application efficiencyCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

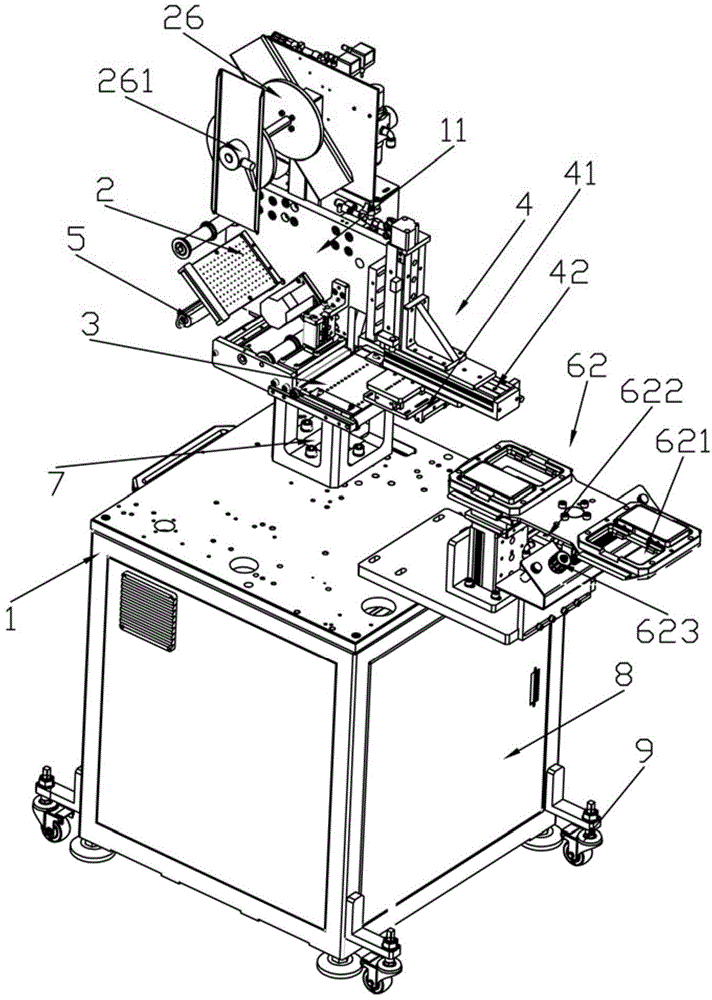

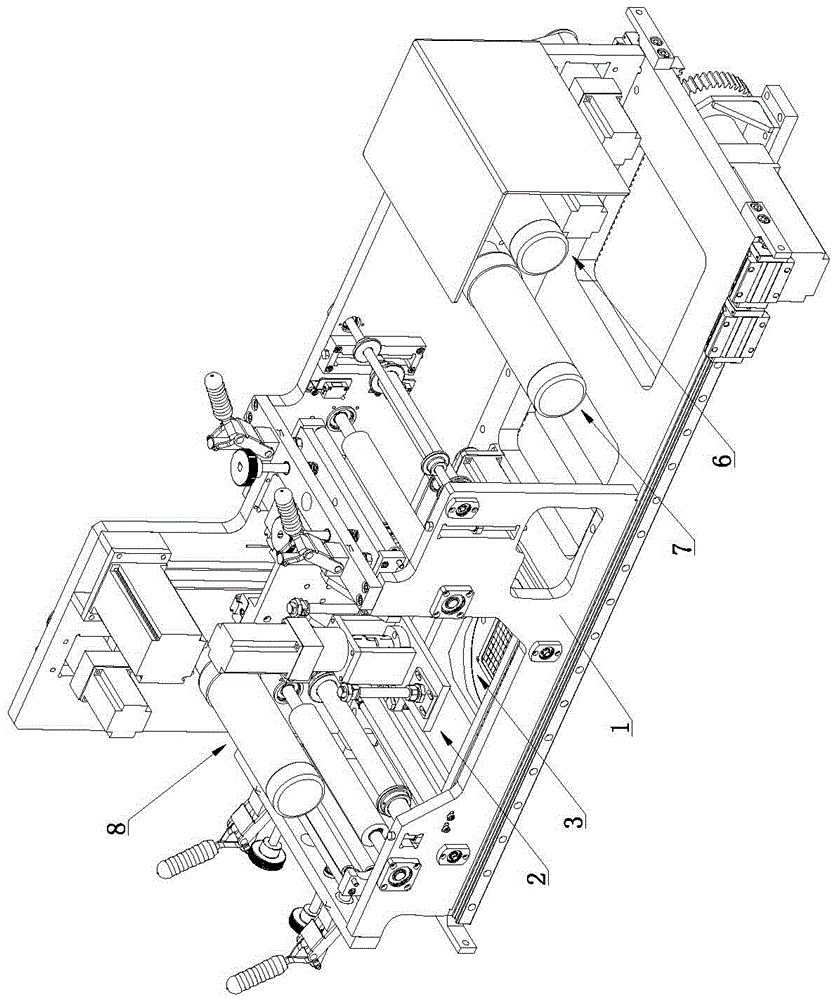

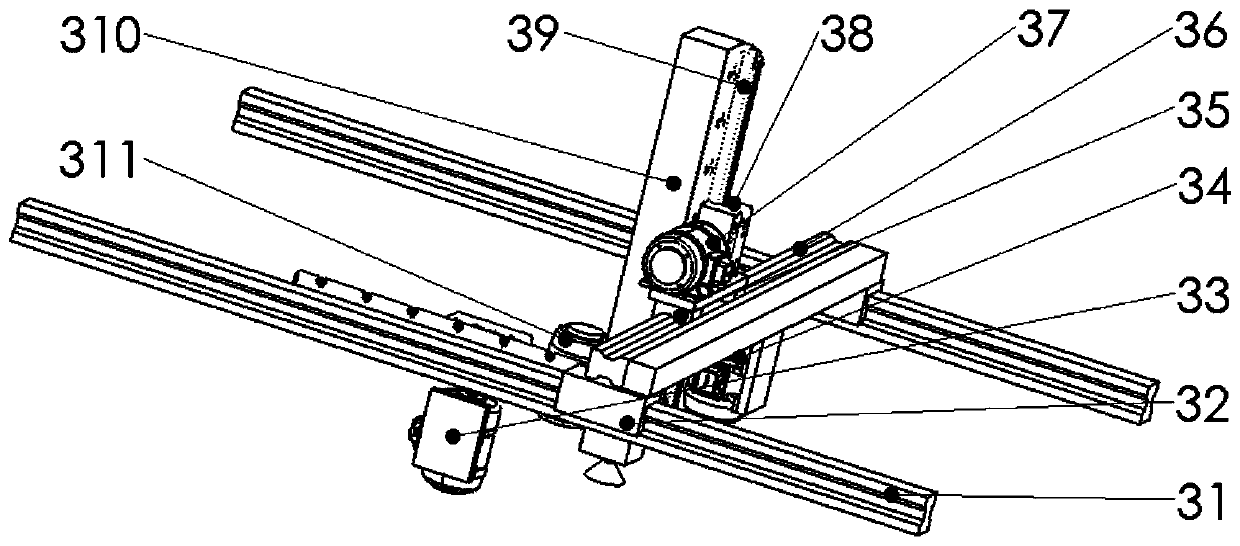

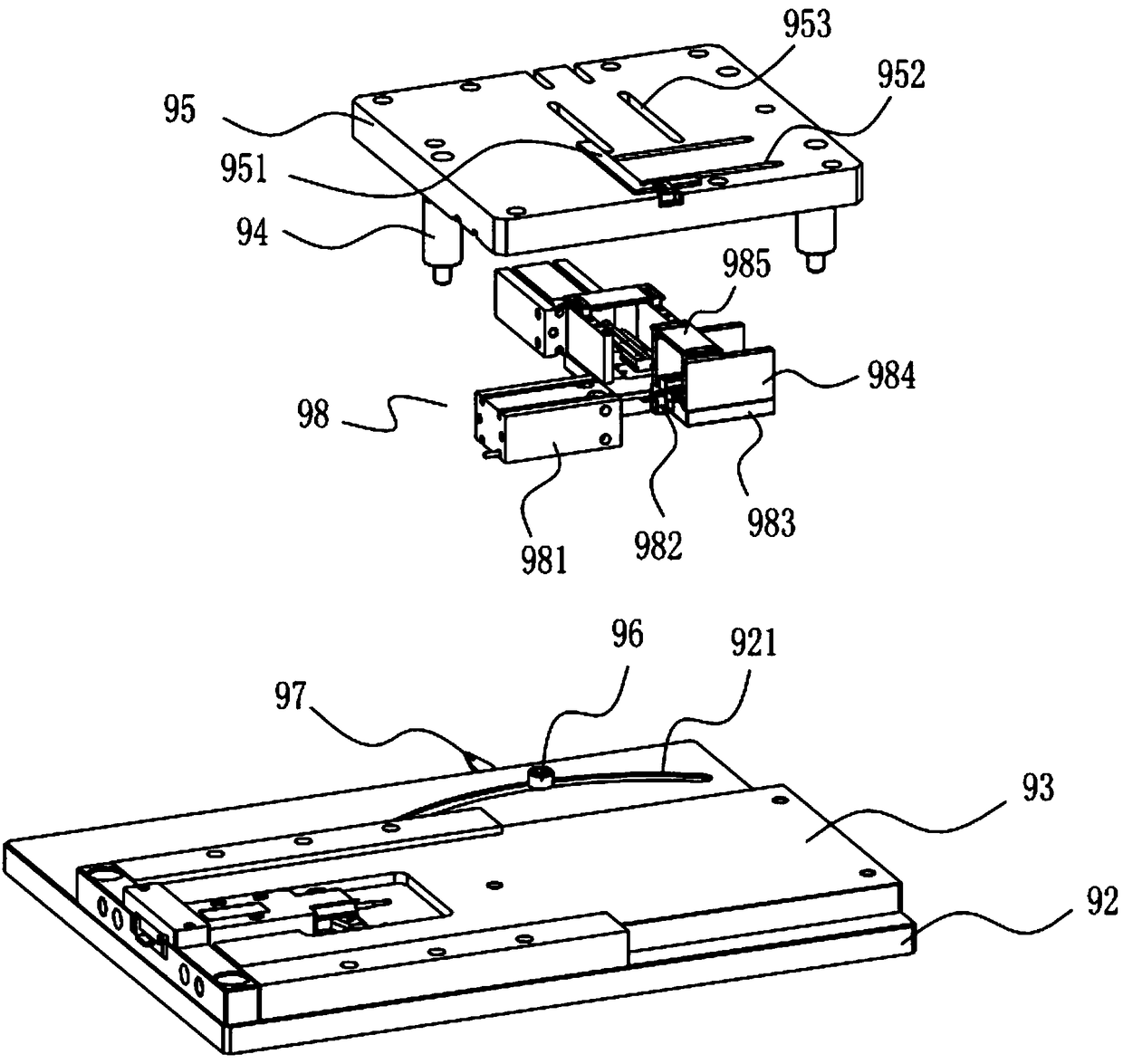

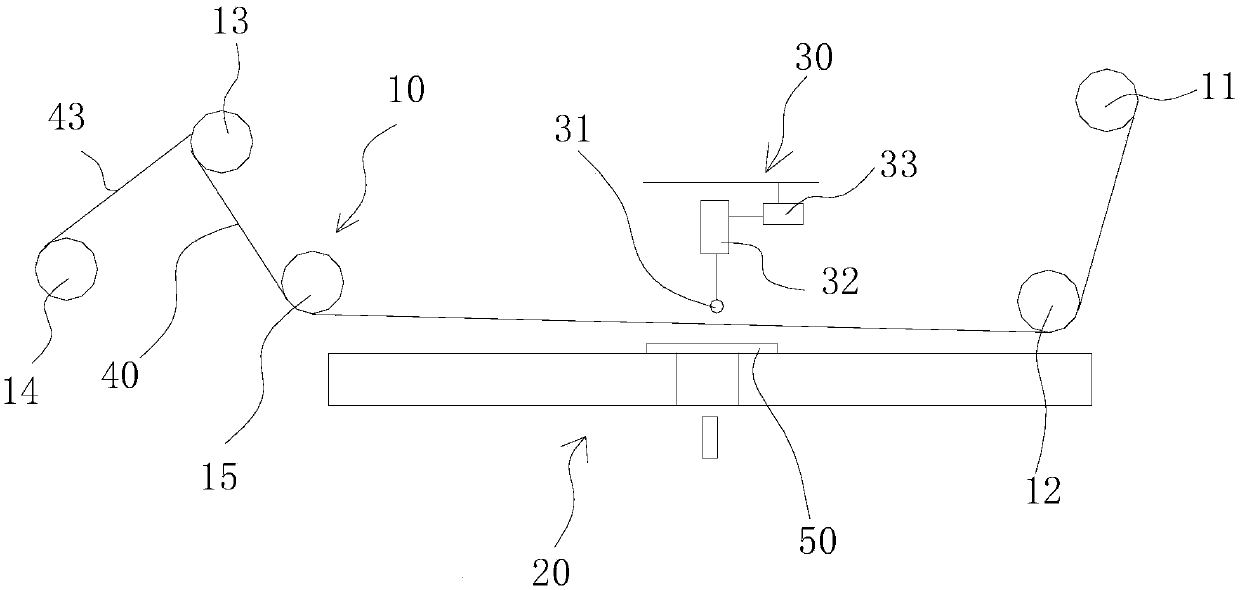

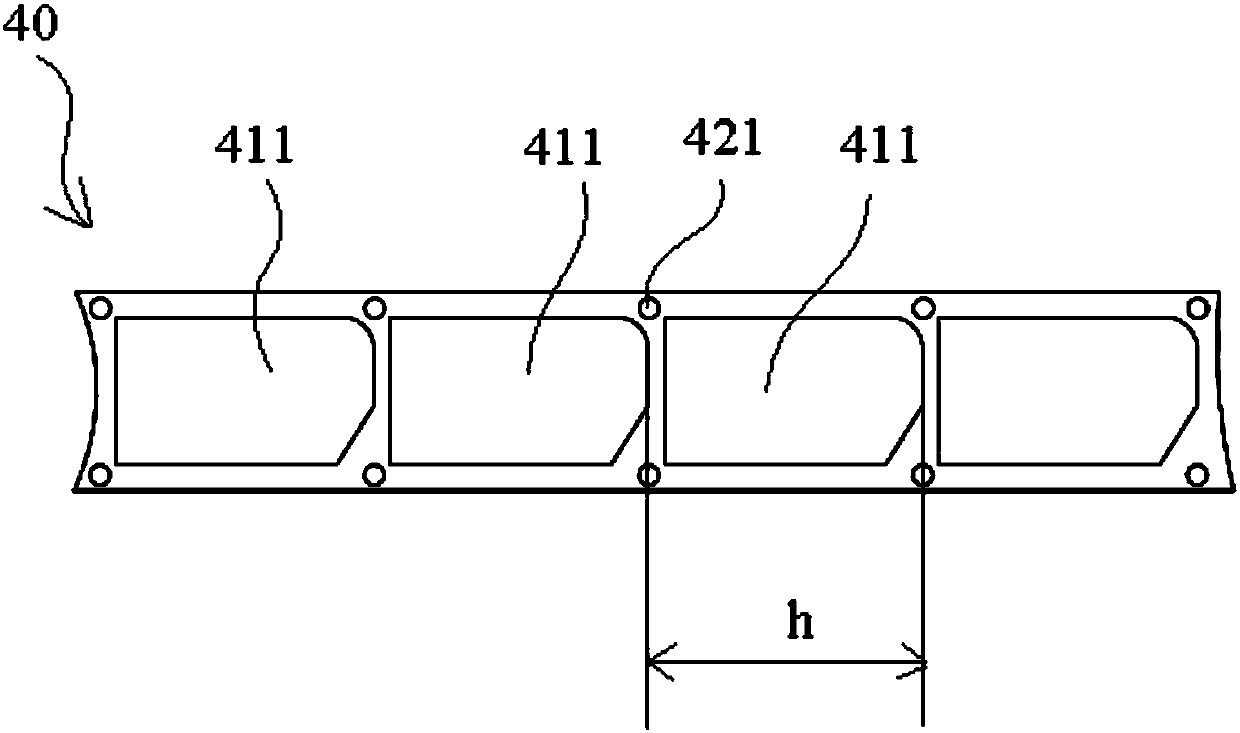

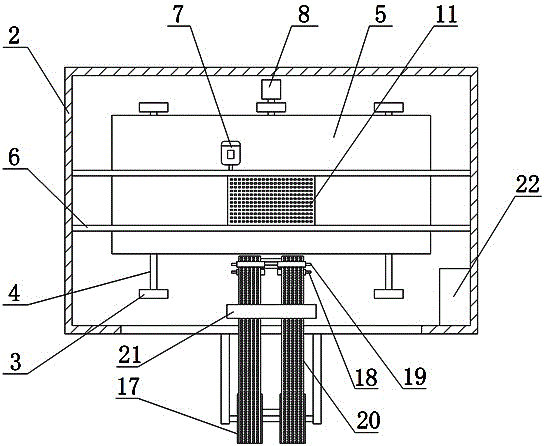

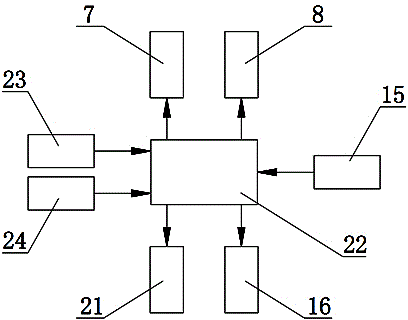

The invention belongs to the technical field of film sticking machines, and particularly discloses an automatic film sticking machine and a film sticking method based on the automatic film sticking machine. The automatic film sticking machine comprises a controlling unit and an executing mechanism, wherein the executing mechanism comprises a machine frame, a worktable, a wiping mechanism and a mechanical arm; the worktable is used for clamping electronic products and tempered-glass films, and positioning the tempered-glass films; the wiping mechanism is used for wiping screens of the electronic products; the mechanical arm is used for sucking the tempered-glass films and moving the tempered-glass films to the electronic products; and through the cooperation of the worktable, the wiping mechanism and the mechanical arm, the cleaning work before sticking the tempered-glass films is completed jointly, and then the tempered-glass films are stuck, so that the film sticking precision of theelectronic products is enhanced, the film sticking efficiency of the electronic products is improved, and humans are replaced during sticking films and the working fatigue of the humans is relieved.

Owner:NINGXIA UNIVERSITY

High-accuracy full-automatic film adhering equipment

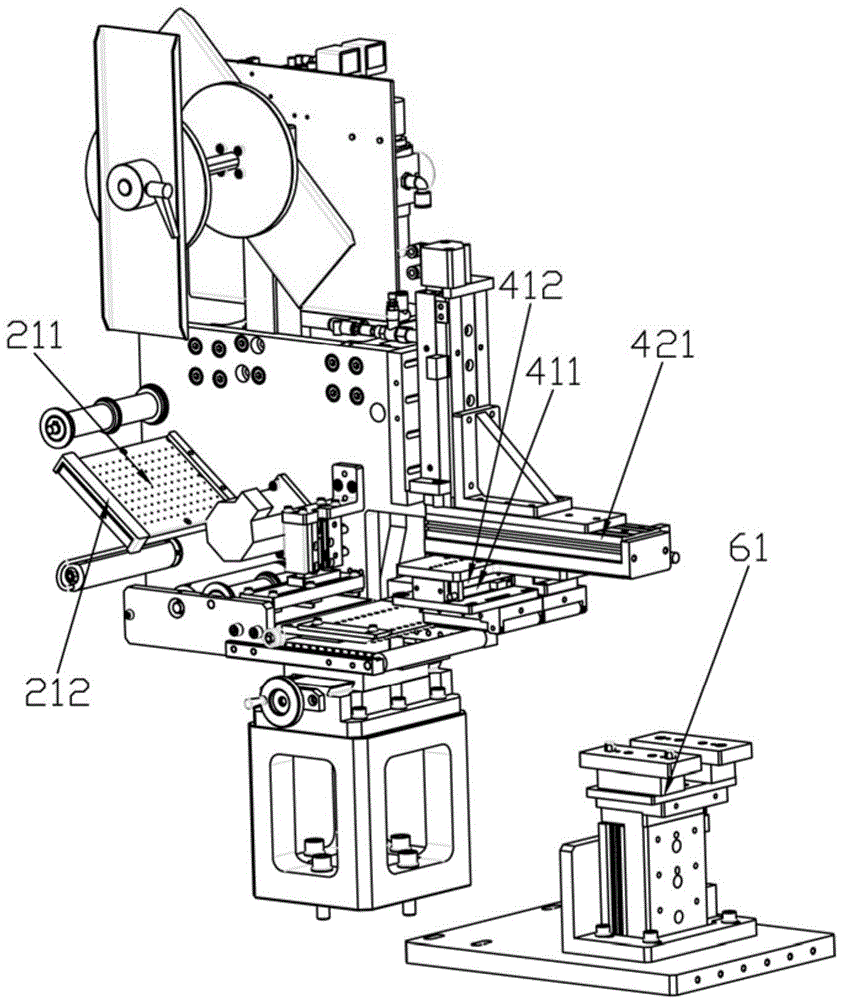

The invention relates to the technical field of automatic film adhering equipment, and particularly relates to high-accuracy full-automatic film adhering equipment. The high-accuracy full-automatic film adhering equipment comprises a rack, a working table, a loading and unloading mechanism, an automatic film adhering manipulator, a detection mechanism, a discharging mechanism, a stripping mechanism and a control mechanism, wherein the working table is arranged at the upper part of the rack; the loading and unloading mechanism is arranged on the working table and used for loading and unloadinga product; the automatic film adhering manipulator is arranged on the working table, positioned at one end of the loading and unloading mechanism and used for automatically taking a material to adherea film; the detection mechanism is arranged on the working table, positioned above the manipulator and used for detecting and correcting a film material; the discharging mechanism is arranged on theworking table, positioned at one side of the loading and unloading mechanism and used for discharging and rolling up the film material; the stripping mechanism is positioned at one side of the discharging mechanism and used for stripping off the film material; the control mechanism is arranged on the rack and used for controlling the film adhering equipment to work. The high-accuracy full-automatic film adhering equipment integrally adopts full-automatic setting, so that both human and material resources are saved; a protective film is adhered after being corrected in the film adhering process, so that film adhering accuracy and film adhering efficiency are greatly improved, and integral reliability is high.

Owner:东莞市威耐科智能装备有限公司

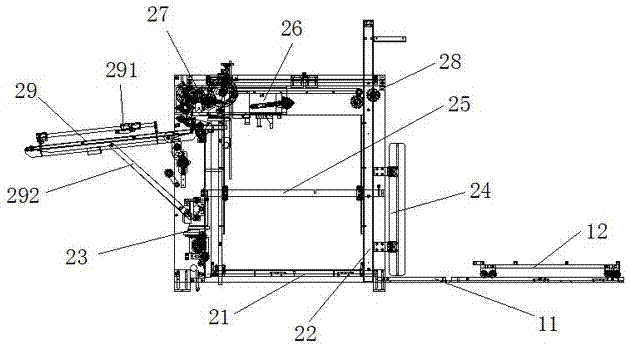

Automatic laminator

ActiveCN107792423AReduce labor intensityRealize automatic film sticking operationFinal product manufacturePackagingRobot handBarcode

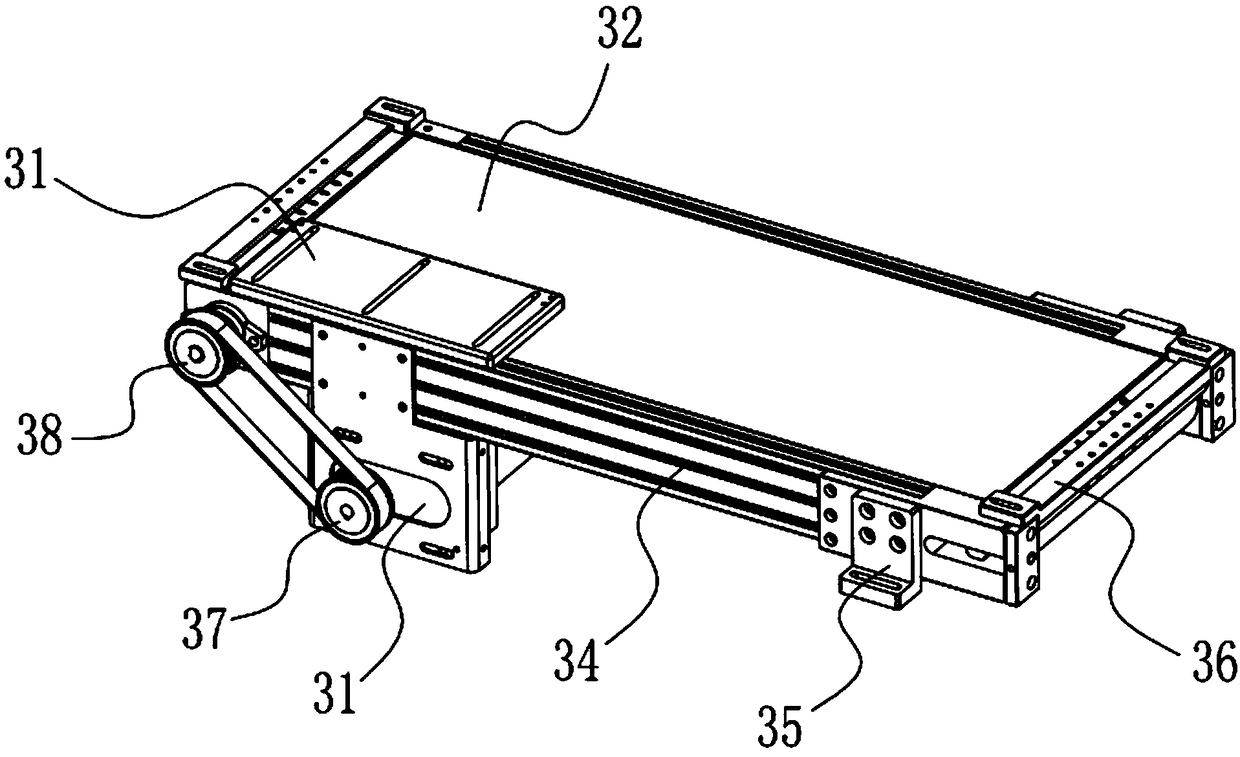

The invention discloses an automatic laminator which comprises a transplant jacking mechanism, a product positioning frame, a first discharging component, a second discharging component, a third discharging component, an edge covering and laminating mechanism, a conveying mechanism, a barcode scanning gun, a short-edge material laminating mechanical-arm component, a long-edge material laminating mechanical-arm component, a short-edge material peeling mechanism, a long-edge material peeling mechanism, a short-edge material detecting device, a long-edge material detecting device, a product short-edge camera positioning component, a product long-edge camera positioning component, etc., which are arranged on an operation table. Through the mutual coordination and match of the transplant jacking mechanism, the material peeling mechanisms, the laminating mechanical-arm components, the edge covering and laminating mechanism, the conveying mechanism, etc., the automatic laminator completes theprocess of feeding, positioning, material peeling, laminating, edge covering, discharging, etc. in order. The automatic laminator realizes the automatic laminating operation of products, reduces thelabor intensity of workers, shortens the laminating time, greatly improves the laminating precision and the laminating efficiency, and reduces the production cost.

Owner:苏州才哲智能科技有限公司

Windowing film laminating machine

InactiveCN107097520ALeveling and adjusting balanceImprove flatnessPrinting press partsFully automaticAutomation

The invention discloses a windowing film laminating machine comprising a pre-folded paper feeding frame, a paper conveying mechanism, a glazing oil head mechanism, a drying mechanism, a film laminating main machine, a chain cutter paper cutting mechanism and a paper collecting mechanism. Fully-automatic feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting of paper can be integrated together; the film laminating machine conducts operation automatically in the whole process, and the automation operation degree is high; a servo motor is adopted to drive the glazing oil head mechanism to smear glue on the paper, so that the whole machine conducts a series operation of feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting and the like on the paper with the consistent speed, and accordingly the high precision and good effect of glue smearing, film sticking and cutting of the paper, using is convenient and rapid, the cost is low, and the windowing film laminating machine is especially suitable for paper with a window; and the problems that labor strength is large, and the labor cost is high due to the fact that the paper is subjected to traditional manual operation of glue smearing, film sticking, cutting and the like are solved.

Owner:广东鑫佳机械科技有限公司

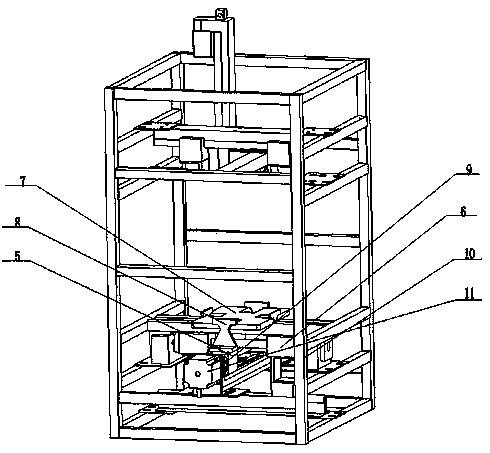

Full-automatic mobile phone film sticking device and film sticking method

The invention relates to a full-automatic mobile phone film sticking device and film sticking method, and belongs to the field of machinery. The device comprises a mobile phone positioning and clamping mechanism, a mobile phone film positioning and clamping mechanism, a film bottom plate removing mechanism and a mobile phone film sticking mechanism which are vertically distributed, wherein the mobile phone positioning and clamping mechanism is located on the lower side, the mobile phone film positioning and clamping mechanism is located in the middle, the film bottom plate removing mechanism is located in the middle and located on the lower side of the mobile phone film positioning and clamping mechanism, the mobile phone film sticking mechanism is positioned on the upper side, and the mobile phone positioning and clamping mechanism, the mobile phone film positioning and clamping mechanism, the film bottom plate removing mechanism and the mobile phone film sticking mechanism are all connected to a main frame body through bolts and corner pieces. The device has the advantages of being novel in concept, simple in structure and convenient to use, the full-automatic mobile phone film sticking function can be realized on mobile phone toughened films, the device is widely applicable to mobile phones of various sizes and various models, the production efficiency is greatly improved, and practicability is high.

Owner:JILIN UNIV

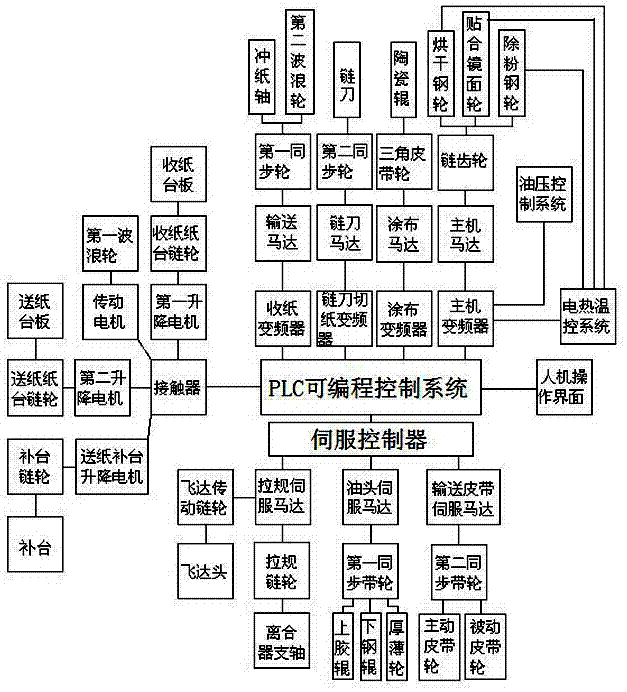

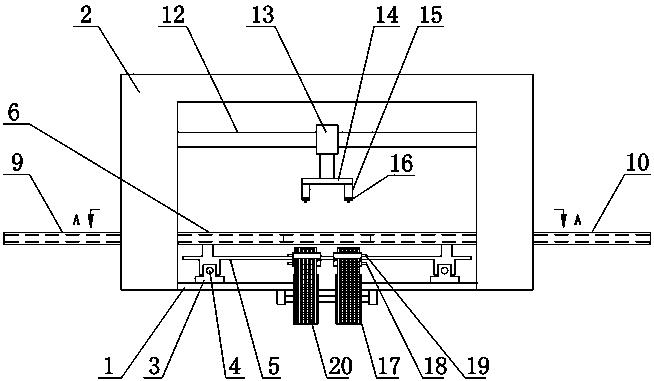

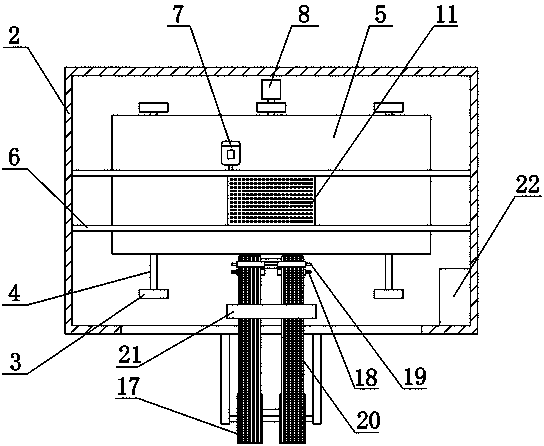

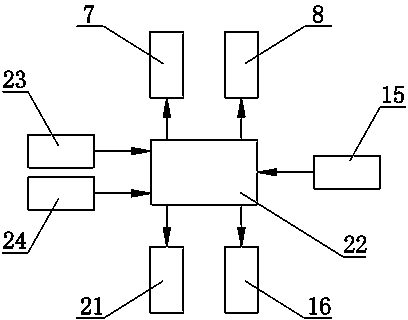

Servo control system for full-automatic laminating machine

ActiveCN107310243AAvoid driftingImprove the accuracy of film applicationLamination ancillary operationsControlling laminationFrequency changerTemperature control

The invention relates to a servo control system for a full-automatic laminating machine. The servo control system comprises a PLC programmable control system, a servo controller, a contactor, a paper-receiving frequency converter, a chain knife paper-cutting frequency converter, a coating frequency converter, a mainframe frequency converter, a man-machine operation interface, an oil head servo motor, an upper rubber roller, a lower steel roller, thick and thin wheels, a driving pulley, a driven pulley, a paper impact shaft, a chain knife, a ceramic roller, an oil pressure control system, an electric heating temperature control system, a drying steel wheel, an attaching mirror surface wheel and a powder-removing steel wheel and the like. Each frequency converter, each servo motor and the contactor are controlled through the PLC programmable control system, so that not only can operation front-rear speeds of each component of the whole machine be kept consistent, but also paper feeding, conveying, dedusting, gluing, film pasting pressurization, slitting and recycling are integrated, the paper film pasting precision is high, film pasting efficiency is high, a film pasting effect is good, and the servo control system is suitable for film pasting for paper of different specifications and different thicknesses and is convenient to use.

Owner:广东鑫佳机械科技有限公司

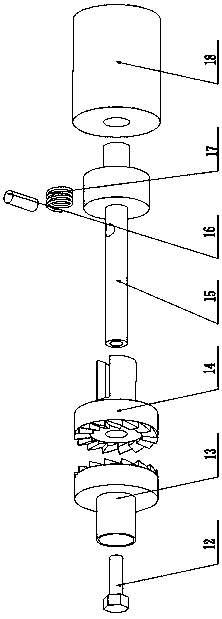

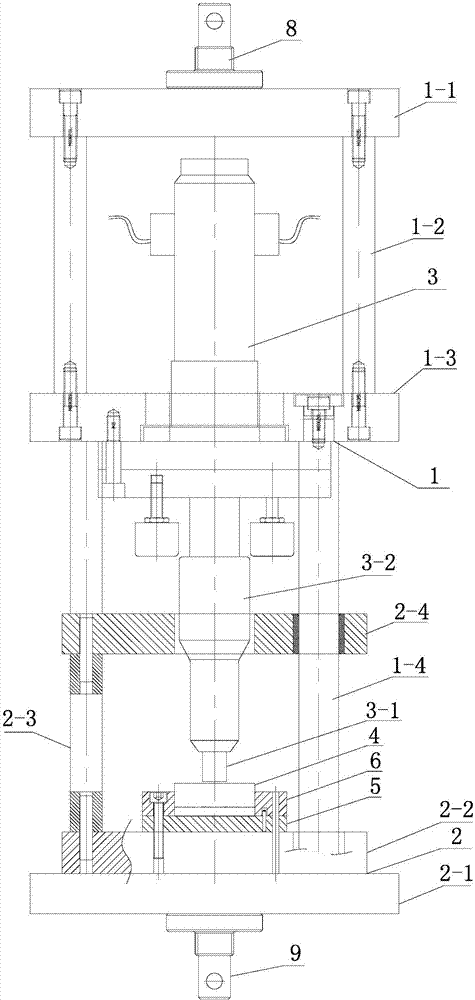

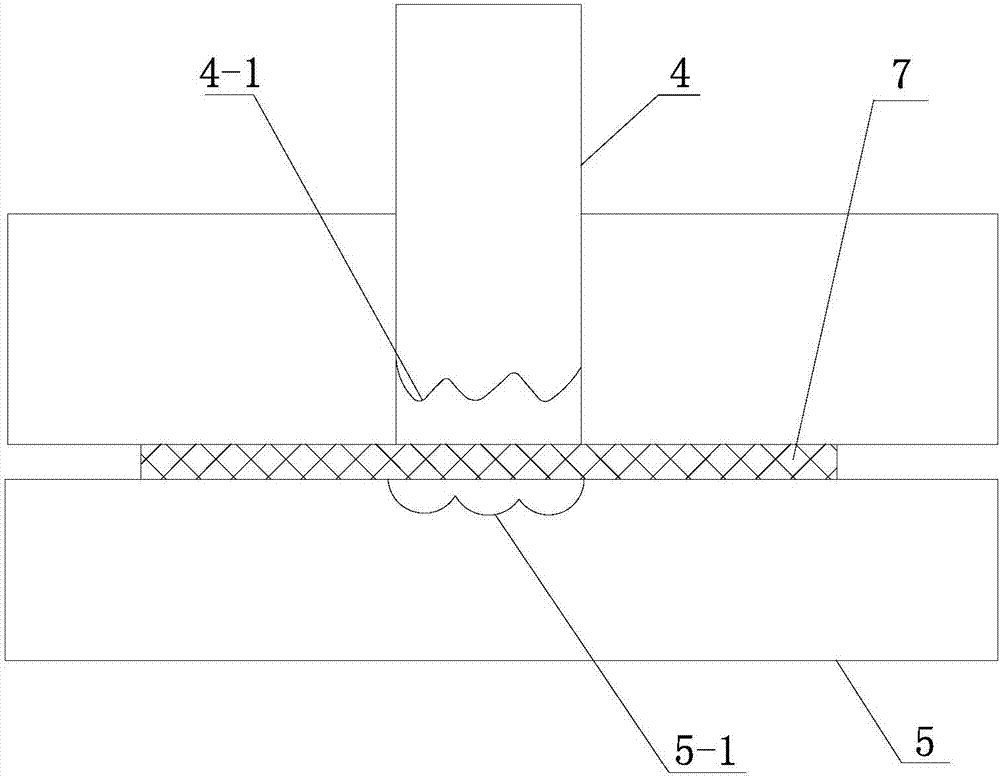

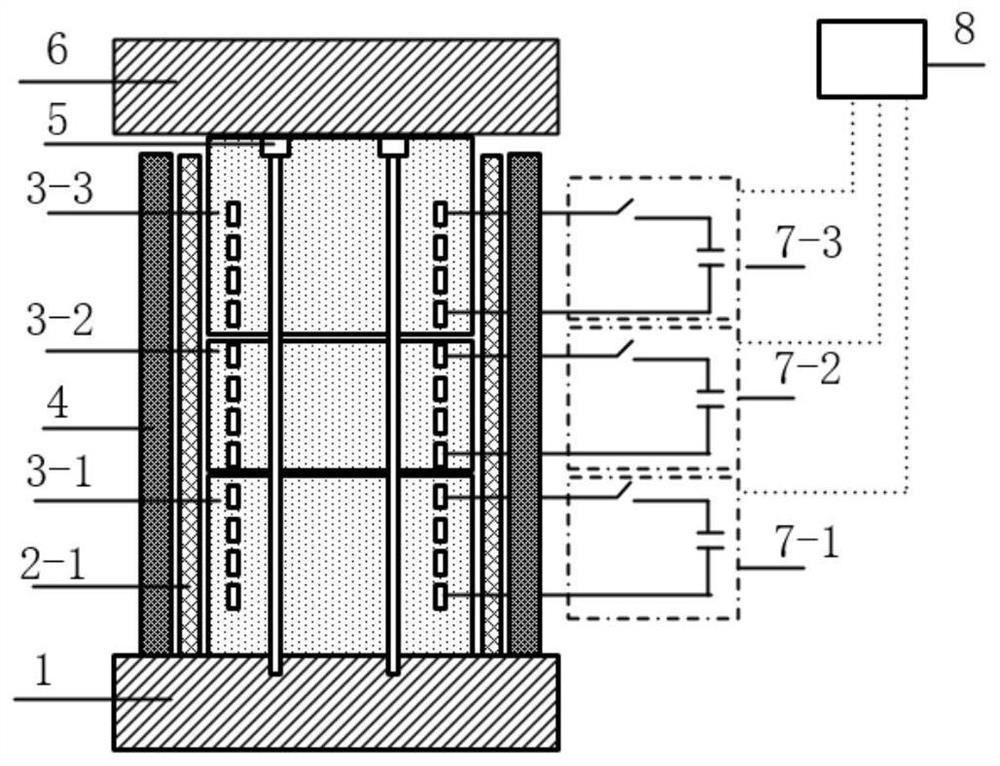

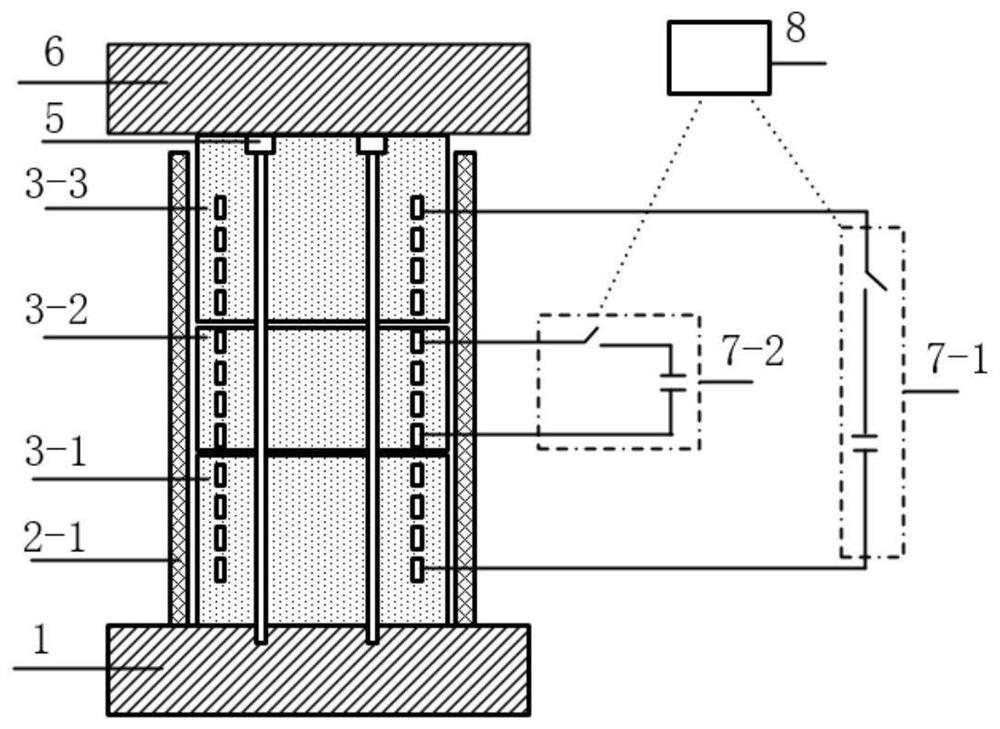

Ultrasonic vibration auxiliary micro-bulging device and method for thin-wall complex-curved-surface micro-structure component

ActiveCN107971381AImprove plastic deformation abilityHigh elongationMicro structureUltrasonic vibration

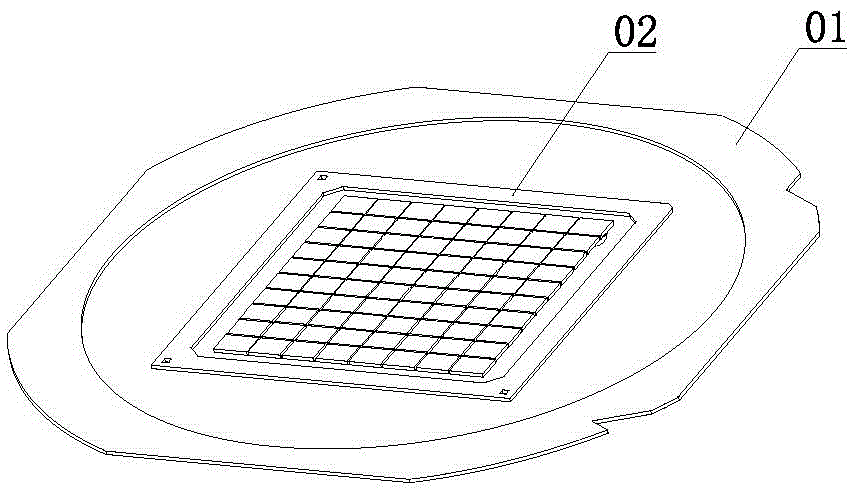

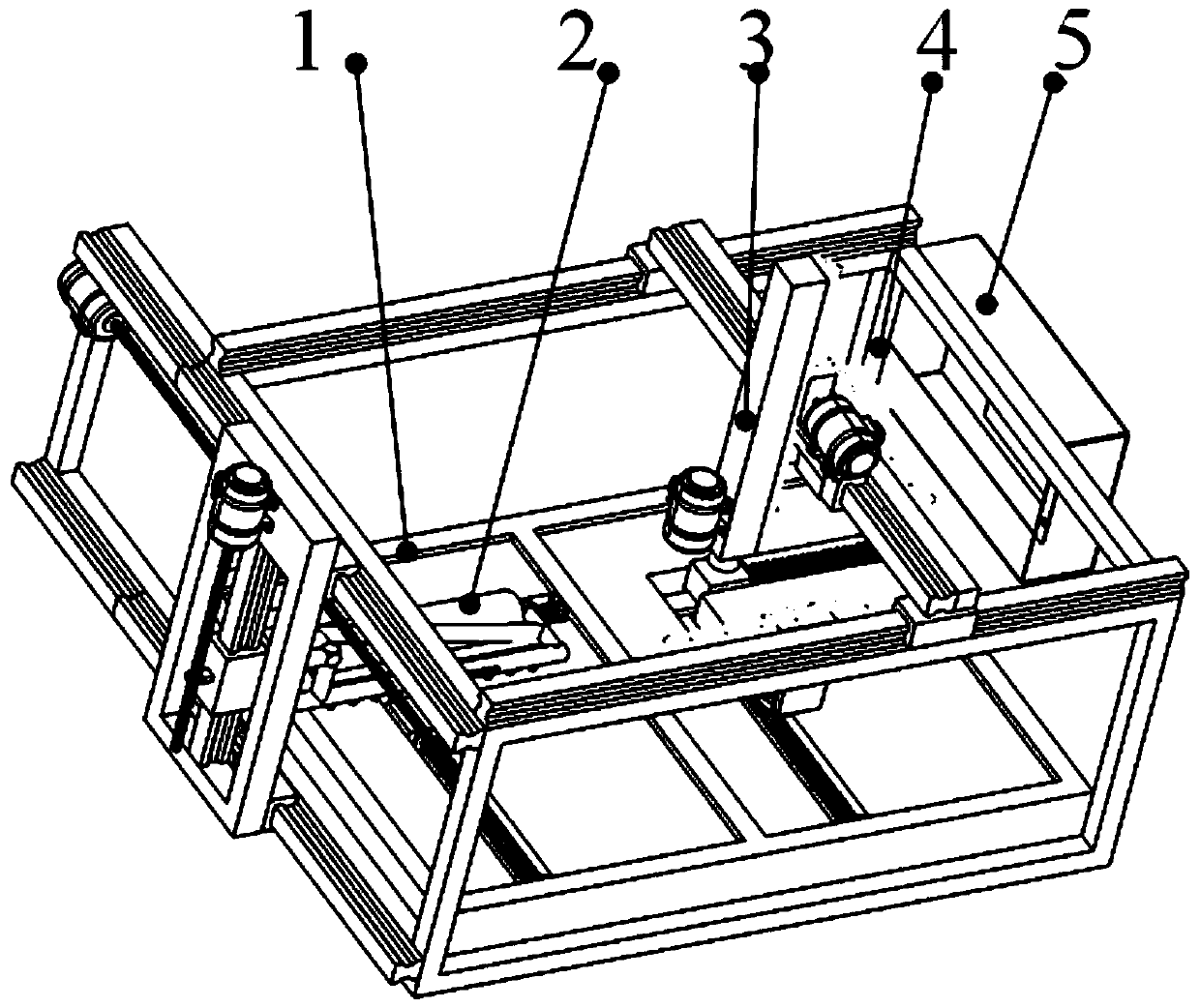

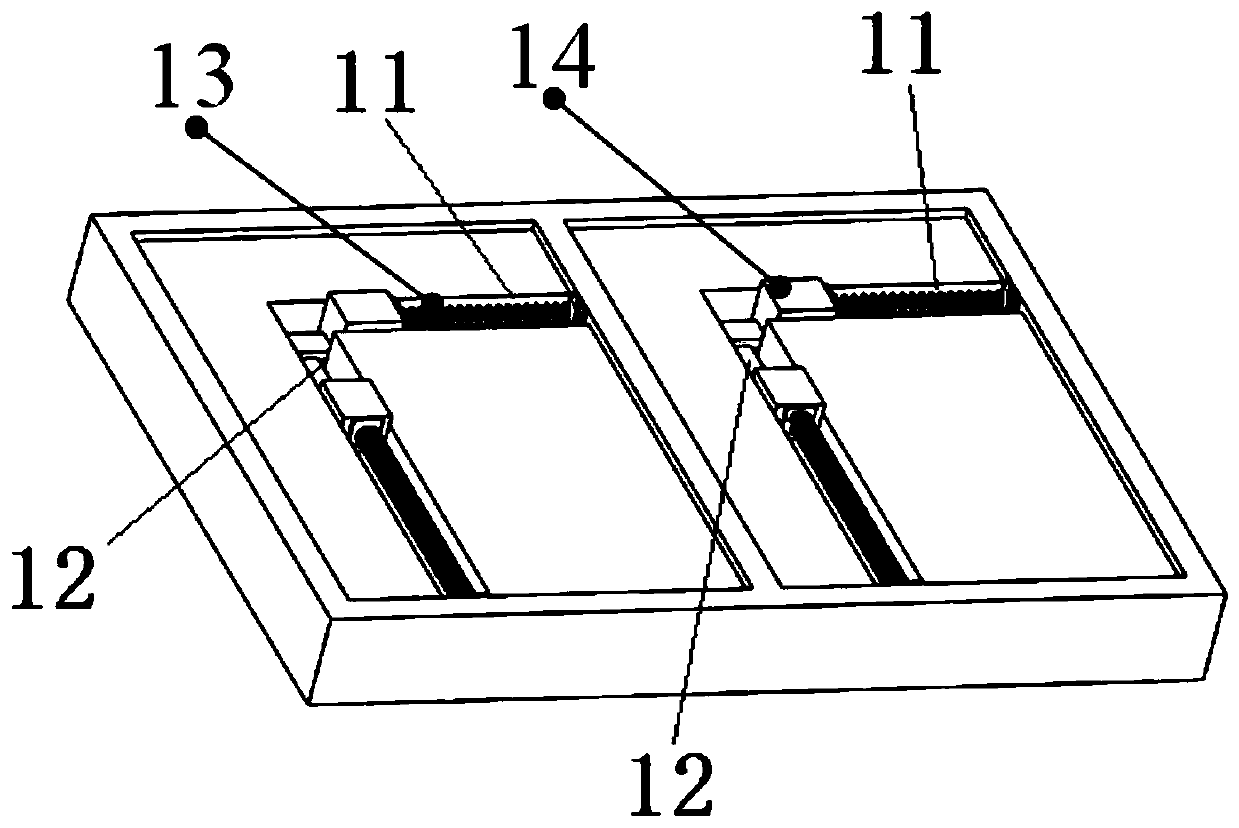

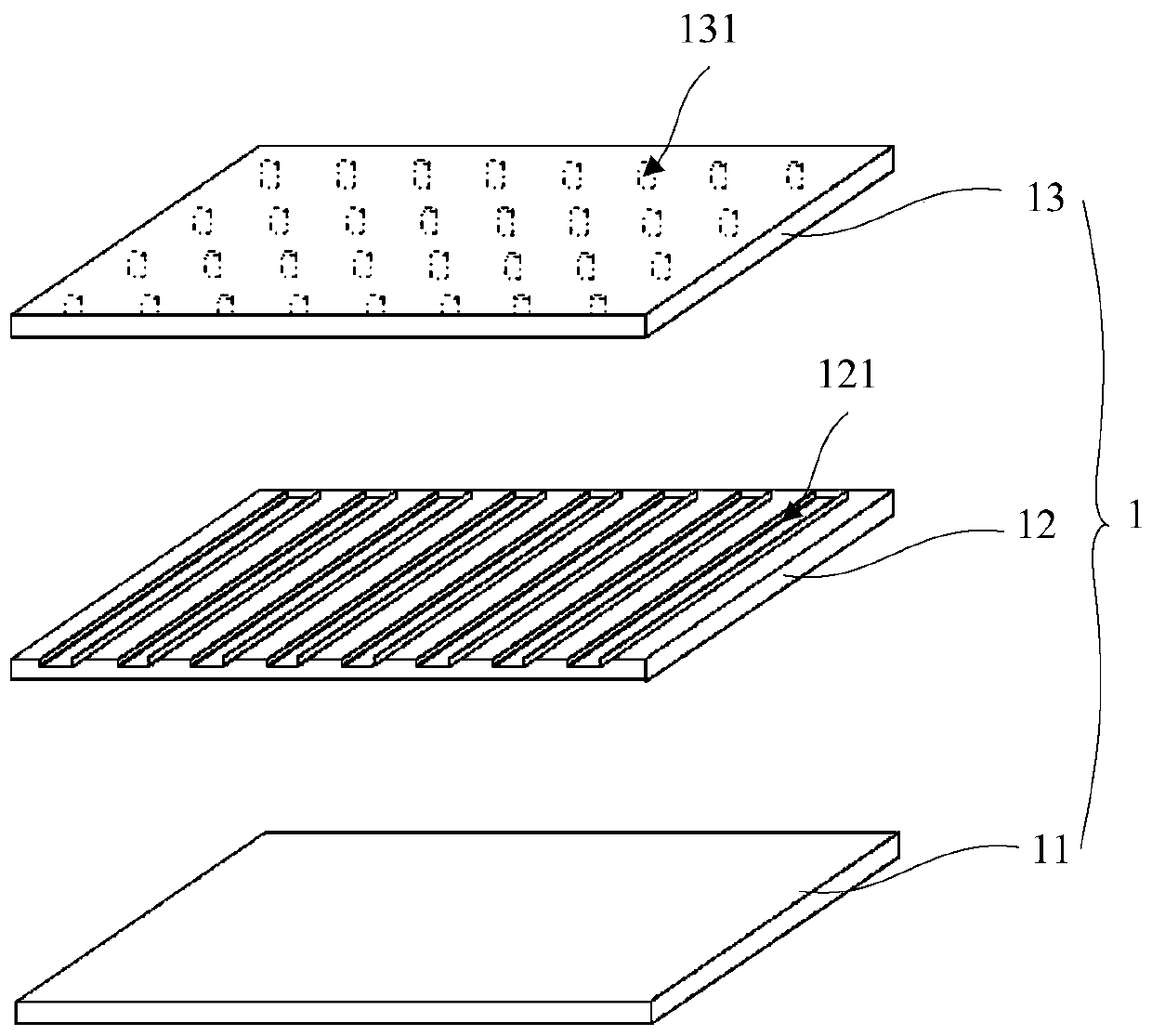

The invention discloses an ultrasonic vibration auxiliary micro-bulging device and method for a thin-wall complex-curved-surface micro-structure component, and relates to a thin-wall complex-curved-surface micro-structure forming device and method. The device and the method aim to solve the problem that the thin-wall complex-curved-surface micro-structure component cannot be manufactured by adopting an existing technology. The device comprises an upper connecting base, a lower connecting base, an ultrasonic vibration source, a male die, a female die and a material pressing plate, wherein the ultrasonic vibration source is arranged on the upper connecting base, the upper connecting base is vertically arranged on the lower connecting base in a sliding mode, the female die is arranged on thelower connecting base, the male die is arranged in an inner hole of the material pressing plate in a sliding mode, arrayed convex micro-structures are arranged on the lower surface of the male die, arrayed concave micro-structures are arranged on the upper surface of the female die, and the convex micro-structures are matched with the concave micro-structures. The micro-forming method comprises the following steps that 1, the device is assembled; and 2, a blank plate is subjected to micro-bulging so as to obtain the thin-wall complex-curved-surface micro-structure-array component.

Owner:HARBIN INST OF TECH

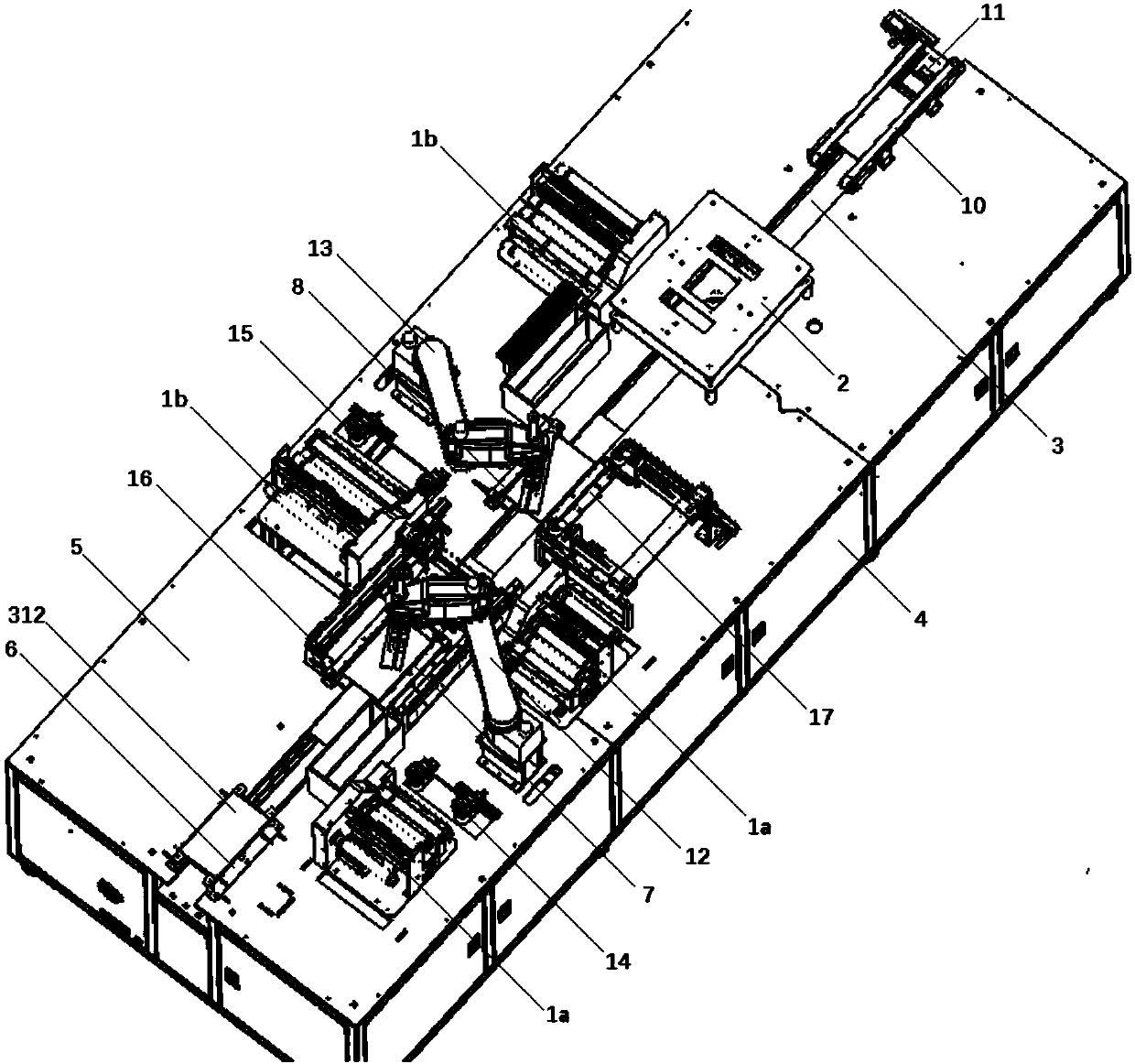

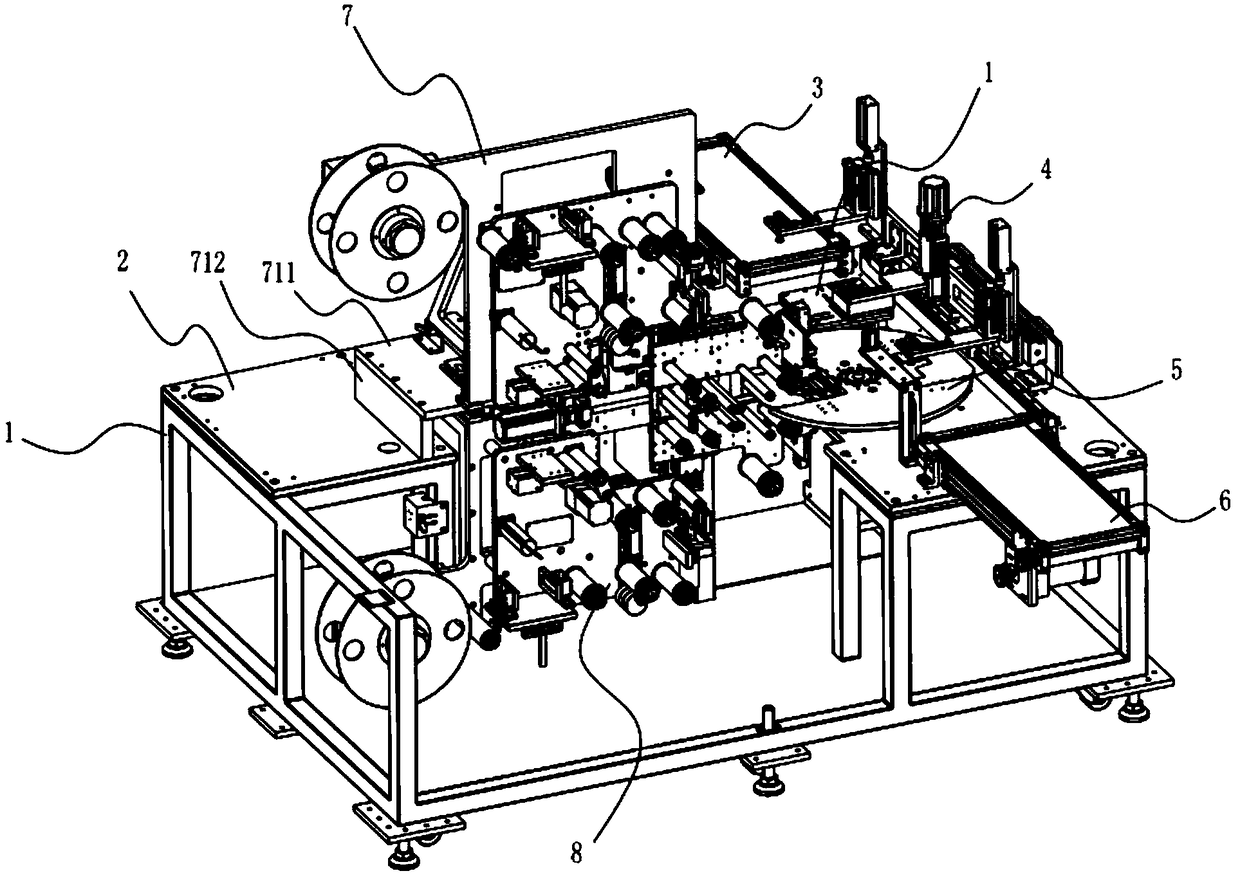

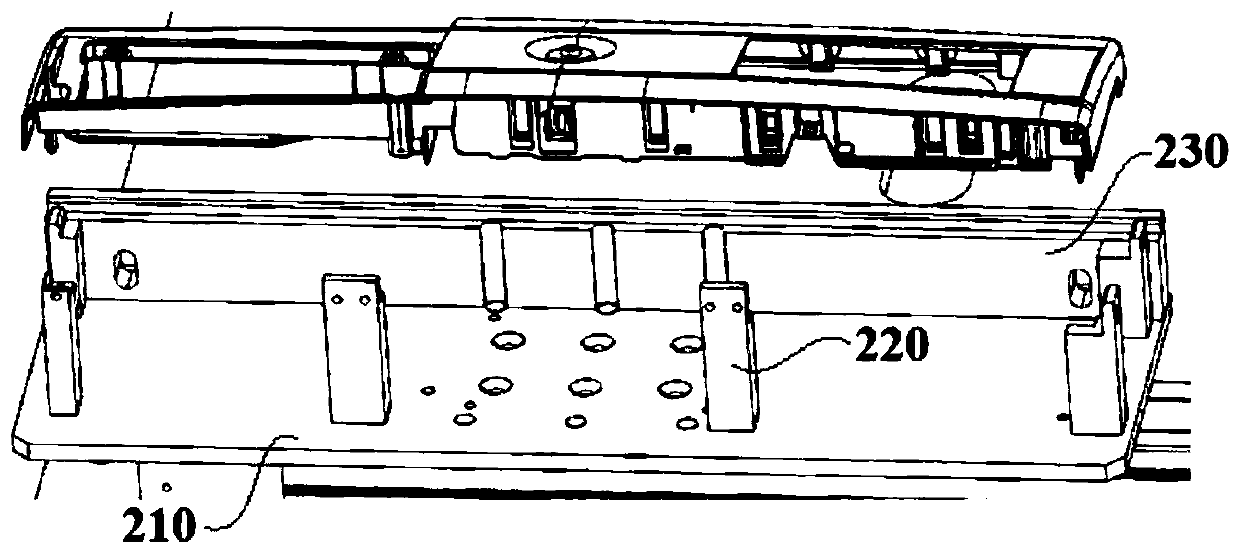

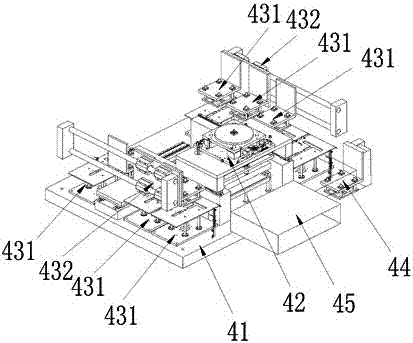

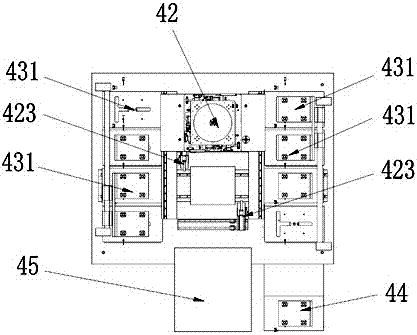

Gum topping equipment

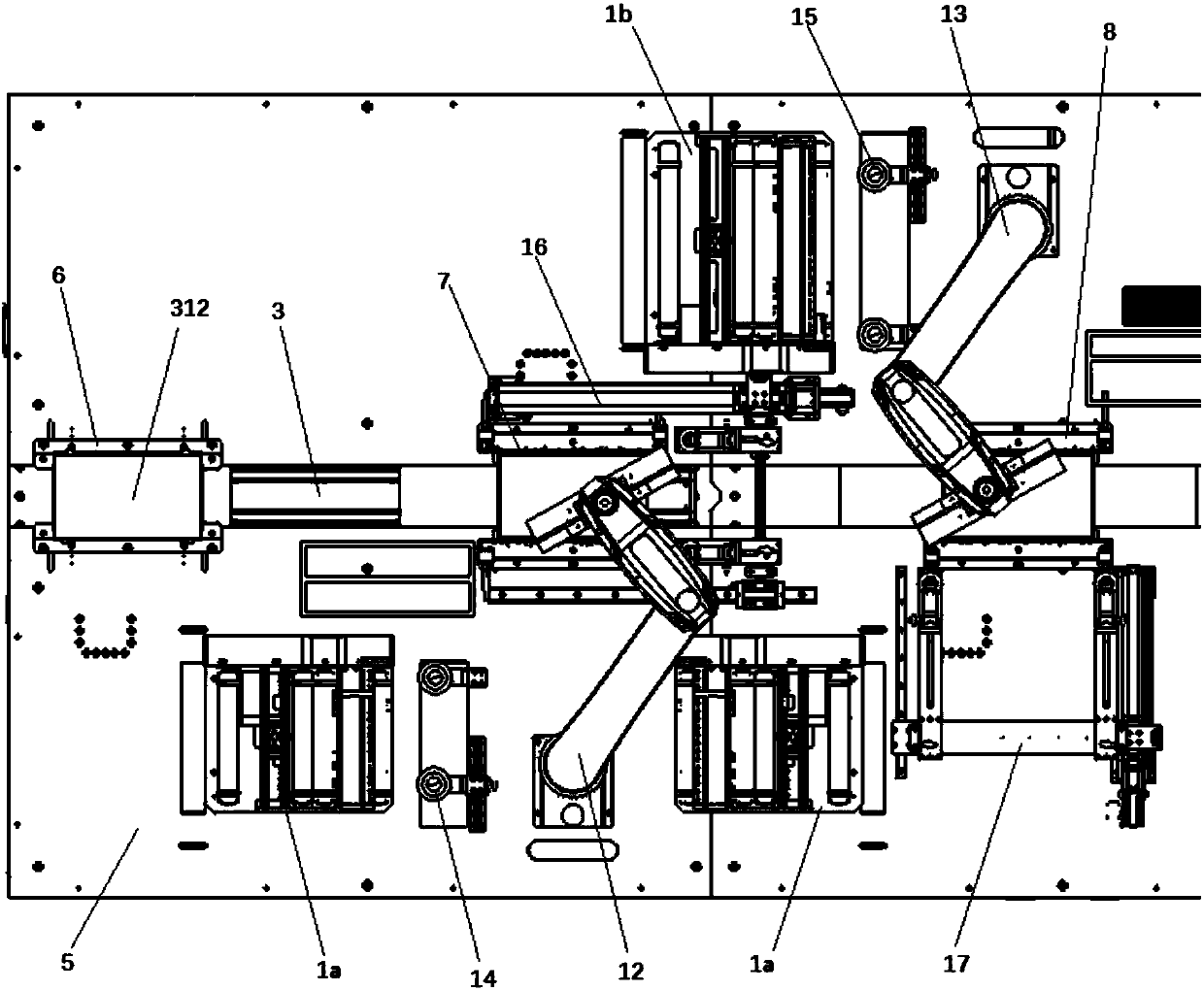

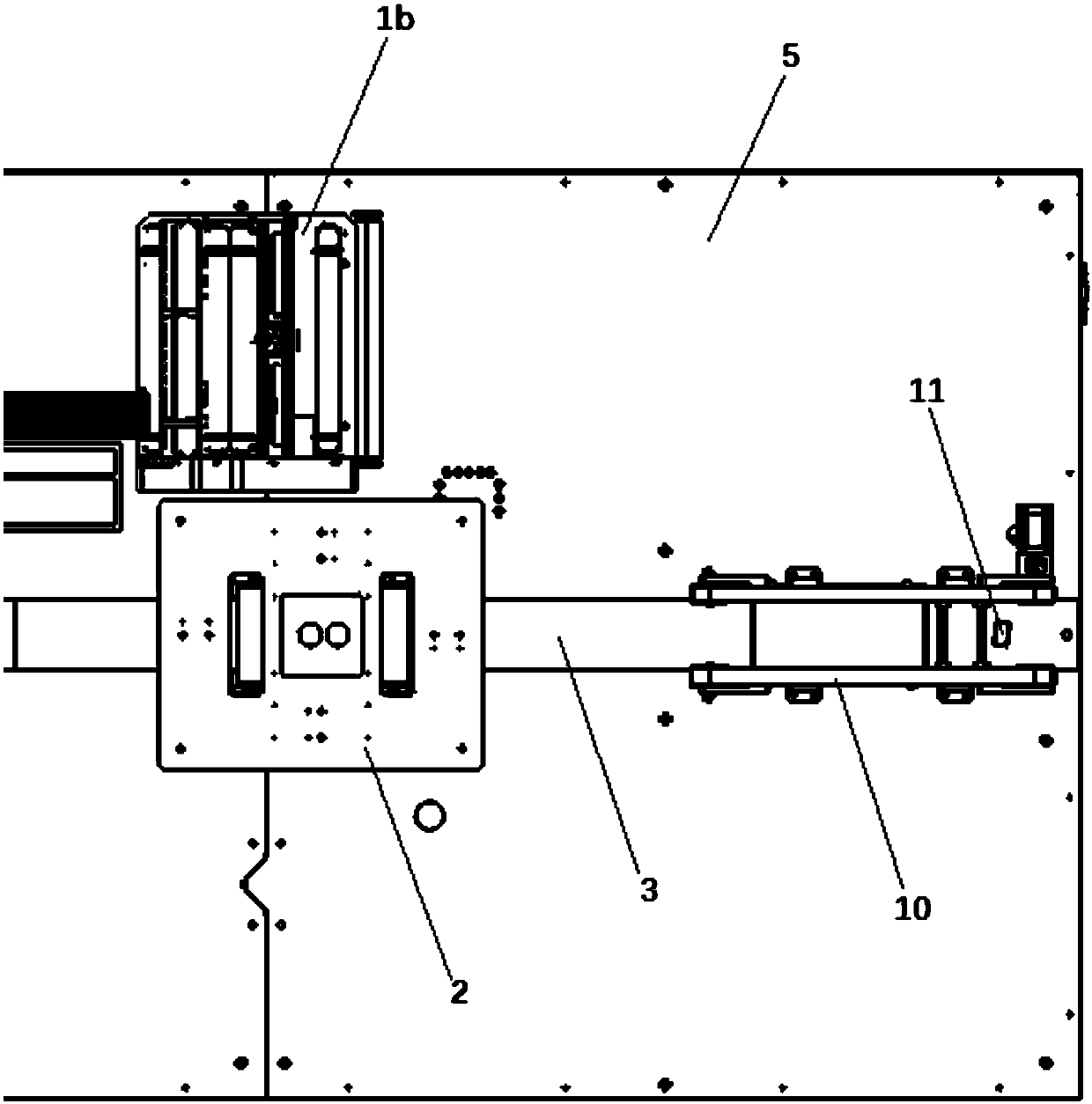

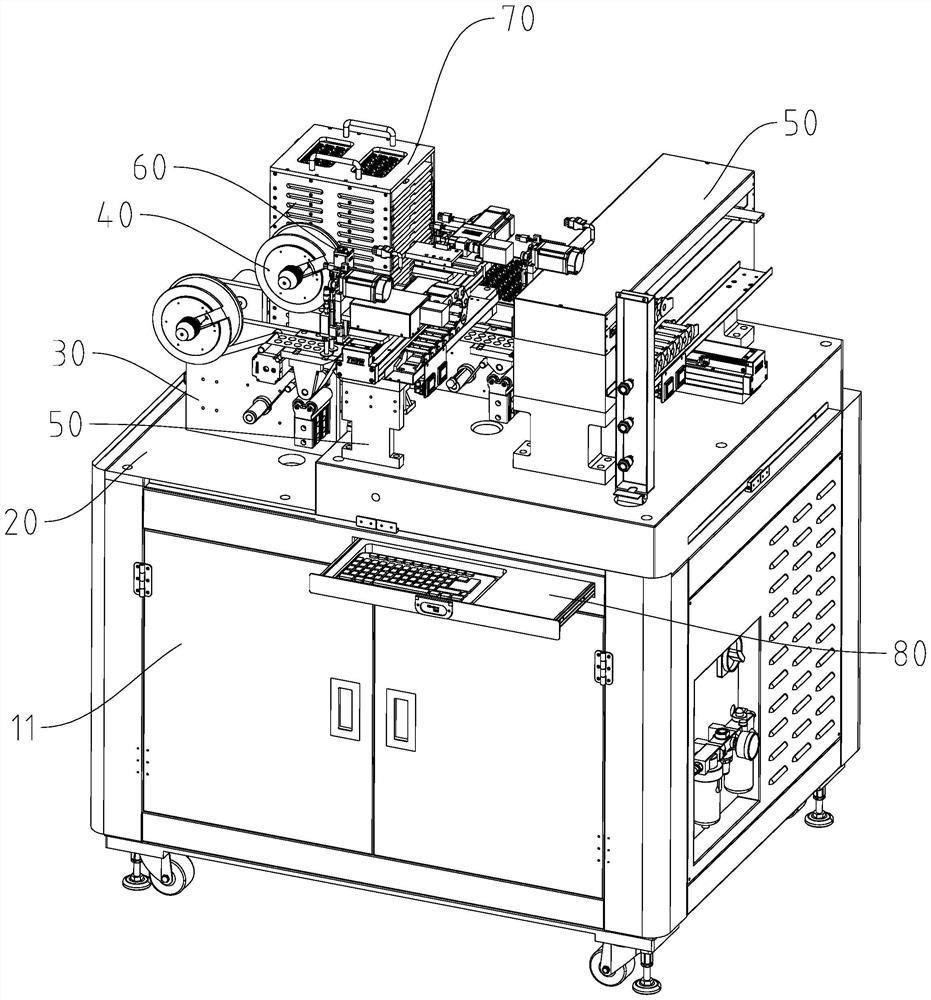

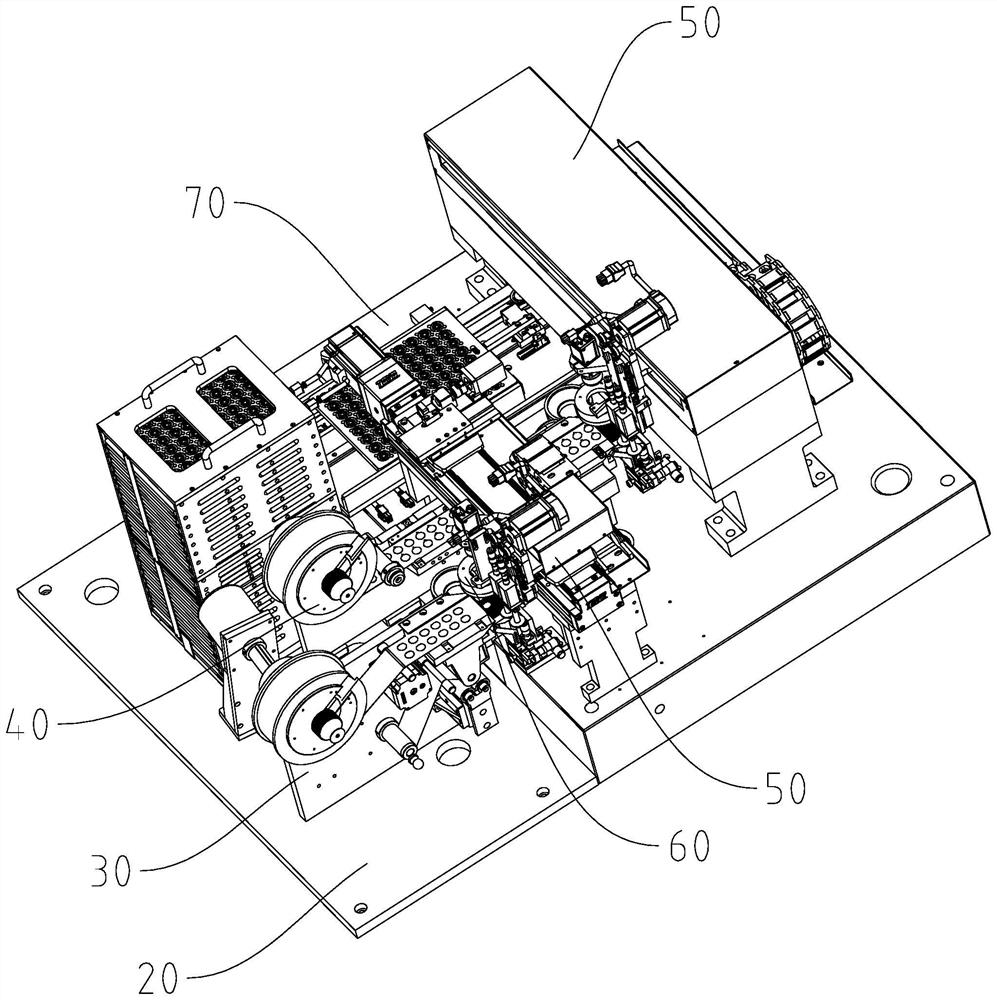

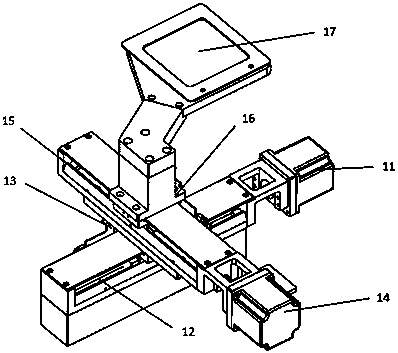

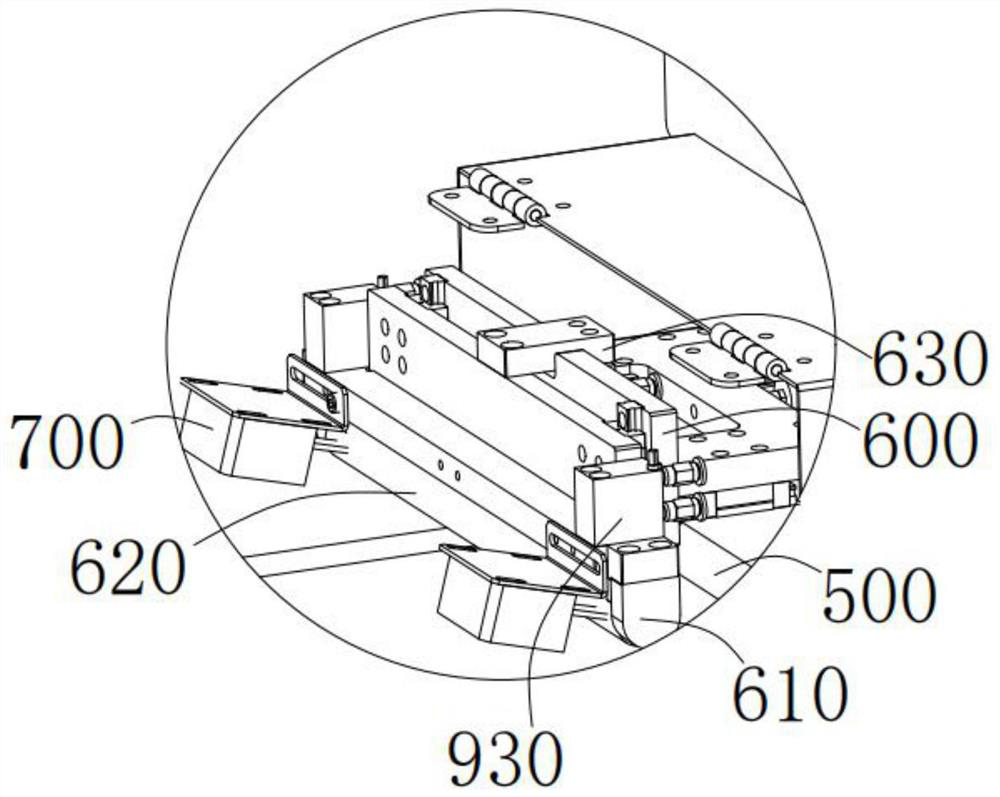

PendingCN109326816AImprove the accuracy of film applicationImprove film qualityAssembling battery machinesFinal product manufactureEngineeringManipulator

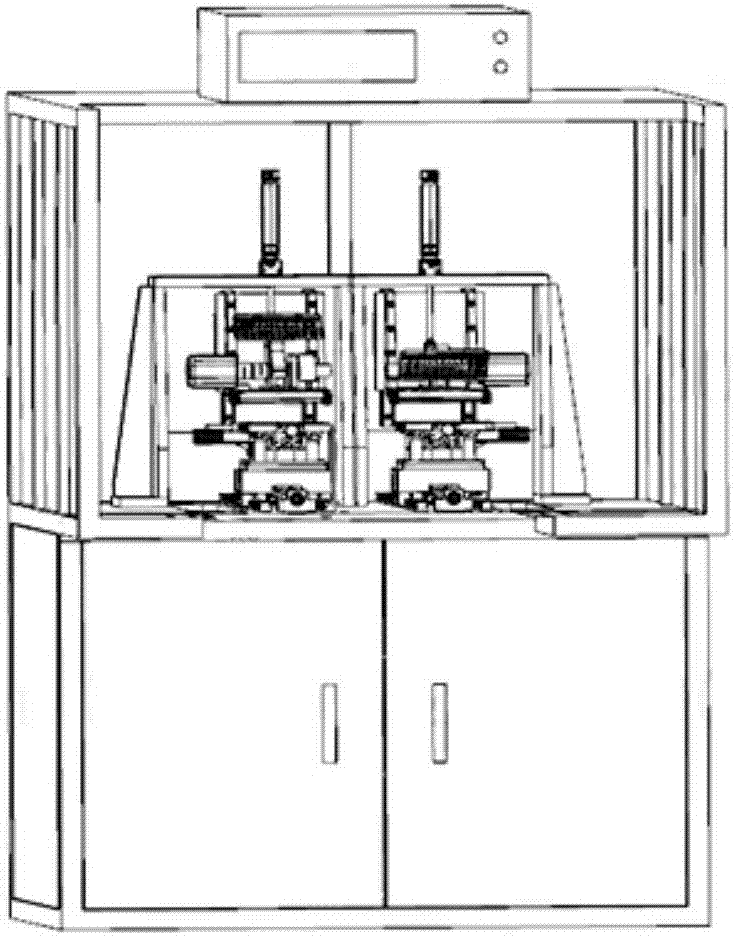

The invention relates to gum topping equipment. The gum topping equipment comprises a stander, a bottom plate I installed on the stander as well as a positioning apparatus, a manipulator apparatus, aloading / blanking apparatus, a two-side gum topping apparatus and a discharging apparatus which are installed on the bottom plate I, wherein the loading / blanking apparatus is surrounded by the positioning apparatus, the manipulator apparatus, the loading / blanking apparatus, the two-side gum topping apparatus and the discharging apparatus; the positioning apparatus and the discharging apparatus arerespectively arranged oppositely along an X axial direction; the two-side gum topping apparatus and the manipulator apparatus are uniformly arranged oppositely along a Y axial direction; the two-sidegum topping apparatus comprises an upper gum topping assembly and a lower gum topping assembly which are symmetrically arranged; the loading / blanking apparatus is at least provided with two carrier stations which are annularly arranged in an array manner; the at least two carrier stations are respectively provided with a hollowed part, and the hollowed parts are positioned between the upper gum topping assembly and the lower gum topping assembly.

Owner:ALLEGRO TECH

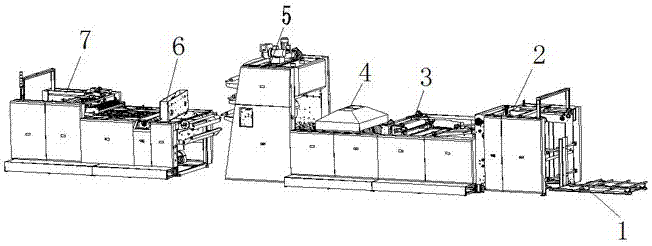

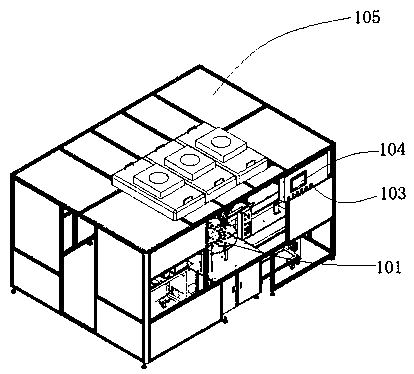

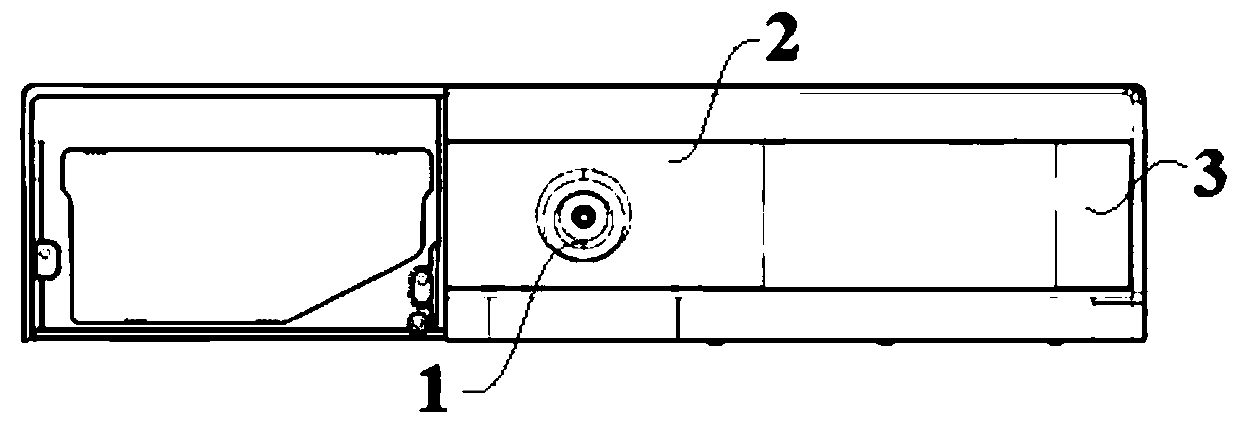

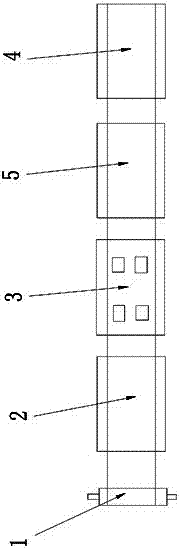

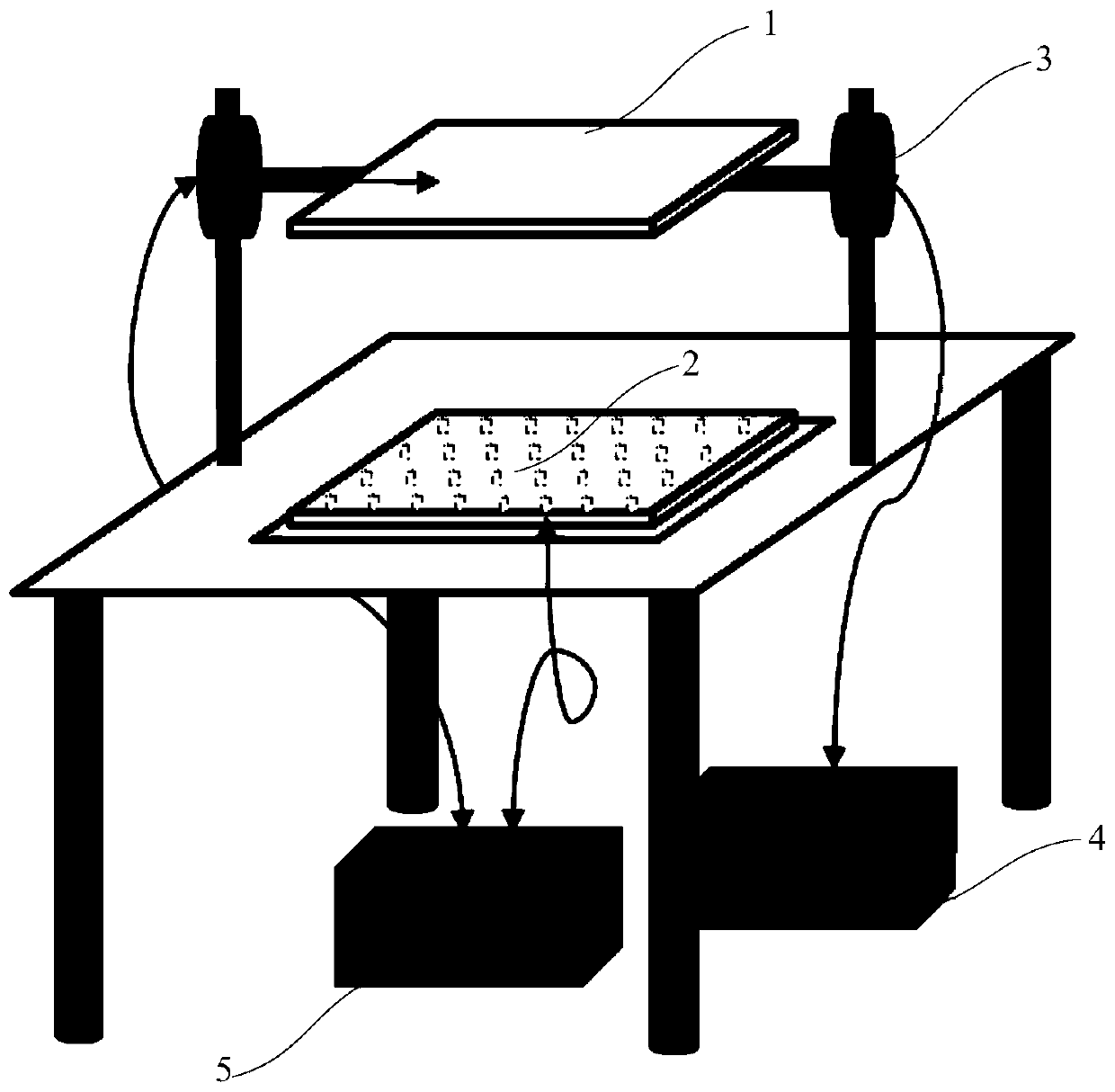

An automatic mobile phone film sticking film vending machine and its automatic film sticking film vending method

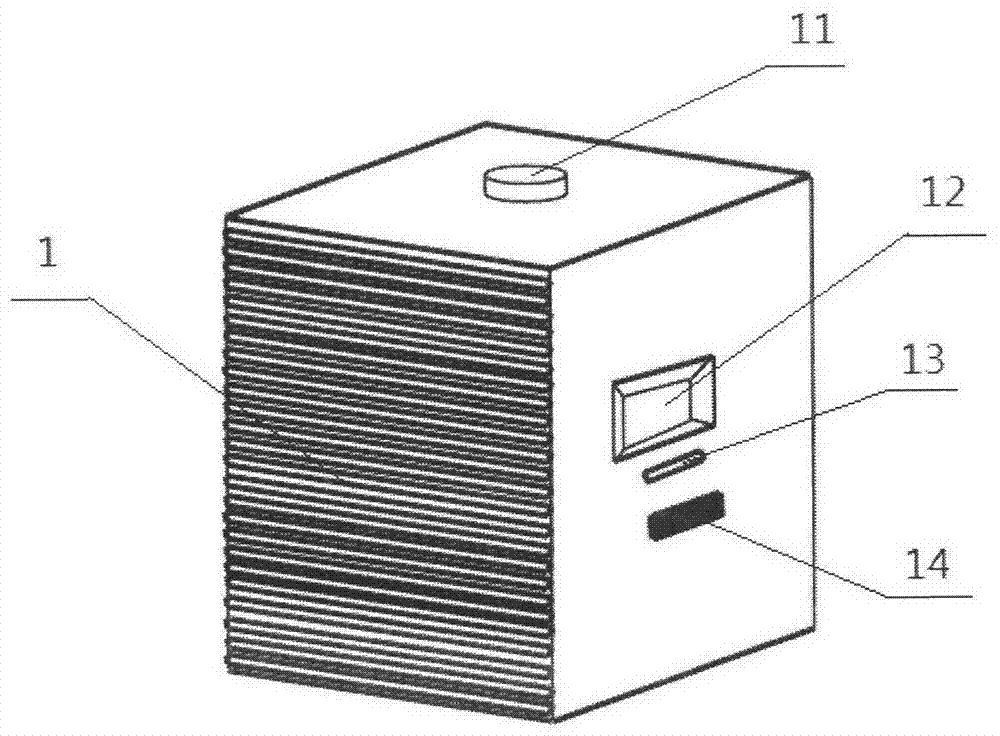

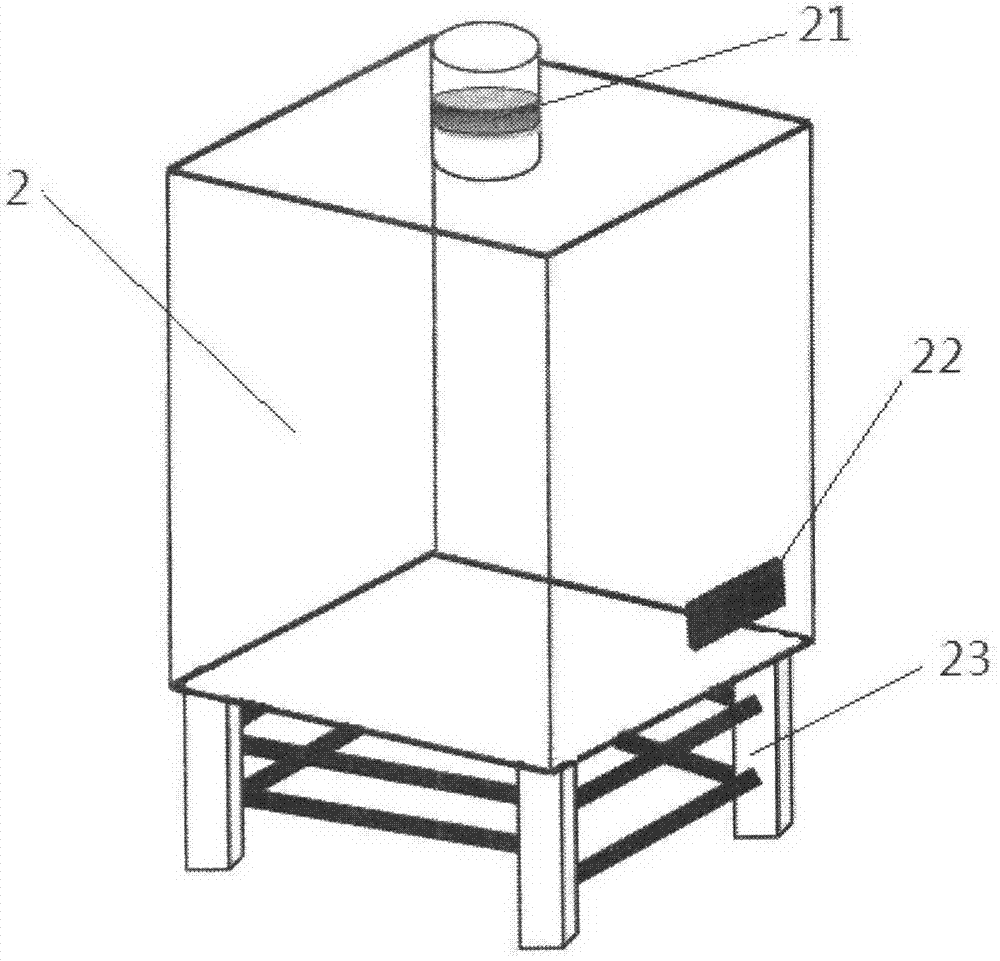

InactiveCN105197288BImprove compatibilityReduce intermediate costsCoin-freed apparatus detailsPackagingThe InternetMobile phone

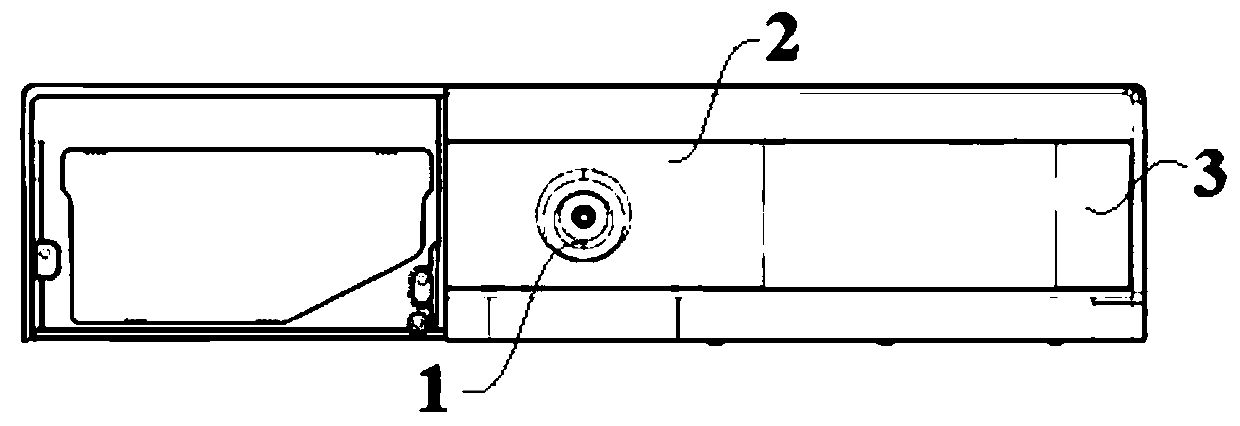

The invention discloses an automatic mobile phone film vending machine and an automatic film vending method thereof, comprising an automatic vending device (1), a glass clean room (2), a feeding device (3), a laser device (4), a bonding device (5), the feeding device (3), the laser device (4), and the bonding device (5) are placed in the glass clean room (2), and the glass clean room (2) is placed in the automatic In the vending device (1); the laser device (4) is located at the left end side of the feeding device (3), and the bonding device (5) is located at the right end of the feeding device (3); the The horizontal center line of the mobile phone platform delivery guide rail (513) and the cutting delivery platform (36) is the same straight line. The invention increases the precision of film sticking, improves work efficiency, improves the compatibility of the original film, saves costs, realizes the integration of film sticking and film sales, and reduces the intermediate cost of the film sticking industry.

Owner:张华

Film sticking machine

PendingCN110723346AStrong bonding and beautiful appearanceImprove the accuracy of film applicationWrapping material feeding apparatusAdhesive beltMechanical engineering

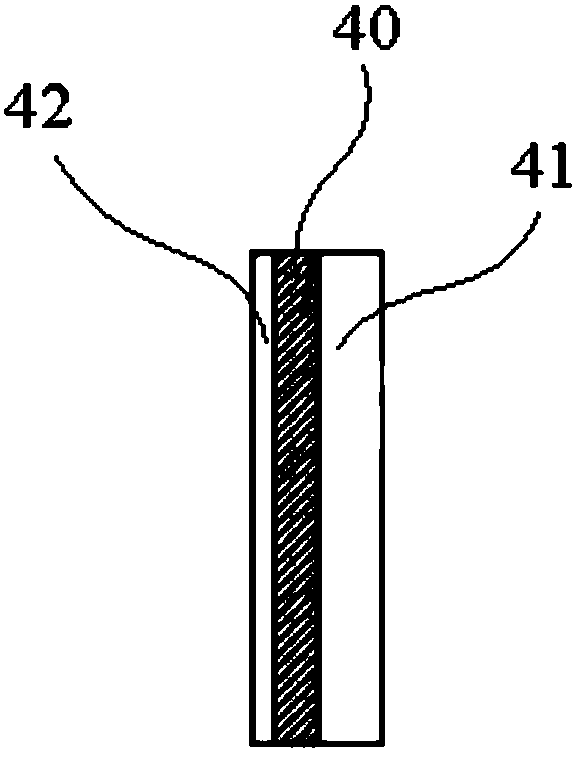

The invention discloses a film sticking machine, and belongs to the technical field of magnetic material manufacturing. The film sticking machine comprises a conveying device, a positioning device, afilm sticking device and a control device. The conveying device is used for conveying tape. The tape includes a first release film and a plurality of tape units with the same outer contours as piecesto be stuck with films, the tape units are arranged on the first release film uniformly in the length direction, and the first release film is provided with a plurality of first release film units overlapping with the tape units in a cut mode. The positioning device is used for placing and positioning the pieces to be stuck with the films. The film sticking device applies certain pressure when thetape units are aligned with the pieces to be stuck with the films to enable the tape units to be attached to the pieces to be stuck with the films. The control device is used for controlling the single tape feeding length of the tape to be equal to the spacing between the initial positions of every two adjacent tape units in the tape feeding direction. The film sticking machine has high film sticking accuracy, and the tape firmly adheres to magnetic sheets and the appearance is attractive after film sticking.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

High-speed precision film attaching equipment

ActiveCN106240898AReduce movement distanceShort timeWrapping material feeding apparatusPackaging automatic controlEngineeringCcd camera

The invention relates to high-speed precision film attaching equipment. The high-speed precision film attaching equipment comprises a base, a feeding mechanism, a film delivering mechanism, a film suction mechanism and a controller. The feeding mechanism is arranged in the length direction of the base. The film suction mechanism is mounted on the base and located above the feeding mechanism. The film delivering mechanism is arranged at one side of the base. The feeding mechanism comprises movable supports, a longitudinal movement plate and a transverse movement sliding bracket. The two movable supports are symmetrically fixed to the base. A longitudinal movement guide rail is mounted on each movable support. The longitudinal movement plate is mounted on the longitudinal movement guide rails in a sliding-fit manner. The transverse movement sliding bracket is fixed to the longitudinal movement plate and internally provided with a material containing box in a matched manner. The film delivering mechanism comprises film delivering rollers, film carrying belts and a dragging mechanism. The film suction mechanism comprises a movable support, a slide block, CCD cameras and material suction air cylinders. The controller is connected with a transverse movement servo driving mechanism, a longitudinal movement servo driving mechanism, the CCD cameras, the material suction air cylinders and a material dragging mechanism. The high-speed precision film attaching equipment has the beneficial effects of being high in film attaching efficiency and precision.

Owner:CHENGDU HOMIN TECH

Film laminating method of washing machine control panel automatic film laminating machine

InactiveCN110027203AGuaranteed accuracyReduce the cascading effectDomestic articlesAdsorptive membraneLaundry washing machine

The invention discloses a film laminating method of a washing machine control panel automatic film laminating machine and belongs to the technical field of washing machine processing. The washing machine control panel automatic film laminating machine comprises a manipulator mounted on the upper surface of a base, a first picking and placing unit, a second picking and placing unit and a strippingunit, wherein the first picking and placing unit and the second picking and placing unit are arranged on the two sides of the manipulator and used for storing films; the front end of the manipulator is provided with a first suction plate and a second suction plate which are used for adsorbing the films; the stripping unit comprises an upper clamping block and a lower clamping block, the upper clamping block and the lower clamping block are oppositely arranged on a third supporting plate and used for clamping release paper on the films, and the third supporting plate is perpendicularly mountedon the upper surface of the base. The washing machine control panel automatic film laminating machine moves and picks the films twice to reduce the adhesion effect between the two adjacent films in the moving and picking process, ensures the accuracy of the manipulator adsorbing the films, then ensures the accuracy degree of sticking the films on washing machine control panels during subsequent processing and improves the product quality.

Owner:马鞍山甬兴模塑有限公司

Full-automatic mobile phone film laminating method

The invention discloses a full-automatic mobile phone film laminating device, which comprises a workbench, a feeding device, a film laminating device, a blanking and conveying device and a blanking and clamping device, wherein a turntable is arranged on the workbench, the feeding device, the film laminating device and the blanking and conveying device are sequentially arranged on the periphery ofthe turntable, a second rack on one end of blanking and conveying device, connected with the turntable, is also provided with the blanking and clamping device; according to the invention, at least twofilm laminators are provided, and the laminators can be operated at the same time, the working time is saved, the working efficiency is improved, and a correction mechanism is also arranged, so thatautomatic correction can be carried out according to the size of a work piece, the application range is wide, and the film laminating precision is high.

Owner:来安县祥瑞机电科技有限责任公司

Full-automatic film adhering and testing device for mobile phones

InactiveCN107796830ARealize automatic film stickingImprove the accuracy of film applicationMaterial analysis by optical meansPackagingTest efficiencyMobile phone

The invention discloses a full-automatic film adhering and testing device for mobile phones. The full-automatic film adhering and testing device comprises a feeding module, a film adhering module, a CCD detecting module and an alarm module, wherein the feeding module comprises a protective-film feeding roller and a sucker connected below the protective-film feeding roller, and the sucker is used for sucking a protective film output by the protective-film feeding roller; the film adhering module comprises a mechanical arm and a film frame, and the mechanical arm is used for driving the sucker to move and pressing the protective film onto the film frame; the CCD detecting module is used for detecting the fitting precision of the protective film and the film frame, and the alarm module transmits an alarm prompt signal when the fitting precision exceeds a set range. By the arrangement, the full-automatic film adhering and testing device has the advantages that full-automatic film adheringcan be achieved, film adhering quality can be detected, film adhering precision can be increased, and testing efficiency can be increased.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

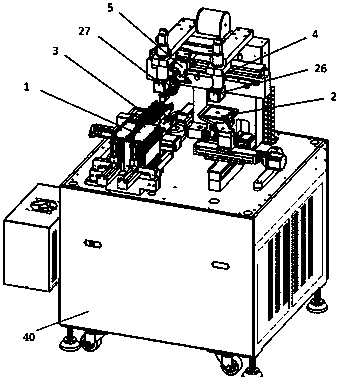

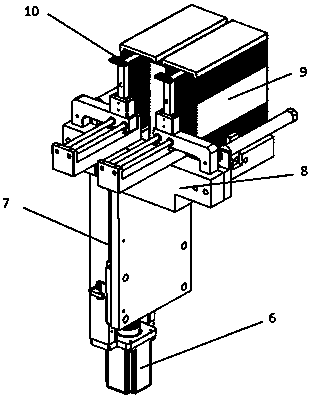

Washing machine controlling panel automatic laminating machine

PendingCN110001045AImprove the accuracy of film applicationQuality assuranceDomestic articlesManipulatorEngineering

The invention discloses a washing machine controlling panel automatic laminating machine, and belongs to the technical field of washing machine processing. The laminating machine comprises a manipulator which is installed on the upper surface of a base, a first taking and placing unit, a second taking and placing unit and a removing unit, wherein the first taking and placing unit and the second taking and placing unit are arranged on the two sides of the manipulator and used for storing membranes; the front end of the manipulator is provided with a first suction plate and a second suction plate which are used for absorbing the membranes; the removing unit comprises an upper clamping block and a lower clamping block which are oppositely arranged on a third supporting plate and used for clamping releasing paper on the membranes, and the third supporting plate is vertically installed on the upper surface of the base. According to the laminating machine, the first and second taking and placing units are arranged on the upper surface of the base, only one membrane is absorbed when the membranes are absorbed by the suction plates of the manipulator, the deflection of other membranes caused by the action of suction force does not take place to effectively improve the laminating precision, and the quality of a product is ensured.

Owner:马鞍山甬兴模塑有限公司

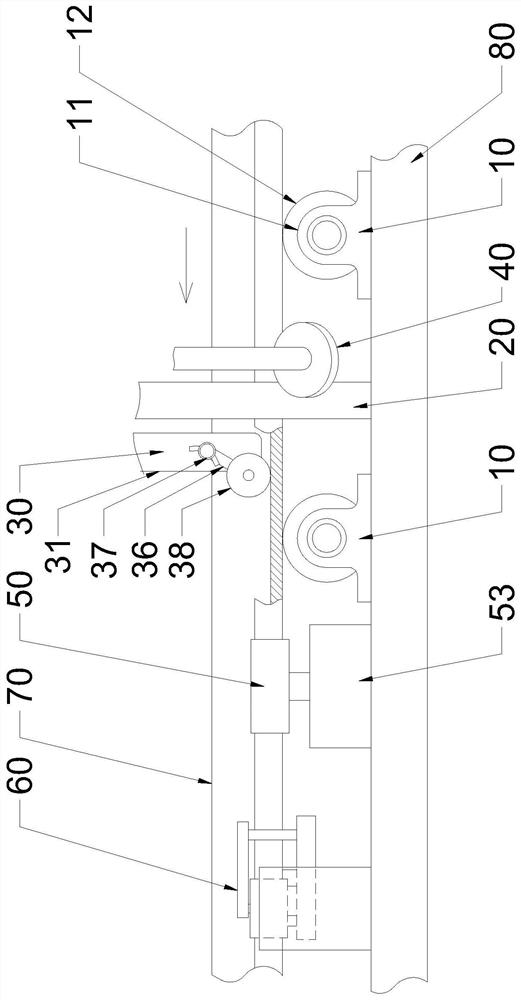

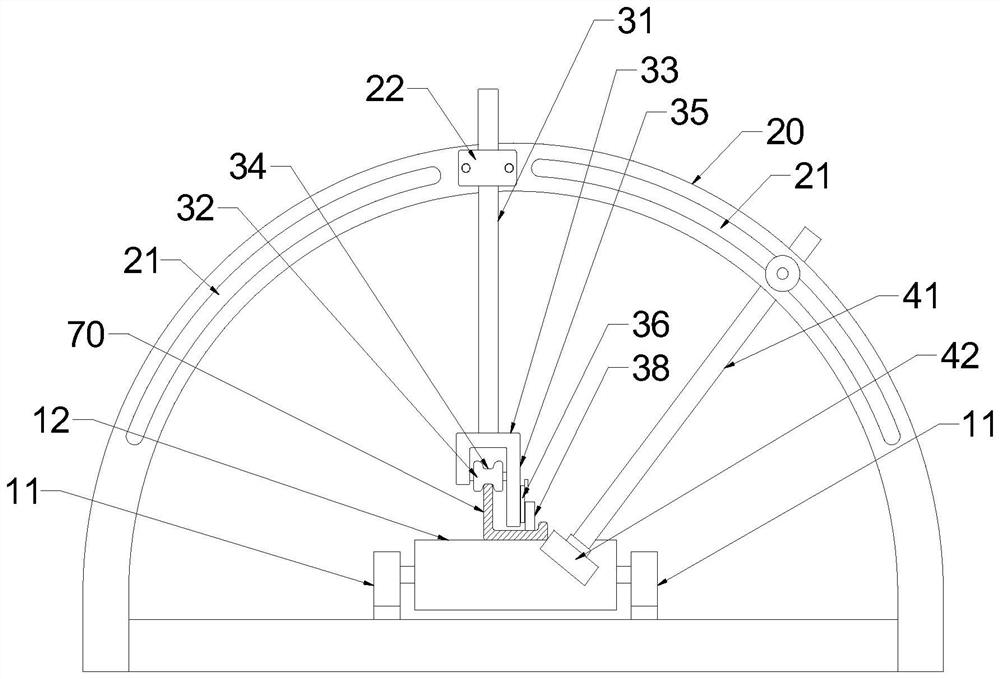

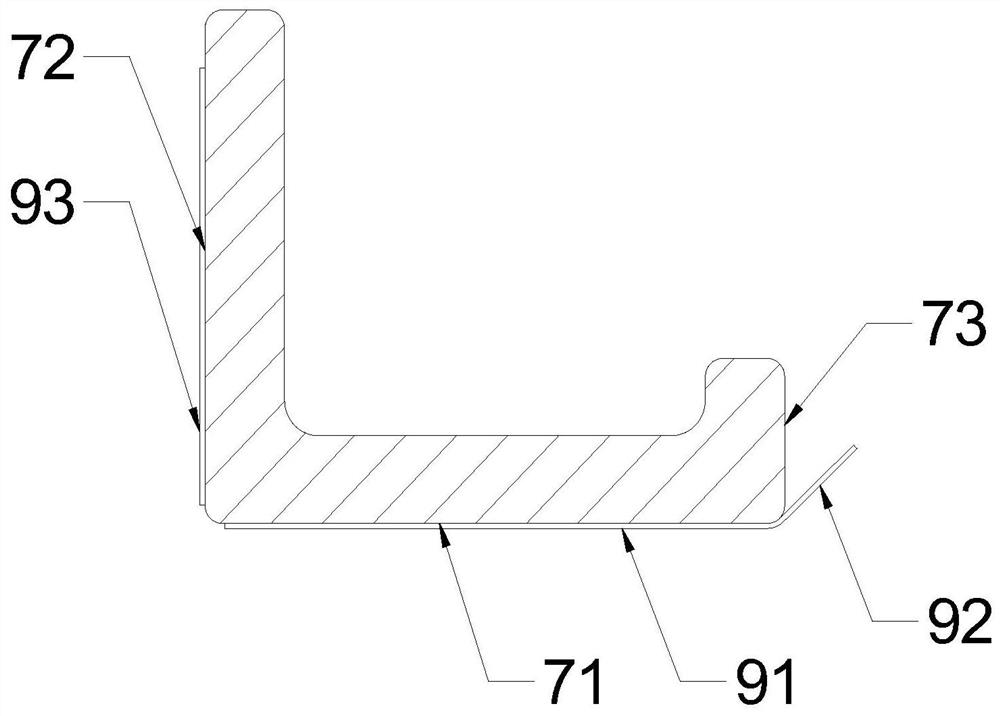

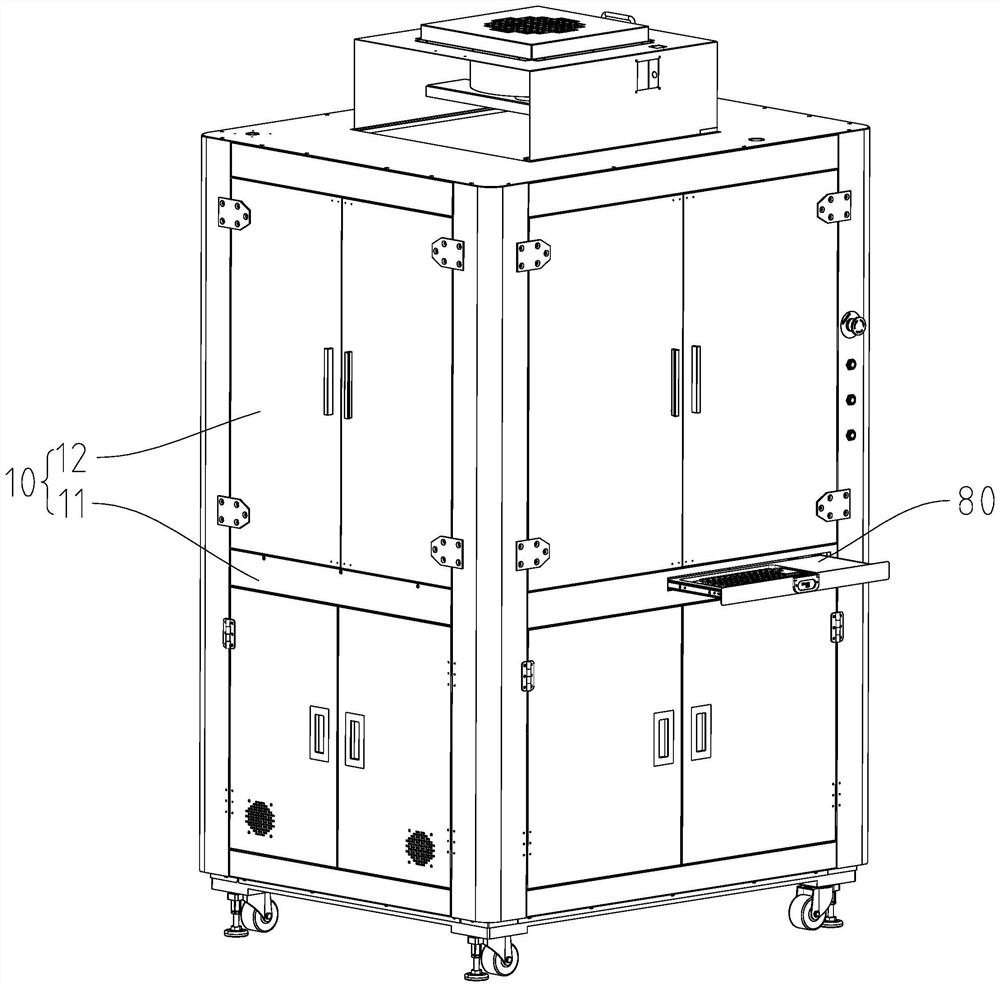

Film pressing mechanism and film pressing method of profile film sticking machine

PendingCN112157903APrevent shaking up and downProcess stabilityMechanical engineeringKinetic friction

The invention provides a film pressing mechanism and film pressing method of a profile film sticking machine. The film pressing mechanism of the profile film sticking machine comprises a supporting assembly, an adjusting frame, a jacking assembly and an edge folding assembly, wherein the supporting assembly is used for supporting a profile, and the profile comprises a bottom wall, a first side wall and a second side wall; the adjusting frame is used for adjusting the height of the jacking assembly or the inclination angle of the edge folding assembly, and is in a semi-circular ring shape and provided with an arc-shaped hole; the jacking assembly comprises a first supporting rod installed on the adjusting frame and a first rolling wheel installed at the lower end of the first supporting rod, and the first rolling wheel is in rolling friction with the top of the first side wall of the profile; and the edge folding assembly is located at the downstream of a bottom film unwinding barrel, and comprises a second supporting rod and a second rolling wheel installed at the lower end of the second supporting rod, the upper end of the second supporting rod is fastened into the arc-shaped hole, the second rolling wheel can be in rolling friction with a connecting edge of the bottom wall and the second side wall, and the right side of the bottom film is turned over obliquely upwards to forma pre-folded edge. According to the invention, the problems that a profile film sticking machine is low in film sticking efficiency, and bubbles and wrinkles exist during film sticking can be solved.

Owner:南京鸿发有色金属制造股份有限公司

High-precision intelligent wearable film pasting equipment

PendingCN113511365ASave manpower and material resourcesImprove the accuracy of film applicationWrapping material feeding apparatusPackaging automatic controlMaterial resourcesTouchscreen

The invention discloses high-precision intelligent wearable film pasting equipment. The equipment comprises a rack, a workbench, a first feeding mechanism, a second feeding mechanism, two material taking and placing mechanisms, two detection mechanisms, a feeding and discharging mechanism and a control mechanism. According to the equipment, Fresnel films are adsorbed on the first feeding mechanism through the material taking and placing mechanisms, the Fresnel films are detected through the detection mechanisms, then the Fresnel films are placed on the second feeding mechanism, the Fresnel films are adsorbed on the second feeding mechanism through the material taking and placing mechanisms, the Fresnel films are detected again through the detection mechanisms, then the Fresnel films are placed on sapphire touch screens of the feeding and discharging mechanism, the sapphire touch screens full of the Fresnel films are returned to a bin and discharged by the feeding and discharging mechanism, and then the sapphire touch screens without the Fresnel films are conveyed to a bin and fed through the feeding and discharging mechanism. The whole film pasting equipment adopts full-automatic arrangement, manpower and material resources are saved, the film pasting precision and the film pasting efficiency are greatly improved, and the overall reliability is high.

Owner:东莞市威耐科智能装备有限公司

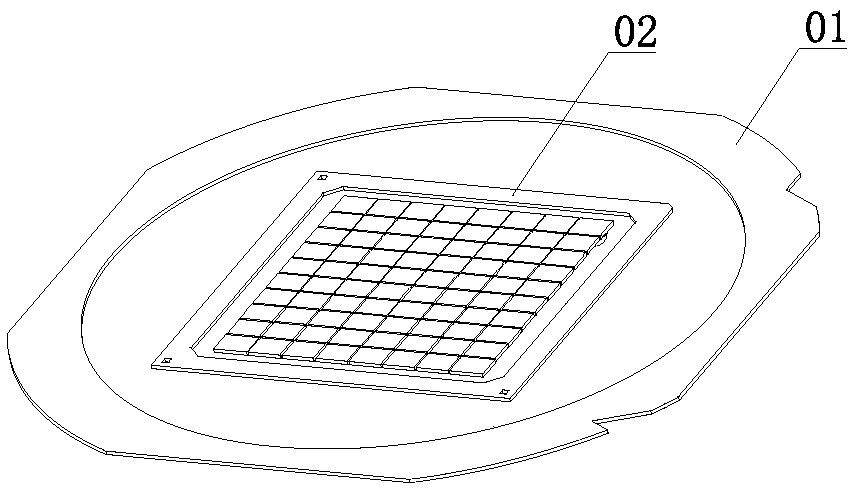

Multi-size chip based COB automatic film sticking machine matched with multiple diaphragms

PendingCN107839329AImprove work efficiencyReduce complexityControlling laminationLaminationEngineeringMechanical engineering

The invention discloses a multi-size chip based COB automatic film sticking machine matched with multiple diaphragms. The multi-size chip based COB automatic film sticking machine matched with the multiple diaphragms comprises a case; the case is provided with a feeding mechanism, a clamp table, a crystal source table, two lens components and a film sticking mechanism; the clamp table is arrangedat the discharge end of the feeding mechanism; the crystal source table and the clamp table are arranged side by side; one lens component is arranged above the clamp table; the other lens component isarranged above the crystal source table; and the film sticking mechanism is installed above the crystal source table through a bracket. The multi-size chip based COB automatic film sticking machine matched with the multiple diaphragms can effectively solve the problem of film sticking of chips in multiple sizes, reduces the film sticking processing time and improves the chip film sticking quality.

Owner:深圳市佳思特光电设备有限公司

Method for curved surface screen film sticking

InactiveCN109367873AExpand the scope of workImprove efficiencyPackagingAutomatic controlAssembly line

The invention discloses a method for curved surface screen film sticking and relates to the technical field of AMOLED mobile phone screen film sticking. The method for the curved surface screen film sticking comprises the steps that firstly, a feeding robot is used to absorb and place a curved surface screen in a tray on a turntable station; secondly, a film sticking robot is used to place the film on the curved surface screen on a turntable and carry out the machine film sticking; and then, a blanking robot is used to read a code on the curved surface screen after the film sticking is completed and put the curved surface screen in the next station. Firstly, the method for the curved surface screen film sticking adopts the three robots to work together instead of manual film sticking to improve the efficiency and accuracy of film sticking; secondly, compared with the assembly line type, the working mode of cooperation between the robots and the turntable occupies less space, and the working range of the robots is larger, so that the speed and the efficiency are improved; and finally, by changing a jig, the method can meet the requirements of different sizes of the curved surface screens. In addition, the method for the curved surface screen film sticking adopts full automatic control and has the advantages of simple steps, high efficiency, good adhesion effect and effective improvement of the rate of good products.

Owner:SHANGHAI WEISONG IND AUTOMATION +1

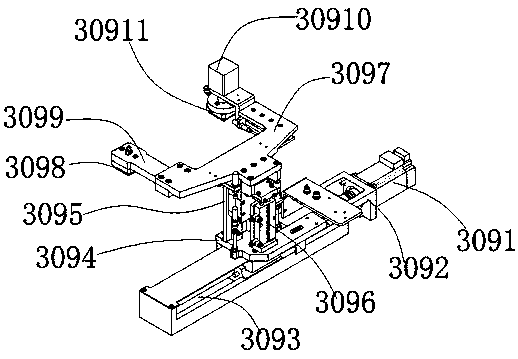

Automatic laminating machine table and laminating method thereof

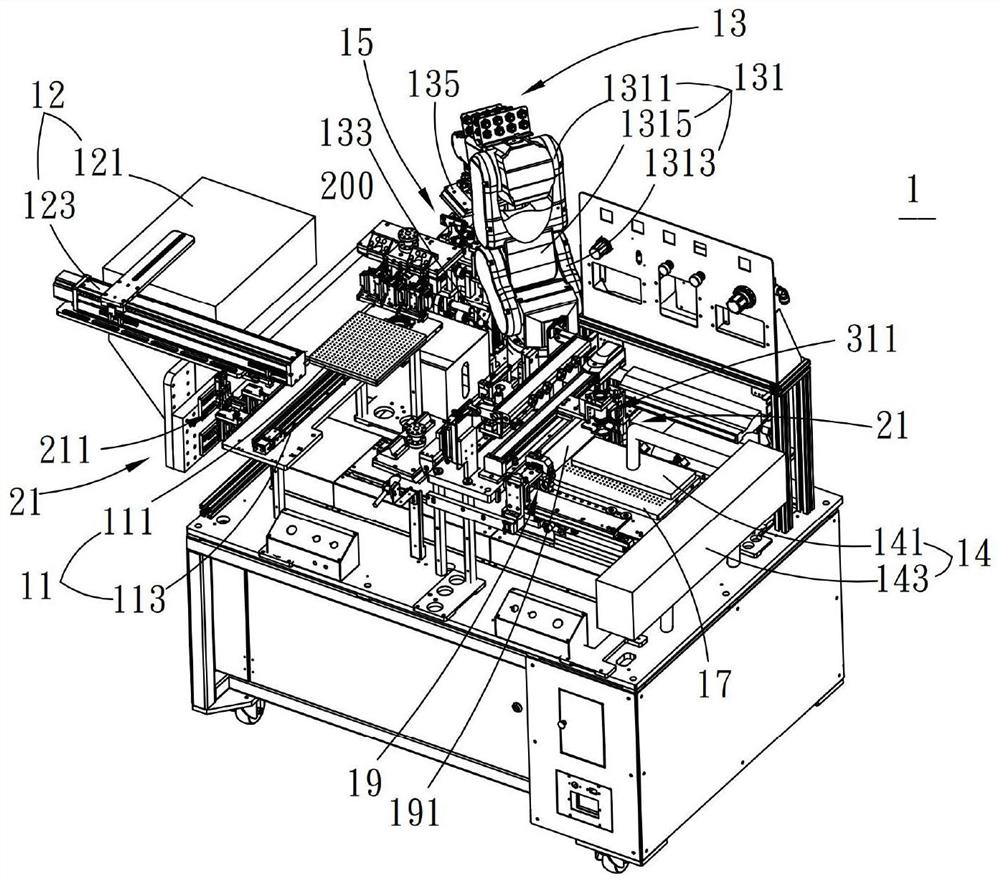

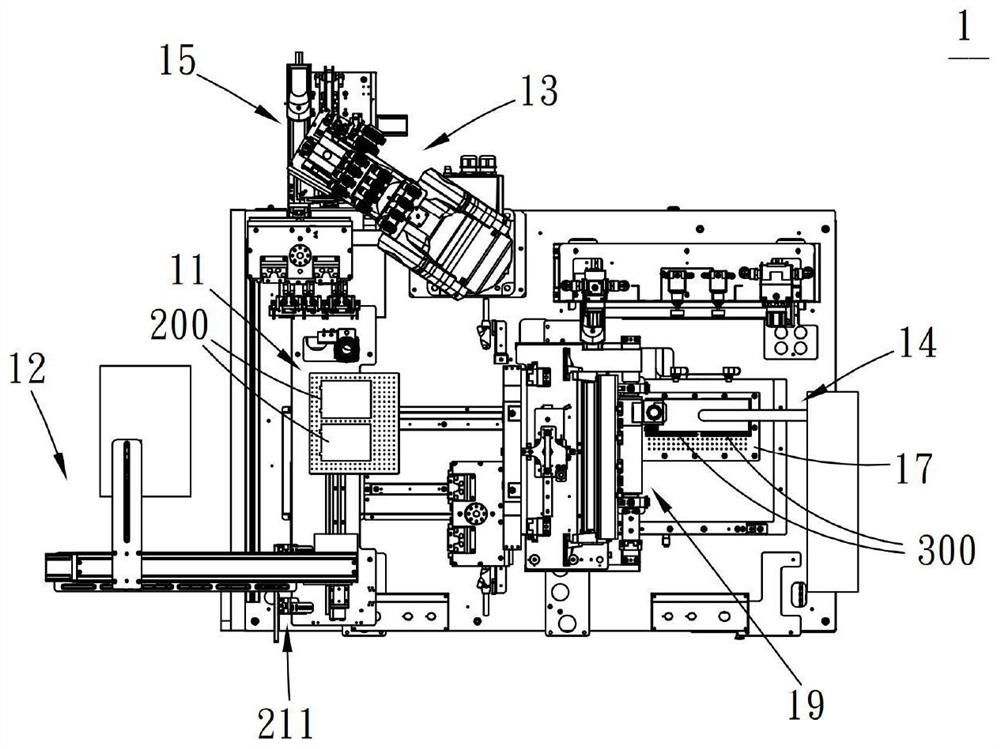

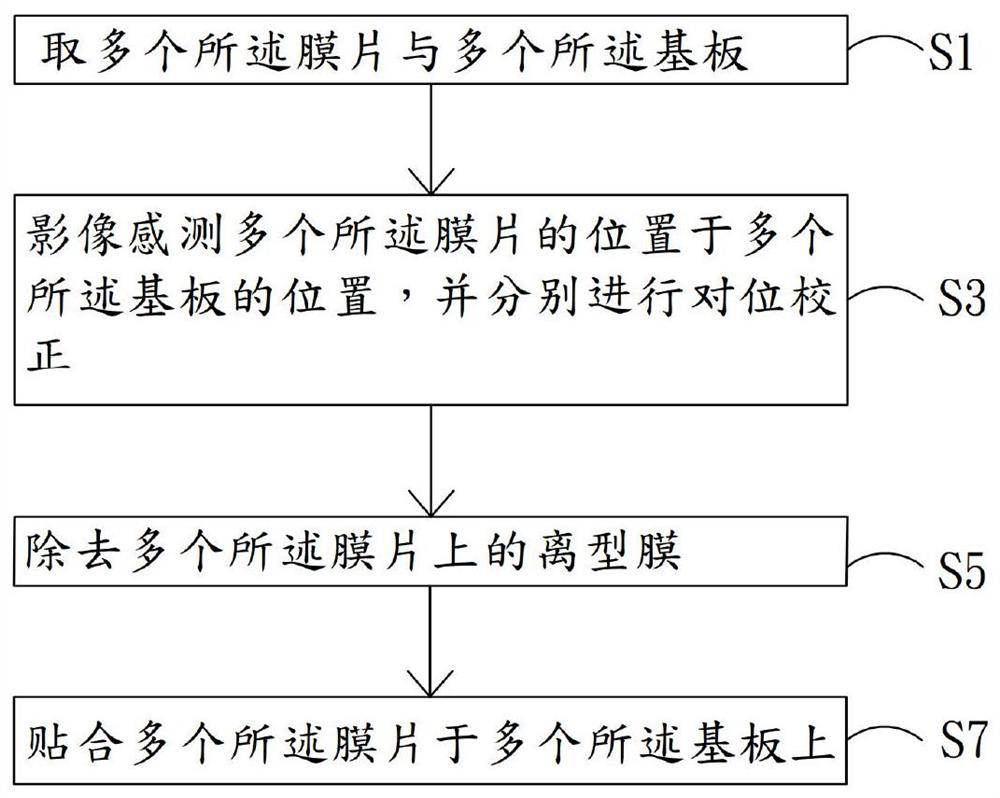

ActiveCN112677467AImprove the accuracy of film applicationImprove film application efficiencyRobotic armEngineering

The invention provides an automatic laminating machine table. The automatic laminating machine table comprises a feeding platform, a mechanical arm, a film removing mechanism, a laminating platform, a pressing mechanism and an alignment mechanism. The feeding platform is used for bearing multiple films, and the mechanical arm is used for taking up the multiple films. The film removing mechanism is located on the moving path of the mechanical arm and used for removing release films on the multiple films. The laminating platform is used for bearing multiple substrates, and the mechanical arm is used for placing the multiple films on the multiple substrates correspondingly. The pressing mechanism is arranged above the laminating platform, the pressing mechanism presses the films and the substrates, and the alignment mechanism senses the positions of the multiple films relative to the feeding platform or / and the positions of the multiple substrates relative to the laminating platform through images and performs alignment correction. The automatic laminating machine table has the functions of automatic film tearing, automatic alignment, automatic laminating precision correction and the like. Therefore, the automatic production efficiency is improved.

Owner:TRANSCEND OPTRONICS (YANGZHOU) CO LTD

A fpc encapsulation process

ActiveCN105059608BShorten the production cycleReplace manual operationWrapping material feeding apparatusFlexible circuitsEngineering

The invention relates to the technical field of flexible circuit board production, and in particular to an FPC encapsulating process. The FPC encapsulating process includes the following steps that A, a covering film is fed through a roller and conveyed to a drilling machine; B, the covering film enters the drilling machine so that a positioning hole can be punched, and the covering film is then conveyed to a die cutting machine after the positioning hole is punched; C, windowing work is conducted on the covering film by a plurality of die cutting heads by means of the die cutting machine, and all the die cutting heads can independently move in the X axis and the Y axis and can rotate; and E, the covering film enters an automatic film sticking machine so as to be stuck to a FPC board. By means of the FPC encapsulating process, the production cycle can be shortened, manual operation is replaced, and the production efficiency and the film sticking accuracy are improved.

Owner:GUANGDONG HUAHENG INTELLIGENT TECH CO LTD

An automatic laminating machine

ActiveCN106379593BAvoid wastingAvoid pollutionWrapping material feeding apparatusMechanical engineering

The invention relates to the technical field of film covering, in particular to an automatic film covering machine which comprises a rack, a film cutting device arranged on the rack, a film feeding mechanism used for conveying a film to the lower side of the film cutting device and a film covering device used for pressing a film sheet cut by the film cutting device on the surface of a product; and the film cutting device is composed of a film cutting lifting seat, a cutter mounting plate arranged on the film cutting lifting seat, cutter components arranged on the cutter mounting plate, a film cutting lifting drive mechanism used for driving the film cutting lifting seat to lift up and down and a film cutting rotary drive mechanism used for driving the cutter mounting plate to rotationally cut the film. According to the automatic film covering machine, feeding and rotary cutting of the film are automatically carried out, film covering is carried out on the cut film sheet, and the size of the cut film can be regulated online according to the size of the product, thus the film sheet is prevented from wasting, the film is cut when being adhered, the time of transferring the film sheet is shortened, the film sheet is also prevented from being polluted, the film adhering accuracy and the production efficiency are improved, and the rate of a good product is increased.

Owner:东莞市豪斯特热冲压技术有限公司

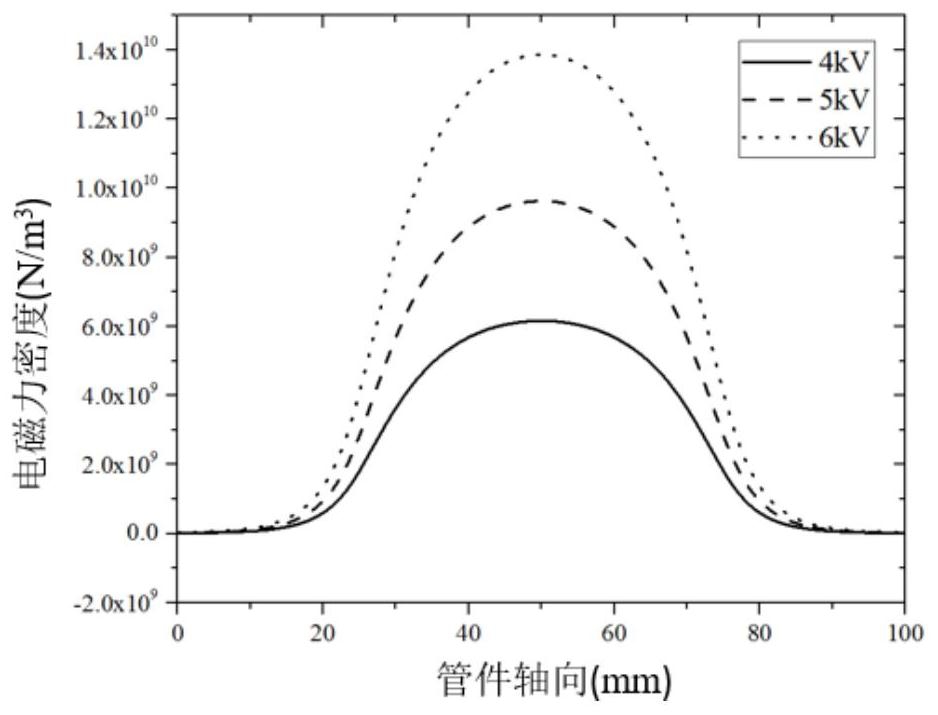

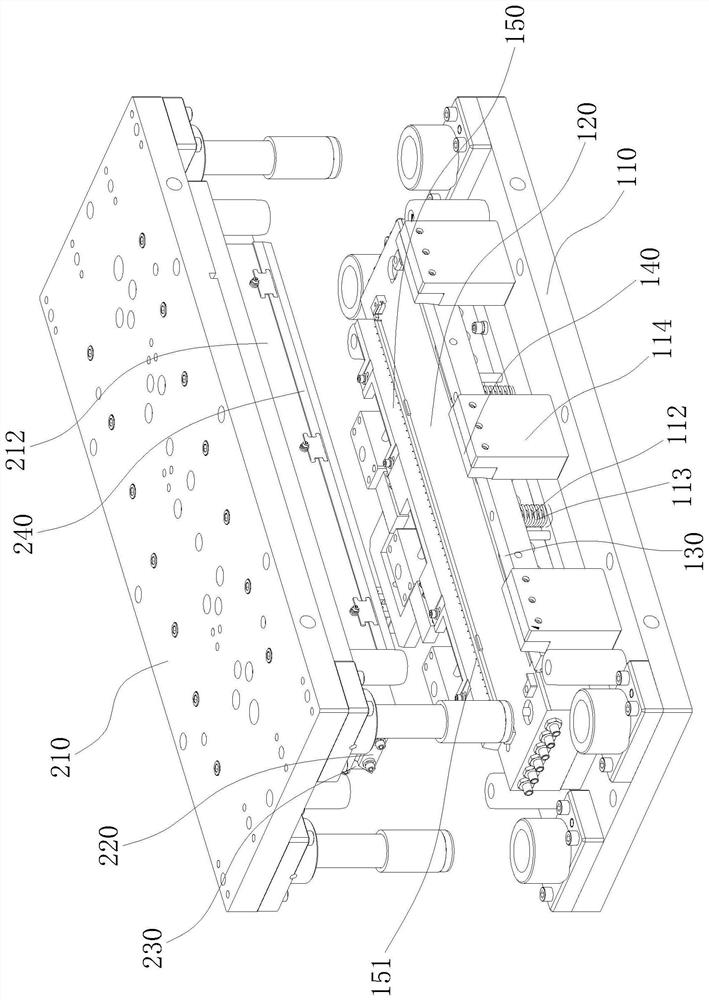

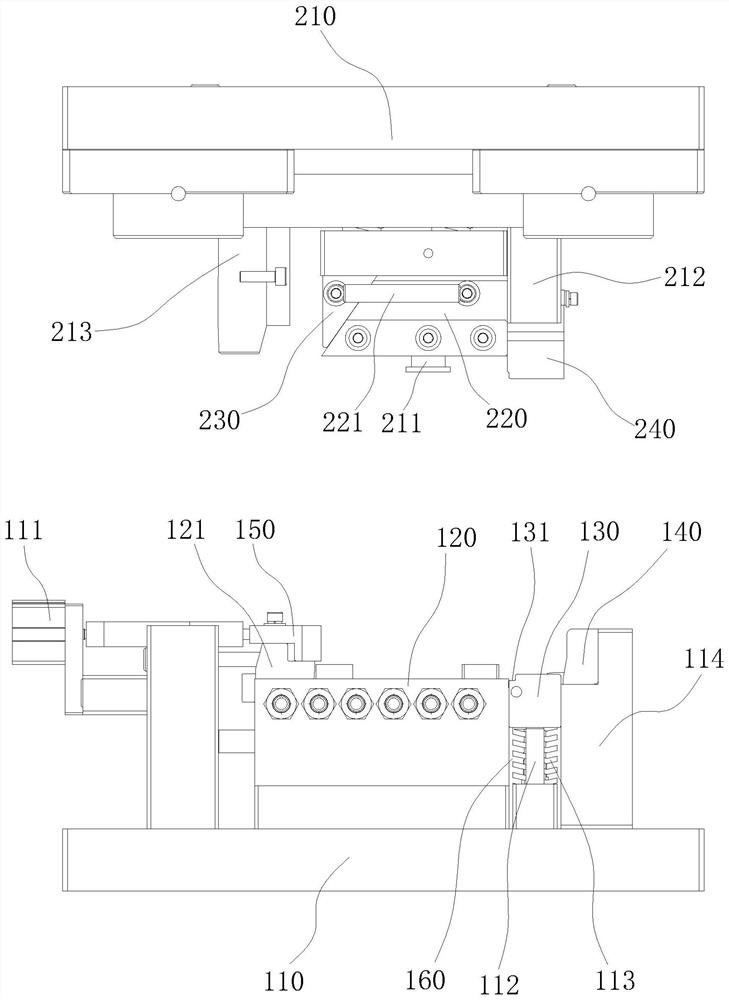

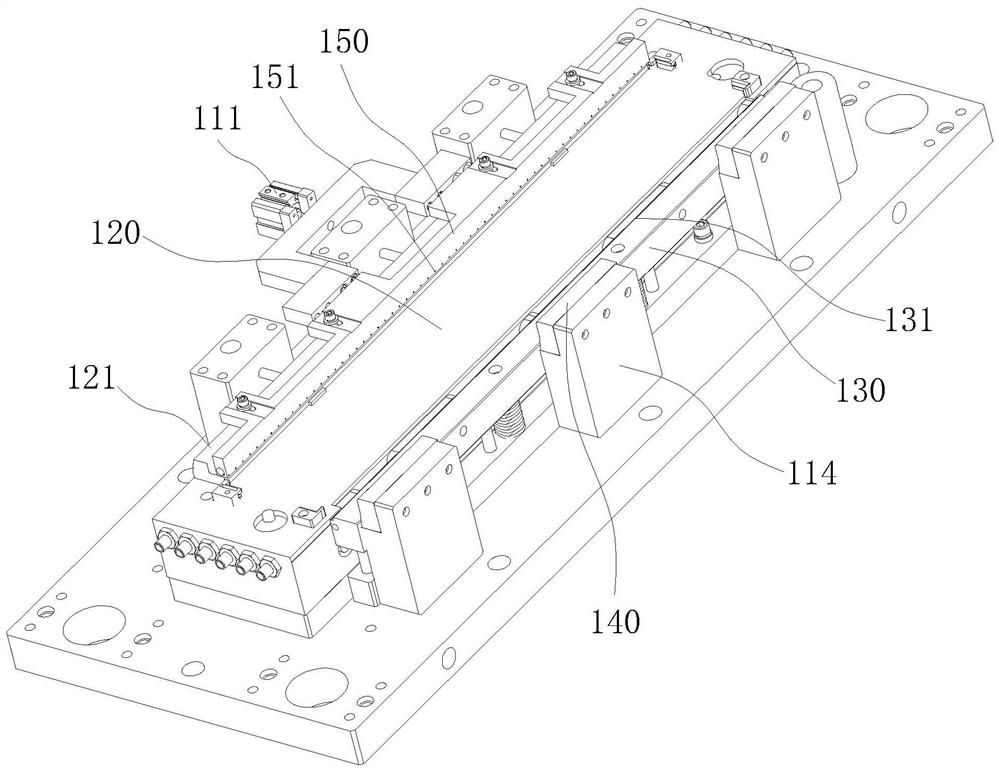

Electromagnetic forming device and method for metal pipe fittings

ActiveCN111515291BAdapt to different actual needsImprove the accuracy of film applicationShaping toolsMetal formingPipe fitting

The invention discloses an electromagnetic forming device and method for metal pipe fittings, belonging to the technical field of metal forming manufacturing, comprising: a plurality of forming coils coaxially arranged inside the metal pipe fitting to be formed; Forming mold; power supply module, including multiple pulse power supplies and discharge sequence control modules, multiple pulse power supplies are connected to multiple forming coils; the pulse power supply is used to pass pulse current to each forming coil, so that induced eddy currents are generated in the metal pipe to be formed , The magnetic field generated by the pulse current and the induced eddy current generate an electromagnetic force, and the metal pipe to be formed is deformed to the shape of the forming mold under the action of the electromagnetic force. The invention obtains different electromagnetic force field distribution characteristics by changing the discharge parameters of a single forming coil, meets different force field requirements, solves the problem of single electromagnetic force distribution characteristics in traditional electromagnetic forming, and can effectively improve the flexibility of electromagnetic forming and the metal Molding accuracy of pipe fittings.

Owner:HUAZHONG UNIV OF SCI & TECH

Quick film pasting mechanism for Z-shaped aluminum profile

PendingCN113977965AAssembly precisionIncrease productivityHybrid vehiclesElectrical batteryEngineering

Owner:MINTH AUTOMOTIVE TECH RES & DEV CO LTD

High-speed precision film lamination equipment

ActiveCN106240898BReduce movement distanceShort timeWrapping material feeding apparatusLaminationEngineeringCcd camera

The invention relates to high-speed precision film attaching equipment. The high-speed precision film attaching equipment comprises a base, a feeding mechanism, a film delivering mechanism, a film suction mechanism and a controller. The feeding mechanism is arranged in the length direction of the base. The film suction mechanism is mounted on the base and located above the feeding mechanism. The film delivering mechanism is arranged at one side of the base. The feeding mechanism comprises movable supports, a longitudinal movement plate and a transverse movement sliding bracket. The two movable supports are symmetrically fixed to the base. A longitudinal movement guide rail is mounted on each movable support. The longitudinal movement plate is mounted on the longitudinal movement guide rails in a sliding-fit manner. The transverse movement sliding bracket is fixed to the longitudinal movement plate and internally provided with a material containing box in a matched manner. The film delivering mechanism comprises film delivering rollers, film carrying belts and a dragging mechanism. The film suction mechanism comprises a movable support, a slide block, CCD cameras and material suction air cylinders. The controller is connected with a transverse movement servo driving mechanism, a longitudinal movement servo driving mechanism, the CCD cameras, the material suction air cylinders and a material dragging mechanism. The high-speed precision film attaching equipment has the beneficial effects of being high in film attaching efficiency and precision.

Owner:CHENGDU HOMIN TECH

Film tearing device of encapsulating machine and film tearing method thereof

PendingCN112373863ALow costIncrease productivityArticle unpackingStructural engineeringMechanical engineering

The invention provides a film tearing device of an encapsulating machine and a film tearing method thereof. A covering film feeding device of the encapsulating machine comprises a film tearing platform used for placing a covering film with release paper, a feeding assembly used for moving the covering film, a film tearing manipulator and a clamp used for pressing the covering film with the releasepaper, wherein a vacuum film rolling platform used for fixing the covering film with the release paper is arranged on the left side of the film tearing platform; the feeding assembly is used for transferring the covering film which is not torn to the film tearing platform; and the film tearing manipulator is arranged on the upper side of the film tearing platform, the lower end of the film tearing manipulator is fixedly connected with a pressing platform, and the film tearing manipulator can drive the pressing platform to reciprocate up and down. According to the film tearing device of the encapsulating machine and the film tearing method thereof, manual film tearing is replaced by full-automatic film tearing, so that the production efficiency and the film pasting precision are improved,and the labor cost is saved; and meanwhile, the production of covering films of various different types can be considered, a large number of tool clamps do not need to be manufactured, and a large amount of clamp cost is saved.

Owner:深圳市正光智能自动化有限公司

Film laminating machine

ActiveCN106486402BHigh degree of production automationReduce operating errorsSemiconductor/solid-state device manufacturingEngineeringVacuum pump

The invention provides a film pasting and pressing integration machine. The machine comprises an upper plate form, a lower platform and a transmission and turning device. The upper platform comprises a hard substrate, a first flexible material covering the hard substrate and a second flexible material covering the first flexile material. Multiple groove channels are formed in the first flexible material. Multiple first openings are formed in positions, corresponding to the grooves, of the second flexible material. The groove channels are connected with a vacuum pump. The lower platform comprises a substrate. Second openings are formed in the substrate. One end of each second opening is connected with the vacuum pump. The transmission and turning device is connected between the upper platform and the lower platform and used for up-down transmitting the upper platform and controlling turning of the platform. According to the invention, by using the film pasting and stitching integration machine to paste films, film pasting precision can be effectively controlled; film pasting time is shortened; and an air bag is used for pressing the films, so gas in the films can be effectively squeezed out and bubbles and folds can be reduced.

Owner:IRAY IMAGE TECH TAICANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com