Washing machine controlling panel automatic laminating machine

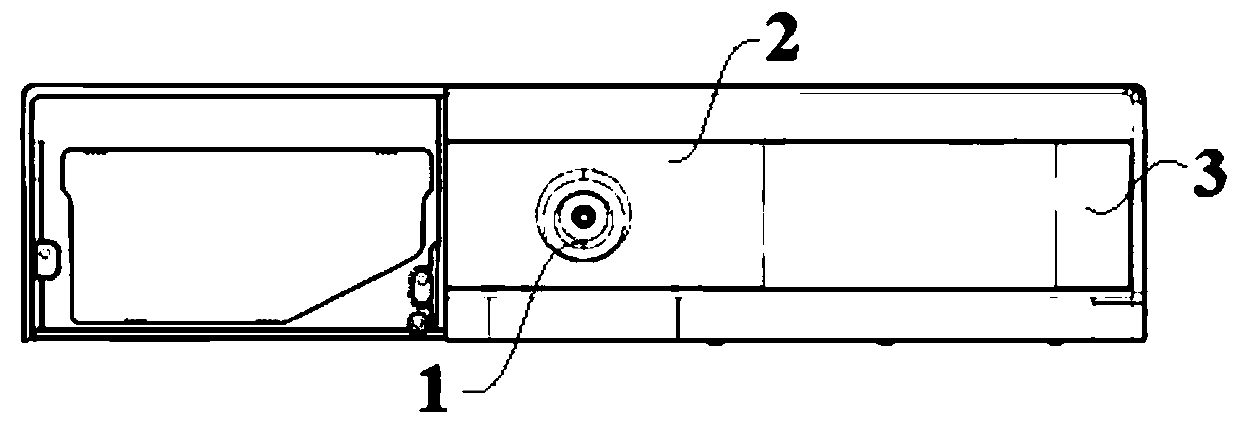

A technology for control panels and washing machines, which is applied to household components, household appliances, and other household appliances, etc. It can solve the problem of low precision of sticking film, achieve the effect of ensuring quality and improving the precision of sticking film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

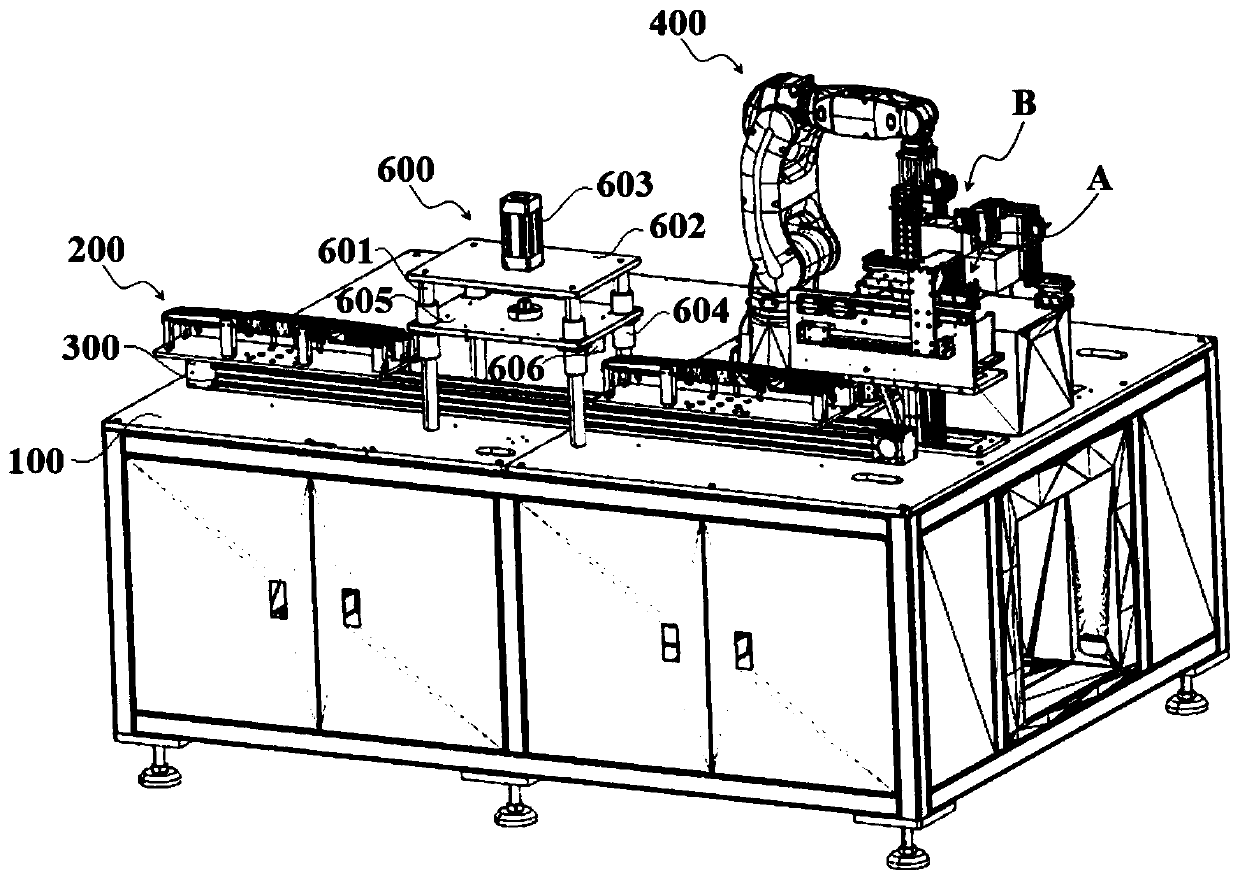

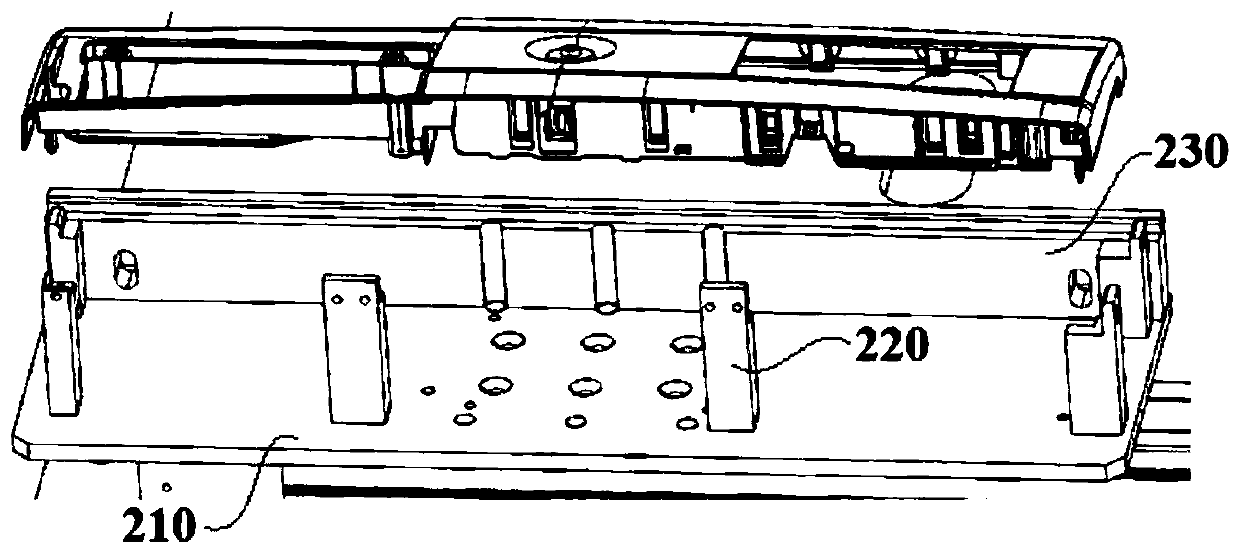

[0038] combine figure 2, an automatic laminating machine for a washing machine control panel in this embodiment includes a manipulator 400 and a tear-off unit installed on the upper surface of the base 100, wherein the front end of the manipulator 400 is provided with a first suction plate 421 and a second suction plate 431 is used to absorb the film. The manipulator 400 can rotate in three-dimensional space. Specifically, the manipulator 400 rotates to control the first suction plate 421 to absorb the first film, and the second suction plate 431 is used to absorb the second film. Since the first diaphragm and the second diaphragm are pasted with a release paper at the bottom of the diaphragm before the first diaphragm and the second diaphragm are pasted, the first diaphragm and the second diaphragm are protected, and the release paper needs to be torn off before pasting. In this embodiment, the release paper at the bottom of the diaphragm is torn off by the tear-off unit, su...

Embodiment 2

[0053] A kind of washing machine control panel automatic lamination machine of this embodiment is basically the same as embodiment 1, further, in combination Figure 4 The shape of the longitudinal section of the baffle plate 520 of the first pick-and-place unit in this embodiment is L-shaped, and a waist-shaped groove 521 is opened on the bottom of the L-shape. 520 is perpendicular to each other, and a fixing member such as a fixing bolt or a fixing pin passes through the waist-shaped groove 521 and is connected with the horizontal mounting plate 510 . In this embodiment, by changing the relative position between the waist-shaped groove 521 and the fixing part in the waist-shaped groove 521, the distance between the two baffles 520 is changed, that is, the size of the diaphragm storage place is changed to facilitate storage of different sizes. Diaphragm, but also easy to place the diaphragm.

[0054] In addition, the horizontal installation plate 510 of the first pick-and-pl...

Embodiment 3

[0061] An automatic film laminating machine for a washing machine control panel in this embodiment is basically the same as in Embodiment 2. Furthermore, in this embodiment, a plurality of suction nozzles 580 are provided on the suction plate 572, and the suction nozzles 580 are far away from the end of the suction cylinder 571. There is a suction cup on the top, which is used to adsorb the diaphragm. The end of the suction nozzle 580 close to the adsorption cylinder 571 is provided with a suction port 581. The suction port 581 communicates with the trachea. By increasing the gas in the trachea, the pressure of the gas on the suction cup is increased. When the suction cup absorbs the diaphragm, there is less air between the two, thereby generating a certain degree of vacuum, thereby achieving the effect of adsorbing the diaphragm.

[0062] combine Figure 4 , preferably, there are four suction nozzles 580 in this embodiment, and the four suction nozzles 580 are respectively ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com