Quick film pasting mechanism for Z-shaped aluminum profile

A film sticking mechanism and aluminum profile technology, applied in the field of aluminum profile thermal sticking, can solve the problems of poor working environment, inaccurate assembly, and inability to apply the Z-type single-product aluminum profile thermal sticking process, etc., to achieve high production efficiency and improve sticking accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

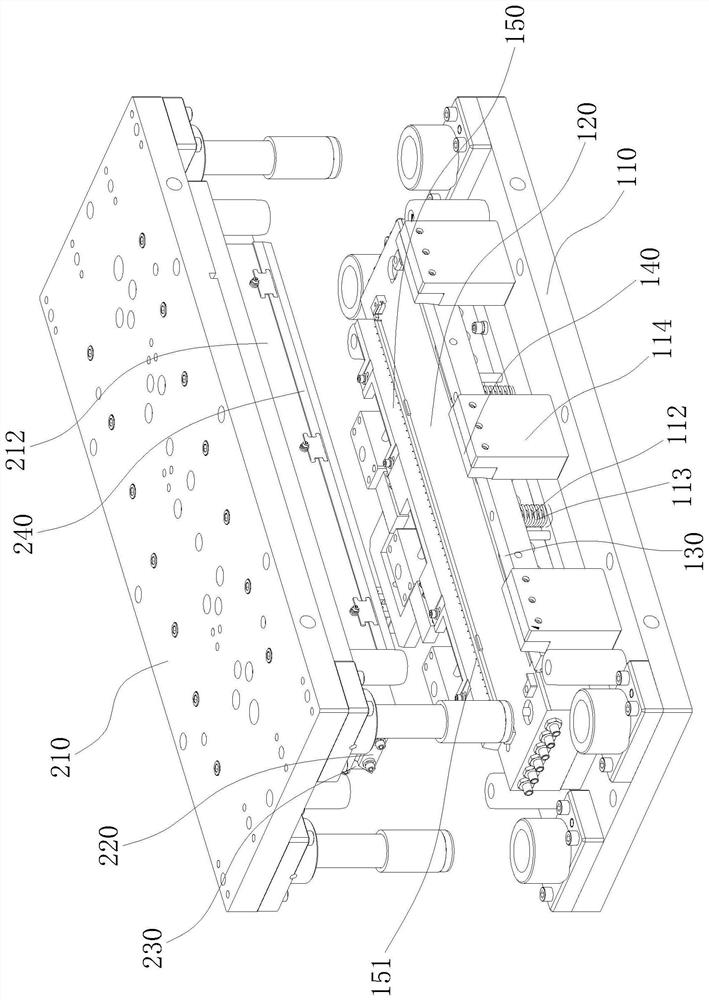

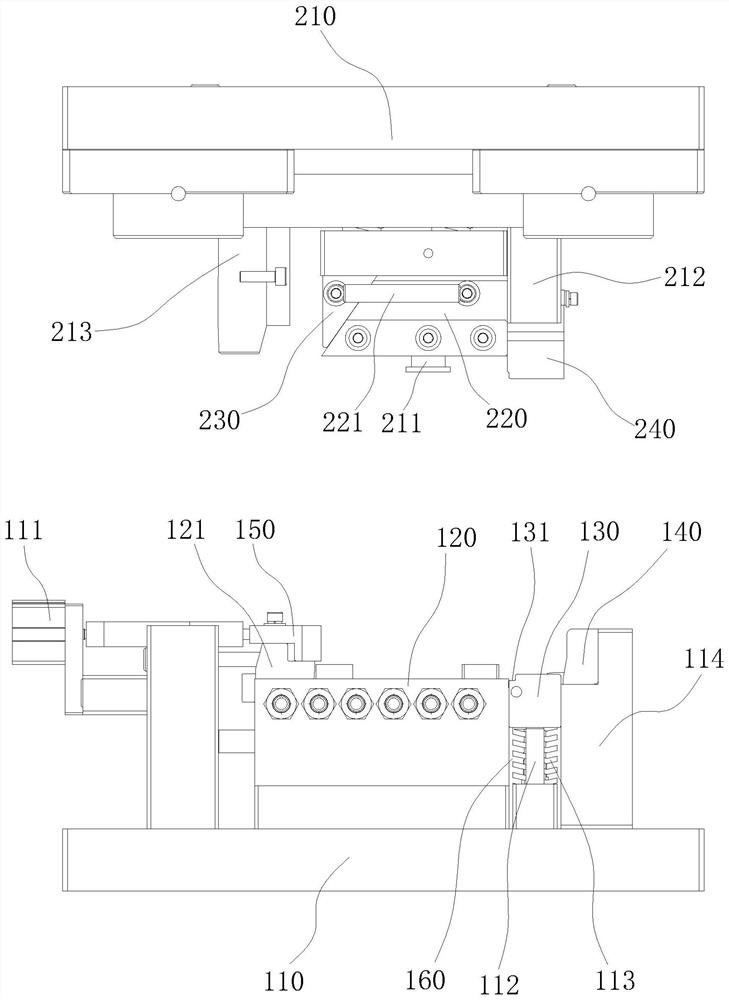

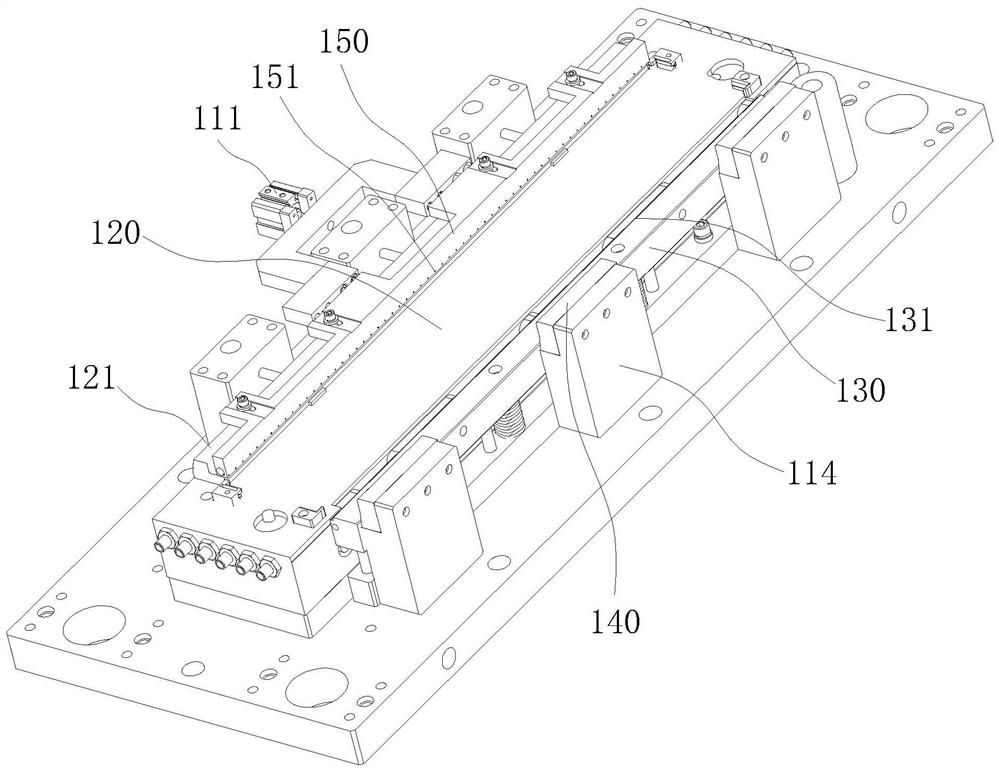

[0034] Such as Figure 1-8 As shown, a Z-shaped aluminum profile fast film sticking mechanism includes: an upper mold unit and a lower mold unit. 300 and the insulating film 400 can be quickly and reliably positioned, and the mold can automatically realize the lamination and compression of the workpiece 300 and the insulating film 400 in three directions, and then the workpiece 300 and the insulating film 400 are quickly and quickly carried out on the mold. Heating and cooling, so as to realize the effect of automatic thermal film application. In addition, the functions of rapid heating, heat preservation and pressure maintaining, rapid cooling and pressure and temperature monitoring of the workpiece 300 can also be set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com