Film pressing mechanism and film pressing method of profile film sticking machine

A film laminating mechanism and film laminating machine technology, which is applied in the field of profile film laminating equipment, can solve problems such as unstable film laminating action, low film lamination efficiency, and air bubbles, shorten the time for adjusting the tension of film materials, improve operating efficiency, and equipment compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

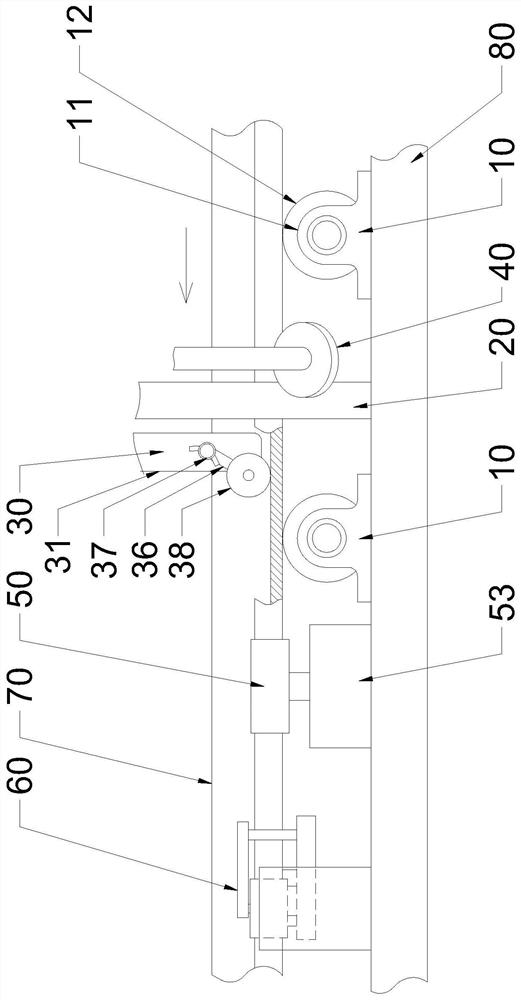

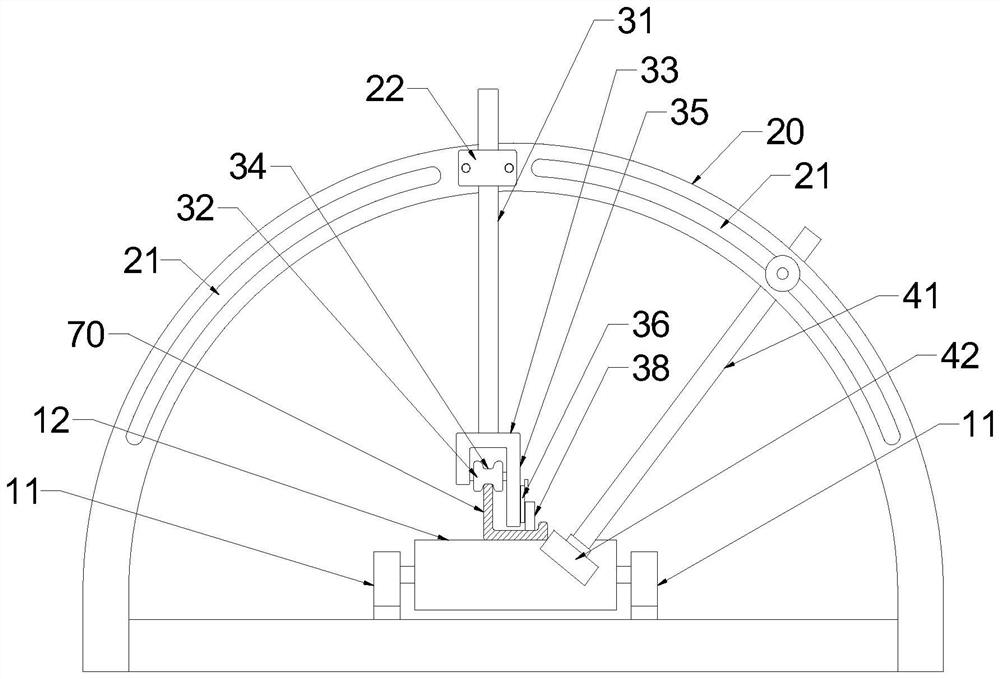

[0047] Such as Figure 1 to Figure 8As shown, the present embodiment discloses a laminating mechanism of a profile film laminating machine, including a supporting assembly 10 , an adjusting frame 20 , a pressing assembly 30 , a hemming assembly 40 , a laminating assembly 50 and a leveling assembly 60 .

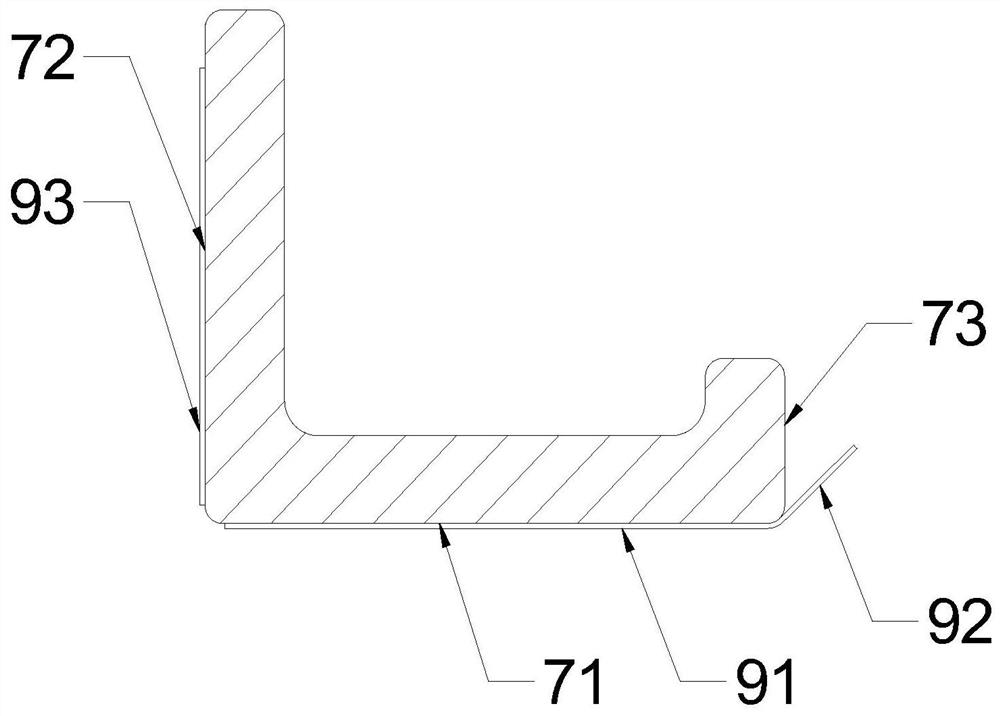

[0048] Please refer to figure 1 , the support assembly 10 is used to support the elongated profile 70. The profile 70 of this embodiment includes a bottom wall 71 and a first side wall 72 and a second side wall 73 extending upward from the left and right sides of the bottom wall 71 respectively. One side wall 72 is higher than the second side wall 73 . The support assembly 10 includes a bearing seat 11 installed on the frame 80 and support rollers 12 installed horizontally on the bearing seat 11 at both ends, and multiple sets of support assemblies 10 are installed on the frame 80 at intervals to support the profile 70 smoothly .

[0049] Please refer to figure 2 , the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com