Novel impingement plate structure for heat exchanger

A technology of anti-shock plate and heat exchanger, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. process medium short circuit and other problems, to achieve the effects of good structural stability, simple structure and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

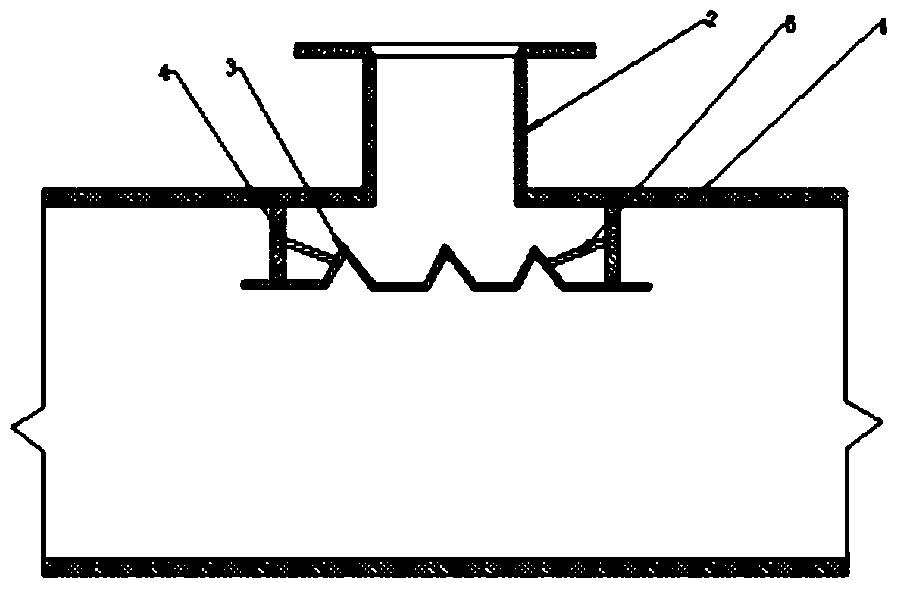

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The inverted V-shaped anti-shock plate 3 is a flat plate structure with V-shaped protrusions, the inverted V angle is 30-60°, and is welded to the lower end of the heat exchanger intake pipe 2 through the rib plate 4. The rib plate 4 is a strip structure, one end is welded on the inner wall of the housing 1 , and the other end is welded on the horizontal section of the inverted V-shaped impact plate 3 . The reinforcement bar 5 is welded between the inverted V-shaped anti-shock plate 3 and the rib plate 4, and the inverted V-shaped anti-shock plate 3 is fixed twice, which also reduces the stress at the welding place between the rib plate 4 and the inverted V-shaped anti-shock plate 3. stress concentration. When the fluid entering from the heat exchanger inlet pipe 2 first flows into the inverted V-shaped anti-shock plate 3, the raised inverted V surface disperses the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com