High-speed precision film attaching equipment

A film sticking equipment and sophisticated technology, applied in automatic control of packaging, external support, transportation and packaging, etc., can solve problems such as difficult operation, reduced film quality, high maintenance cost, etc., to improve position accuracy, shorten moving distance, and improve film sticking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

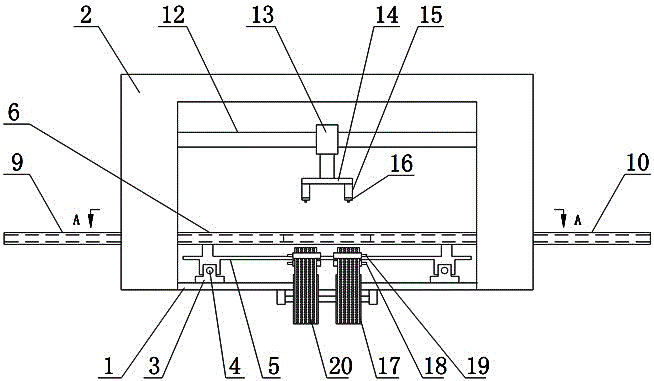

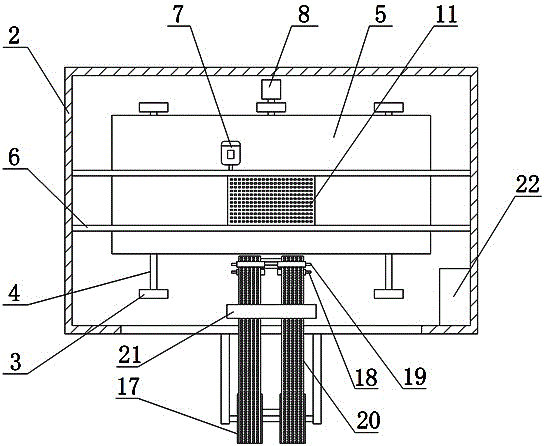

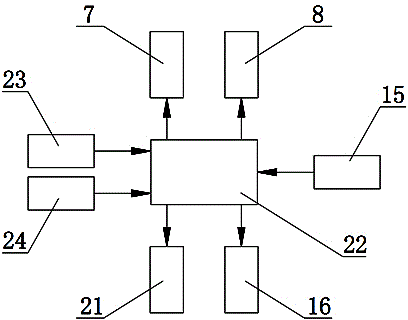

[0024] Such as figure 1 and figure 2 As shown, the high-speed precision film laminating equipment includes a base 1, a feeding mechanism, a film feeding mechanism, a film suction mechanism and a controller 22. The feeding mechanism is arranged along the length direction of the base 1, and the film suction mechanism is installed on the base 1. And the film suction mechanism is located above the feeding mechanism, and the film feeding mechanism is arranged on one side of the base 1. The feeding mechanism includes a moving support 3, a longitudinal moving plate 5 and a lateral moving carriage 6, and two groups of moving supports 3 Symmetrically fixed on the base 1, each group of moving supports 3 is equipped with a longitudinal guide rail 4, the longitudinal guide plate 5 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com