A fpc encapsulation process

A process and station technology, applied in the field of flexible circuit board production technology, can solve the problems of low work efficiency, difficult operation, and inability to guarantee the filming accuracy, and achieve the effect of improving production efficiency and filming accuracy, and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

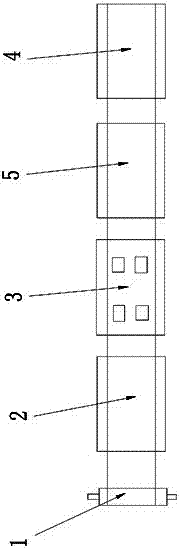

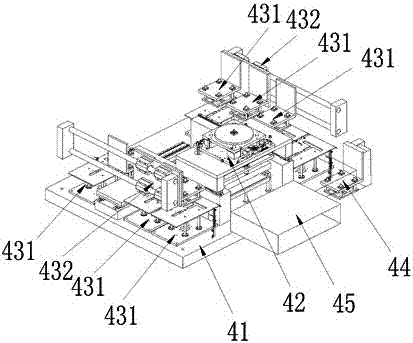

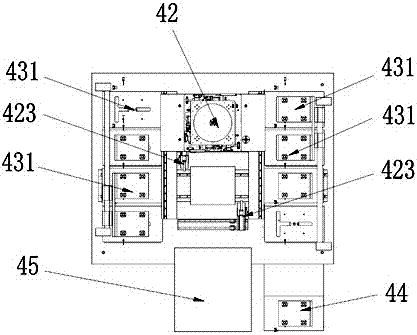

[0038] Attached below figure 1 to attach Figure 4 , and specific embodiments will further illustrate the present invention.

[0039] Such as figure 1 As shown, a FPC encapsulation process includes the following steps: A: the covering film is fed through the roller 1 and sent to the drilling machine 2; B: the covering film enters the drilling machine 2 to make positioning holes, and after finishing After positioning the holes, it is sent to the die-cutting machine 3; C: The die-cutting machine 3 uses multiple die-cutting heads to open windows on the cover film, and each die-cutting head can independently perform X-axis, Y-axis movement and rotational movement; E : Enter the automatic film lamination machine 4 to laminate the FPC board.

[0040] This embodiment can shorten the production cycle, replace manual operations, and improve production efficiency and film-sticking precision.

[0041] In this embodiment, step D is also included between step C and step E. Step D: incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com