Patents

Literature

72results about How to "Replace manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

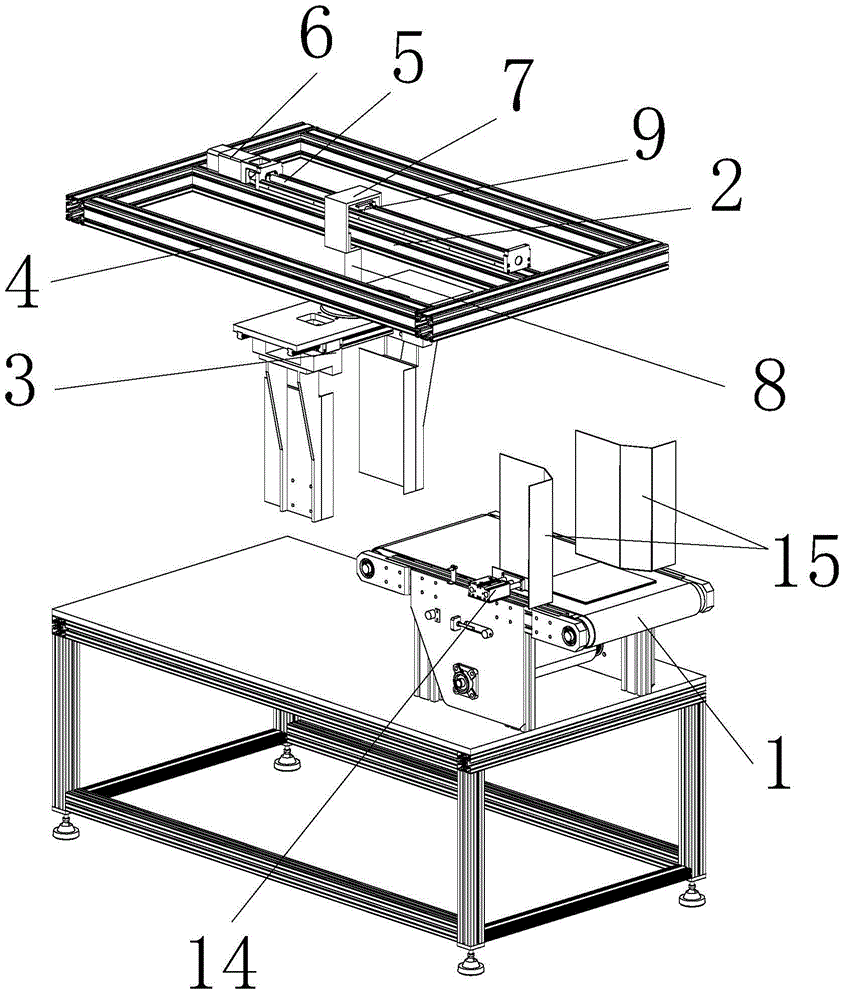

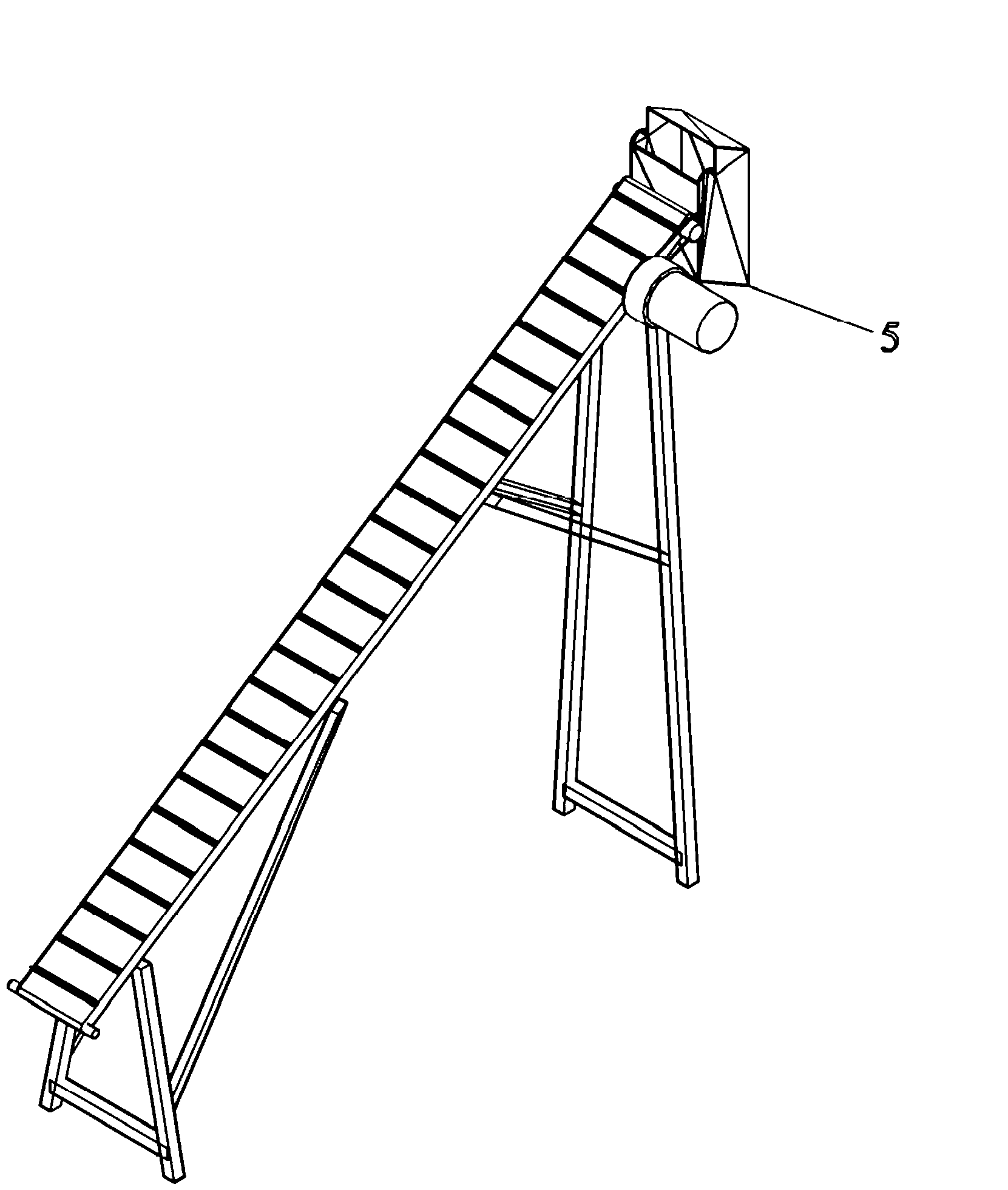

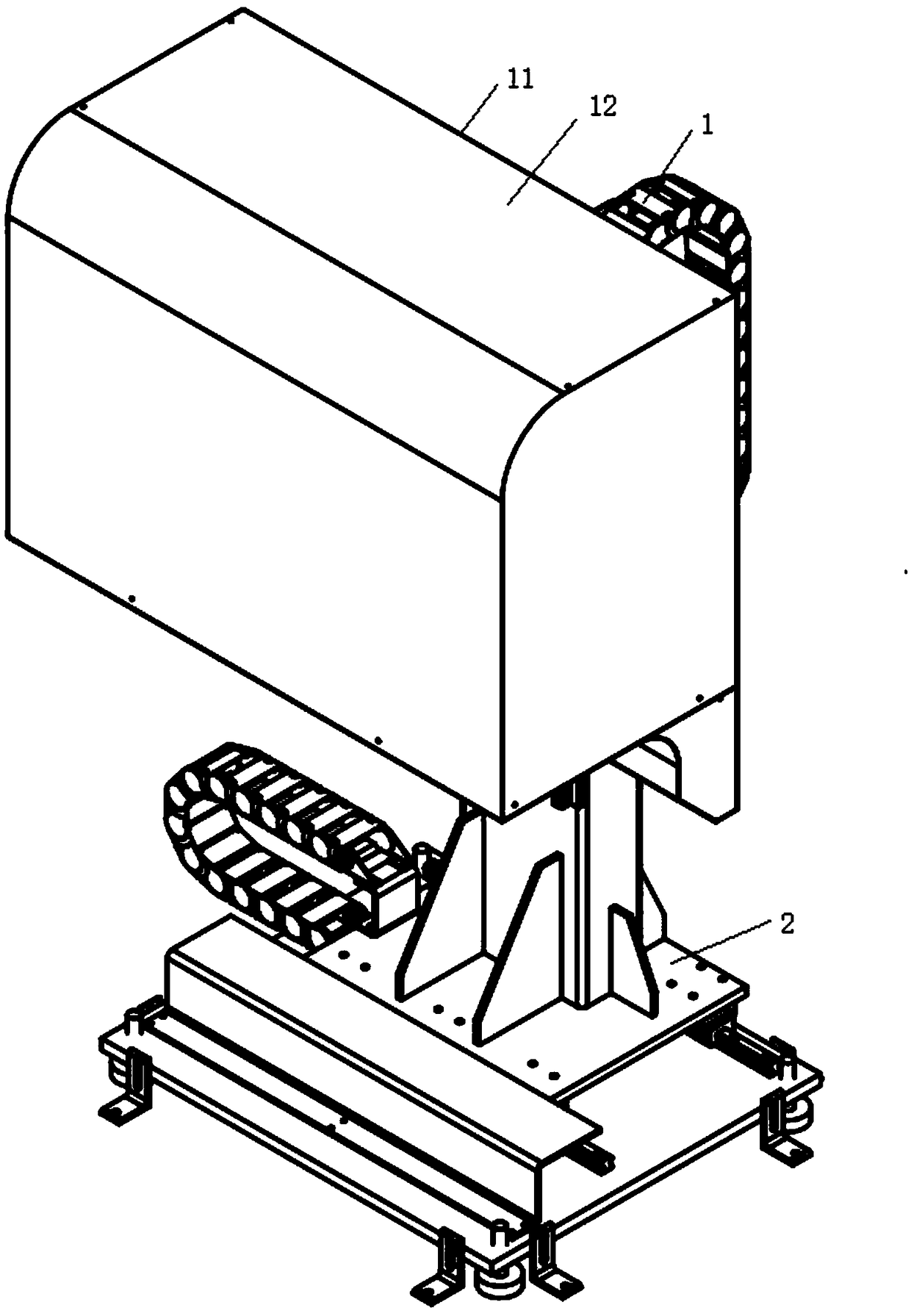

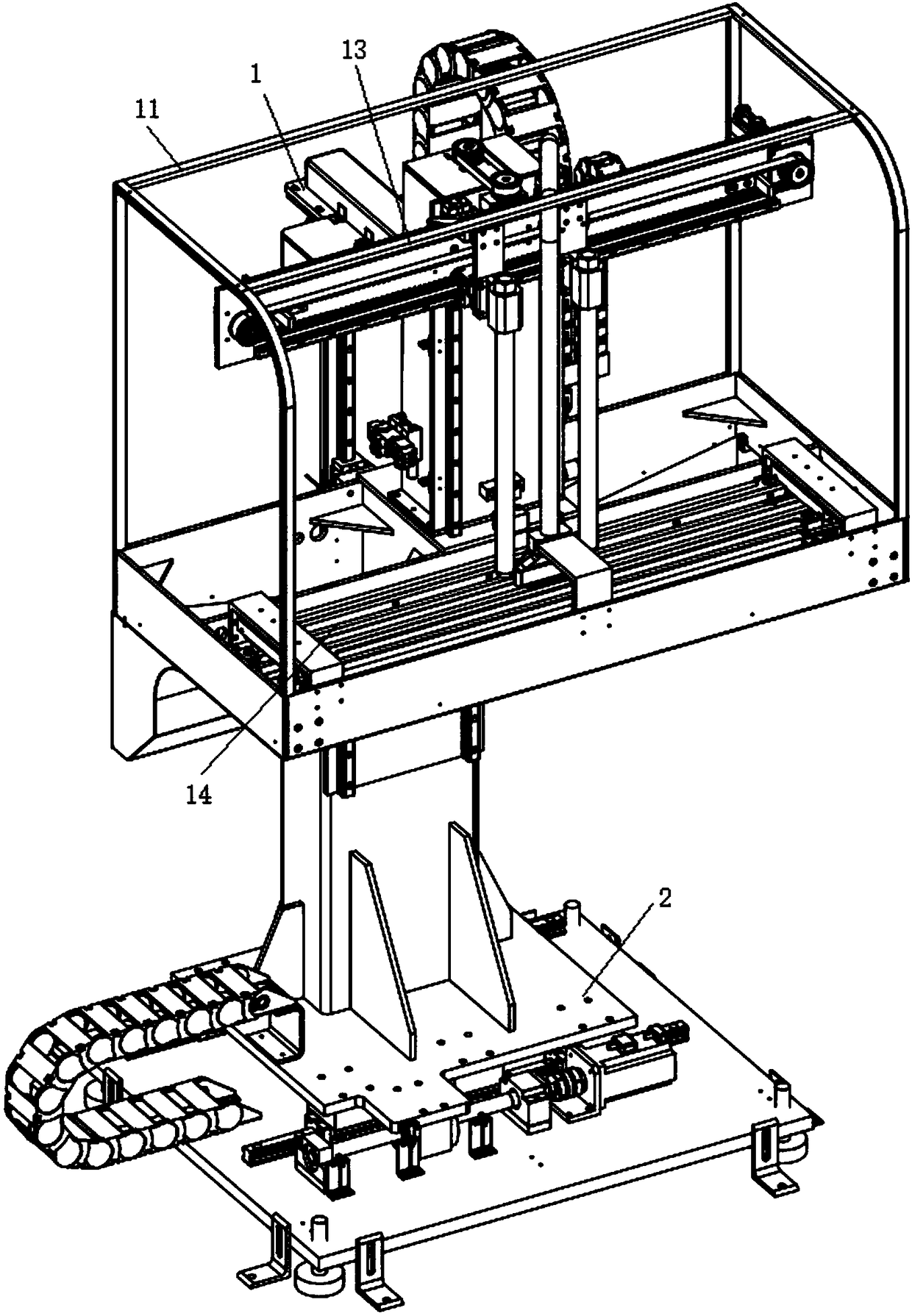

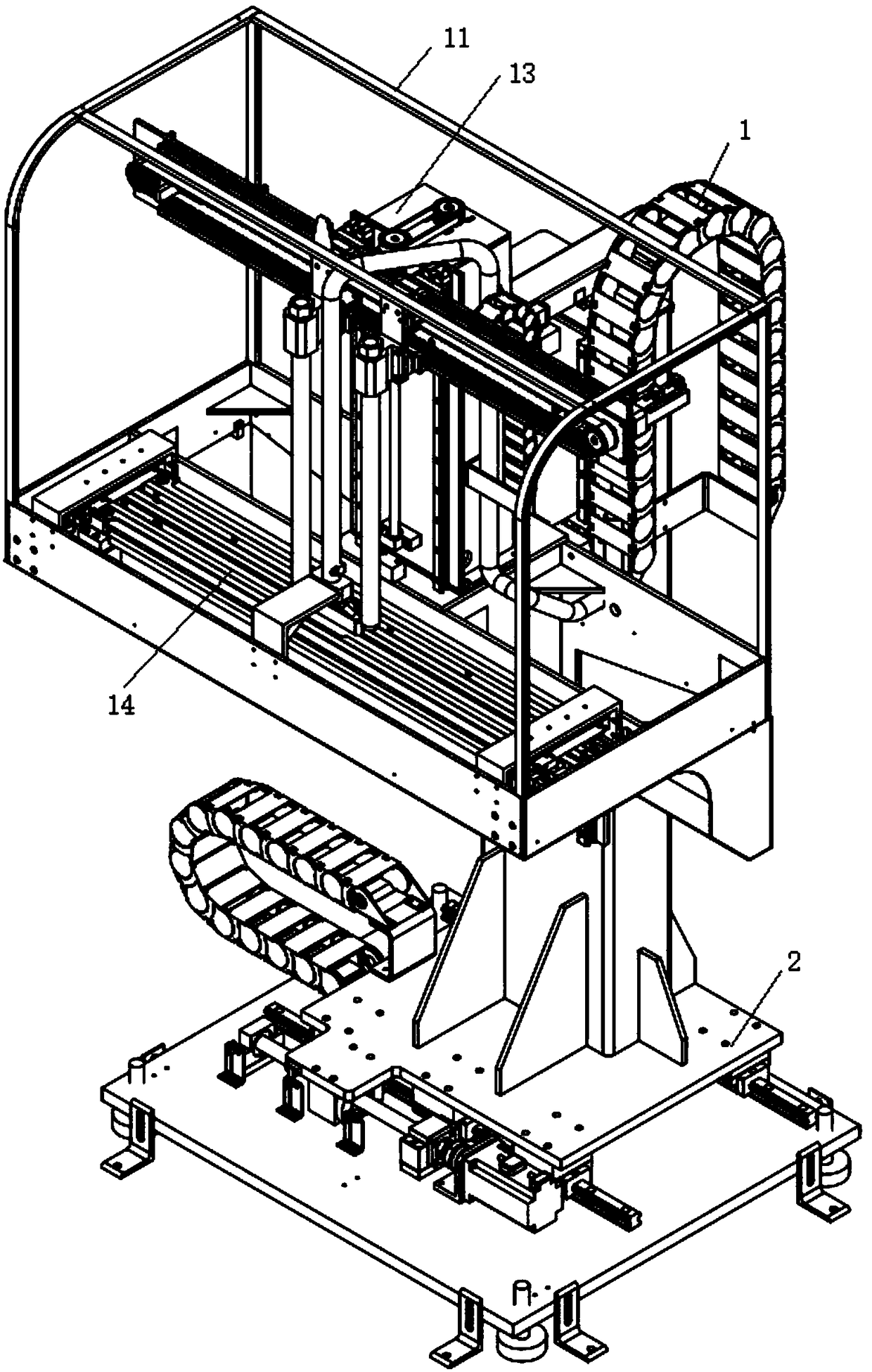

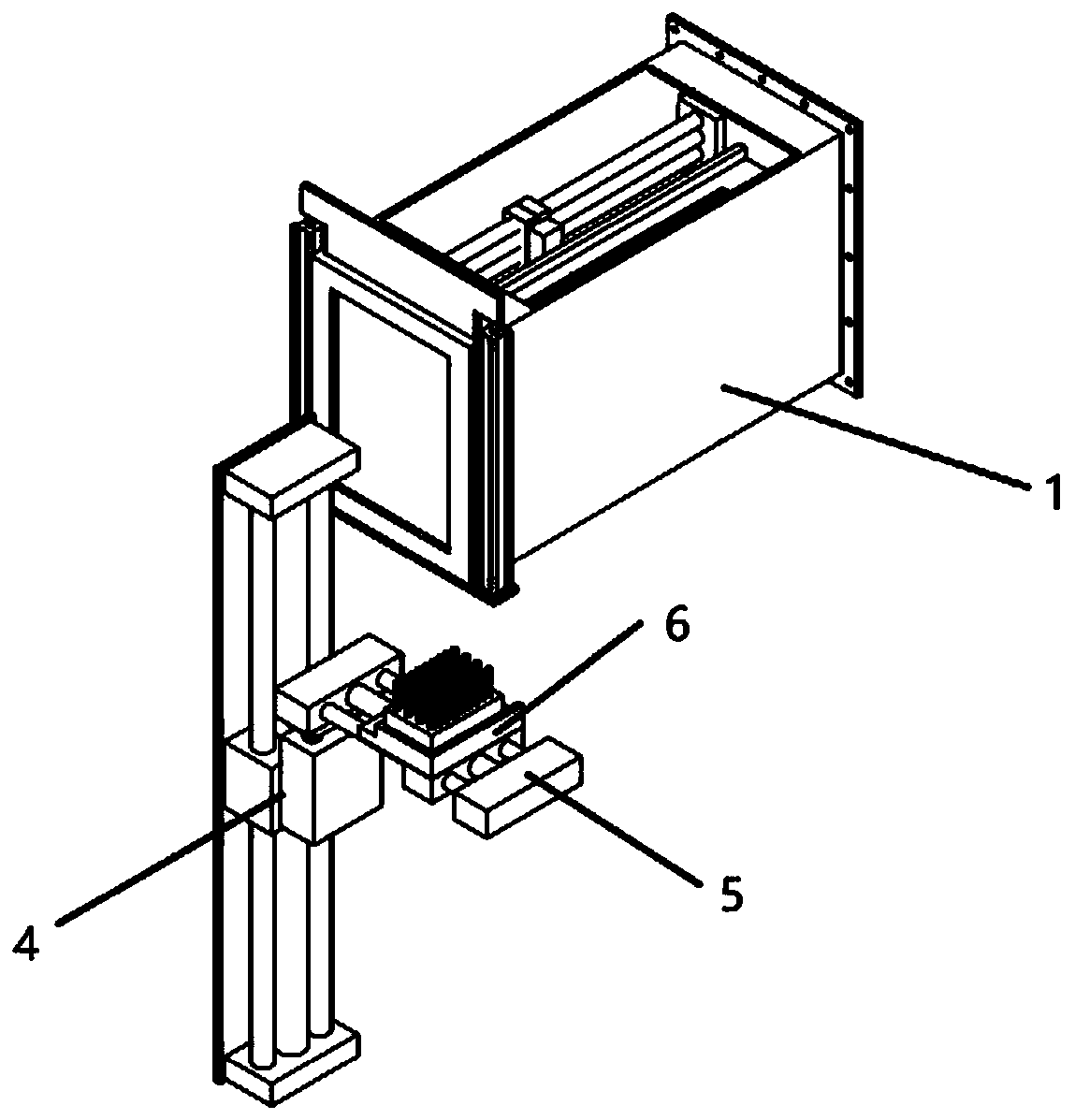

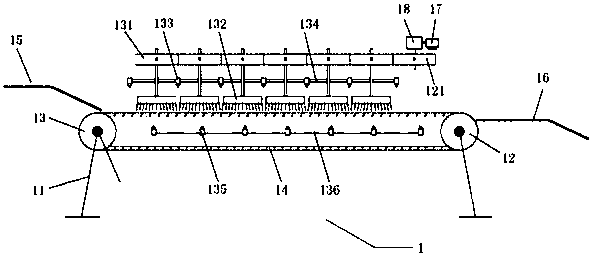

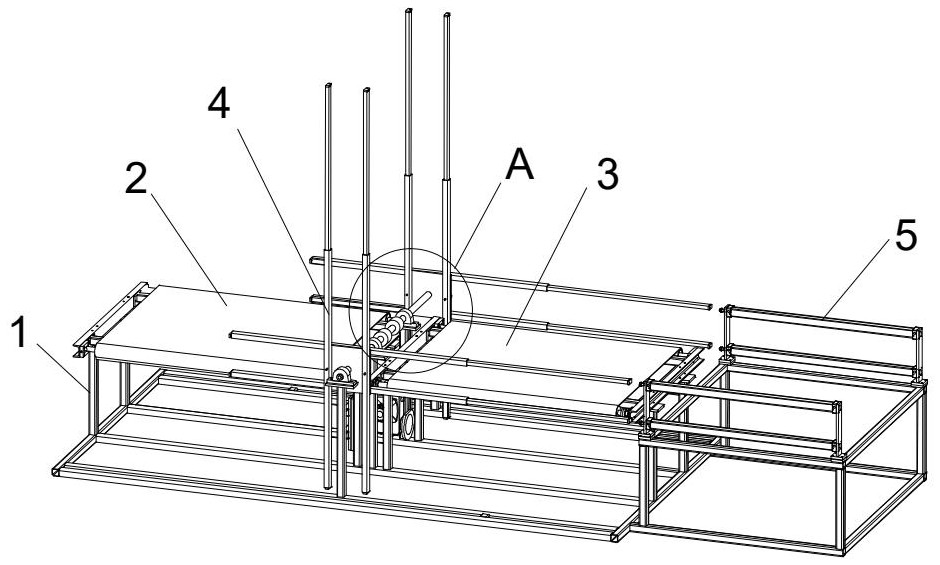

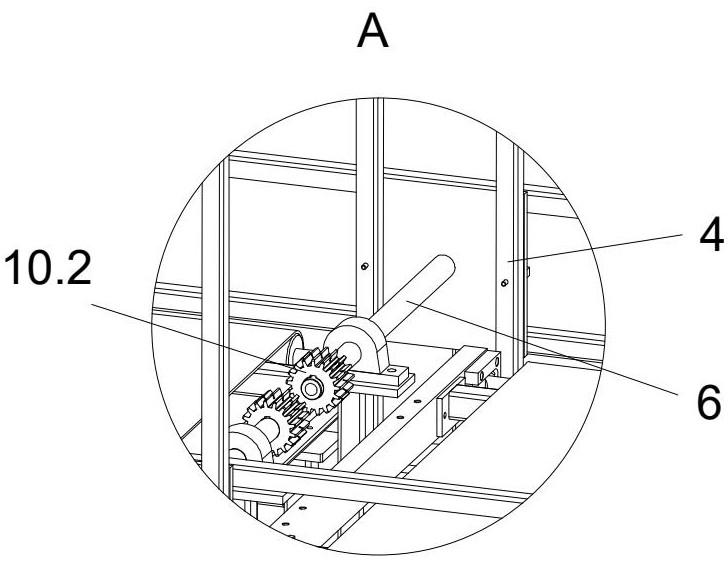

Feeder for automatic sorter of PCB

ActiveCN104874548AHigh degree of automationImprove work efficiencySortingFixed frameElectric machinery

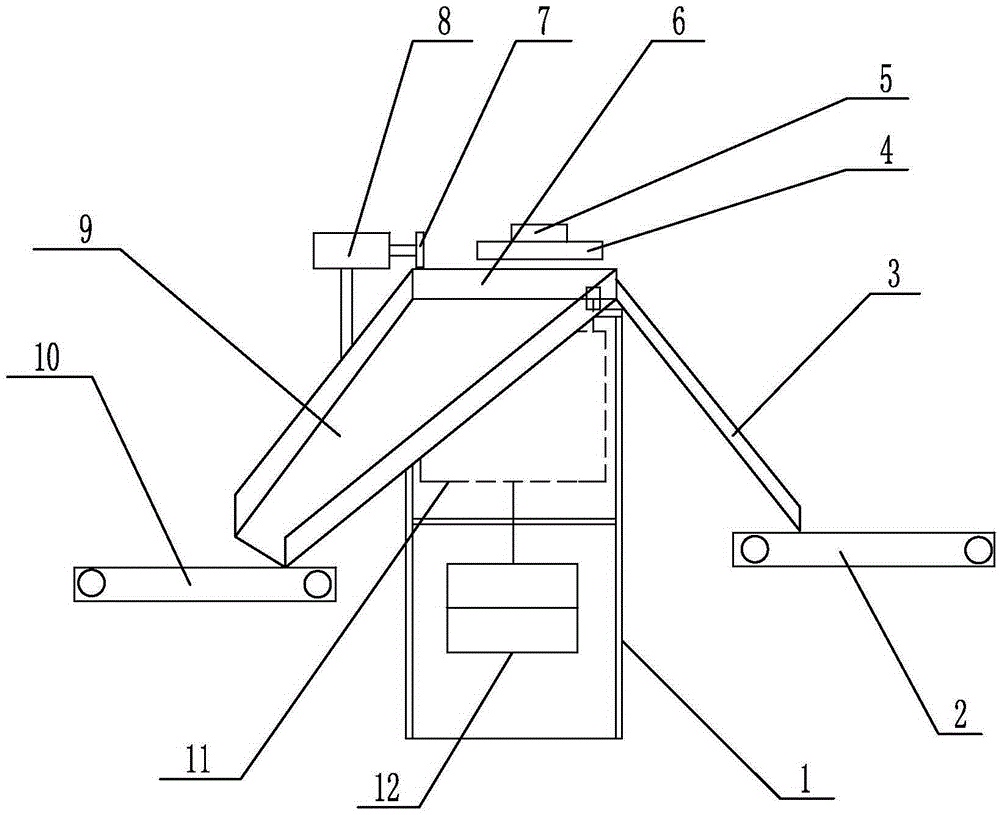

The invention discloses a feeder for an automatic sorter of a PCB. The feeder comprises a conveying belt (1), a walking track (2) and a manipulator (3), wherein the walking track (2) is fixedly installed above the conveying belt (1) via a track fixing frame (4); the top of the walking track (2) is provided with a screw rod (5) and a driving motor (6); the walking track (2) is sleeved with a slide block (7); the slide block (7) is connected with the top of the manipulator (3) via a connecting rod (8); one end of the screw rod (5) is fixedly connected with an output shaft of the driving motor (6); the slide block (7) is provided with a screw hole (9) which is connected with the screw rod (5) in a threaded mode. The feeder has the functions of conveying and automatic feeding, and is relatively high in working efficiency.

Owner:NORTHEASTERN UNIV

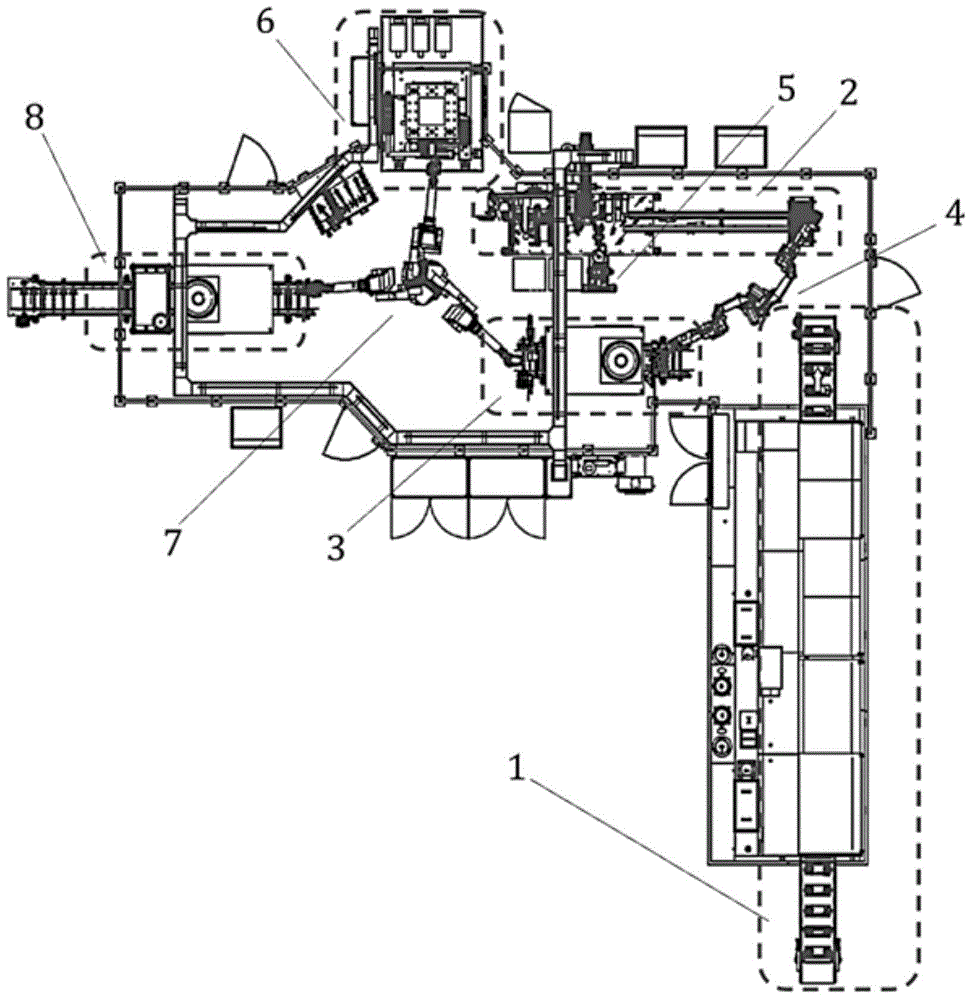

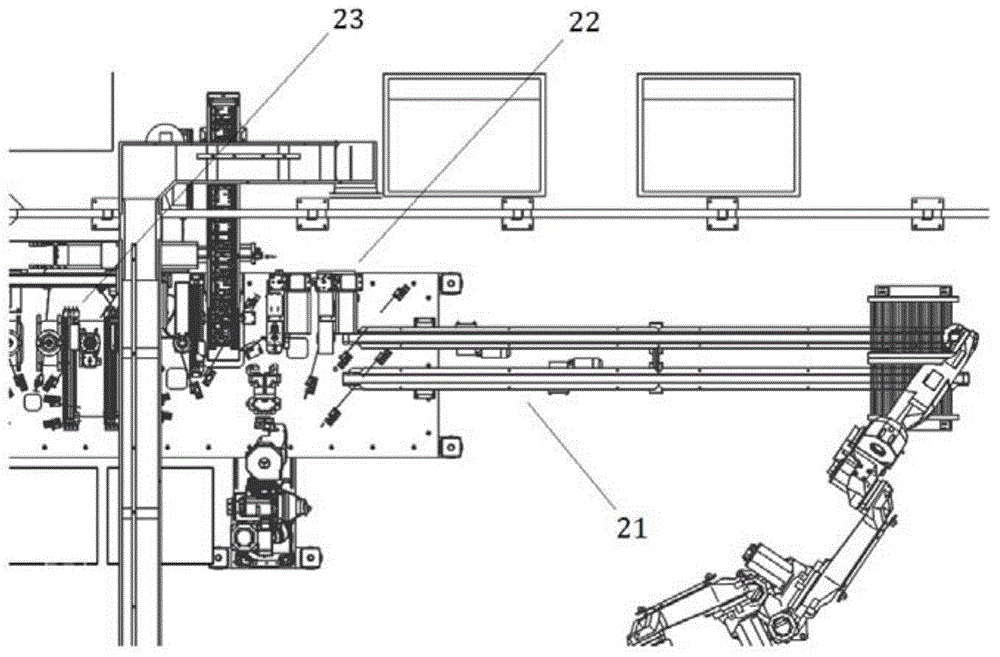

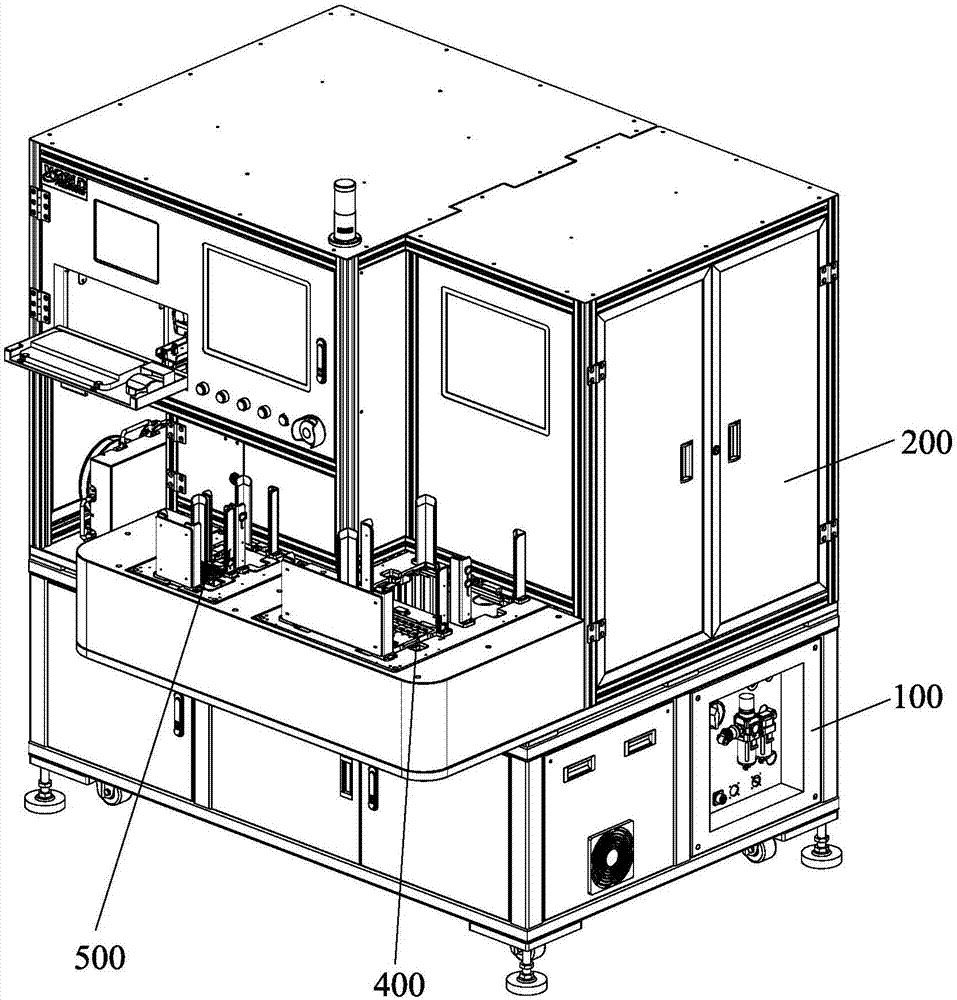

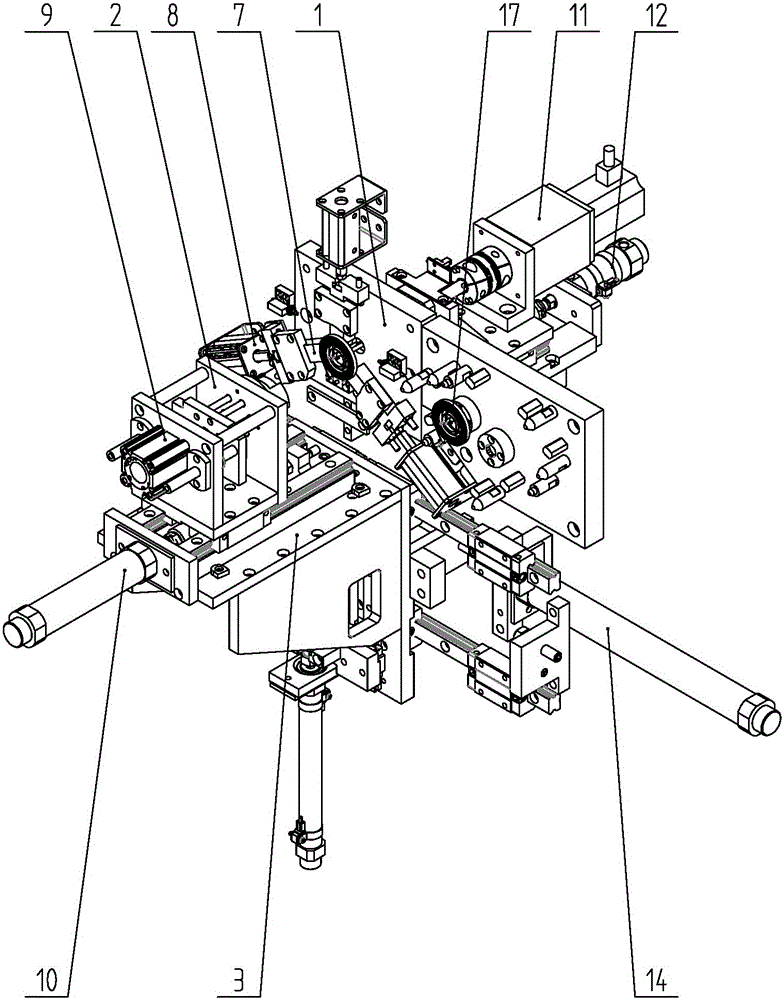

Full-automatic welding machine and welding method thereof

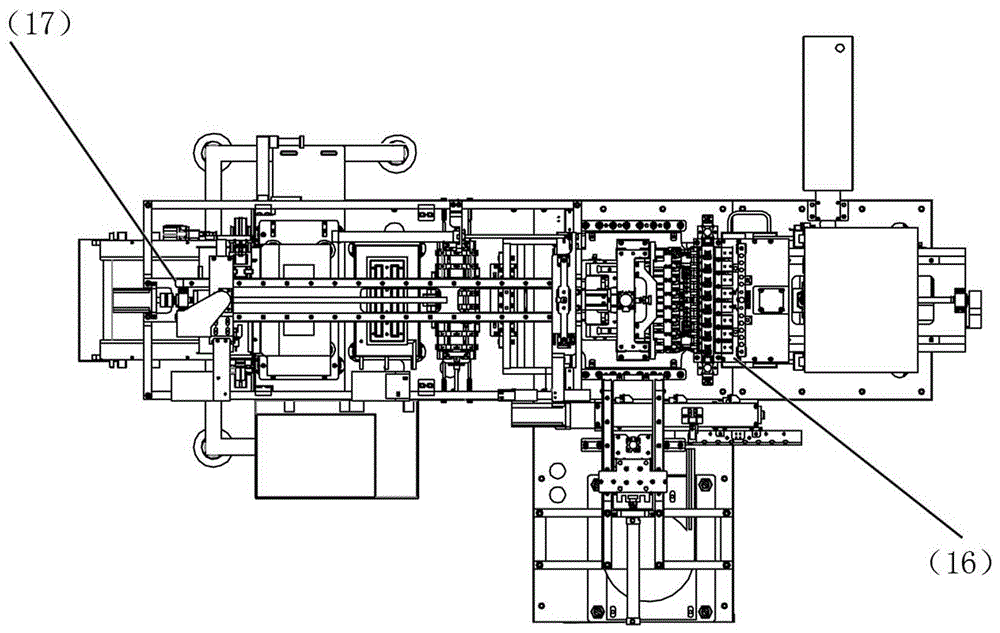

ActiveCN107148163ARealize automatic weldingAchieving processing powerPrinted circuit assemblingEngineeringElectronic component

The invention discloses a full-automatic welding machine, and belongs to the technical field of electronic component welding. The full-automatic welding machine comprises a rack, a feeding mechanism, a welding carrying platform tool, a first loading and unloading mechanism, a welding mechanism, a rotation disc, a plurality of turnover press mechanisms, a second loading and unloading mechanism, a flexible printed circuit (FPC) turnover mechanism, a bonding pad wiping mechanism, a post-welding height detection mechanism, a post-welding charge coupled device (CCD) detection mechanism, an insulation adhesive tape attachment mechanism and an adhesive tape pressure maintaining mechanism, wherein the rotation disc is driven by a rotation driving device. The invention also discloses a welding method of the full-automatic welding machine. The welding method comprises the steps of feeding, tool loading, tool rotation, fine positioning of an FPC, FPC welding, tool unloading, turnover press mechanism loading, turnover and pressing of the FPC after welding, bonding pad wiping, height detection, CCD detection, adhesive tape pasting, adhesive tape pressure maintenance and product flowing out. By the full-automatic welding machine and the welding method, automatic welding and post-welding processing of a pin and a bonding pad are achieved, the production efficiency is improved, and the welding quality of a product and the consistency of the product are ensured.

Owner:WEIFANG LOKOMO PRECISION IND

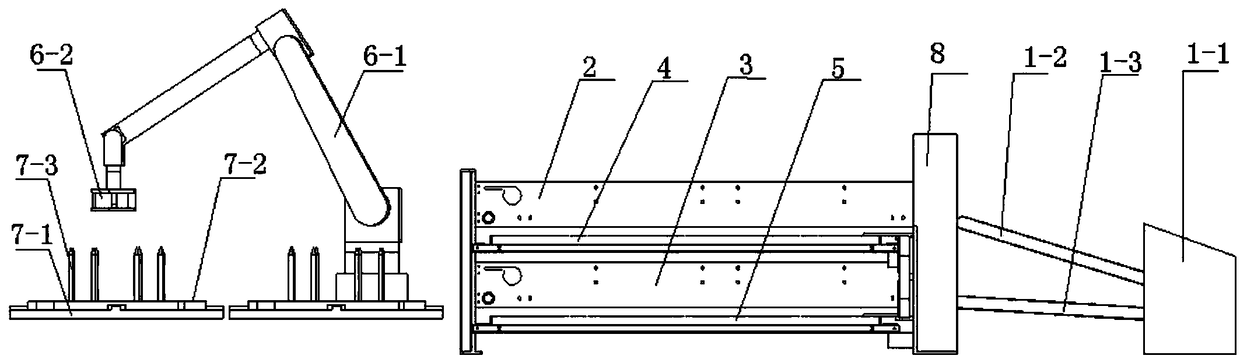

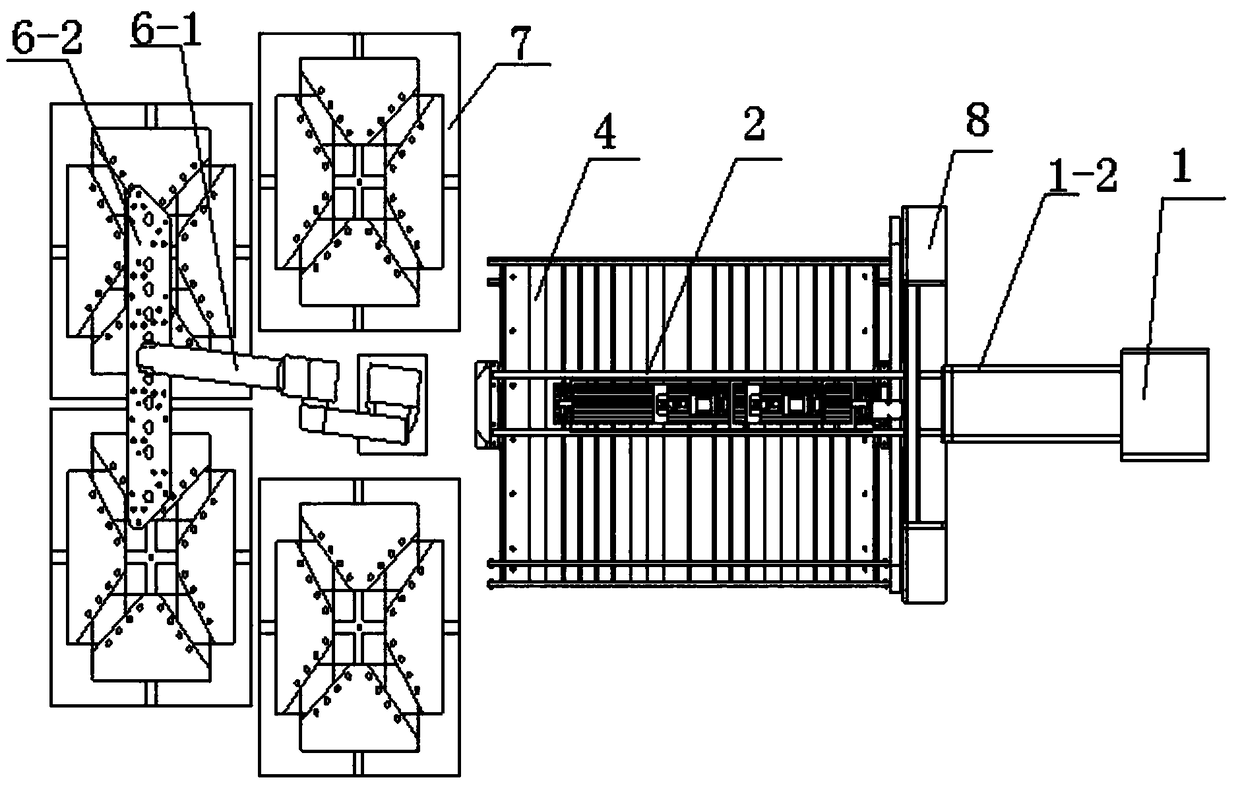

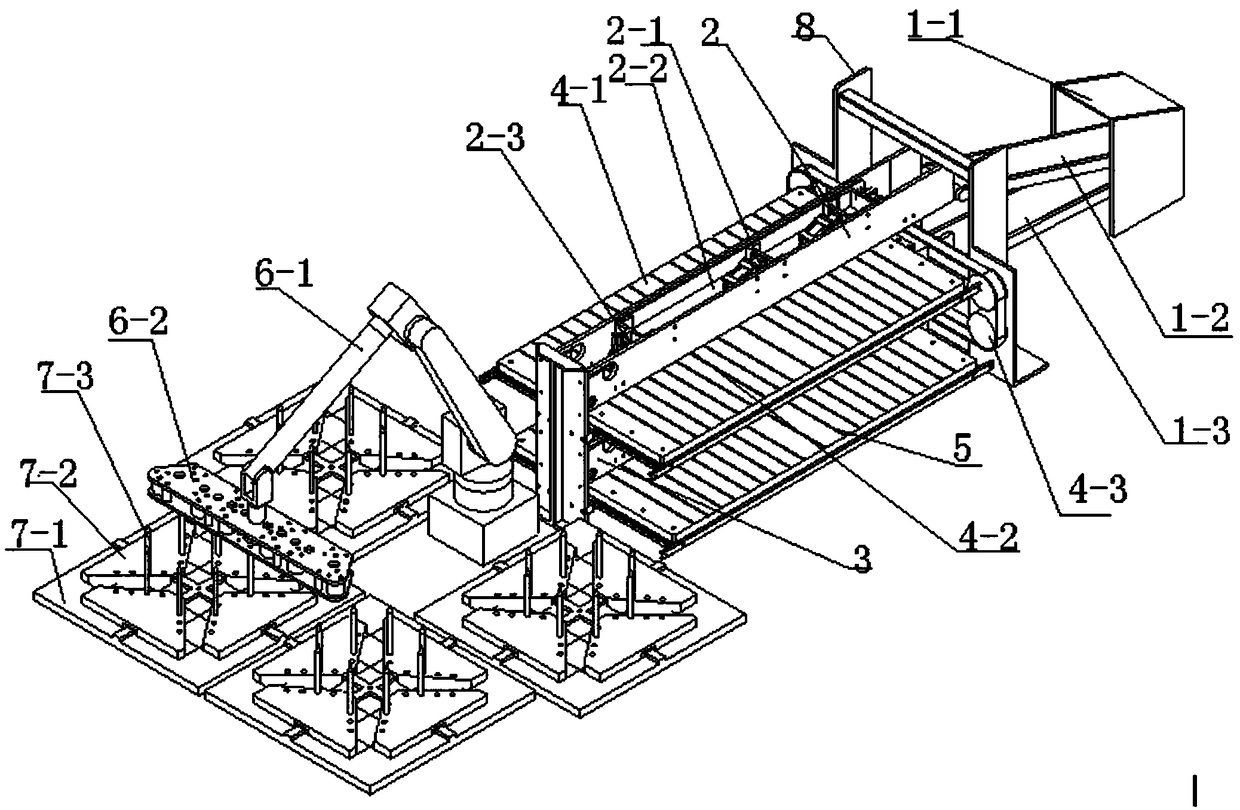

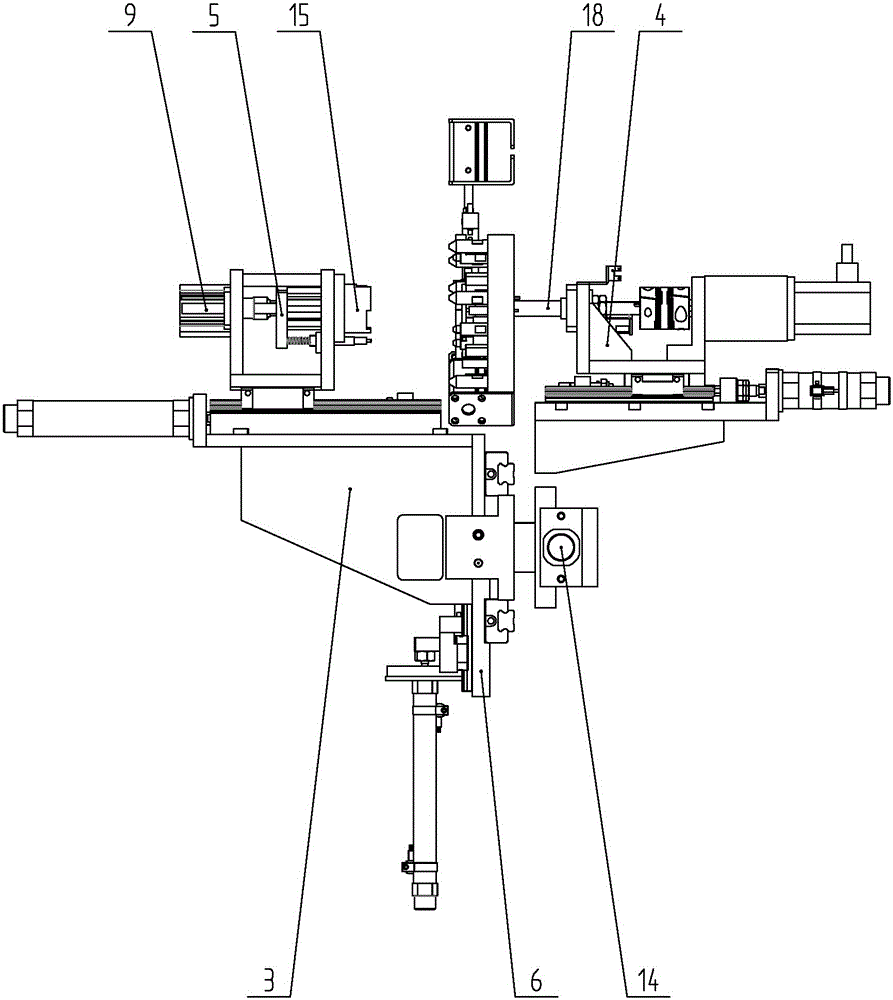

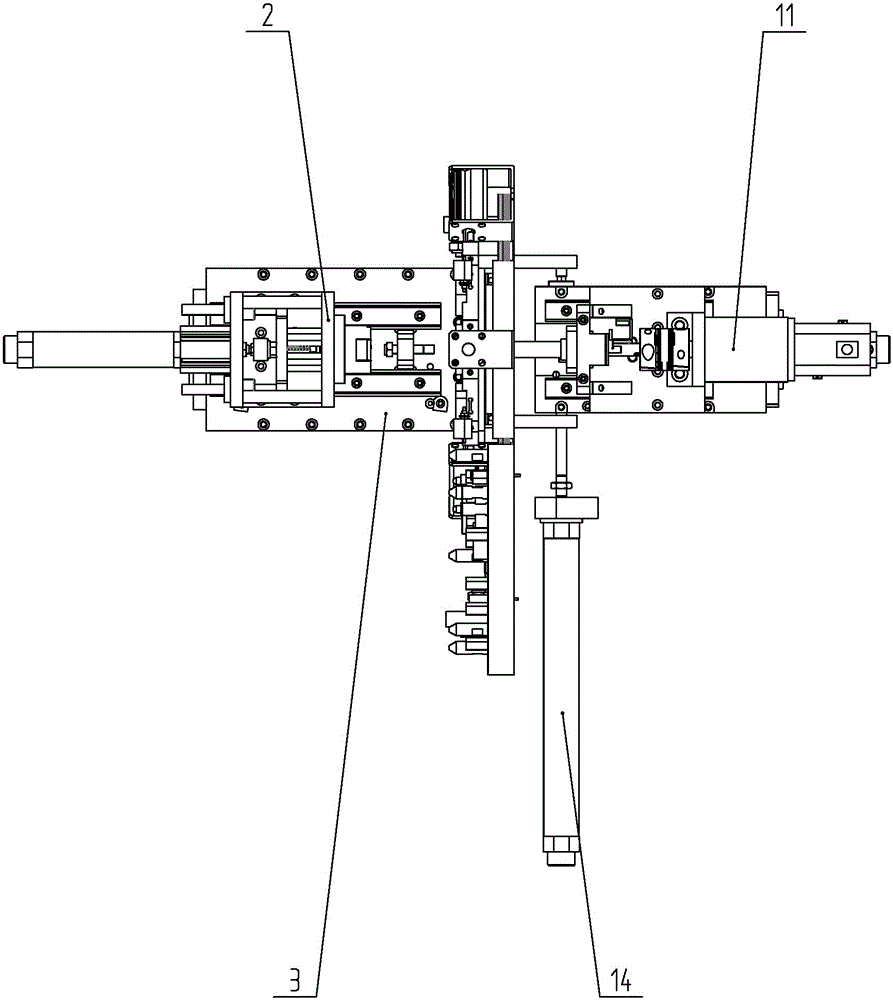

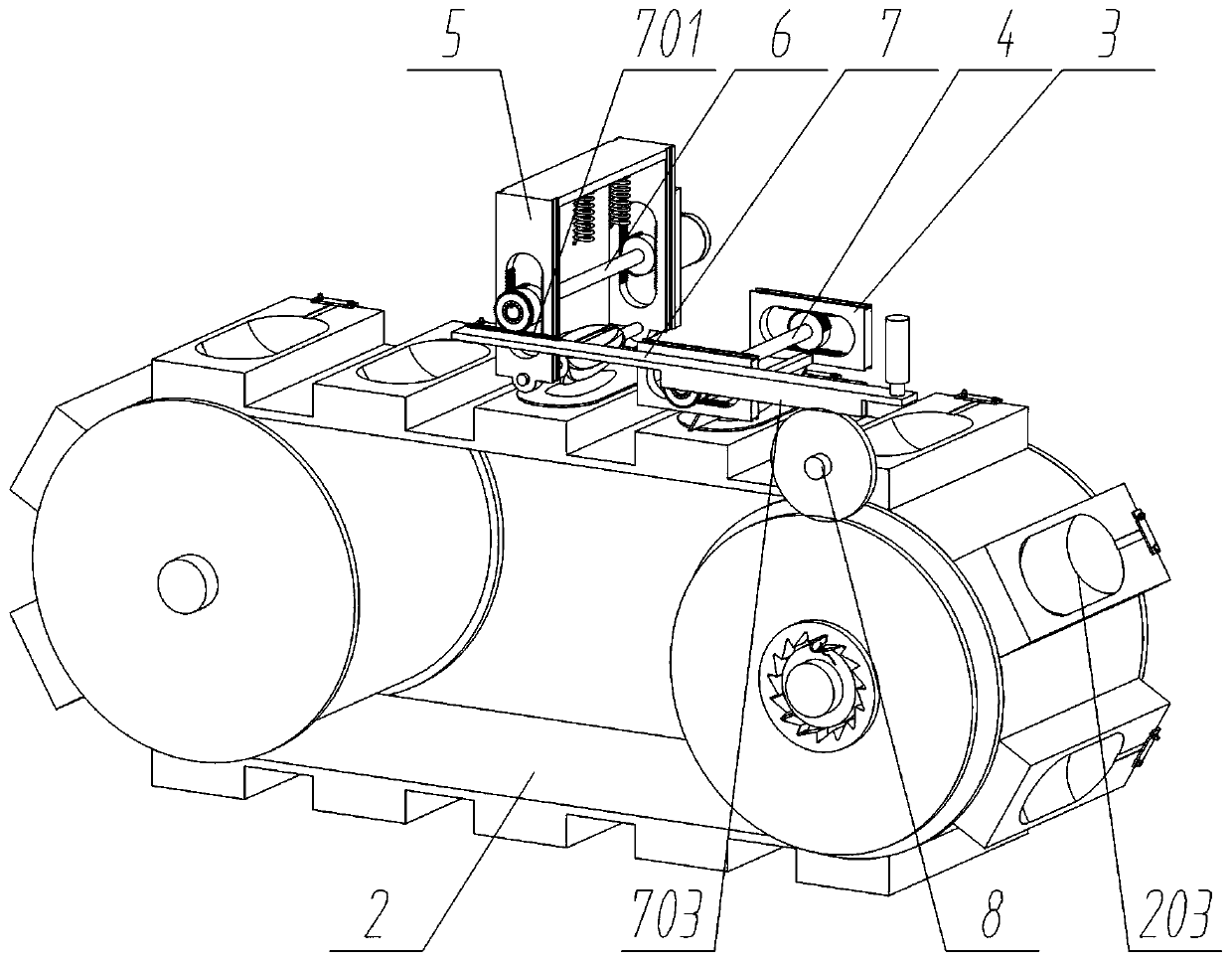

Gear shaft part hot-pressing assembly technology automatic production system

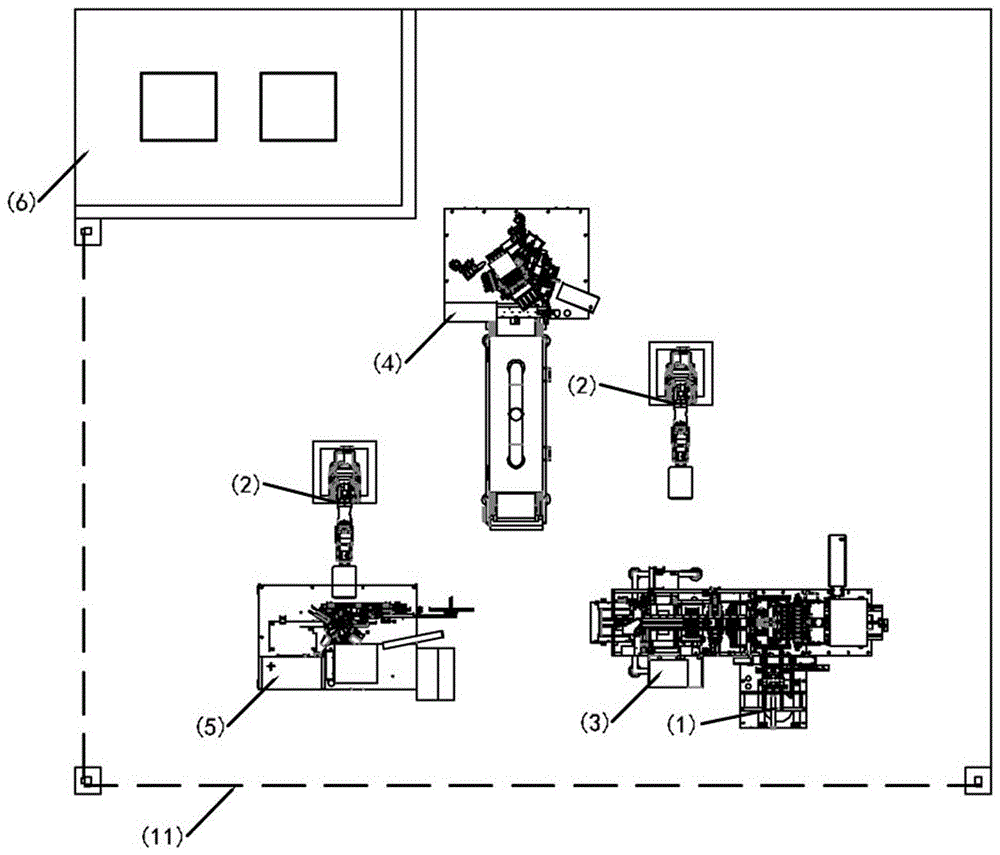

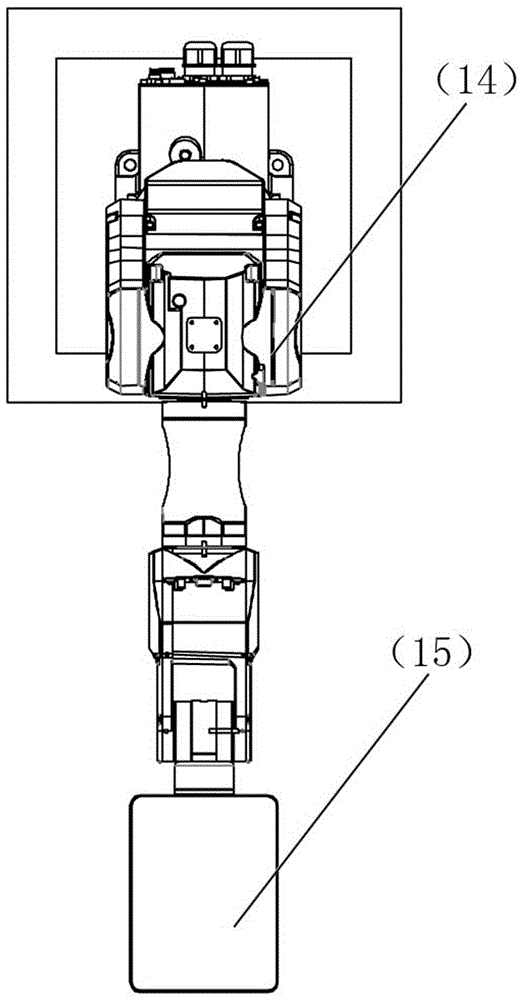

ActiveCN104551531AQuality improvementImprove processing efficiencyMetal working apparatusEngineeringManipulator

A gear shaft part hot-pressing assembly technology automatic production system comprises a cleaning mechanism, a gear heating unit, a shaft cooling unit, a hot pressing unit, a cooling demagnetizing unit and three six degree of freedom manipulators; the gear heating unit and the shaft cooling unit are arranged between the cleaning mechanism and the hot pressing unit; the first six degree of freedom manipulator is arranged between the gear heating unit, the shaft cooling unit and the cleaning mechanism; the second six degree of freedom manipulator is arranged on one side of the gear heating unit; heating of two gear parts, cooling the shaft part and interference assembling of the three parts are achieved through the third six degree of freedom manipulator. According to the gear shaft part hot-pressing assembly technology automatic production system, the machining efficiency is greatly improved, the operation is simple, the automatic degree is high, assembling is easy, the performance is stable, and the quality of machined parts is reliable.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

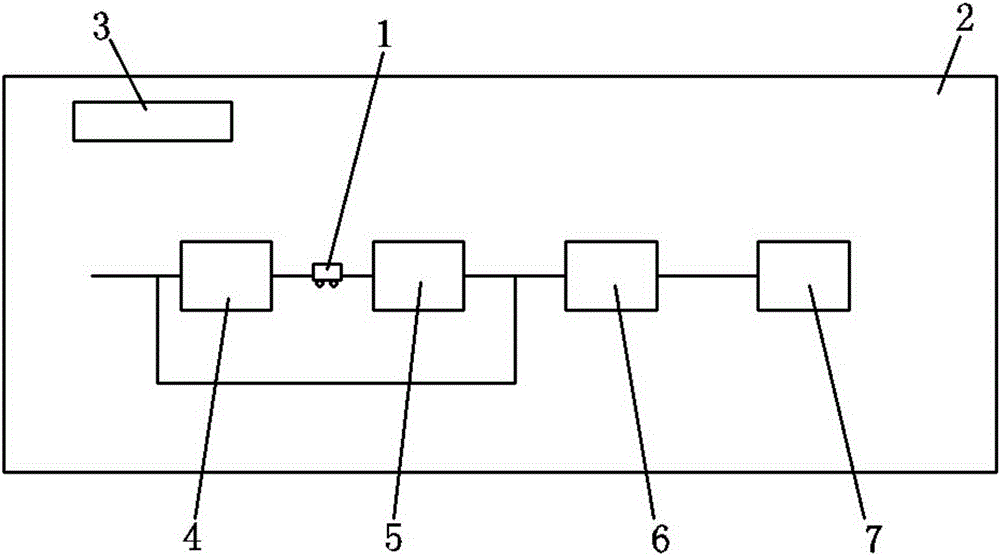

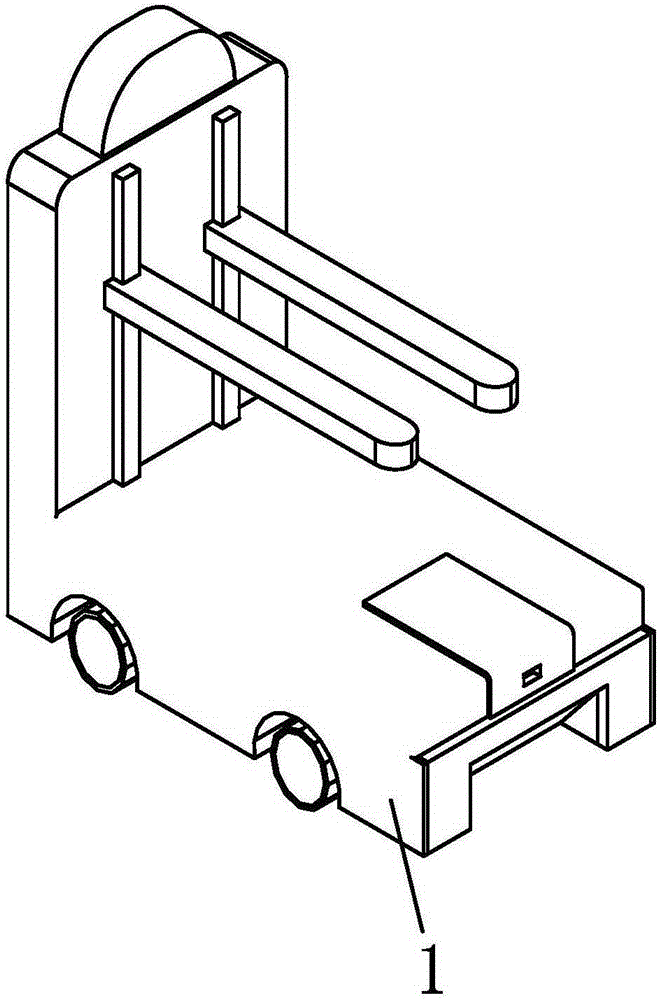

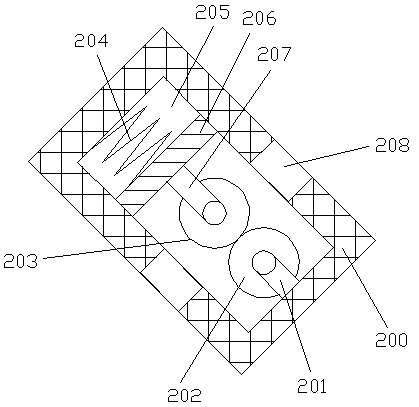

Warehouse logistics conveying system

ActiveCN106608480ARealize automatic logisticsRealize intelligent identificationStorage devicesLogistics managementButt joint

The invention belongs to the technical fields of warehouse logistics and positioning identification and discloses a warehouse logistics conveying system. The warehouse logistics conveying system comprises an unmanned moving van, a working zone and a system server, wherein a producing system, a detecting system and a packaging system are arranged in the working zone, the producing system, the detecting system and the packaging system are all provided with monitoring points and connected into the system server, and the system server sends instructions to the unmanned moving van to select different running rails as paths according to the monitoring state of the producing system, the detecting system or the packaging system. According to the invention, the automatic logistics of products among the producing system, the detecting system and the packaging system is realized, and automatic navigation, automatic loading and unloading and accurate positioning are carried out by identifying the states of the products through the system server, so that the heavy labor load of workers is replaced; the intelligent identification, scheduling and execution of product missions are realized, and manual operation is replaced; great butt joint calibrating mechanisms are arranged for all of product transporting, loading and unloading processes; and products with different height can all be normally loaded and unloaded.

Owner:NANJING NARI GROUP CORP +1

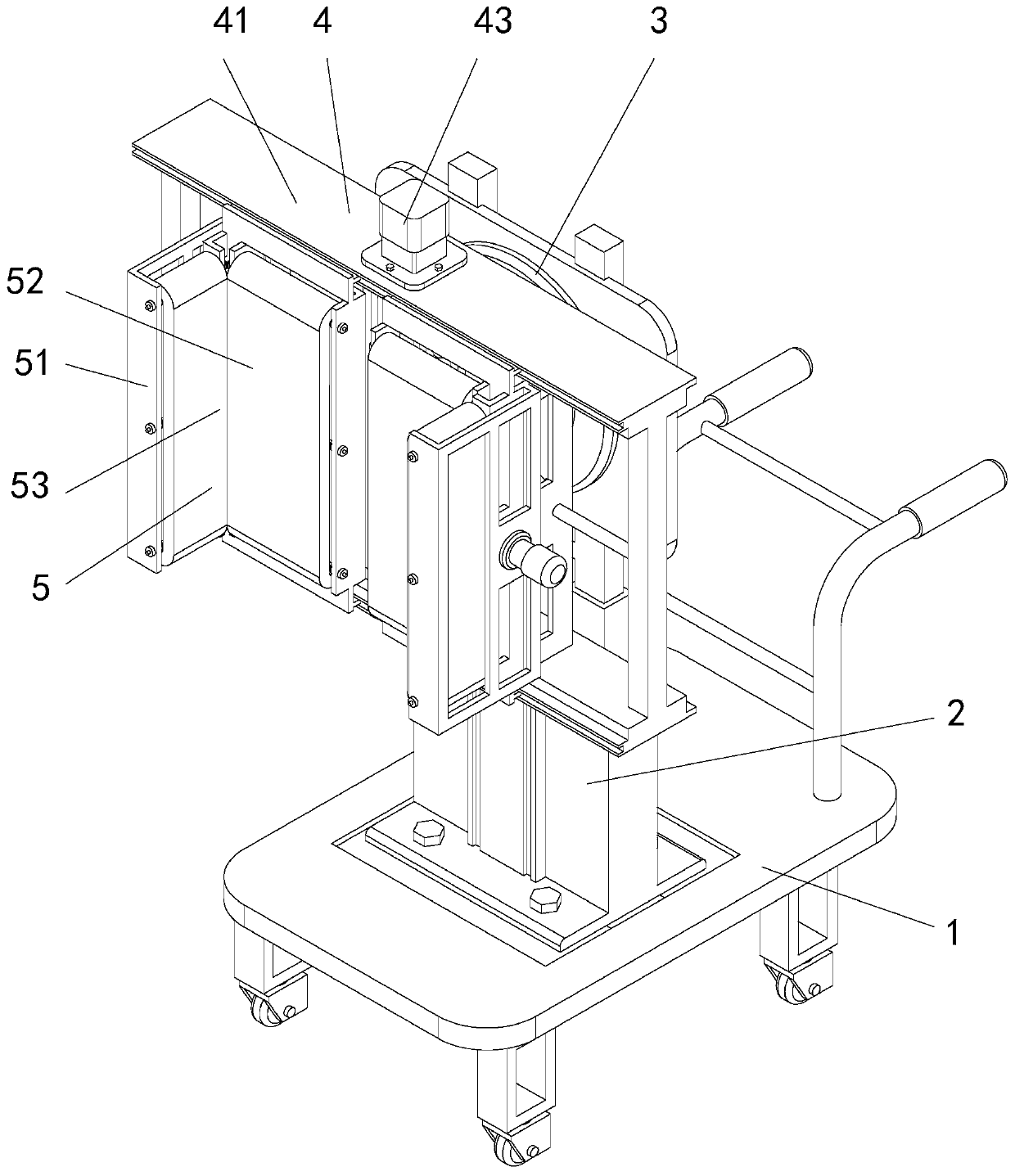

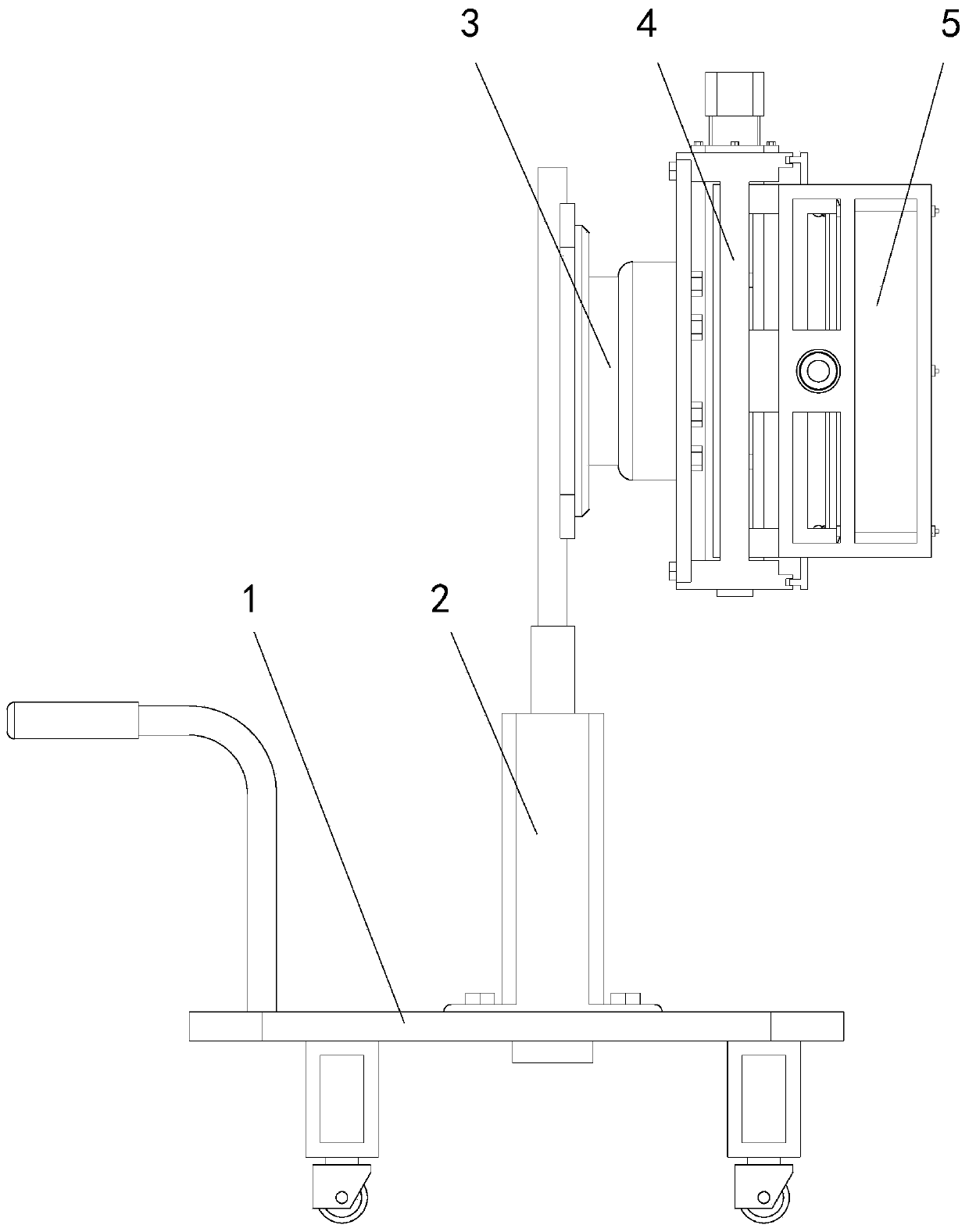

Hand-push and movable wall-attached lamp box cleaning device for subway platform

The invention discloses a hand-push and movable wall-attached lamp box cleaning device for a subway platform. The device comprises a cart, a lifting vertical frame vertically and fixedly arranged on the cart, a rotating table vertically and fixedly arranged at the side end of the lifting vertical frame, an interval adjusting mechanism fixedly arranged on the rotating table and a pair of cleaning mechanisms arranged on the interval adjusting mechanism oppositely; the interval adjusting mechanism comprises a mechanism framework fixedly arranged on the rotating table, two sliding guide rods horizontally and fixedly arranged in the mechanism framework, an adjusting driving mechanism vertically arranged on the mechanism framework, two threaded sleeves in threaded connection with the adjusting driving mechanism, two sliding sleeves arranged on the two sliding guide rods in a sliding mode correspondingly and four connecting rods; and the cleaning mechanisms comprise mechanism frames fixedly arranged on the sliding sleeves, and a cleaning mechanism I and a cleaning mechanism II both arranged on the mechanism frames. According to the cleaning device, a wall-attached lamp box can be cleanedconveniently and quickly, the cleaning speed is high, and the cleaning efficiency is high.

Owner:NANJING FORESTRY UNIV

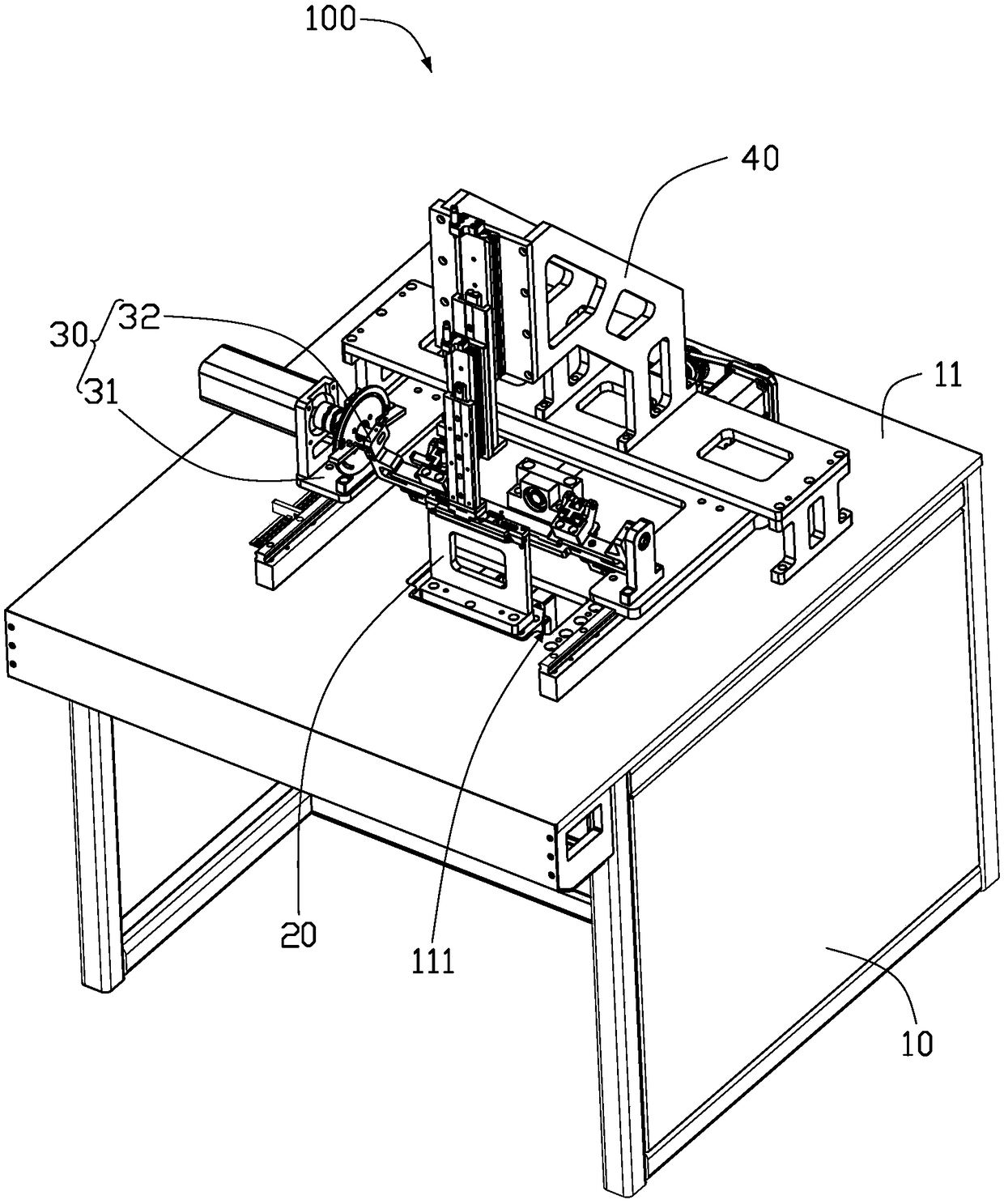

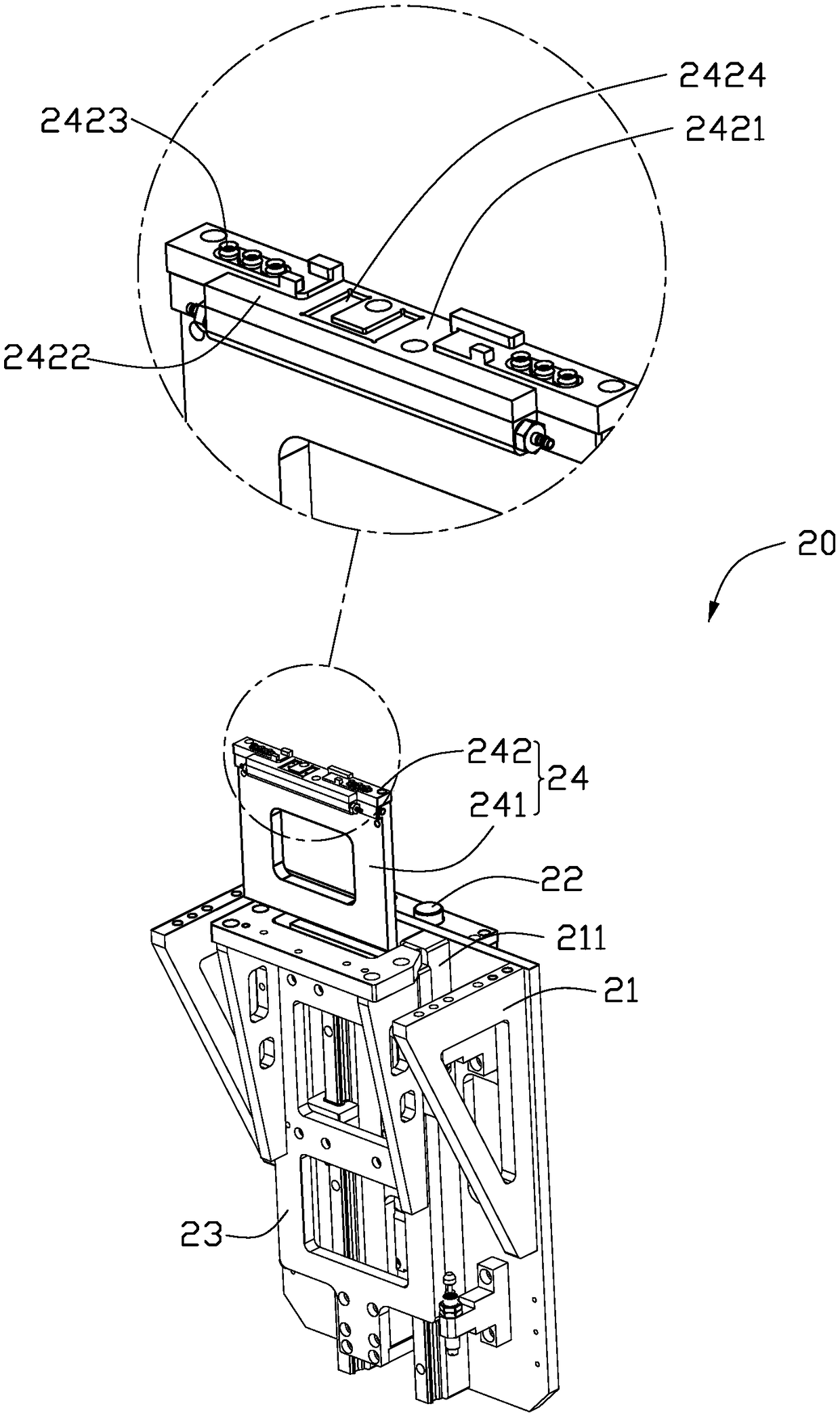

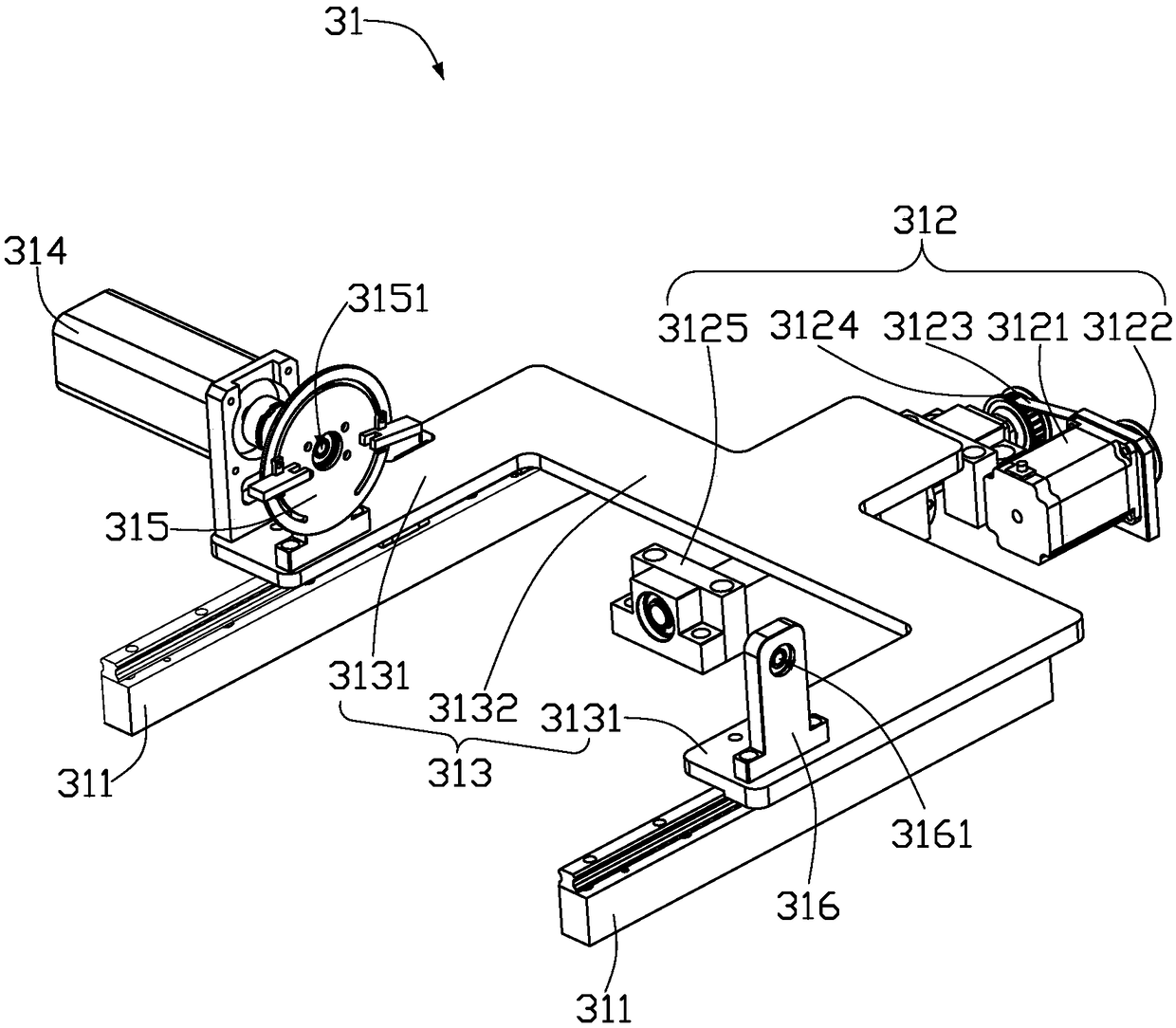

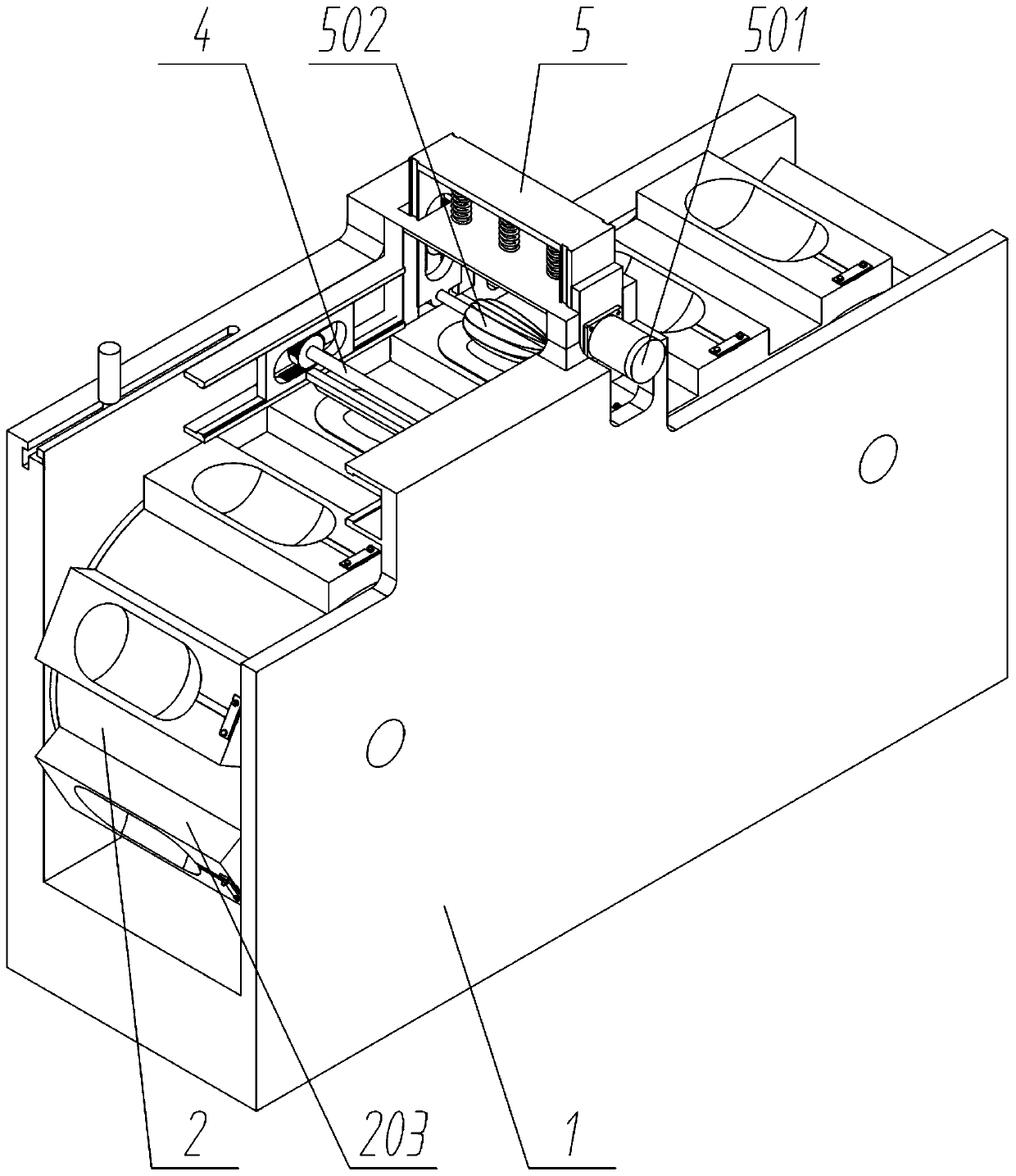

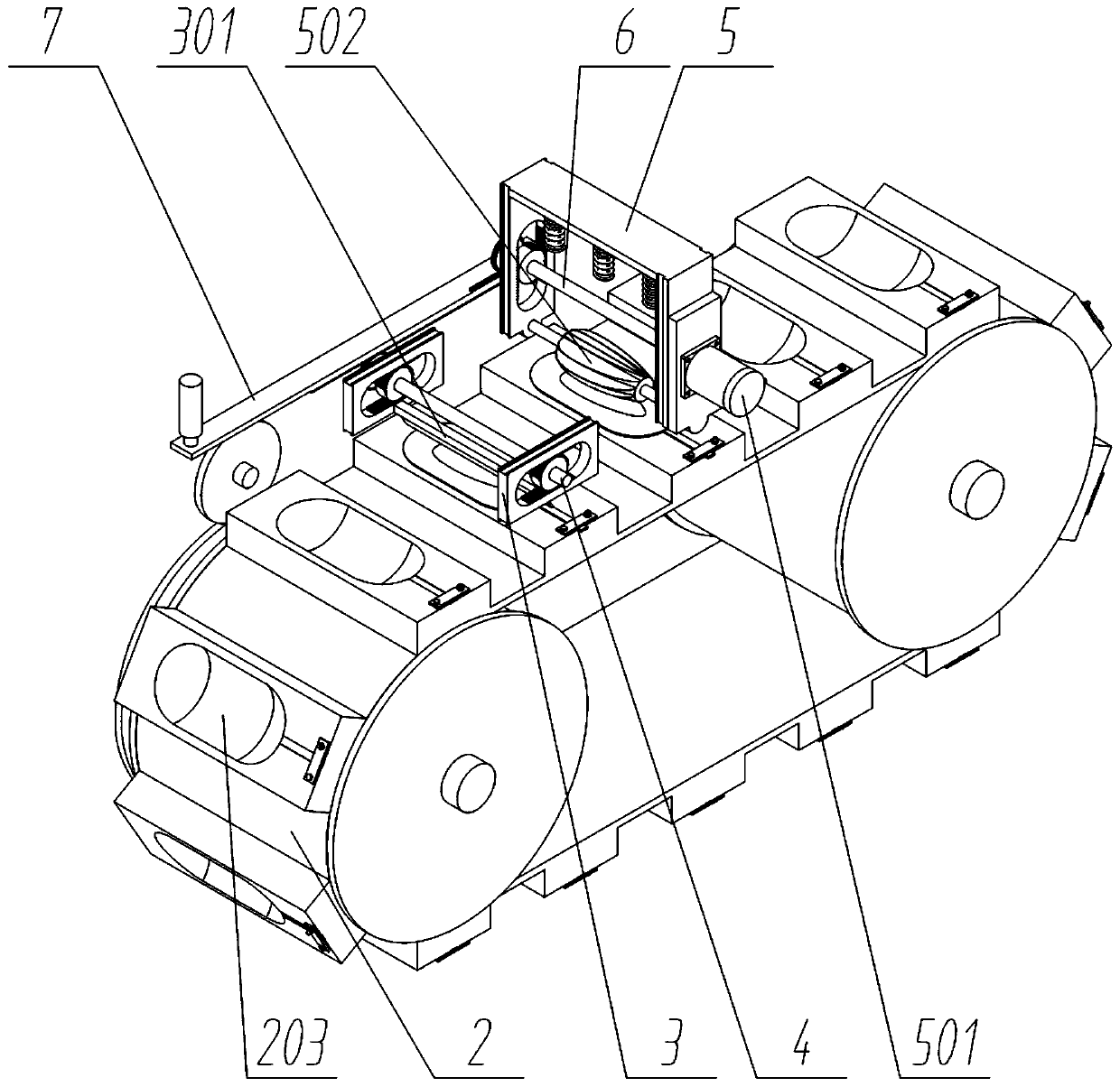

Full-automatic attaching machine of motor frame

ActiveCN106936277ACompact and reasonable layoutIncrease productivityManufacturing dynamo-electric machinesEngineeringReclaimer

The invention discloses a full-automatic attaching machine of a motor frame, and is used for attaching a buffer block to the internal side of a frame outside a mobile phone vibrating motor. The full-automatic attaching machine of the motor frame comprises two material transmission channels which are arranged in parallel, a material loading device and a material unloading device which are arranged at one side of the two material transmission channels, a material taking mechanism which is arranged between the material transmission channels and the material loading device and a material discharging mechanism which is arranged between the material transmission channels and the material unloading device. One end of the two material transmission channels is provided with an attaching device. The full-automatic attaching machine of the motor frame also comprises a buffer block automatic feeding device used for feeding the buffer block to the attaching device. The frame moves to the attaching device along any material transmission channel and completes attaching of the buffer block and then moves back to the material discharging mechanism along the material transmission channel. The full-automatic attaching machine of the motor frame is compact and reasonable in layout and high in production efficiency and production quality so as to effectively replace manual operation.

Owner:DONGGUAN WORLD PRECISION MACHINERY

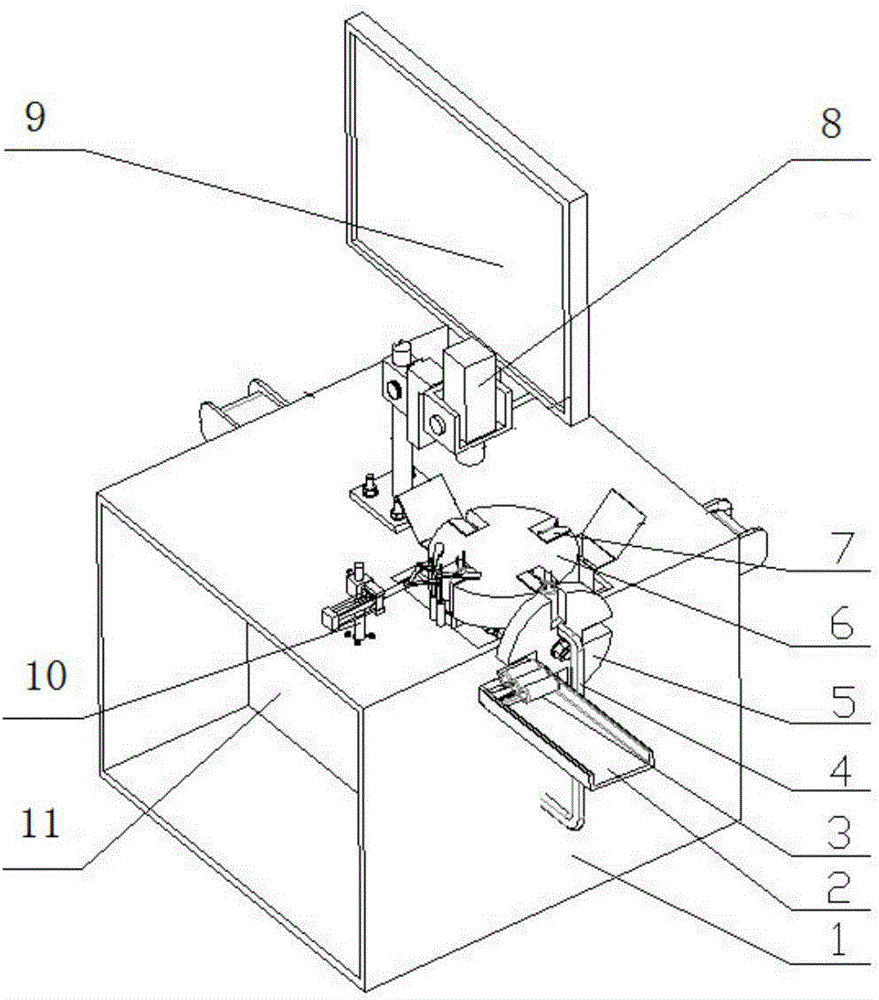

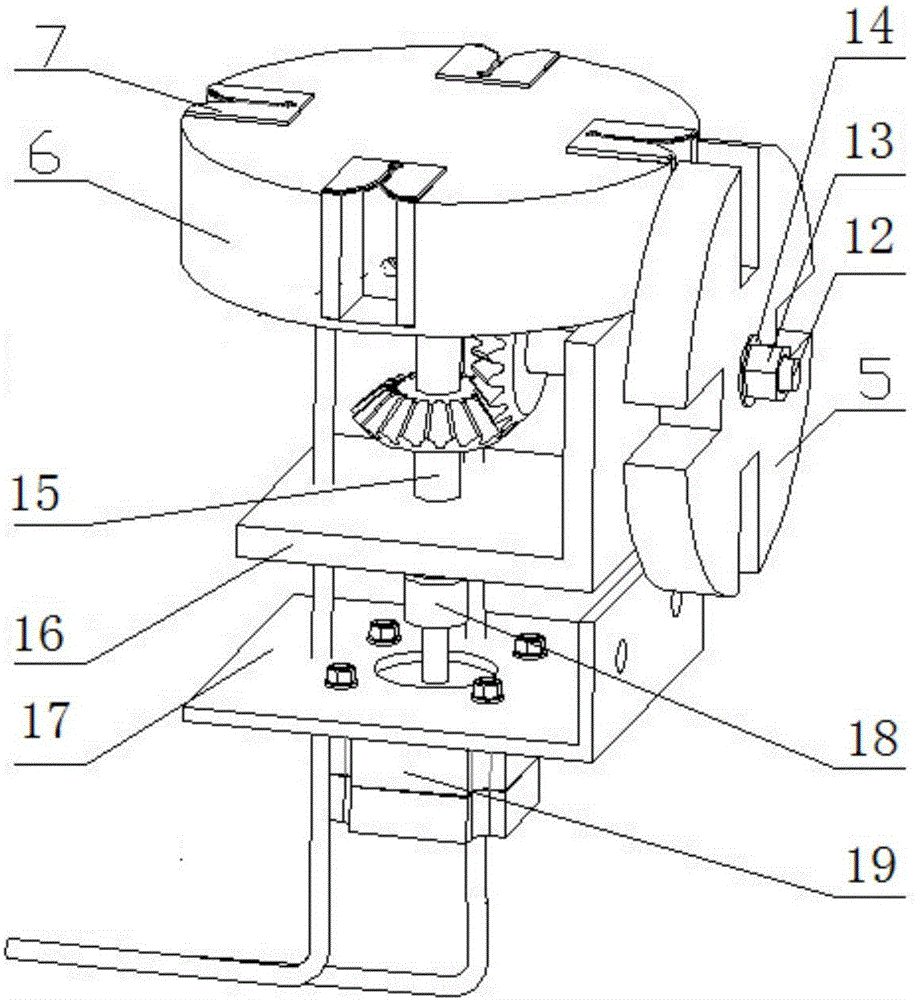

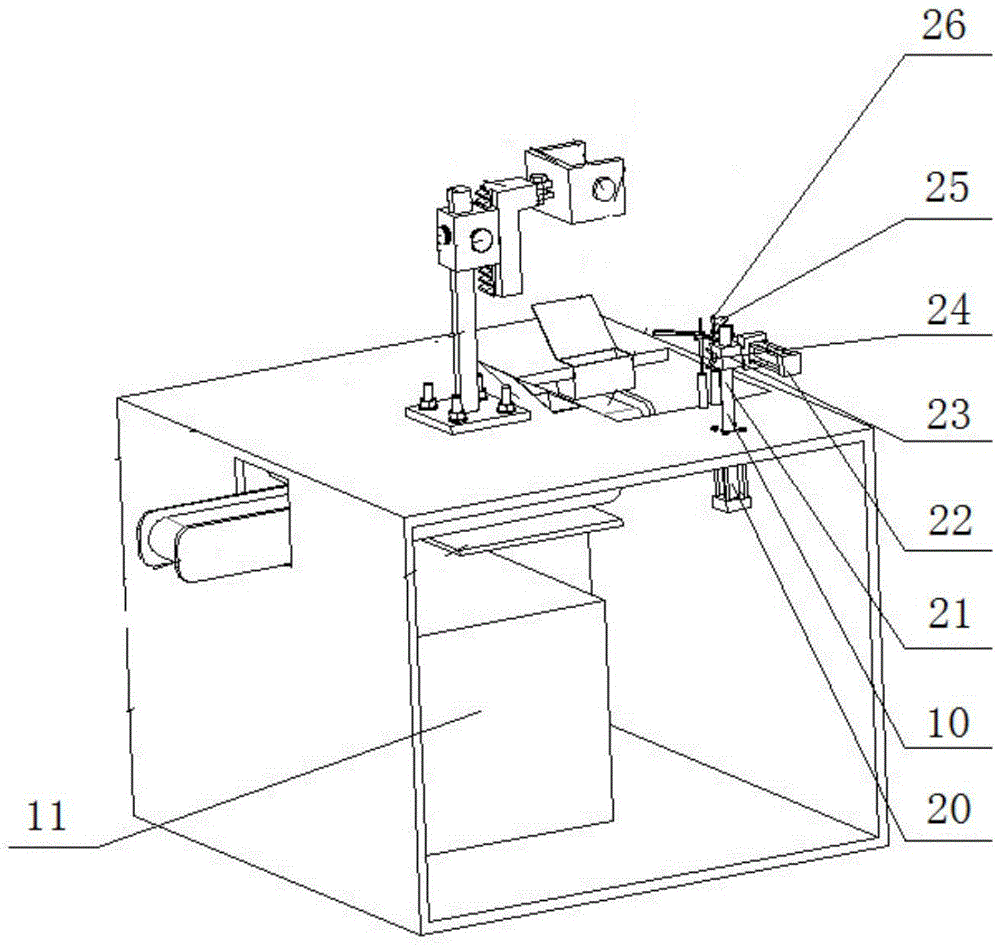

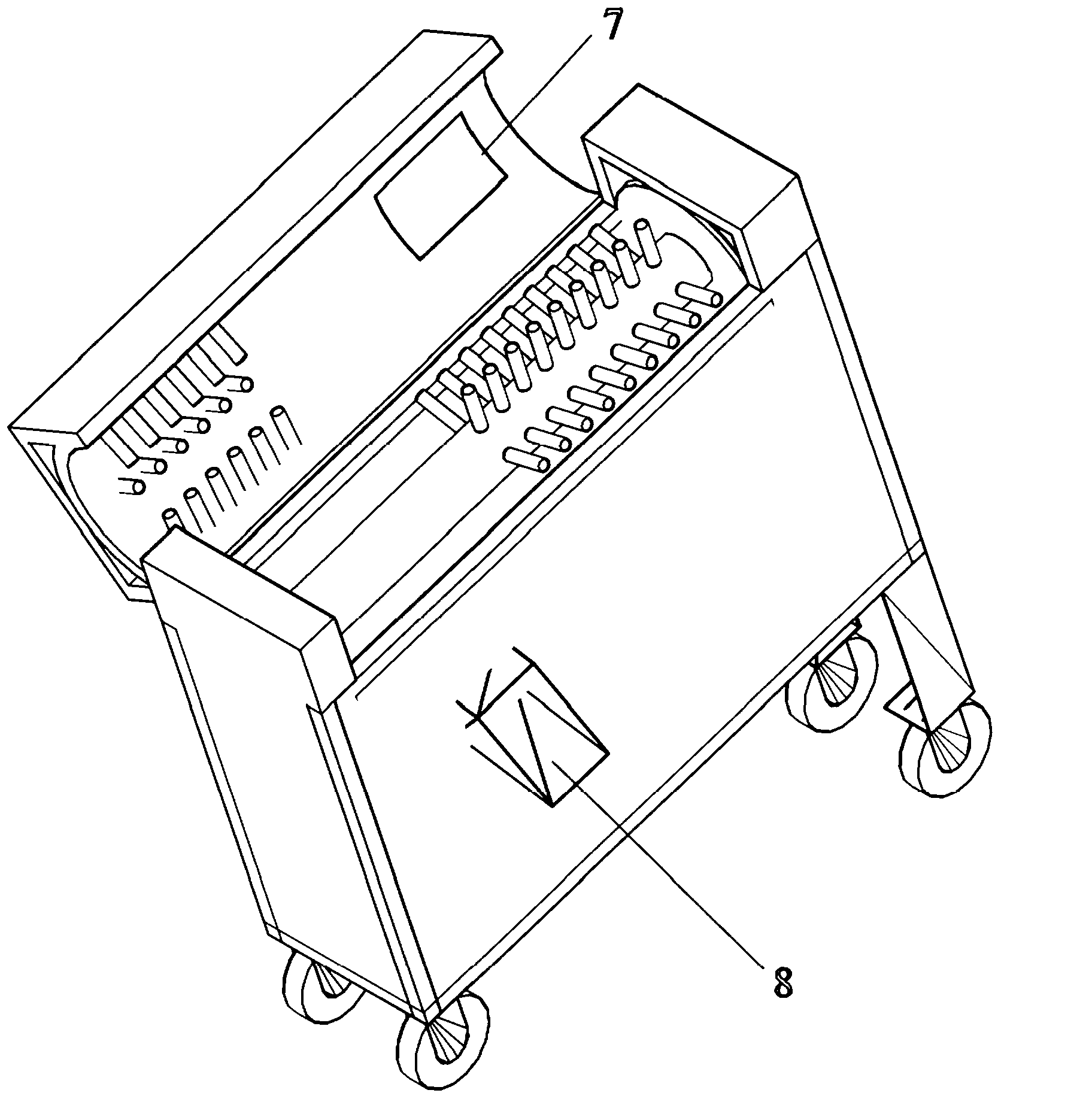

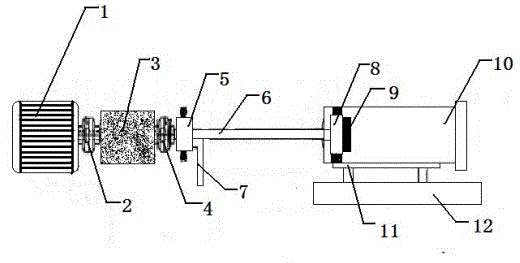

Cylindrical capacitance-type heterotype electronic component whole foot equipment

InactiveCN104882301AImprove the efficiency of the whole footReduce work intensityCapacitor manufactureCapacitanceTransmission system

The invention discloses cylindrical capacitance-type heterotype electronic component whole foot equipment. The equipment comprises a rack, a transmission system, an automatic material distributing system and a whole foot system. The transmission system, the automatic material distributing system and the whole foot system are arranged on the rack. The transmission system comprises a material distributing disc (5), a working disc (6) and a stepping motor (19). The automatic material distributing system comprises a feeding chute (2), a first air blowpipe (4) and an air compressor (11). The whole foot system comprises a first cylinder (20), a second cylinder (22) and a mechanical clamping finger (25) which is provided with a groove (29). By using the equipment in the invention, automation alignment of a cylindrical capacitance pin is realized and manual operation can be completely replaced; whole foot efficiency can be increased and working strength is reduced; precision and whole foot consistency can be increased so that a qualified rate of a subsequent plug-in process is further improved.

Owner:HUBEI UNIV OF TECH

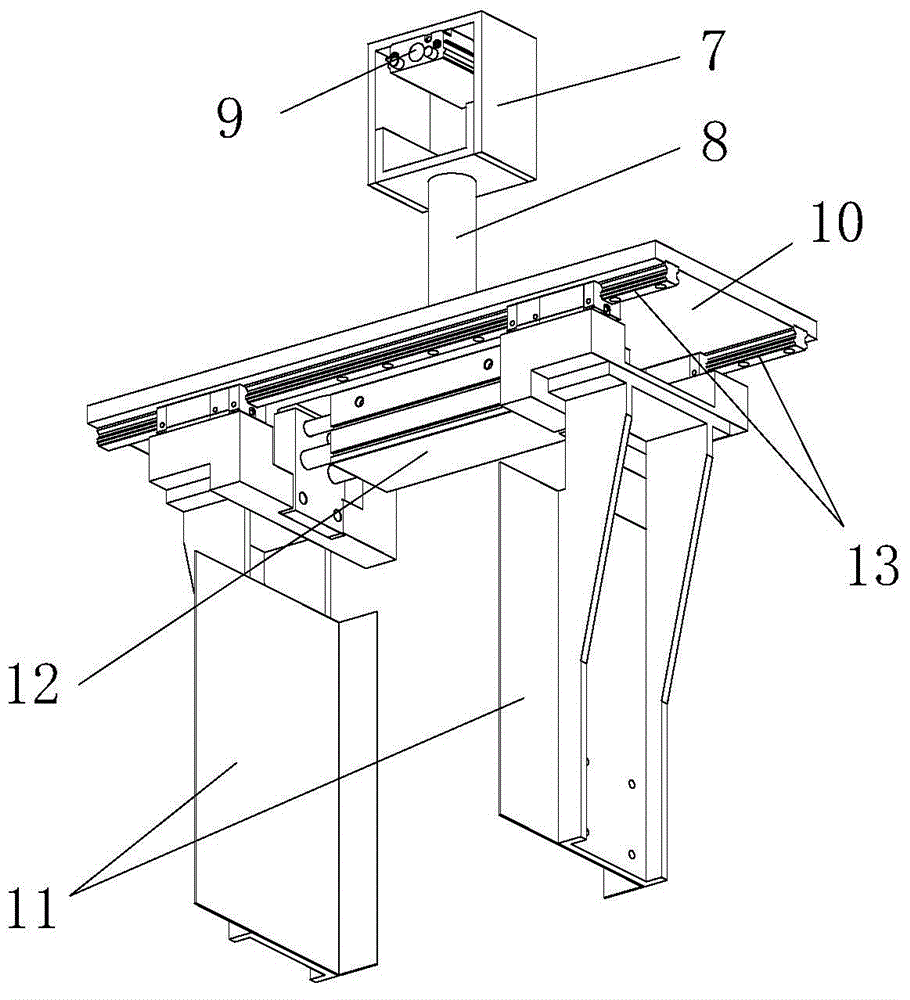

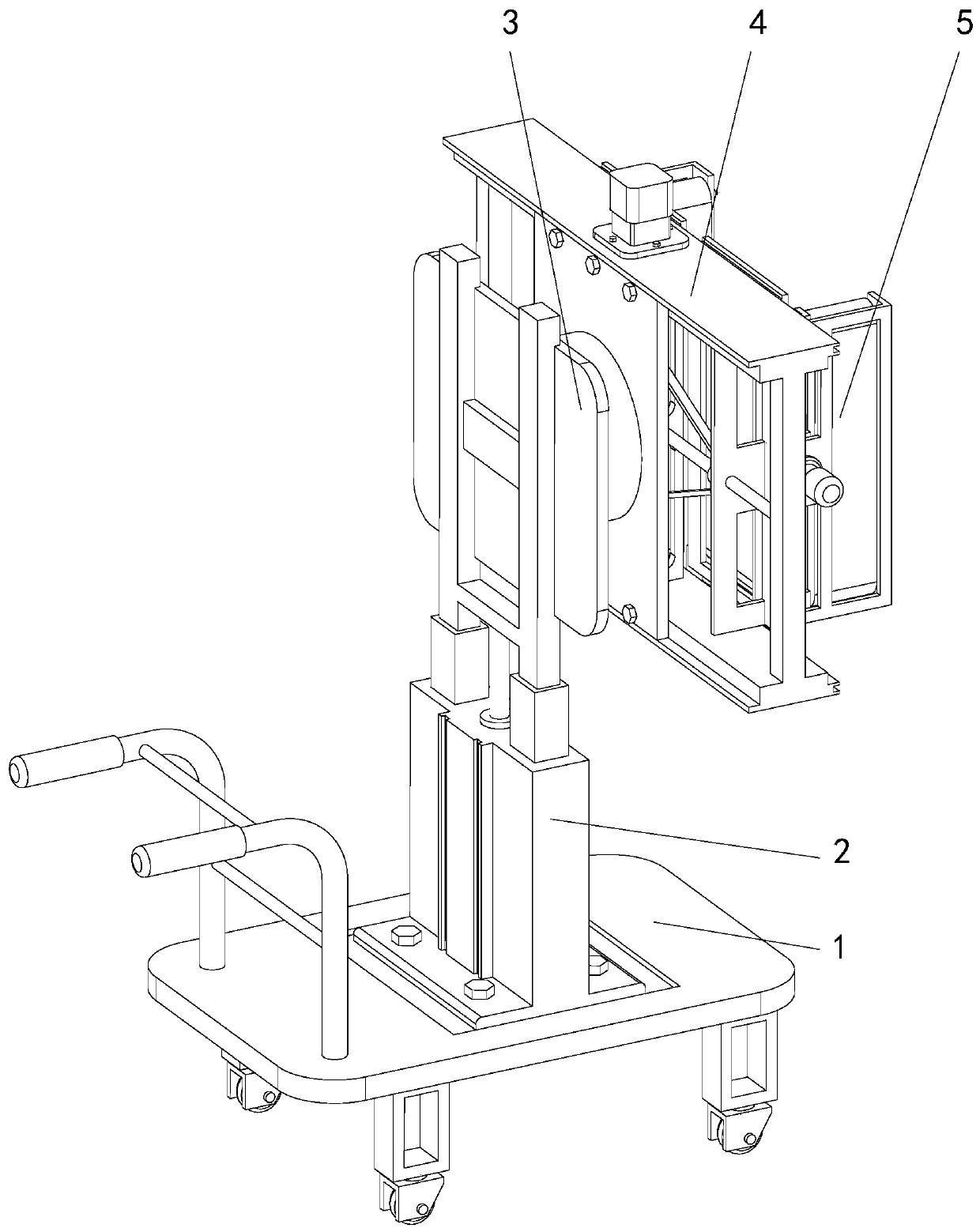

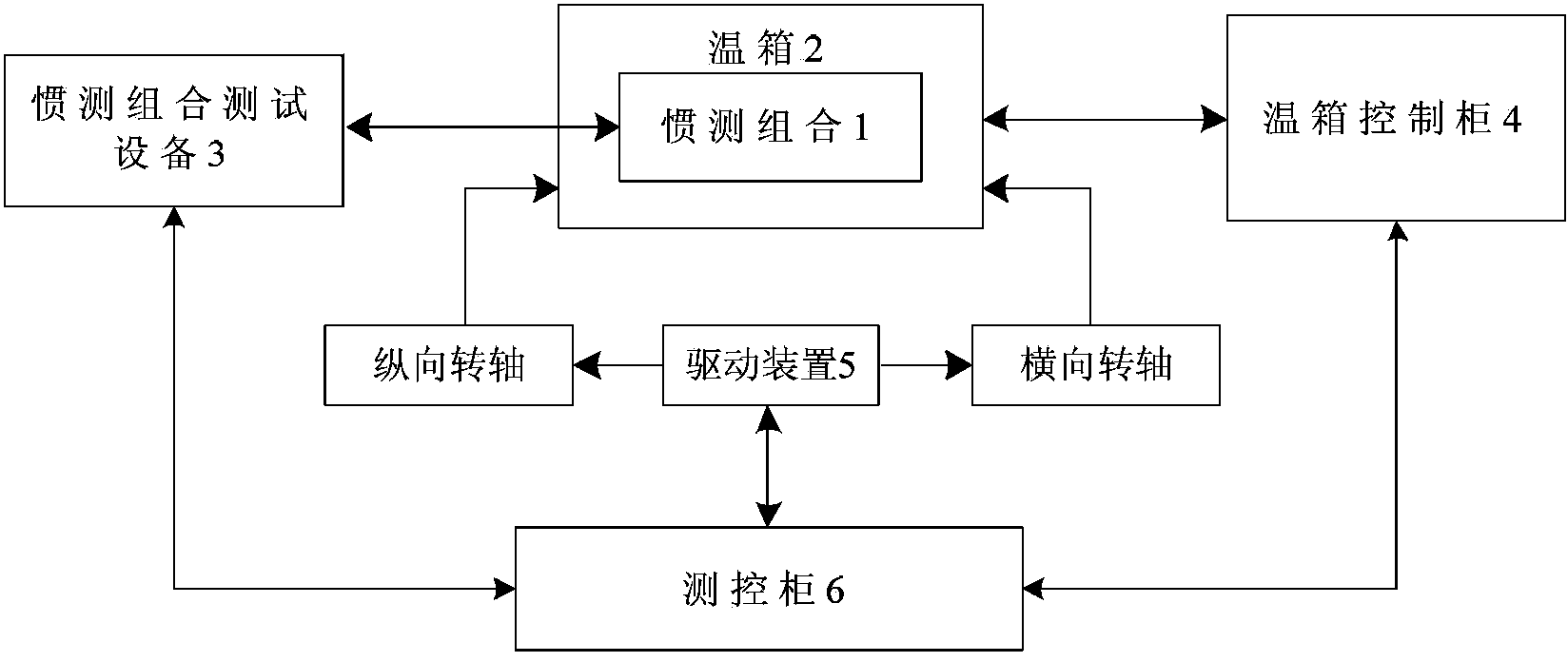

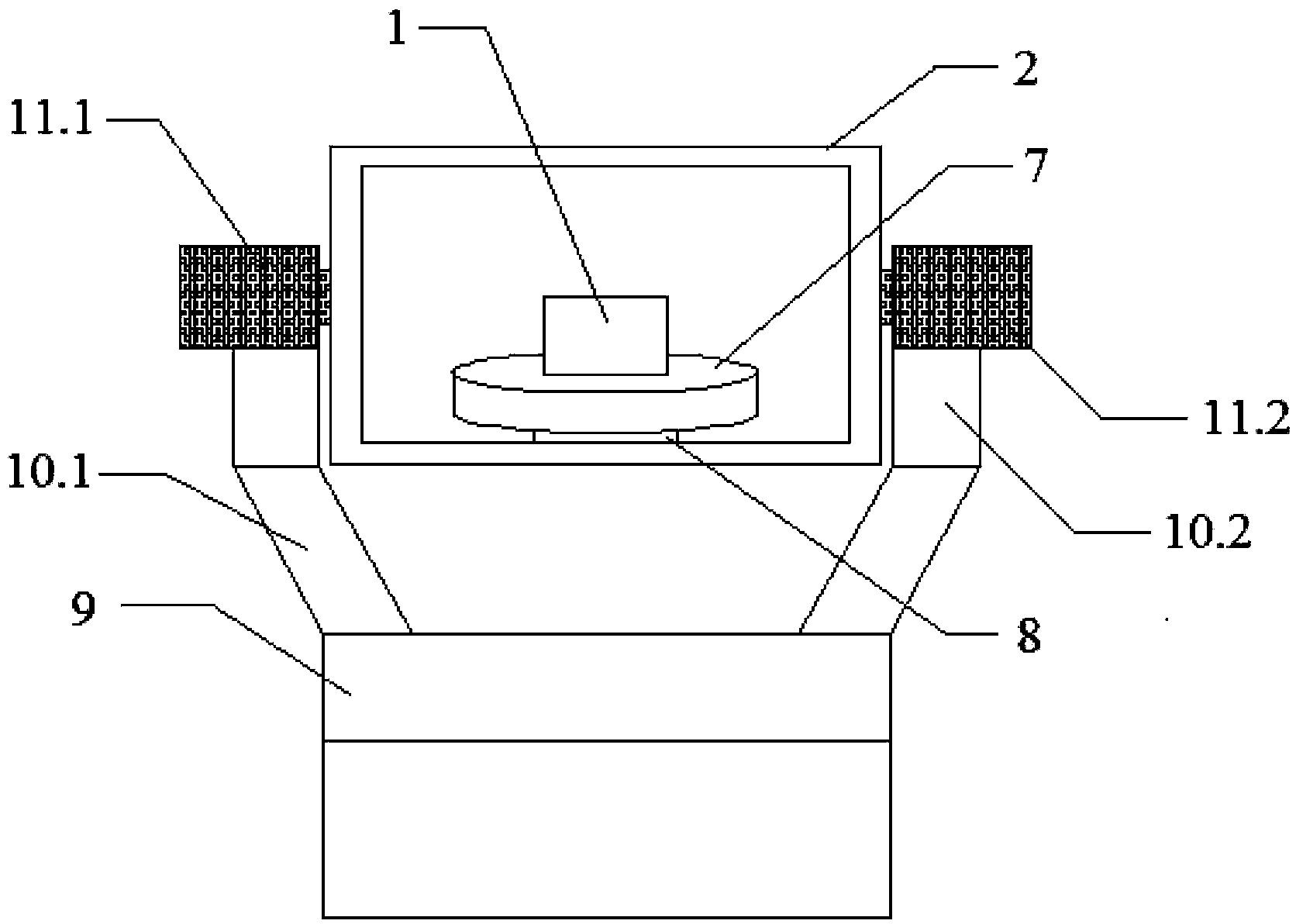

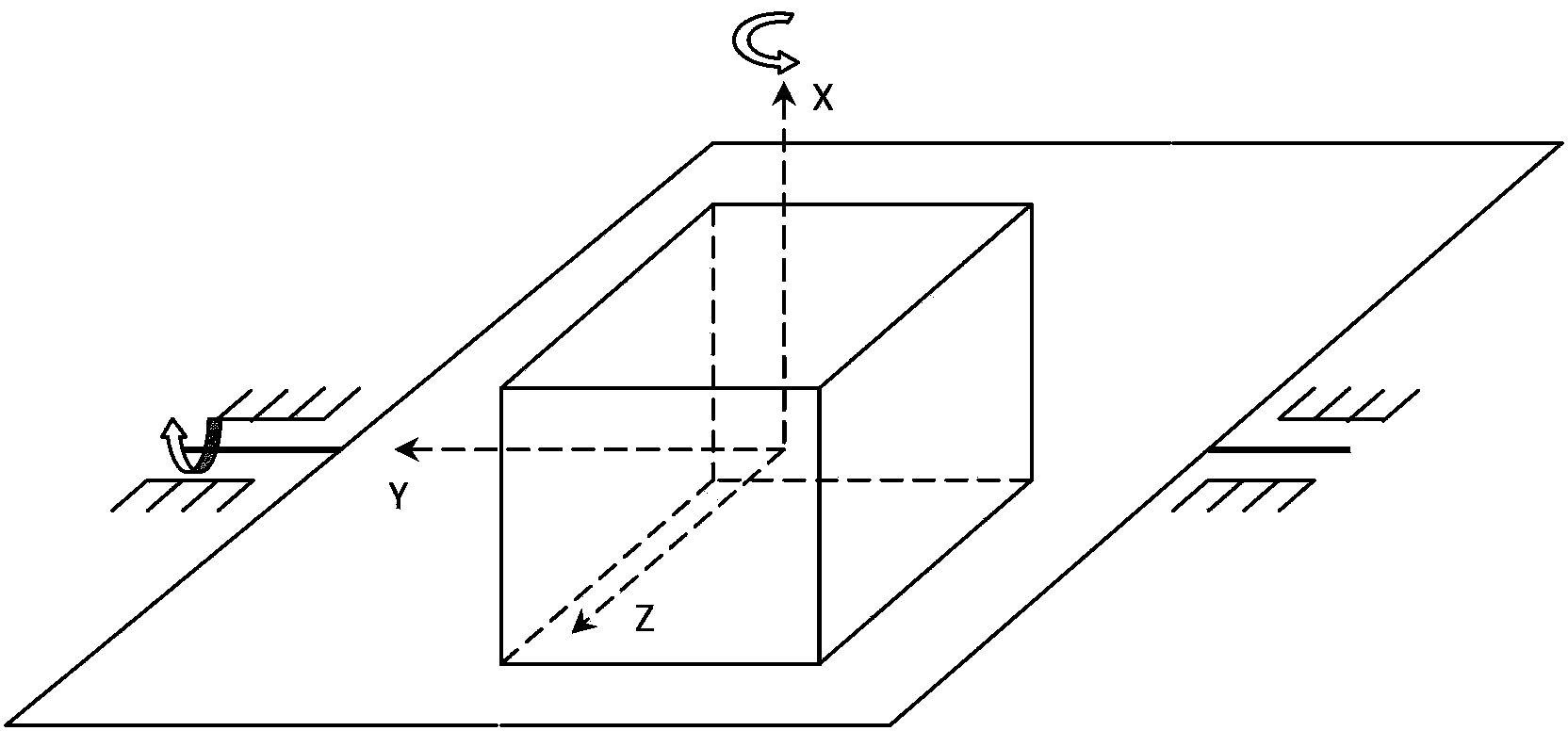

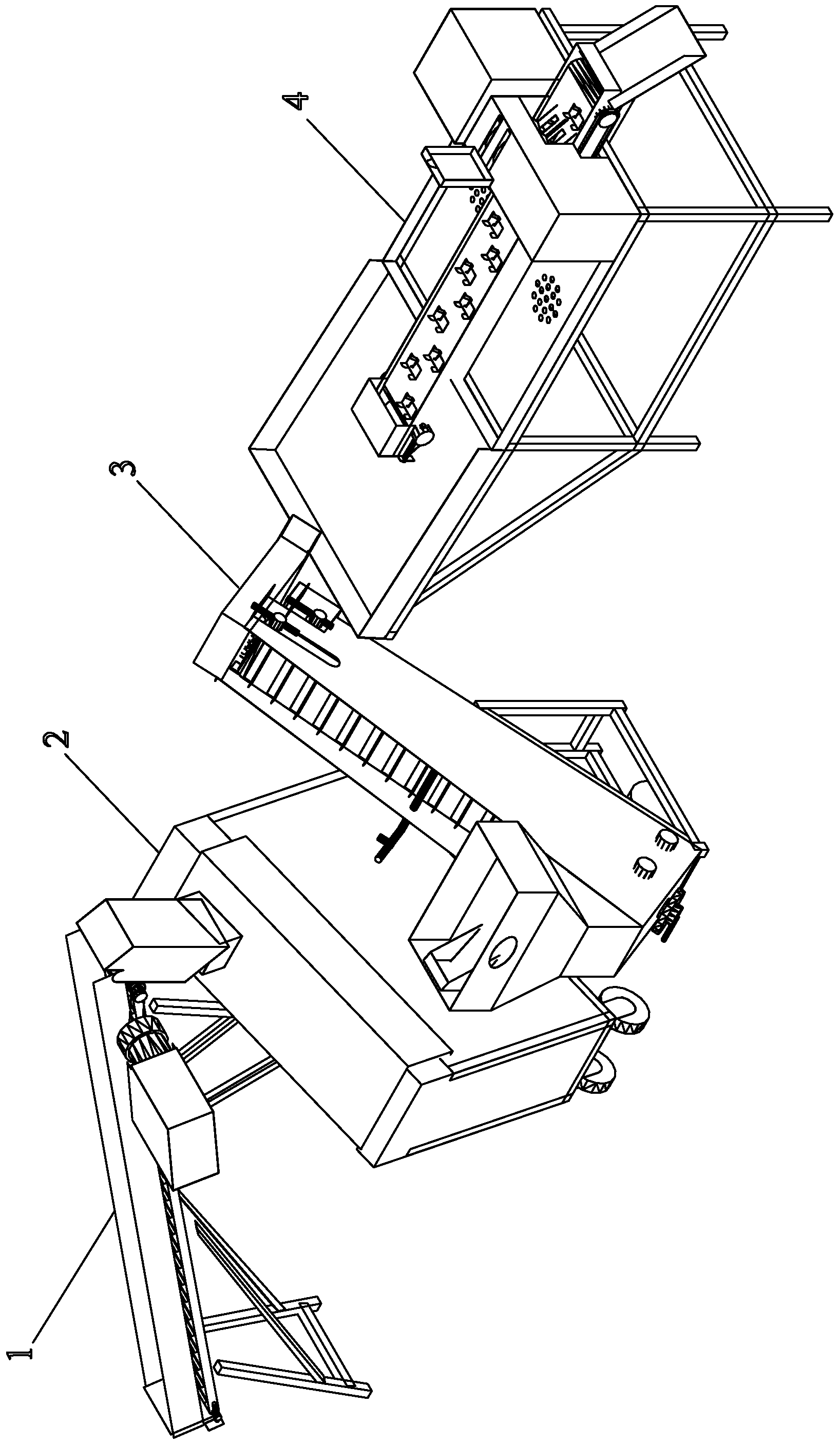

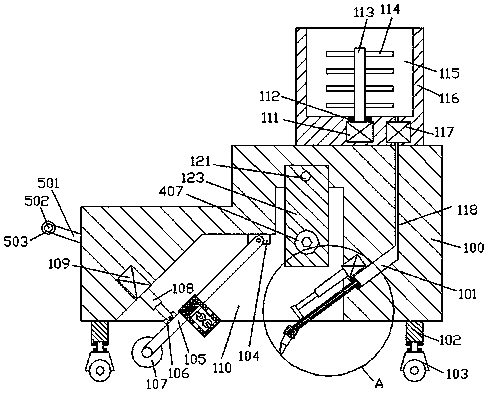

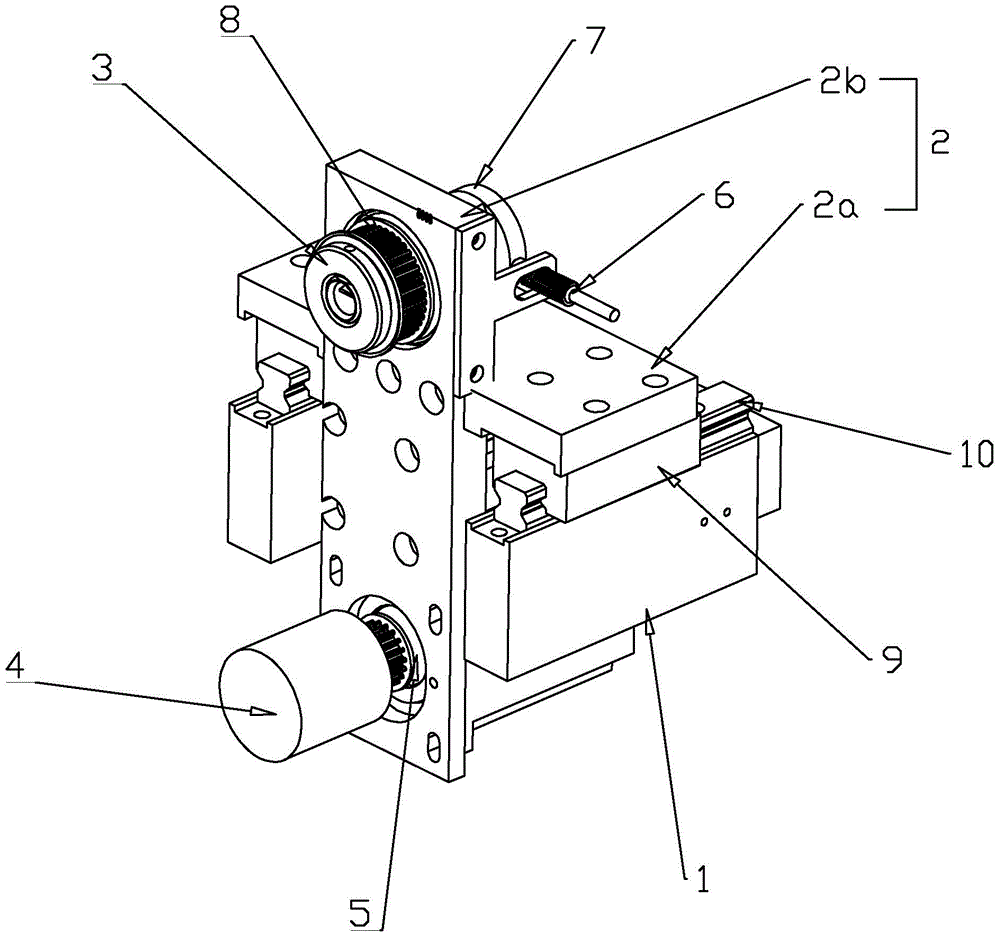

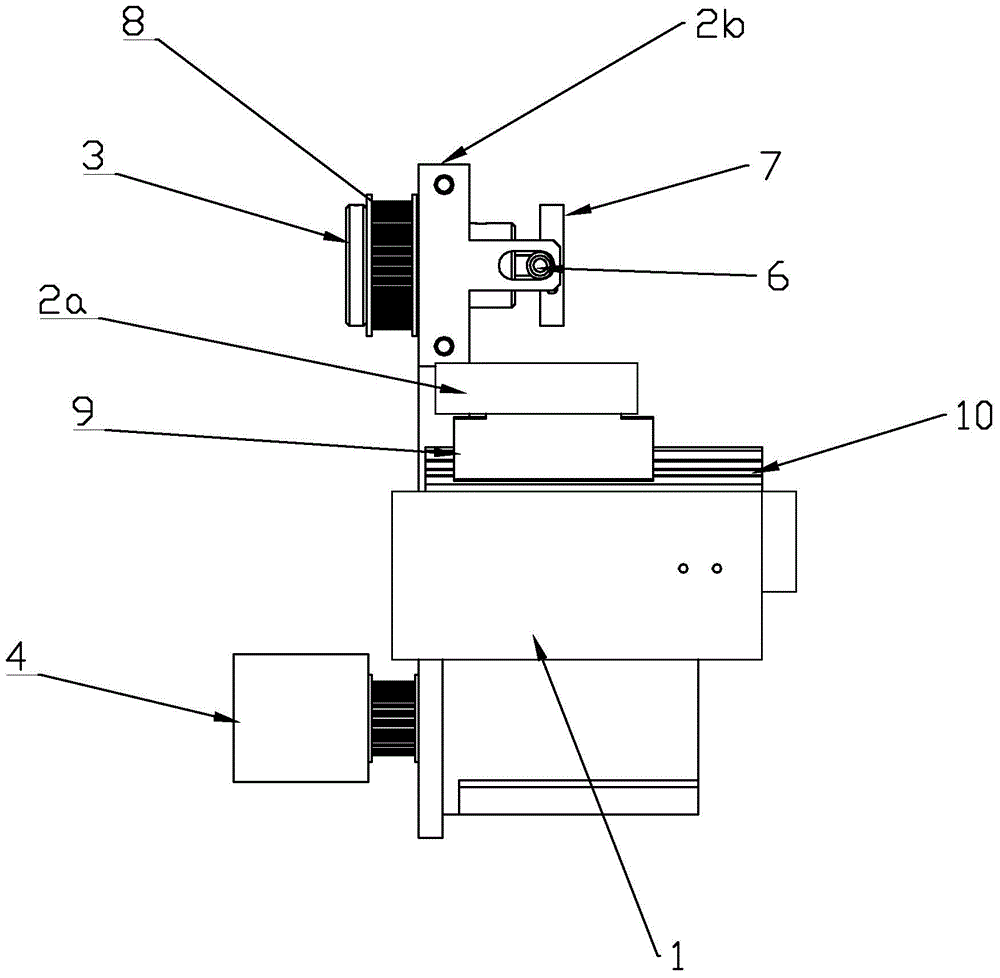

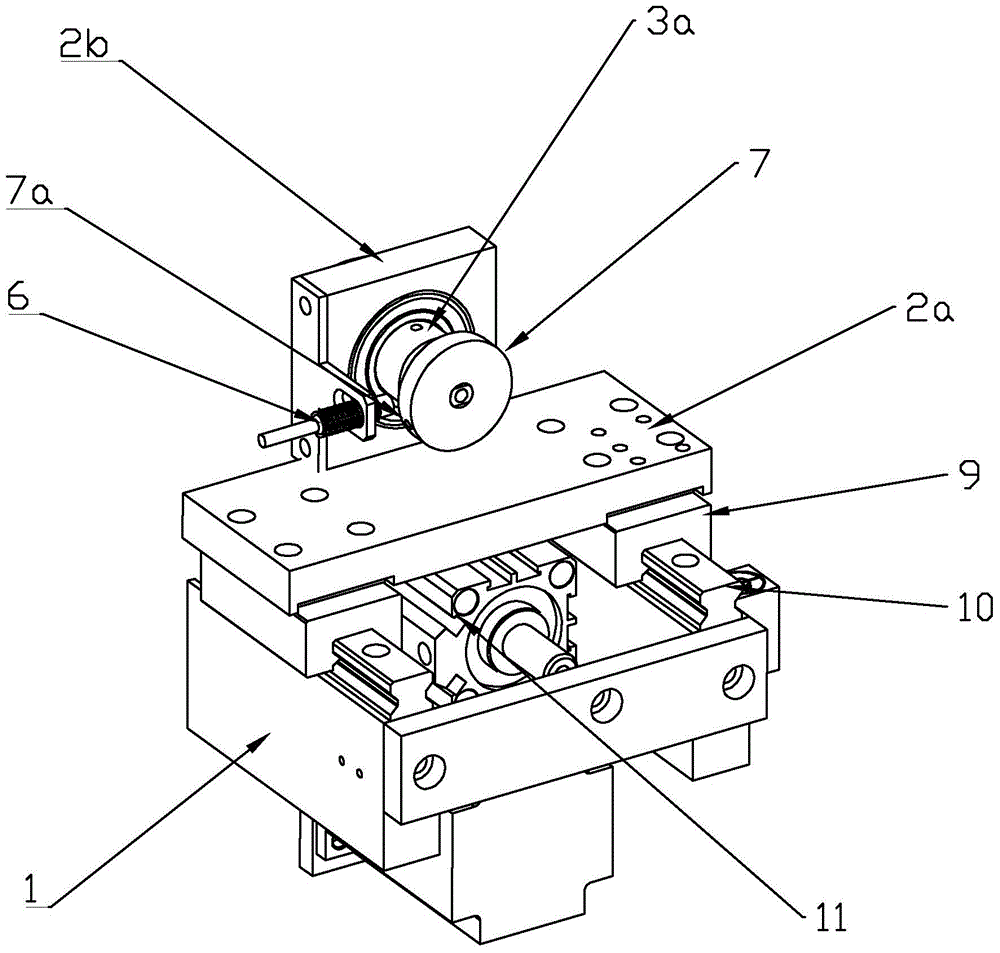

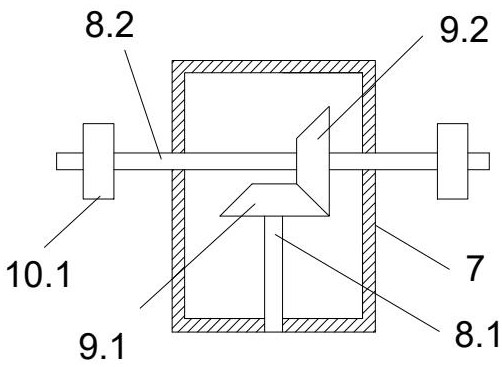

Method and equipment for full-automatic temperature compensation test of inertia measurement assembly

ActiveCN103411611AImprove compensation efficiencyImprove reliabilityNavigation by speed/acceleration measurementsEngineeringInertia

The invention discloses a method and equipment for a temperature compensation full-automatic test of an inertia measurement assembly. The equipment comprises a base, two support frames, two transverse rotating shafts, an incubator, a fixing seat, a longitudinal rotating shaft, a placement table facet, a temperature control cabinet, a driving device, an inertia measurement assembly testing device and a processing unit, wherein the two support frames are arranged on the base; the two transverse rotating shafts are arranged on the two support frames; the left end and the right end of the incubator are respectively connected with the two transverse rotating shafts; the fixing seat is fixedly arranged on the inner wall of the incubator; the longitudinal rotating shaft is arranged on the fixing seat; the placement table facet is fixedly connected with the longitudinal rotating shaft and used for mounting the inertia measurement assembly; the temperature control cabinet is connected with the incubator; the driving device is connected with both the two transverse rotating shafts and the longitudinal rotating shaft; the inertia measurement assembly testing device is connected with the inertia measurement assembly through a CAN bus; the processing unit is connected with the temperature control cabinet, the driving device and the inertia measurement assembly testing device. The full-automatic temperature compensation test of the inertia measurement assembly performed by adopting the equipment provided by the invention has the advantages that the process is automatic, parameters are calculated automatically, the compensation efficiency is high, the reliability is high, and the compensation precision is high.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

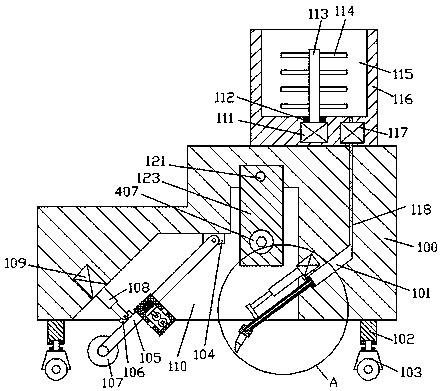

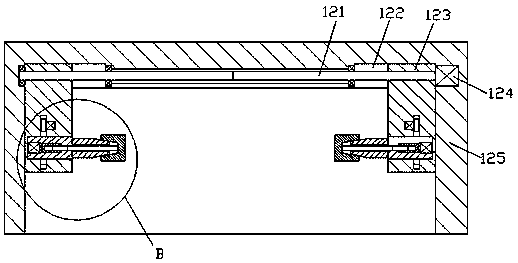

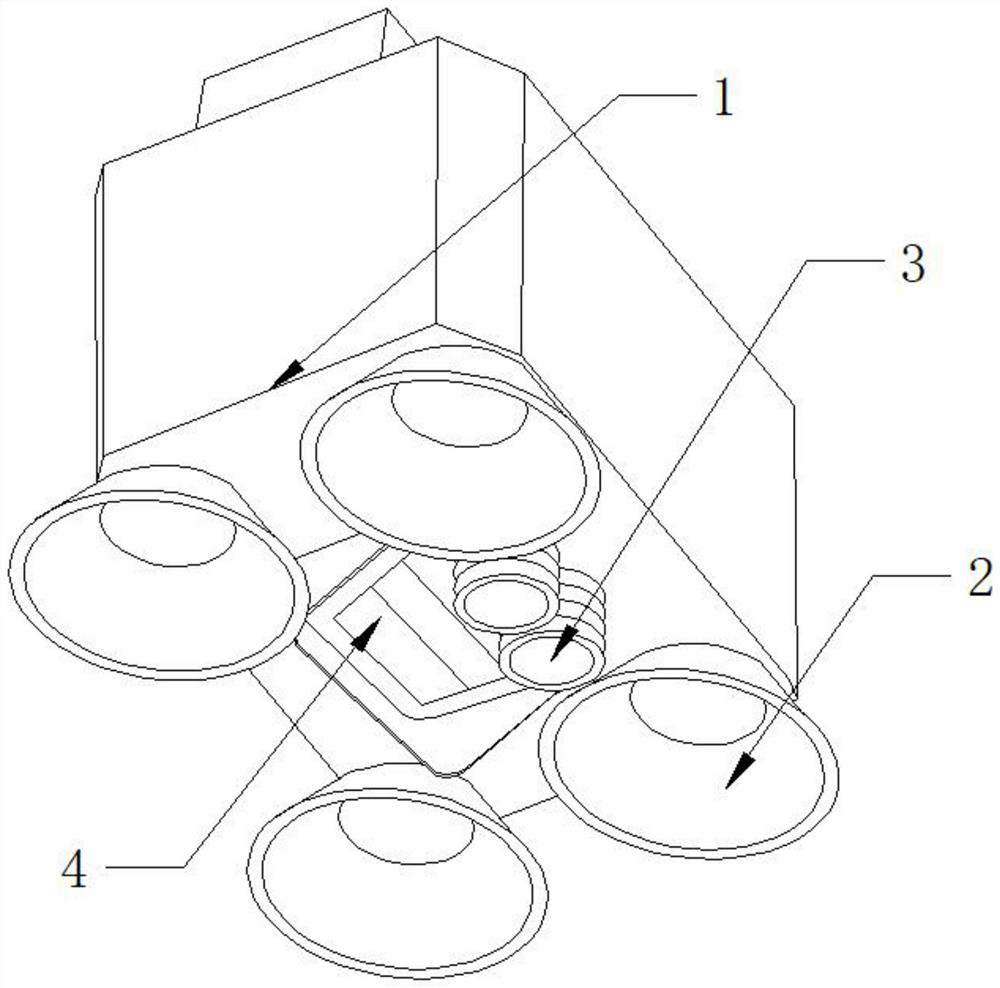

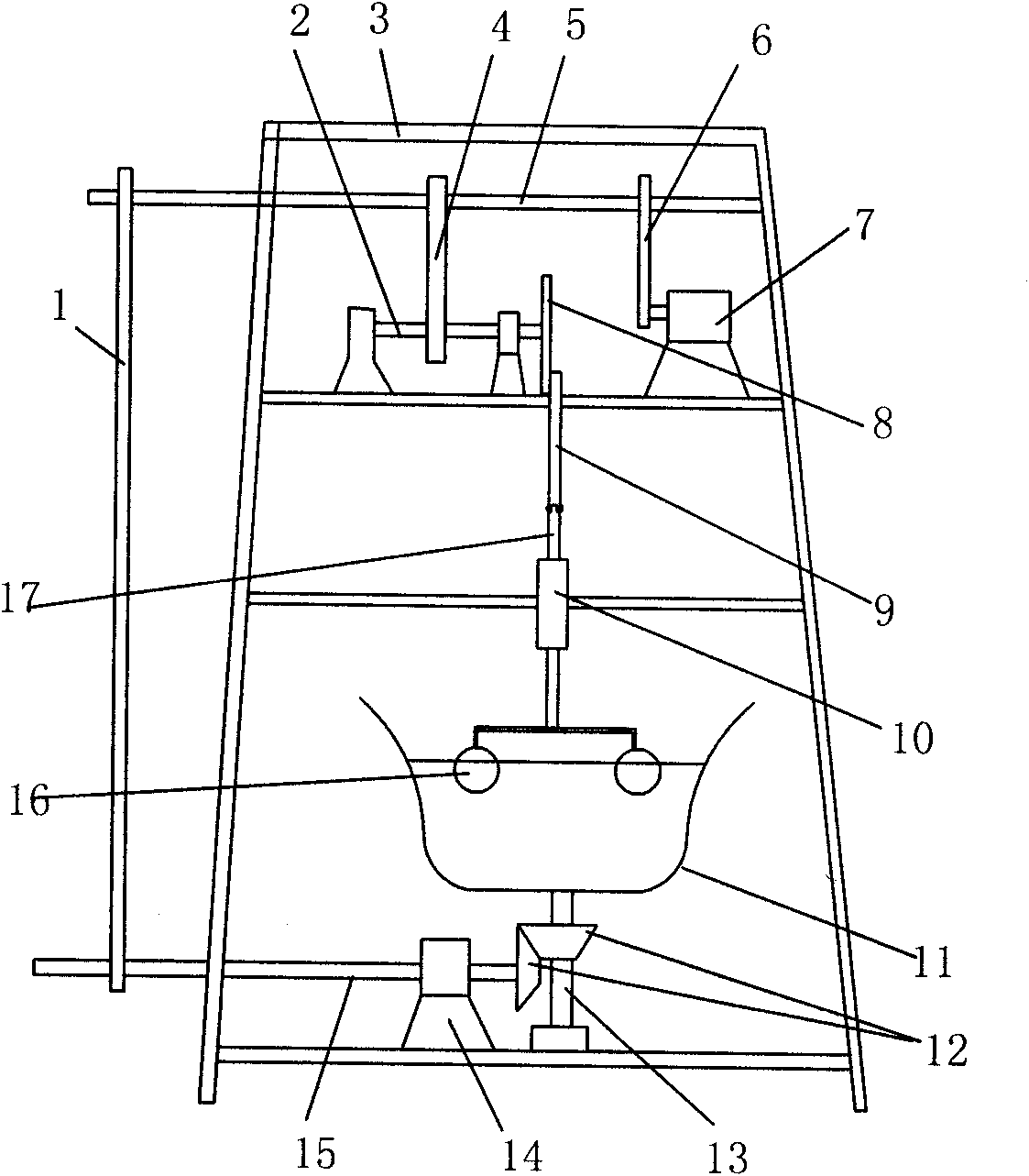

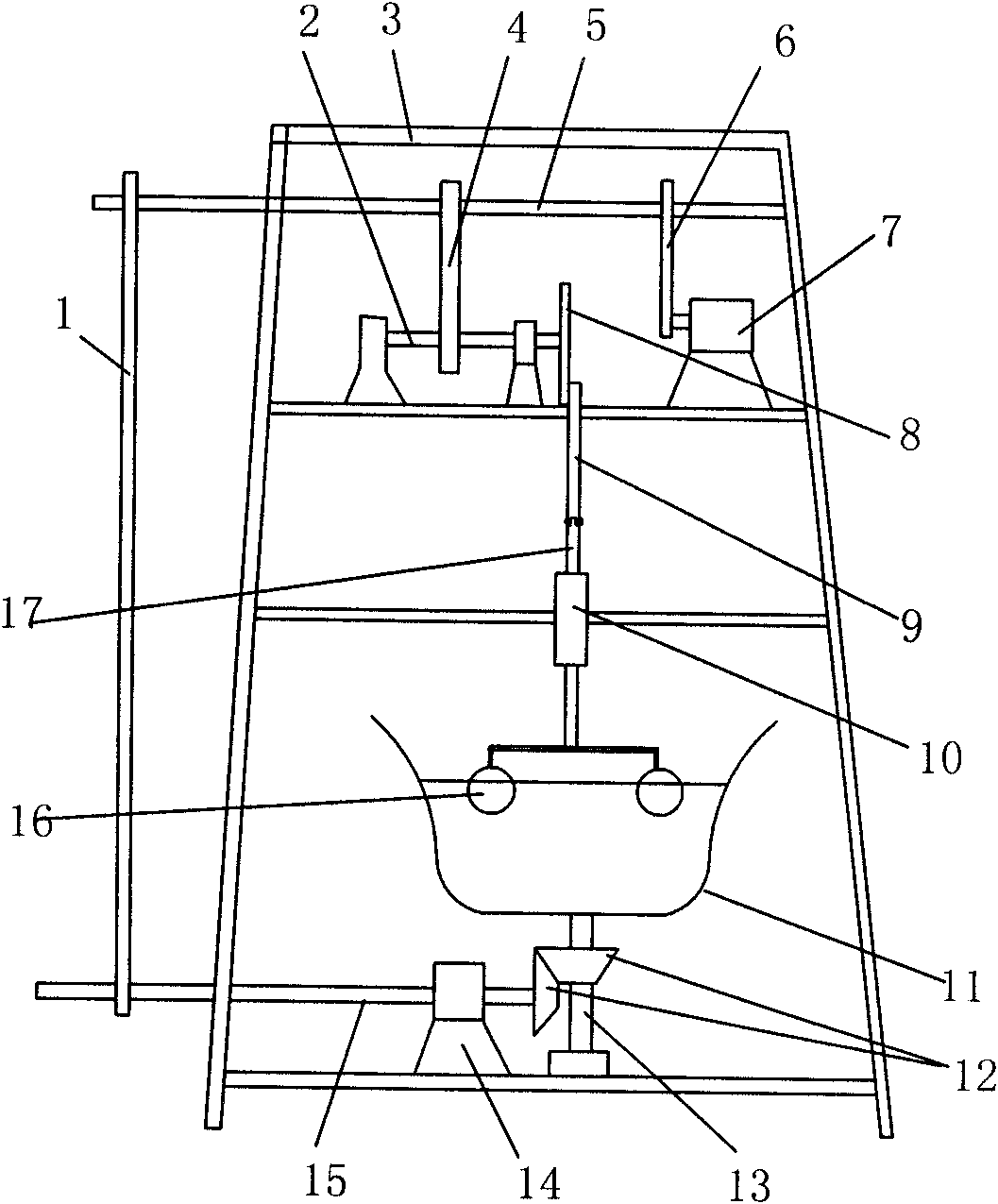

Integrated automatic poultry gizzard degreasing separation equipment

ActiveCN103300122AIncrease productivityShorten the timePoultry eviscerating devicesSedimentation settling tanksFood industryFood sector

The invention discloses integrated automatic poultry gizzard degreasing separation equipment. The integrated automatic poultry gizzard degreasing separation equipment comprises a hoisting machine 1 for loading, a degreasing machine 2 for receiving the loading of the hoisting machine 1 for performing grease gizzard separation, a grease gizzard separating machine 3 for separating mixture of grease liquid after being degreased and poultry gizzard, and a gizzard cutting machine 4 for cutting the separated poultry gizzard. The significant improvement of the integrated automatic poultry gizzard degreasing separation equipment is as follows: after grease flows in a box body of the separating machine, gizzard, grease and waste residue are separated through buoyant force of water. Full automatic degreasing and gizzard grease separation can be performed, and the residue is discharged thoroughly, so that the production efficiency is improved, the time is saved, and the manual operation is replaced. Through the improvement of the equipment, the invention further provides a poultry gizzard machining method, particularly an automatic poultry gizzard degreasing and gizzard grease separation machining technique suitable for food industry.

Owner:朱忠毅

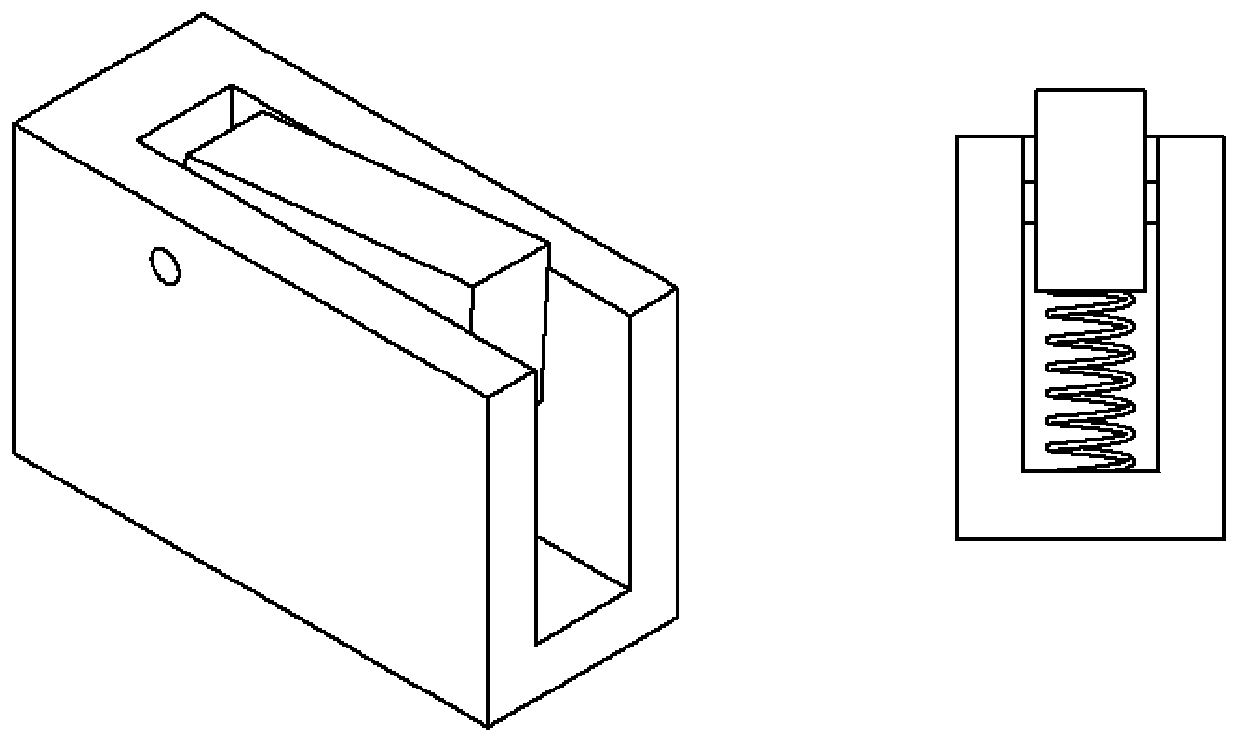

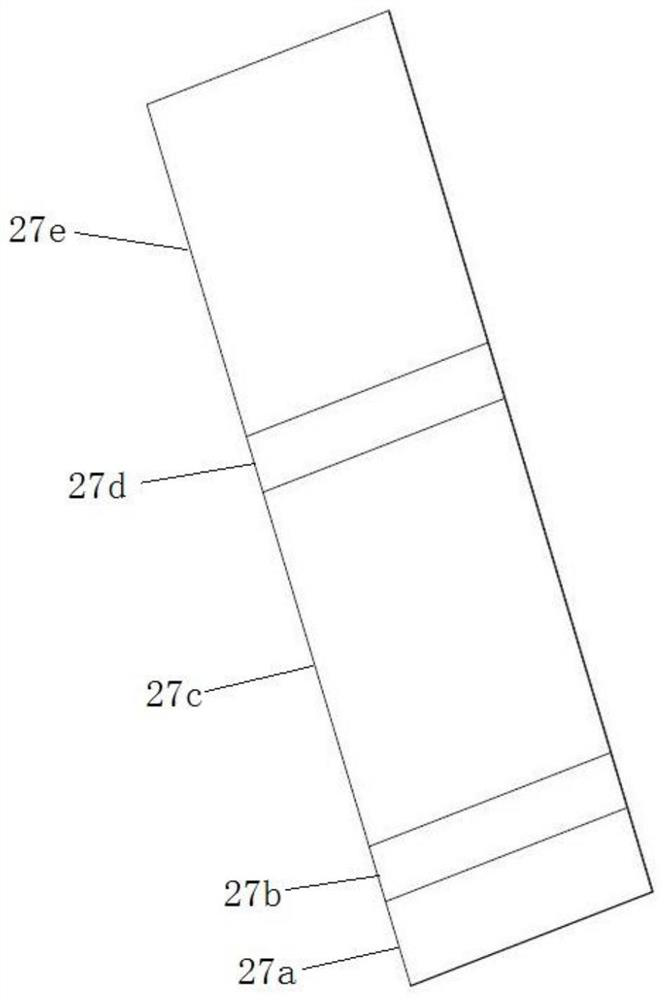

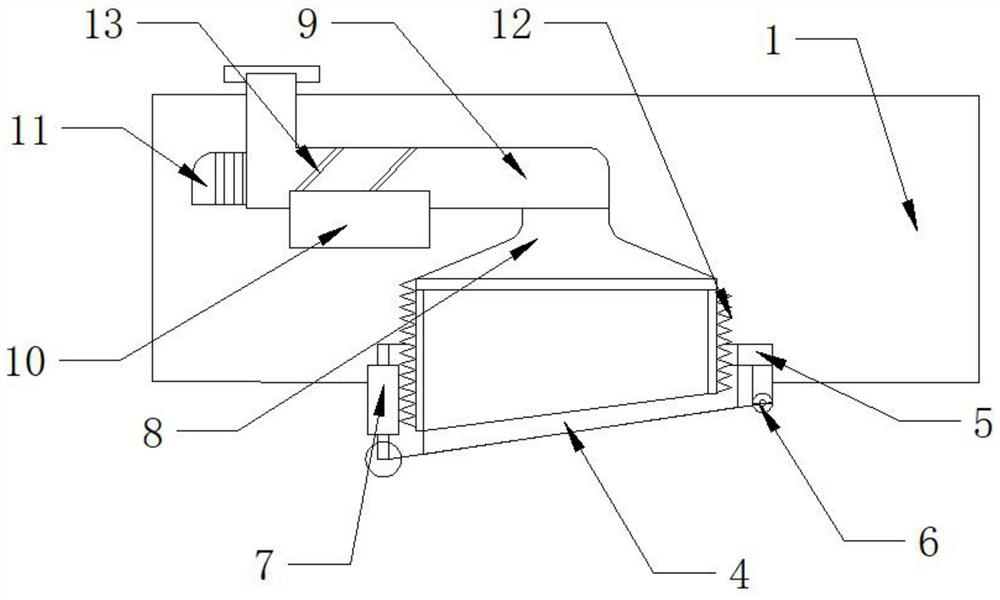

Constructional engineering waterproof construction method

InactiveCN108625551ASimple structureEasy to operateRoof toolsBuilding material handlingPneumatic cylinderPneumatic pressure

The invention discloses a constructional engineering waterproof construction method which refers to constructional engineering waterproof construction equipment. The constructional engineering waterproof construction equipment comprises a construction equipment body and a mixing box fixedly mounted on the construction equipment body; a containing cavity is formed in the bottom end face of the construction equipment body; a first convex block is fixedly arranged on the top wall of the containing cavity; an obliquely-arranged linkage plate is mounted on the first convex block in a hinged mode; asecond convex block is fixedly arranged on the linkage plate, and a first piston rod is mounted on the second convex block in a hinged mode and is in power connection with a first pneumatic cylinder;the first pneumatic cylinder is fixedly arranged in the inner top wall of the containing cavity; a pressing rotating drum is mounted at the tail end of the bottom of the linkage plate in a rotating fit mode; a guiding frame is vertically fixedly arranged in the linkage plate, and a jacking-pressing sliding cavity is formed in the guiding frame; a jacking-pressing plate is arranged in the jacking-pressing sliding cavity in a sliding fit mode; and a jacking-pressing spring is mounted between the upper side of the jacking-pressing plate and the top wall of the jacking-pressing sliding cavity ina jacking-pressing fit mode.

Owner:宁波鄞州国康机械科技有限公司

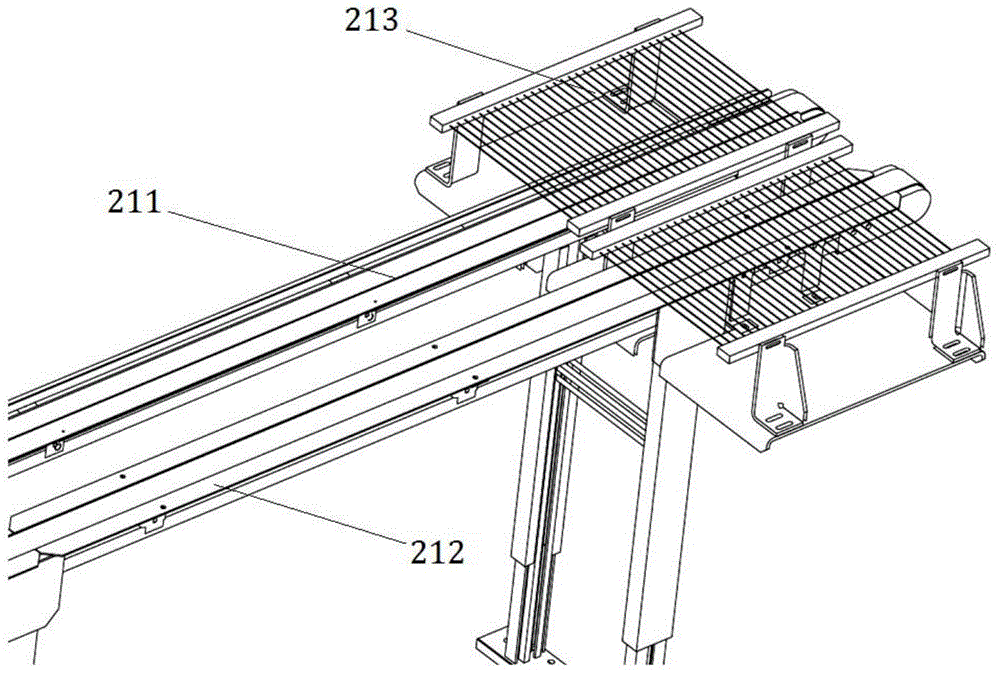

Automatic stacking device of iron core shearing production line

PendingCN108695056AExpand coverageSimple structureInductances/transformers/magnets manufactureProduction lineStack machine

The invention belongs to the technical field of professional electrician equipment, and particularly relates to an automatic stacking device of an iron core shearing production line. The automatic stacking device comprises a frame body, and also at least comprises a material distribution device, an upper-layer conveying device, a lower-layer conveying device, an upper-layer material receiving table, a lower-layer material receiving table, a stacking machine hand, a multi-station stacking table. The upper-layer conveying device, the upper-layer material receiving table, the lower-layer conveying device and the lower-layer material receiving table are sequentially connected to the frame body from top to bottom; the right side of the frame body is connected with the material distributing device, and the stacking machine hand and the multi-station stacking table are arranged on the left side of the frame body; the multi-station stacking table is located below the stacking machine hand. Theproblems that in an existing production line, iron core finished products can be completed through a lot of manual stacking procedures, many manpower resources are occupied by the manual stacking procedures, the labor intensity of workers is high, the production efficiency is low, and the product quality is unstable are solved. The device can achieve quick, orderly and regular stacking, manual operation is replaced, and the manpower resources can be saved.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

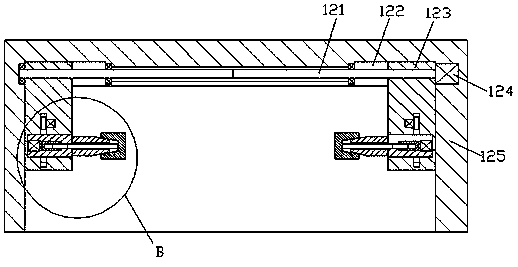

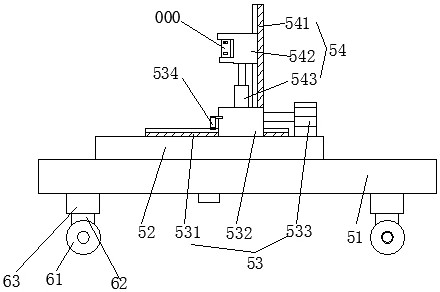

Vacuumization thermal packaging equipment

PendingCN108163256AImprove work efficiencyReduce manufacturing costPackaging by pressurising/gasifyingWrapper twisting/gatheringPlastic packagingElectric machinery

The invention discloses vacuumization thermal packaging equipment comprising a bag sealing mechanism and a moving mechanism. The bag sealing mechanism is slidably connected to the moving mechanism; and the bag sealing mechanism comprises an external housing, a bed frame, a servo bag opening mechanism and a hermetic vacuumizing heat sealing mechanism; the servo bag opening mechanism and the hermetic vacuumizing heat sealing mechanism are fixedly arranged on the bed frame, and the moving mechanism comprises a base plate, a translational guide rail, a translational sliding block, a servo motor for translation, a screw rod for translation, a support baseplate, a support beam, a first vertical guide rail, a vertical screw rod, a servo motor for vertical movement, and a vertical movement slidingblock. The equipment has the integrated functions of bag opening and lifting operation as well as air removal from plastic packing bags and bag sealing operation, and the application range of the equipment is expanded; meanwhile, manual operation is replaced, and the time and labor are saved; the working efficiency is improved, and the production cost is saved; and the convenience is provided foruse, and the product uniformity after sealing is ensured.

Owner:天津镕霖自动化系统工程有限公司

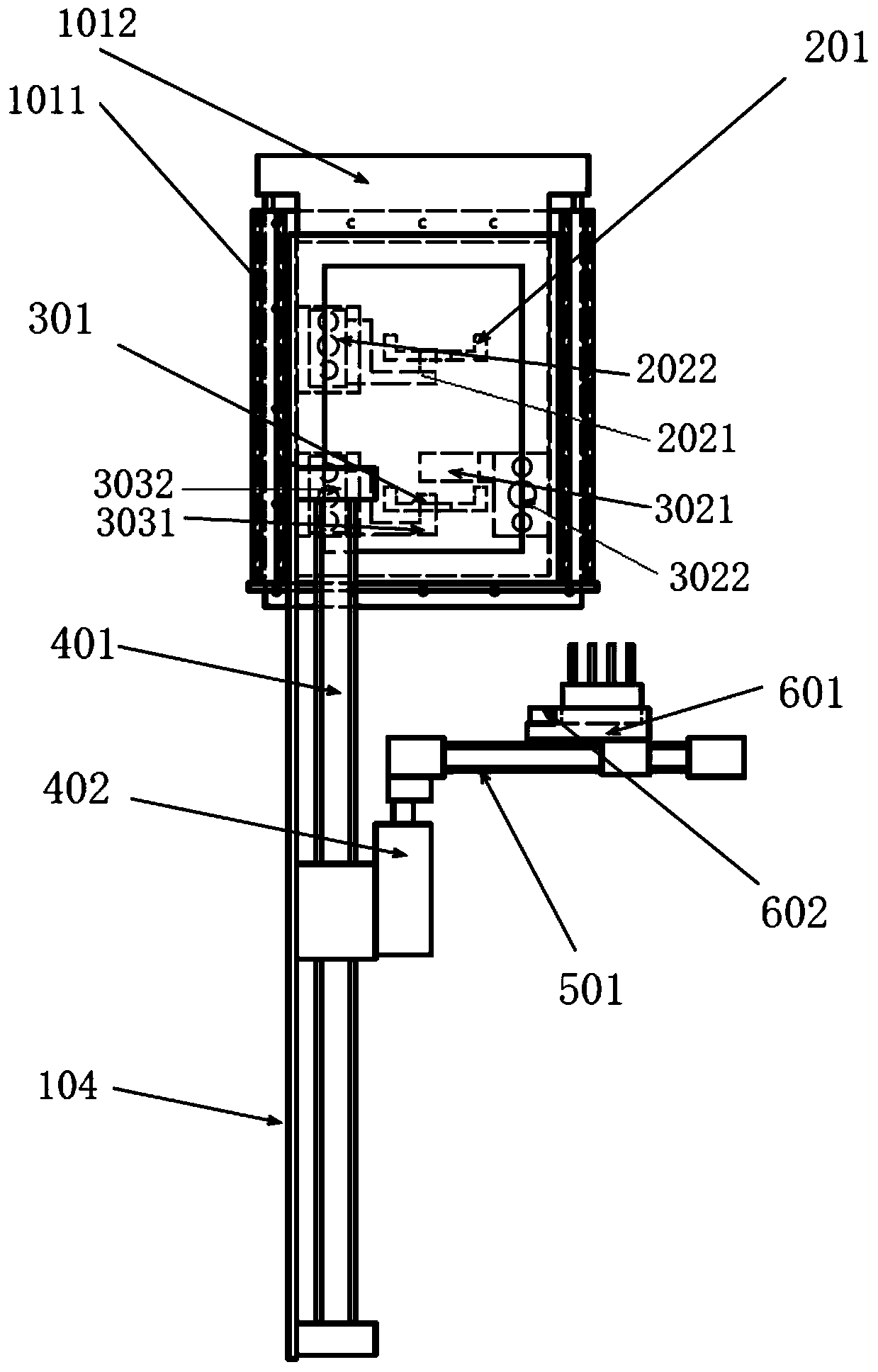

Conveying and transporting device for foundational detonator

PendingCN109764776ARealize automatic turnoverReplace manual operationBlasting cartridgesAmmunition fuzesDetonatorEngineering

The invention relates to the field of civilian-used explosive material production and a conveying and transporting device for a foundational detonator. The conveying and transporting device for the foundational detonator comprises an anti-explosion box body, a feeding module, a mold unloading module, a lifting module, a translation module and a positioning module; when mold unloading is conducted,the lifting module moves to the height of the position of the mold unloading module, the translation module drives an empty mold in the positioning module to horizontally move to the position of themold unloading module, and under the action of the mold unloading module , the empty mold moves to a circumscribed empty mold transporting belt; when feeding is conducted, a mold preparation foundational detonator mold on a circumscribed foundational detonator transporting belt enters the feeding module, meanwhile the lifting module moves to the height of the position of the feeding module, the translation module drives the empty mold in the positioning module to horizontally move to the position of the feeding module, the feeding module drives the mold preparation foundational detonator moldto move into the positioning module, and then the lifting module moves to the fixed feeding position of an operation table. Continuous, automatic, high-reliability and high-safety conveying and transporting of the mold preparation foundational detonator are achieved.

Owner:北京凯米迈克科技有限公司

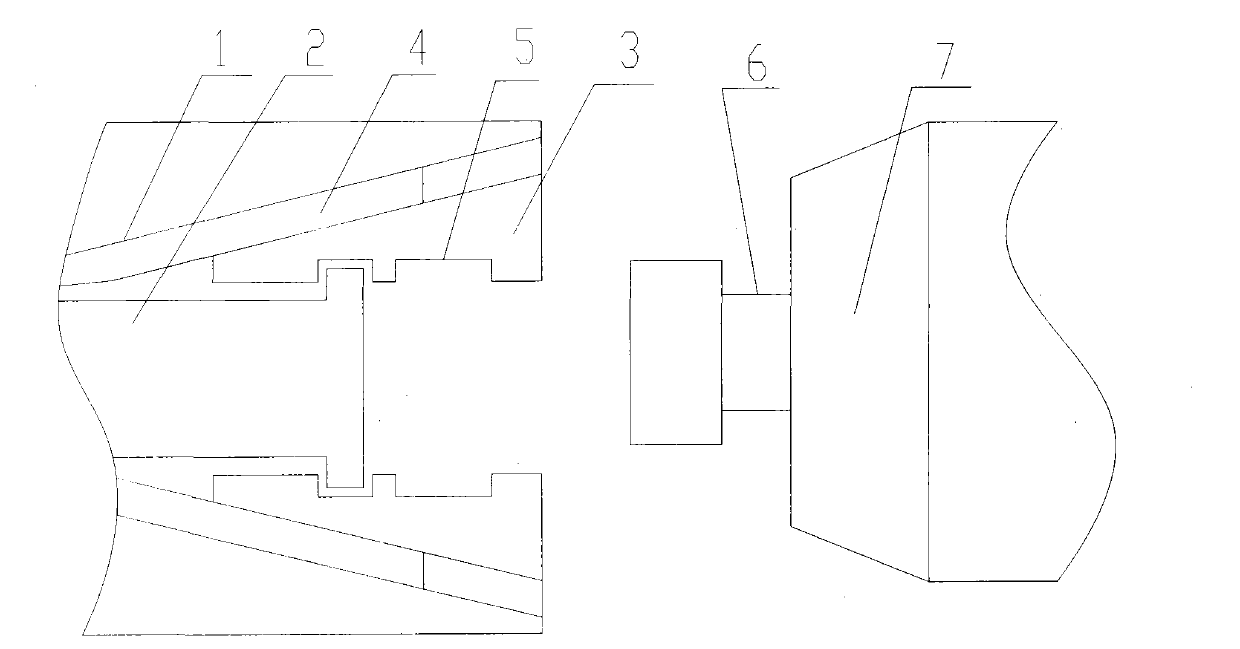

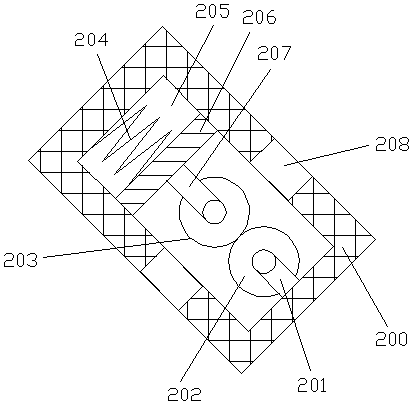

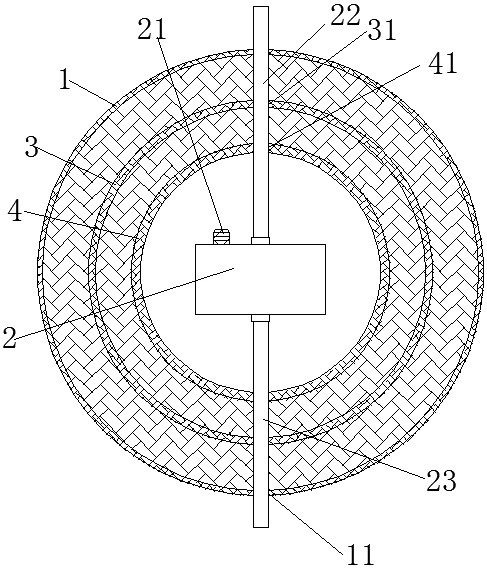

Built-in centering chuck

ActiveCN103273444AStrong clamping forceReplace manual operationWork holdersCamMechanical engineering

The invention discloses a built-in centering chuck. A positioning sleeve is fixed on a spindle inner slope. A movable claw provided with an inner hole is slidably disposed in a movable groove of the positioning sleeve. The outer end face of the movable claw is in slide fit with the spindle inner slope. A movable push-pull rod is disposed on the inner side of the movable claw. A driven cam shaft is matched with movable claw inner hole. The driven cam shaft is provided with a driven cam shaft slope. The inclination angle of each of the spindle inner slope, the positioning sleeve, the outer side of the movable claw, and the driven cam shaft slope is in range of 3-38 degrees. A groove is formed in the movable claw inner hole which can also be matched with the driven cam shaft. The top end of the push-pull rod is provided with steps which allow the movable claw to move. Multiple such movable claws can be disposed. The built-in centering chuck is firm in clamping, capable of automatically positioning and safe, and heavy and repeated manual operations are replaced.

Owner:李恩典

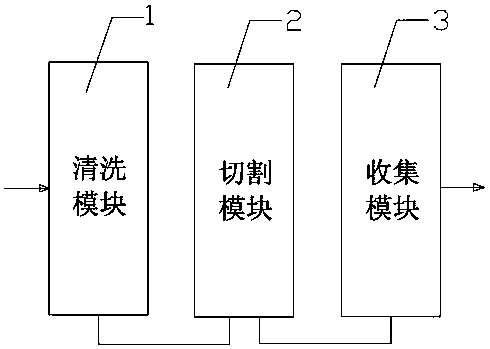

Aloe cleaning, cutting and collecting integrated system

PendingCN108212848AReplace manual operationImprove labor efficiencyCleaning using toolsVegetable peelingAutomatic controlIntegrated systems

The invention discloses an aloe cleaning, cutting and collecting integrated system which comprises a washing module, a cutting module and a collecting module. An aloe outlet of the washing module corresponds to an inlet of the cutting module or is connected with the inlet of the cutting module, and an outlet of the cutting module corresponds to a feed inlet of the collecting module. The aloe cleaning, cutting and collecting integrated system has the advantages that the aloe cleaning, cutting and collecting integrated system which is used as automatic control processing integrated equipment hasmultiple cleaning, cutting and collecting functions, and manual operation can be effectively replaced with the aloe cleaning, cutting and collecting integrated system; the labor intensity can be improved, the automatic production requirements can be met, and accordingly aloe cleaning, cutting and collecting integrated system has an excellent application prospect.

Owner:HAINAN ZHONGCHEN BIOLOGIC ENG

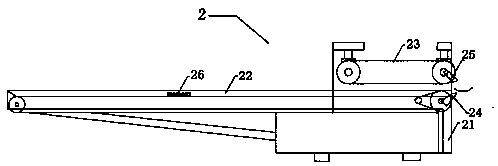

Special mechanical cleaning device for oil cylinder

InactiveCN105583209AImprove assembly qualityHigh cleanliness requirementsHollow article cleaningCouplingReduction drive

A special mechanical cleaning device for an oil cylinder is characterized in that the special mechanical cleaning device for the oil cylinder comprises a motor, a first coupler, a speed reducer, a second coupler, a water distribution pump, a water supply pipe, a liquid returning port, a brush head, a cleaning brush, the oil cylinder, a bracket and a base, wherein the motor is arranged on one side of the device and is a servo motor; a power output end of the motor is connected with the first coupler which is connected with the speed reducer; the second coupler is arranged at the other end of the speed reducer; the water distribution pump is connected with the other end of the second coupler; the water distribution pump is connected with the water supply pipe and the liquid returning port; a cleaning assembly is fixedly installed at the other end of the water supply pipe and comprises the brush head and the cleaning brush; a radial through hole is formed in the brush head; the cleaning assembly stretches into the oil cylinder which is movably installed on the bracket; and the bracket is fixedly installed on the base. The special mechanical cleaning device for the oil cylinder has the beneficial effects of being specialized, automatic, convenient to operate, capable of replacing manual operation, good in cleaning effect, high in work efficiency and capable of improving oil cylinder assembling quality and meeting the requirement of an electro-hydraulic control system for high cleanness of the oil cylinder.

Owner:田玥

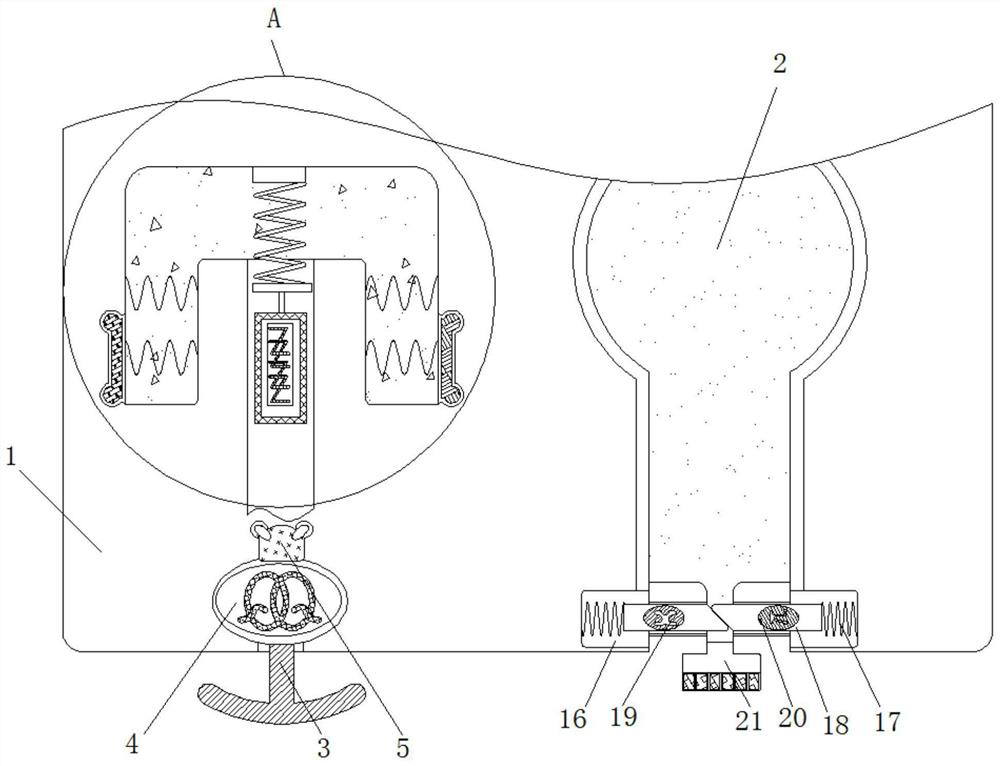

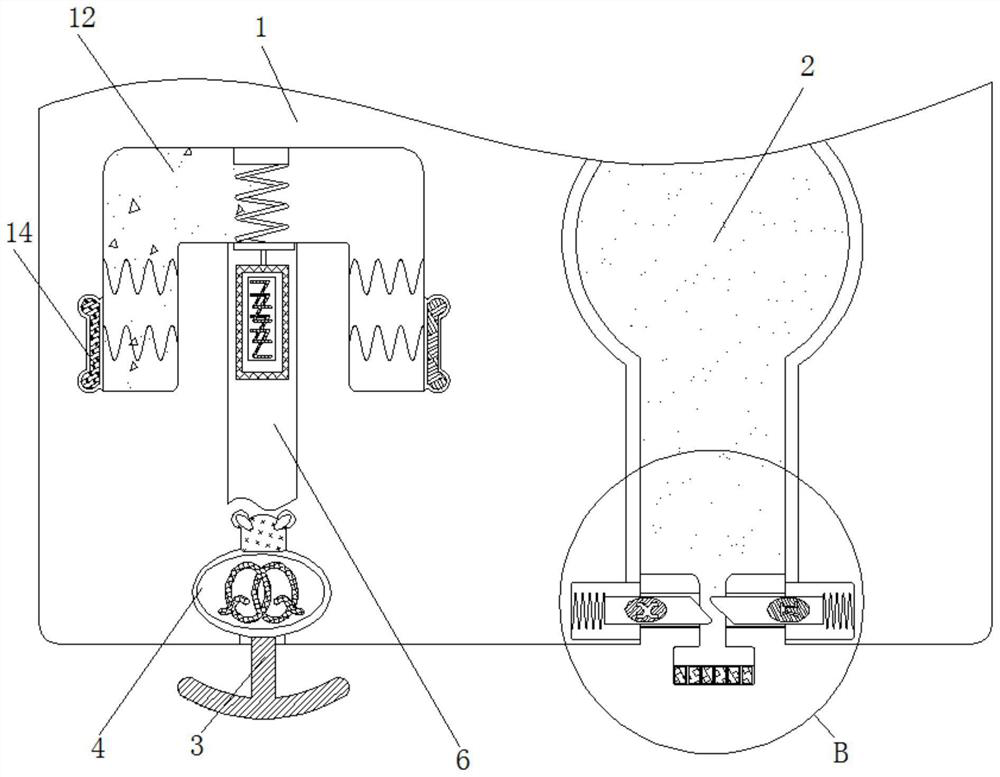

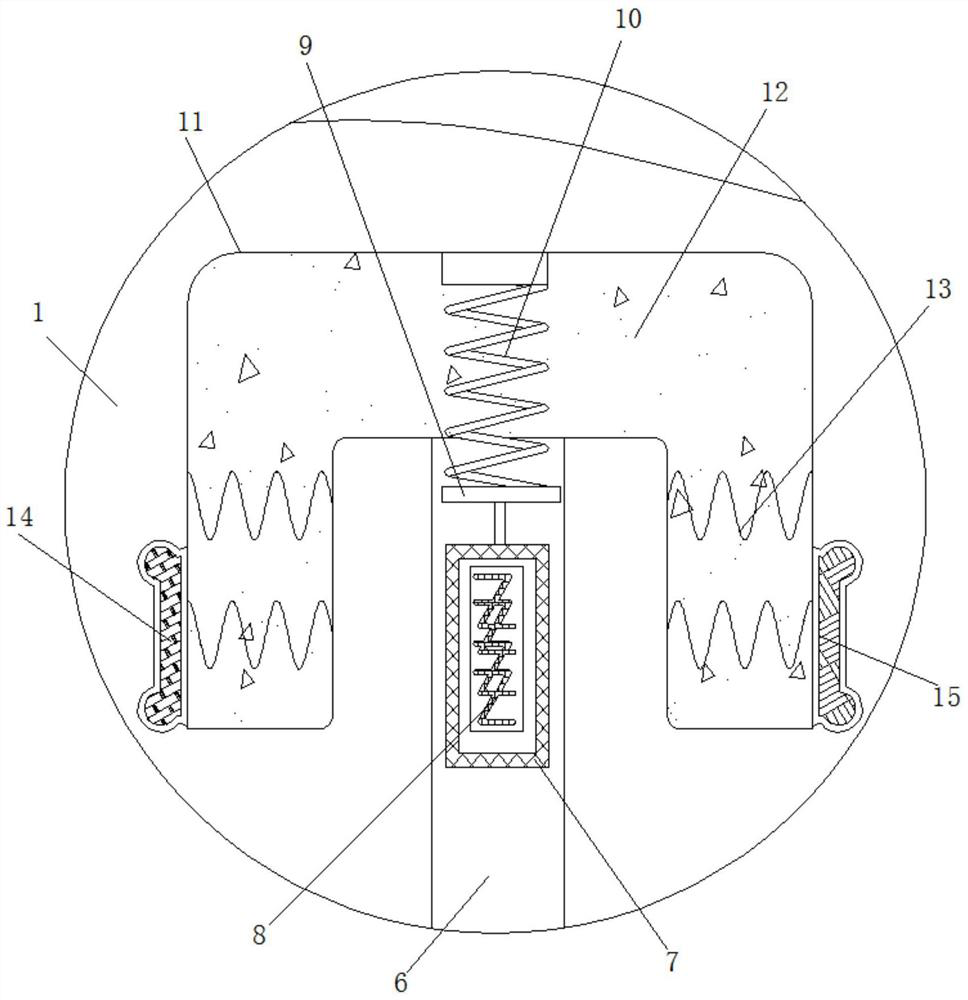

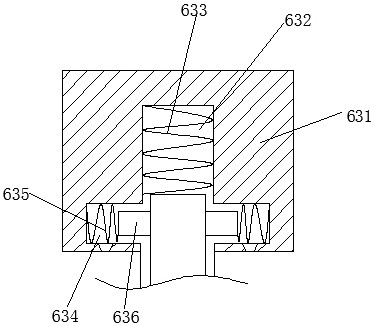

Apparatus of automatically detecting coil spring life

InactiveCN105043747AReplace manual operationImprove efficiencyMachine part testingContinuous measurementCoil spring

The invention discloses an apparatus of automatically detecting a coil spring life. The apparatus comprises a rack. The apparatus is characterized in that the rack is provided with a fixing mechanism, a detection mechanism and a material moving mechanism. The apparatus has the advantages that through a plurality of sliding tables, automatic material taking and automatic emptying functions are realized so that manual operation is replaced and efficiency is increased; a torsion sensor is used to repeatedly measure torsion changes of a coil spring during contraction and elongation processes so as to determine a service life, and a coil spring fracture mode is replaced so that a measurement result is effective and accurate; continuous measurement of the plurality of coil springs can be realized, personnel intervention is not needed during a whole process, the structure is ingenious, and operation and maintenance are convenient.

Owner:沈磊

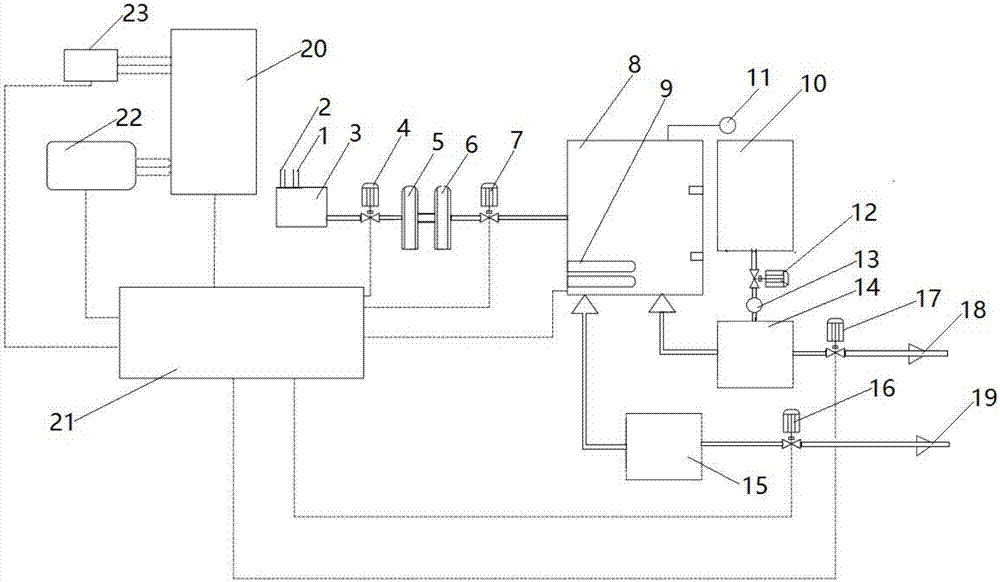

Multifunctional aero-engine cleaning machine

ActiveCN107497740AEasy to useImprove work efficiencySpecific water treatment objectivesWater contaminantsAviationAutomatic control

The invention discloses a multifunctional aero-engine cleaning machine. The multifunctional aero-engine cleaning machine comprises an electric power device, a control device, a water inlet device, a filtering device, a storage device and a mixing cleaning device. The control device and the electric power device are connected electrically. The control device comprises a PLC controller, a liquid level controller, a flow detector and a pressure detector. The water inlet device is connected with the filtering device through a pipeline. The storage device comprises a water storage tank and a solvent box. A water inlet of the water storage tank is connected with an ultrapure water pump. A cleaning solvent is stored in the solvent box. The mixing cleaning device comprises a cleaning box I and a cleaning box II. A water inlet of the cleaning box I is connected with the water storage tank and the solvent box. A water inlet of the cleaning box II is connected with the water storage box. The multifunctional aero-engine cleaning machine can clean an engine by adopting two ways of clear water cleaning and cleaning solvent cleaning, all the devices are automatically controlled by adopting the PLC controller, the mixing proportion of the clear water and the cleaning solvent can be adjusted according to actual demands, manual operation is replaced, and the automation level is improved.

Owner:春秋航空技术发展江苏有限公司

Improved constructional engineering waterproof construction method

InactiveCN108625552ALaying levelAvoid bumpingRoof toolsBuilding material handlingArchitectural engineeringEngineering

The invention discloses an improved constructional engineering waterproof construction method which refers to constructional engineering waterproof construction equipment. The constructional engineering waterproof construction equipment comprises a construction equipment body and a mixing box fixedly mounted on the construction equipment body; a containing cavity is formed in the bottom end face of the construction equipment body; a first convex block is fixedly arranged on the top wall of the containing cavity; an obliquely-arranged linkage plate is mounted on the first convex block in a hinged mode; a second convex block is fixedly arranged on the linkage plate, and a first piston rod is mounted on the second convex block in a hinged mode and is in power connection with a first pneumaticcylinder; the first pneumatic cylinder is fixedly arranged in the inner top wall of the containing cavity; a pressing rotating drum is mounted at the tail end of the bottom of the linkage plate in arotating fit mode; a guiding frame is vertically and fixedly arranged in the linkage plate, and a jacking-pressing sliding cavity is formed in the guiding frame; a jacking-pressing plate is arranged in the jacking-pressing sliding cavity in a sliding fit mode; and a jacking-pressing spring is mounted between the upper side of the jacking-pressing plate and the top wall of the jacking-pressing sliding cavity in a jacking-pressing fit mode.

Owner:宁波鄞州国康机械科技有限公司

Textile dye coating device

PendingCN112501825AEasy to operateLow costTextile treatment machine partsLiquid/gas/vapor textile treatmentDielectric plateEngineering

The invention relates to the technical field of textile fabric coating, and discloses a textile dye coating device. The textile dye coating device comprises a shell, a coating cavity and a sealing cavity; a movable plate is inserted into the bottom of the shell; a piezoelectric crystal is movably connected to the top of the movable plate; a first electromagnet is fixedly connected to the top of the piezoelectric crystal; a limiting groove is formed in the shell; a dielectric plate is movably connected into the limiting groove; and a first magnetic block is fixedly connected into the dielectricplate. According to the textile dye coating device, when tablecloth passes through the bottom of the shell, the movable plate moves upwards to extrude the piezoelectric crystal, so that currents aregenerated on the two sides of the piezoelectric crystal; the first electromagnet is electrified to push the dielectric plate to move upwards, and currents are generated between a positive plate and anegative plate, so that two limiting blocks move towards the two sides; and the interior of the coating cavity is filled with PVC coating, so that the tablecloth can be coated from the bottom of a coating brush, operation is easy, cost is saved, manual operation is replaced, and the working efficiency is improved.

Owner:孙晓梅

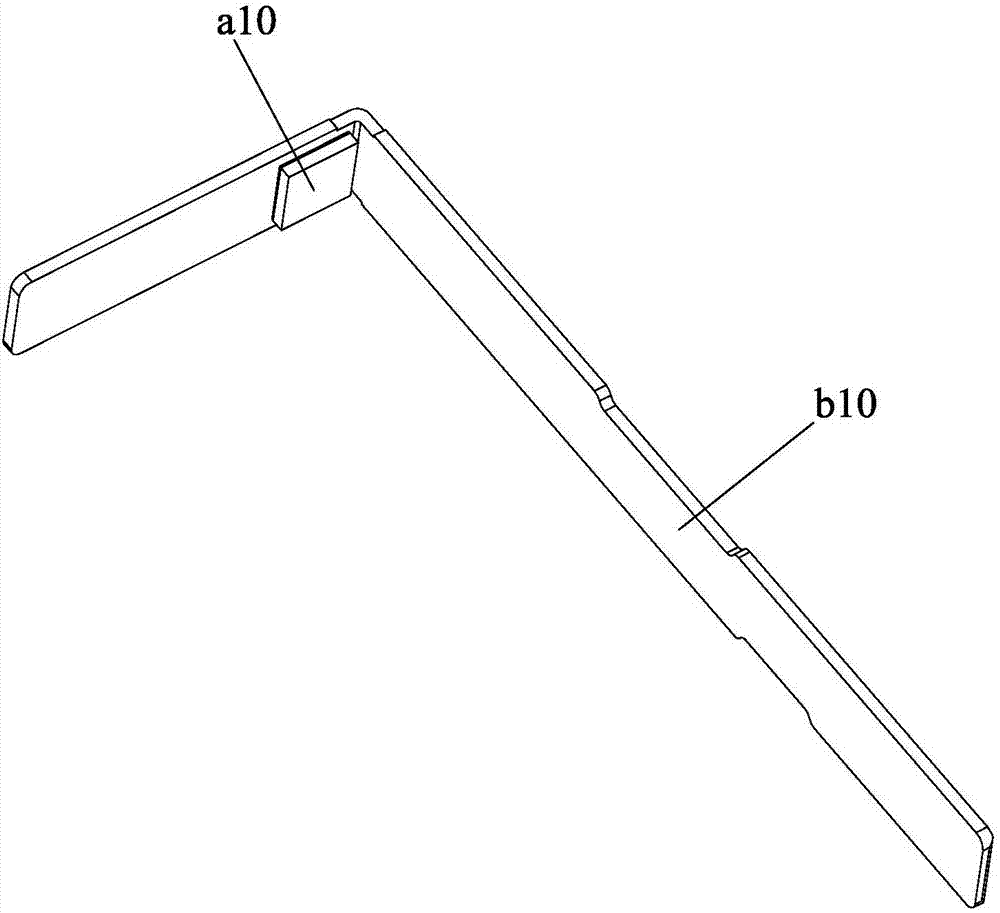

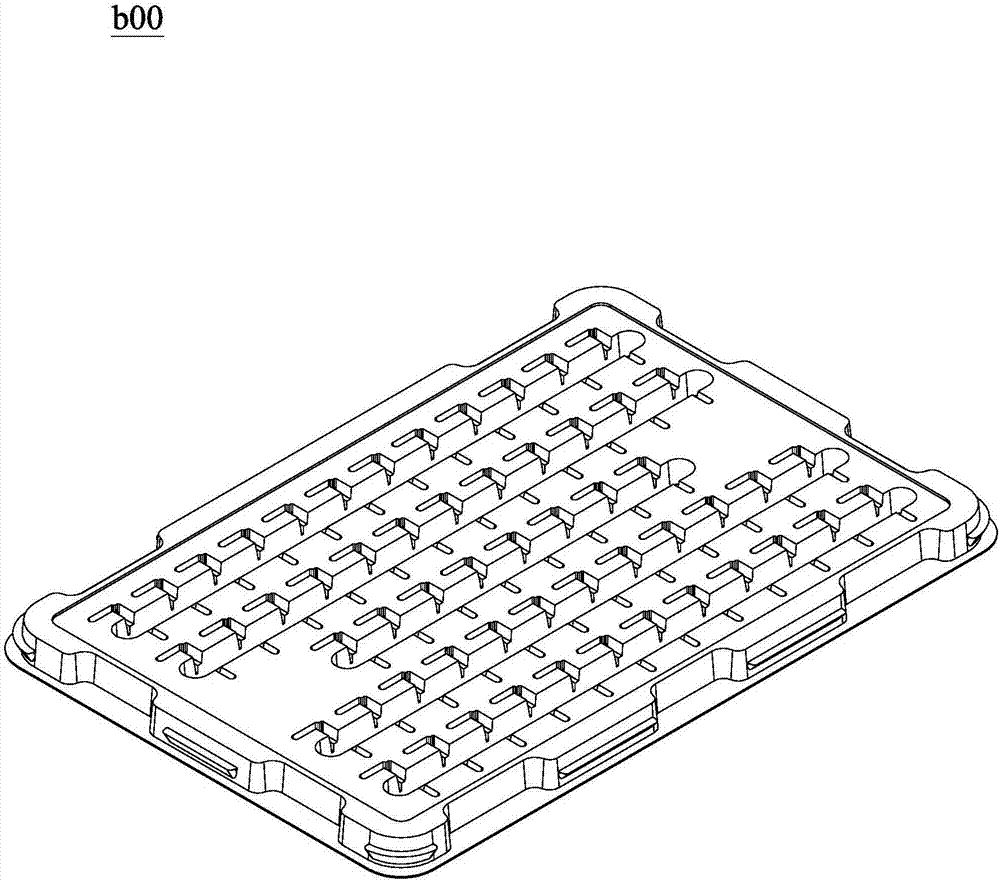

Attaching device

ActiveCN109368213AImprove production efficiency and production stabilityImprove production yieldConveyorsCharge manipulationMoving partsEngineering

The invention provides an attaching device which comprises a bottom plate, a support mechanism and a turnover mechanism. The support mechanism is arranged on the bottom plate and is used for fixing afirst hard plate piece connected to one end of a flexible belt; the turnover mechanism is arranged on the bottom plate and comprises a first moving parts and a second moving parts; the first moving parts has a moving degree of freedom in a horizontal plane on the bottom plate; the second moving parts is rotatably arranged on the first moving parts and is used for placing a second hard plate piececonnected with the other end of the flexible belt; and the turnover mechanism is used for keeping the first moving parts and the second moving parts away from the support mechanism during the moving process through the movement matching of the first moving parts and the second moving parts, and placing the second hard plate piece onto the support mechanism after turning over the second hard platepiece so as to enable the first hard plate piece and the second hard plate piece to fit. The attaching device can be used for automatically attaching workpieces, so that the production efficiency andthe production stability are improved.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Fully-automatic straightening device for workpiece notch

Owner:温岭市卓一自动化设备有限责任公司

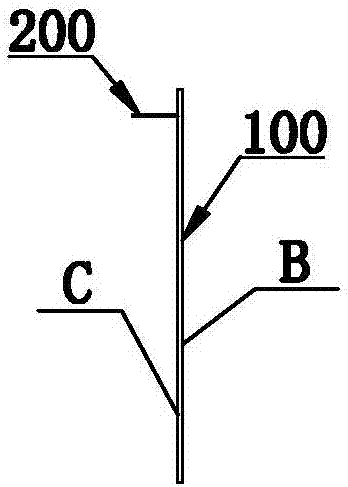

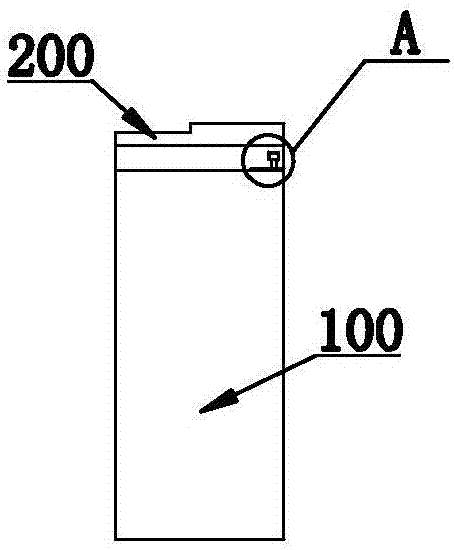

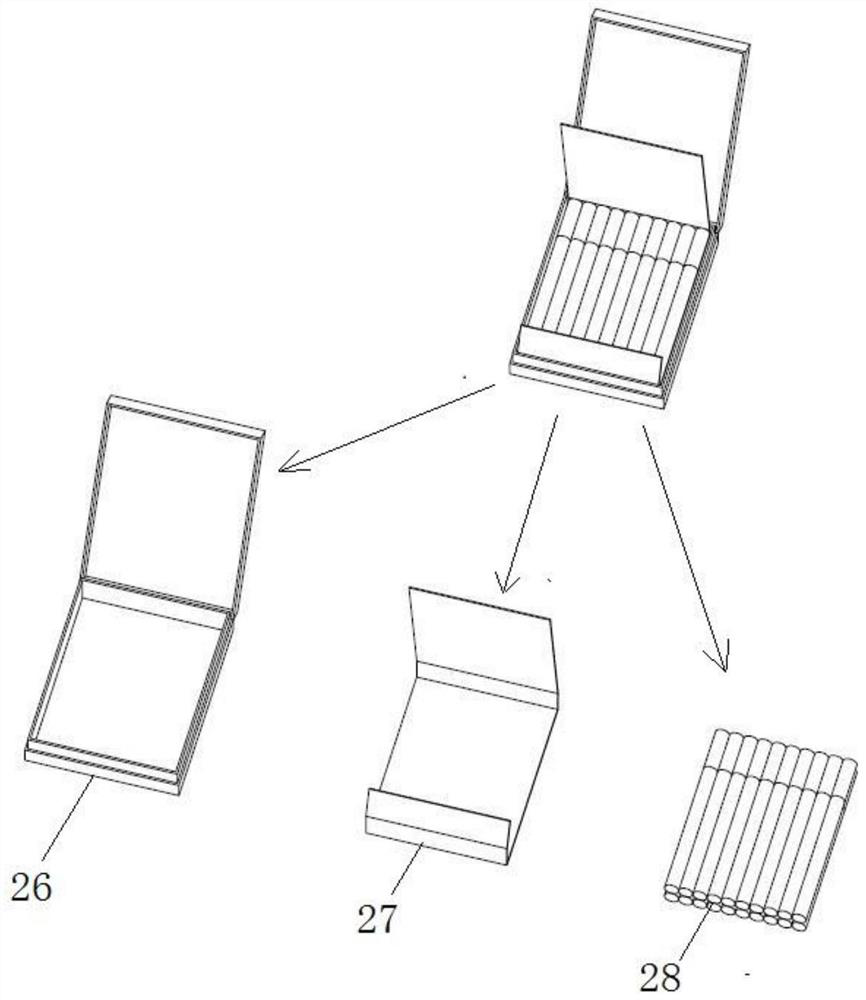

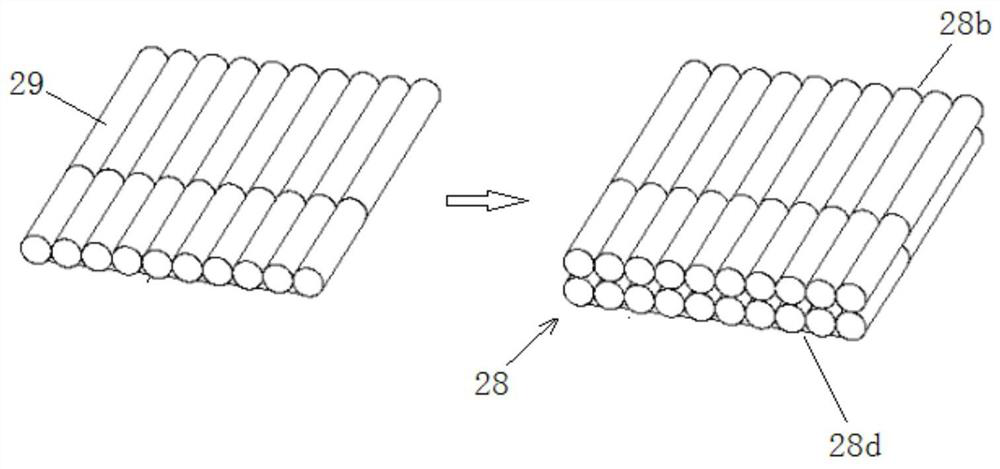

Packaging process of full-open cigarette packet

ActiveCN112896593AQuality assuranceSimple designPackaging cigaretteMechanical engineeringIndustrial engineering

The invention relates to a packaging process of a full-open cigarette packet. The full-open cigarette packet comprises a full-open cigarette case, lining paper and a plurality of rows of cigarette groups when the full-open cigarette packet is finally formed. The packaging process comprises the procedures of A, a cigarette group forming procedure, B, a lining paper conveying and positioning procedure, C, a cigarette case supplying and opening procedure and D, a filling and case closing procedure. In the step A, the multiple rows of cigarette groups are obtained; in the step B, the lining paper is conveyed and positioned; in the step C, the multiple rows of cigarette groups are wrapped with the lining paper, and a lining paper cigarette packet is obtained; in the step C, preparation is made for filling; and in the step D, the full-open type cigarette case is filled with the lining paper cigarette packet, and the opened full-open type cigarette case is completely closed to obtain a complete full-open type cigarette packet. According to the packaging process, packaging work is stepwise, programmed and high in controllability, and the packaging efficiency and quality are improved; and in the whole packaging process, direct contact with the tobacco ends of cigarettes is avoided, tobacco shreds are prevented from falling off, damage to the cigarettes is reduced, and the quality of the cigarette packet is guaranteed.

Owner:SHANGHAI TOBACCO MACHINERY

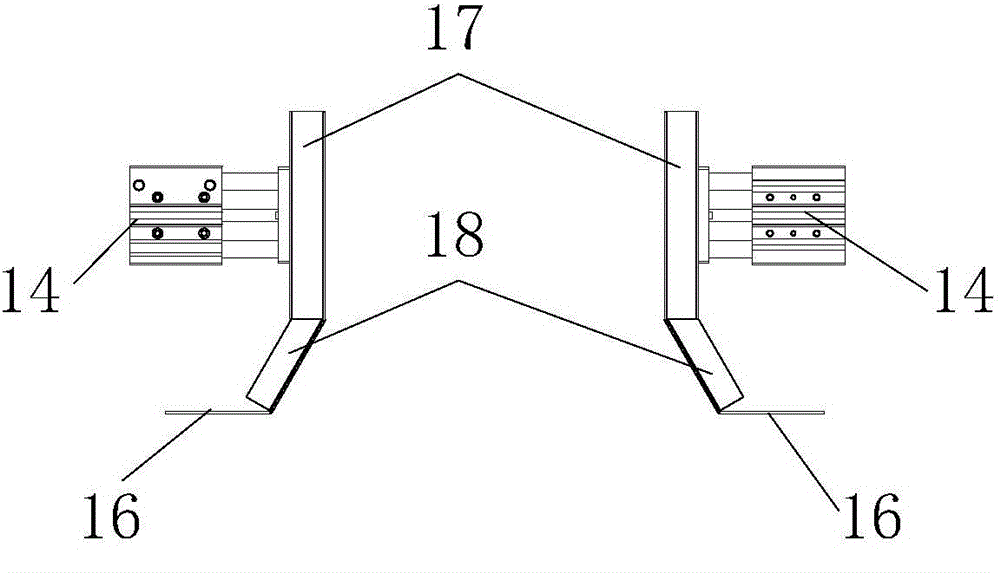

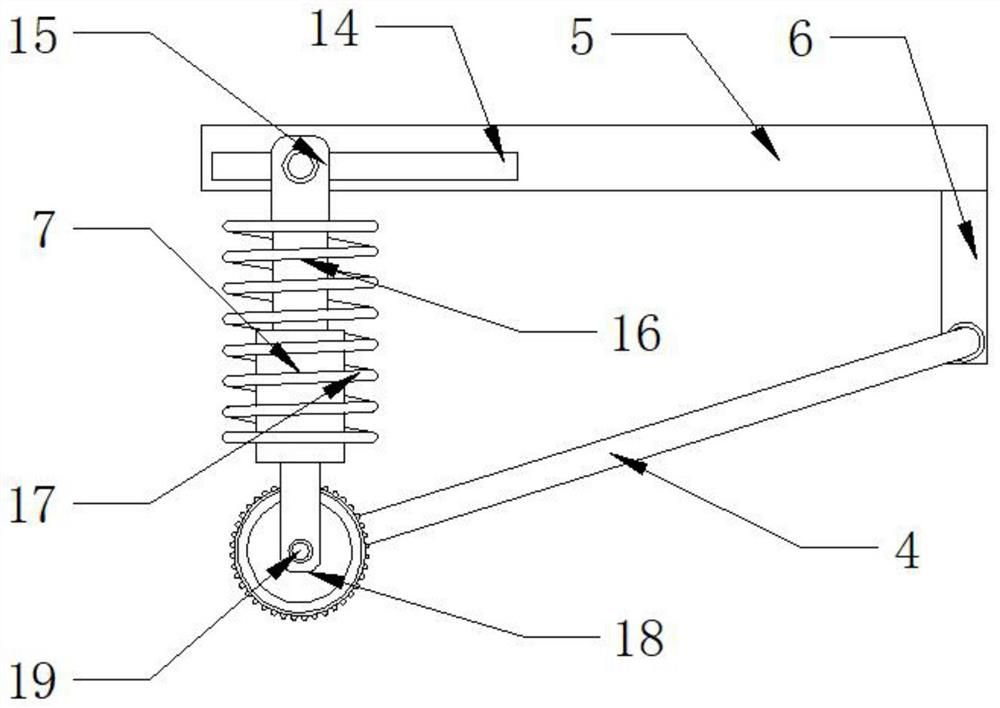

A 90° flip door frame transfer flip mechanism and its application method

The invention discloses a 90° flip door frame transfer flip mechanism and its use method. The flip mechanism includes a bracket, a feed area, a discharge area, a flip assembly, a driving device for driving the flip assembly to realize flip, and a controller; The overturning assembly includes a pair of overturning units that can be overturned synchronously. The overturning units are arranged on both sides of the bracket and are connected to the bracket through a rotating shaft. The overturning unit includes two sets of mutually perpendicular rotating arms, and each set of rotating arms includes Two parallel sleeves and the sliding tube inside the sleeve; the sliding tube and the sleeve are connected by a spring ball plunger; one end of the discharge area of the bracket is set to push the sliding tube to extend from the sleeve The cylinder assembly that goes out to the feeding area; the invention solves the problem of the turning space by setting the rotating arm combined with the sliding tube and the casing, and using the driving effect of the cylinder; the 90-degree turning mode is adopted to shorten the time of feeding twice spacing, improving the flipping efficiency.

Owner:四川和乐门业有限公司 +1

Carriage cleaning robot suction mechanism

InactiveCN111806392AImprove efficiencyImprove cleaning efficiencySievingScreeningAir pumpWaste material

The invention discloses a carriage cleaning robot suction mechanism which comprises a case. Two sets of cleaning discs are arranged at a bottom of the case, two sets of smashing rollers are arranged at the bottom of the case, and a cleaning chassis is arranged at the bottom of the case. A telescopic sleeve bag is connected to an upper end of the cleaning chassis, an integrated cabin is arranged atthe upper end of the telescopic sleeve bag, the integrated cabin is a conical structure, a pipeline is connected to the upper end of the integrated cabin, and an air pump is arranged at an L-shaped bent position of the pipeline. After cleaning is completed, impurities at the bottom need to be cleaned; the case is integrally placed at the bottom of the carriage; the processed impurities are sweptinto the cleaning chassis through the cleaning disc and the smashing rollers; and negative pressure is provided for the pipeline through the air pump, garbage at the bottom is sucked in through the integrated cabin and the telescopic sleeve bag, a filter plate is a two-set inclined filter screen structure, the impurities are filtered in a graded mode, efficiency is improved, the filtered impurities fall into a waste collecting cabin under the action of gravity, and suction and collection of the swept impurities are completed.

Owner:张梅

Automatic weight detection device for agricultural products

InactiveCN106706094ASimple structureSmall form factorSpecial purpose weighing apparatusAgricultural engineeringConveyor belt

The invention relates to agricultural machinery equipment and particularly relates to an automatic weight detection device for agricultural products, which comprises a device body. The upper part of the device body is internally provided with a PLC; the communication port of the PLC is connected with a touch screen arranged at the lower part of the front side of the device body; the top part of the device body is provided with a weighing module; the weighing module is connected with a signal input end of the PLC; propulsion cylinders are arranged above the rear side and the left side of the weighing module; the front end of each propulsion cylinder is connected with a propulsion baffle; a guide plate is arranged corresponding to the propulsion baffle; the tail end of the guide plate is corresponding to a conveyor belt; and the propulsion cylinder is connected with the control output end of the PLC. Through mutual match among the PLC, the weighing module and the cylinder, automatic weighing on the agricultural products is carried out, classification on the agricultural products is completed, the structure is simple, the appearance is compact, the design is reasonable, the device can be mounted to various agricultural product production lines conveniently, the manual detection cost is reduced, the production efficiency is improved, the automatic degree is high, and manual operation is replaced.

Owner:CHONGQING JIANJIAPING AGRI TECH DEV CO LTD

Intelligent grabbing robot system integration of toy motor assembling production line

InactiveCN106425455ARealize assembly productionReplace manual operationAssembly machinesProduction lineSystem integration

The invention relates to an intelligent grabbing robot system integration of a toy motor assembling production line, belongs to the field of industrial robot application, and provides an intelligent assembling production line all-in-one system mainly comprising a robot, a clamp unit, a detection unit, a conveying unit, an assembling unit and a control unit. The intelligent grabbing robot system integration comprises a material feeding unit, a robot unit, an assembling unit, a dispensing and curing unit and a counting and packaging unit. Furthermore, an isolation and protection net is arranged to surround all the units; and the system is provided with a monitoring system which is connected with all unit control cabinets. By the use of the robot, assembling production of a small-sized toy motor is realized, manual operation is replaced, the quality is stable, and the cost is low.

Owner:肇庆市宏华电子科技有限公司

Rocking pot for producing sesame oil

InactiveCN101870916AIncrease productivityRealize mechanized operationFatty-oils/fats productionEngineeringSesame Oils

The invention discloses a rocking pot for producing sesame oil. The rocking pot comprises a pot body [11] for holding a raw material and two rocking balls [16] for stirring the raw material in the pot body [11], and is characterized by further comprising a driving device for driving the rocking balls [16] to move up and down and driving the pot body [11] to rotate, wherein the driving device comprises a frame [3], a pot body rotation driving device and a rocking ball rock driving device which are fixed on the frame [3]. The rocking pot can realize mechanical operation so as to greatly improve the production efficiency of the sesame oil.

Owner:铜陵大通小磨麻油厂

Strickling and grooving device applied to production of ocarina

ActiveCN111231077AIncrease productivityReduce labor intensityCeramic shaping apparatusGear wheelDrive shaft

Owner:林祖扬

Underwater robot

PendingCN112405491ADamage reductionExtended service lifeTesting waterManipulatorManual handlingMechanical engineering

An underwater robot comprises a walking frame and a water quality monitoring sensor. The walking frame comprises a frame body, a rotating disc arranged on the frame body, a horizontal moving structurearranged on the rotating disc and a vertical moving mechanism arranged on the horizontal moving structure, and the water quality monitoring sensor is mounted on the vertical moving mechanism. According to the robot, manual operation is replaced by walking of the robot, thereby, the robot is convenient and safe.

Owner:ZHEJIANG HANLU OCEANIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com