Gear shaft part hot-pressing assembly technology automatic production system

An assembly process and production system technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in liquid nitrogen preparation, danger, and stable and uncertain parts quality, so as to reduce labor intensity and danger , high degree of automation, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

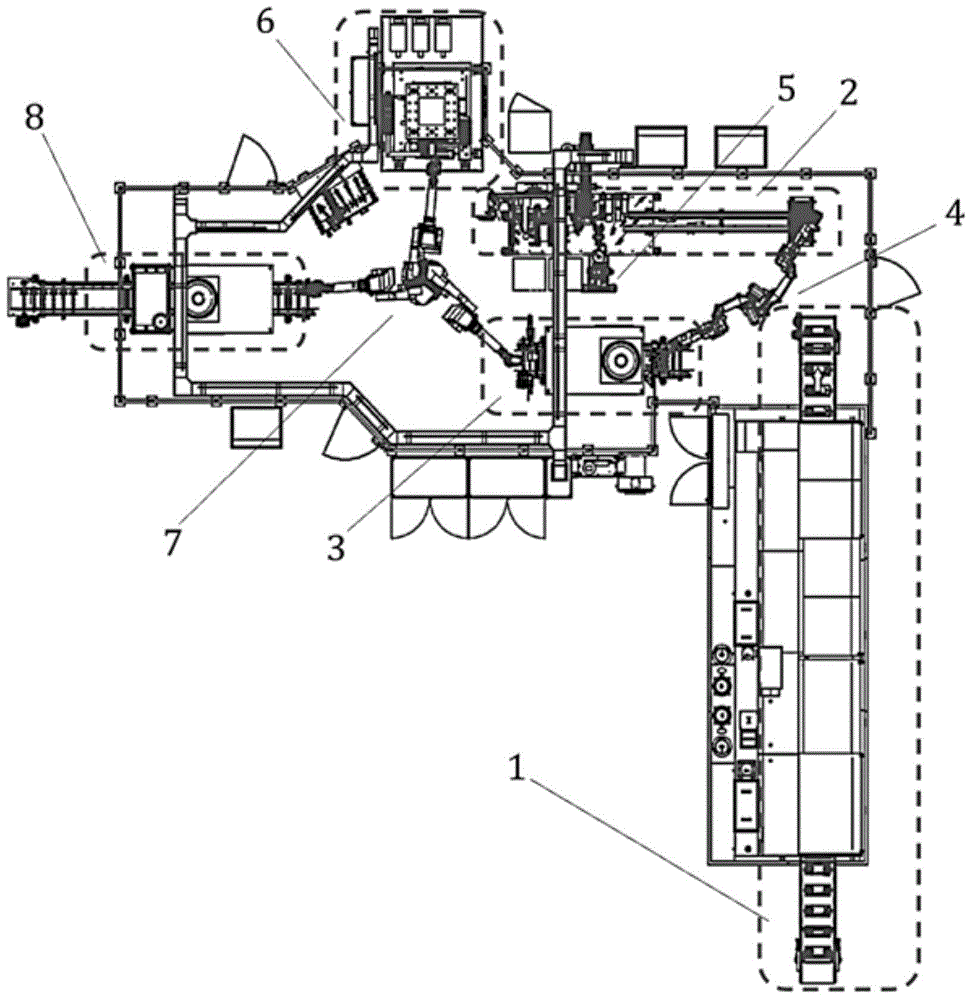

[0042] As shown in Figure 1, the system of this embodiment includes: a cleaning mechanism 1, a gear heating unit 2, a shaft cooling unit 3, a heat pressing unit 6, a cooling and demagnetizing unit 8, and three six-degree-of-freedom manipulators 4, 5, and 7, among which : The gear heating unit 2 and the shaft cooling unit 3 are arranged side by side between the cleaning mechanism 1 and the hot pressing unit 6, the first six-degree-of-freedom manipulator 4 is located between the gear heating unit 2, the shaft cooling unit 3 and the cleaning mechanism 1, and the second The manipulator 5 is located on the side of the gear heating unit 2 , and the third manipulator 7 is located between the heat pressing unit 6 , the shaft cooling unit 3 and the cooling and demagnetizing unit 8 .

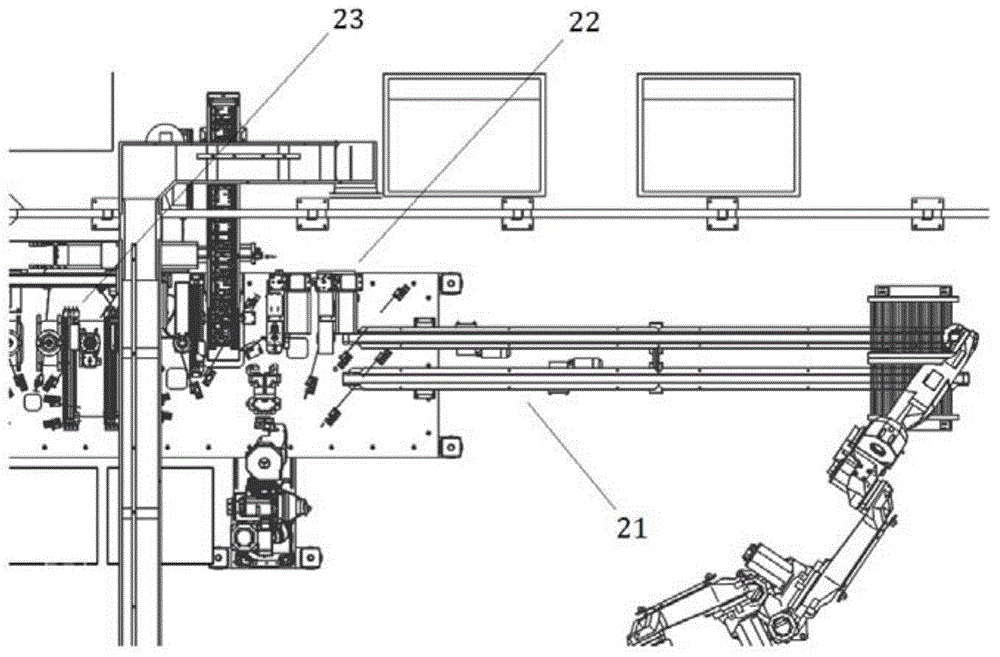

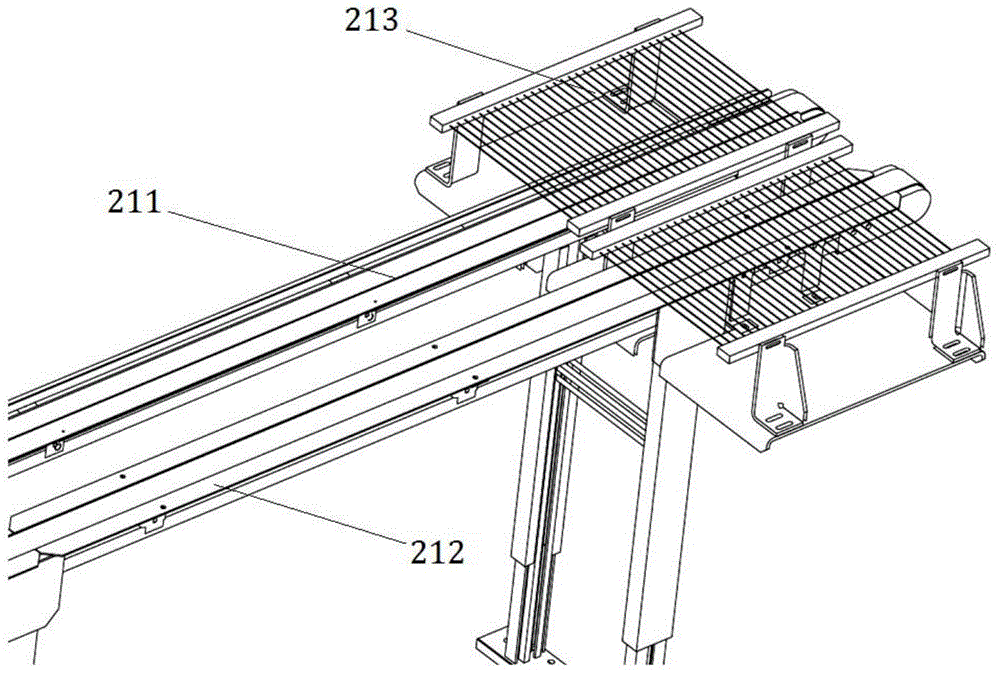

[0043] like Figure 2a , 2b As shown, the gear heating unit 2 includes: a gear feeding device 21, a gear detection unit 22, and a gear heating unit 23 connected in sequence, wherein:

[0044] The gear f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com