Integrated automatic poultry gizzard degreasing separation equipment

A separation equipment, an integrated technology, applied in poultry processing, poultry viscera removal devices, sedimentation tanks, etc., can solve the problems of incomplete slag discharge, a large number of manual labor, and non-separation of gizzard and oil mixing, so as to achieve complete slag discharge. , Improve production efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

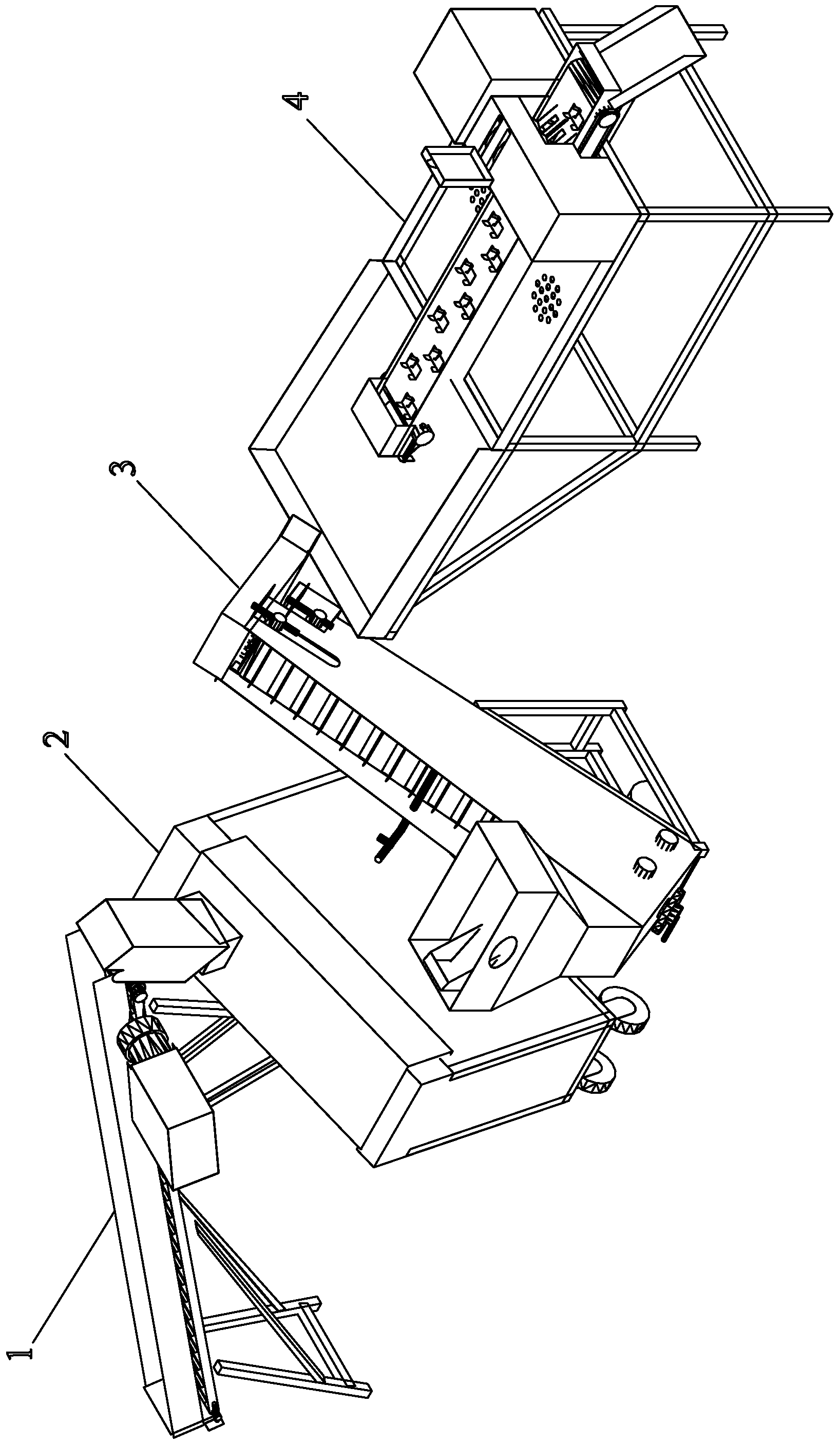

[0022] Such as figure 1 As shown, the integrated automatic poultry gizzard deoiling and separating equipment of the present invention includes a hoist 1 for feeding, a deoiler 2 that receives the feeding of the hoist 1 and separates the gizzard from the gizzard, and deoils the deoiled oil and The oil gizzard separator 3 for separating the poultry gizzard mixture, and the gizzard cutting machine 4 for cutting the separated poultry gizzard.

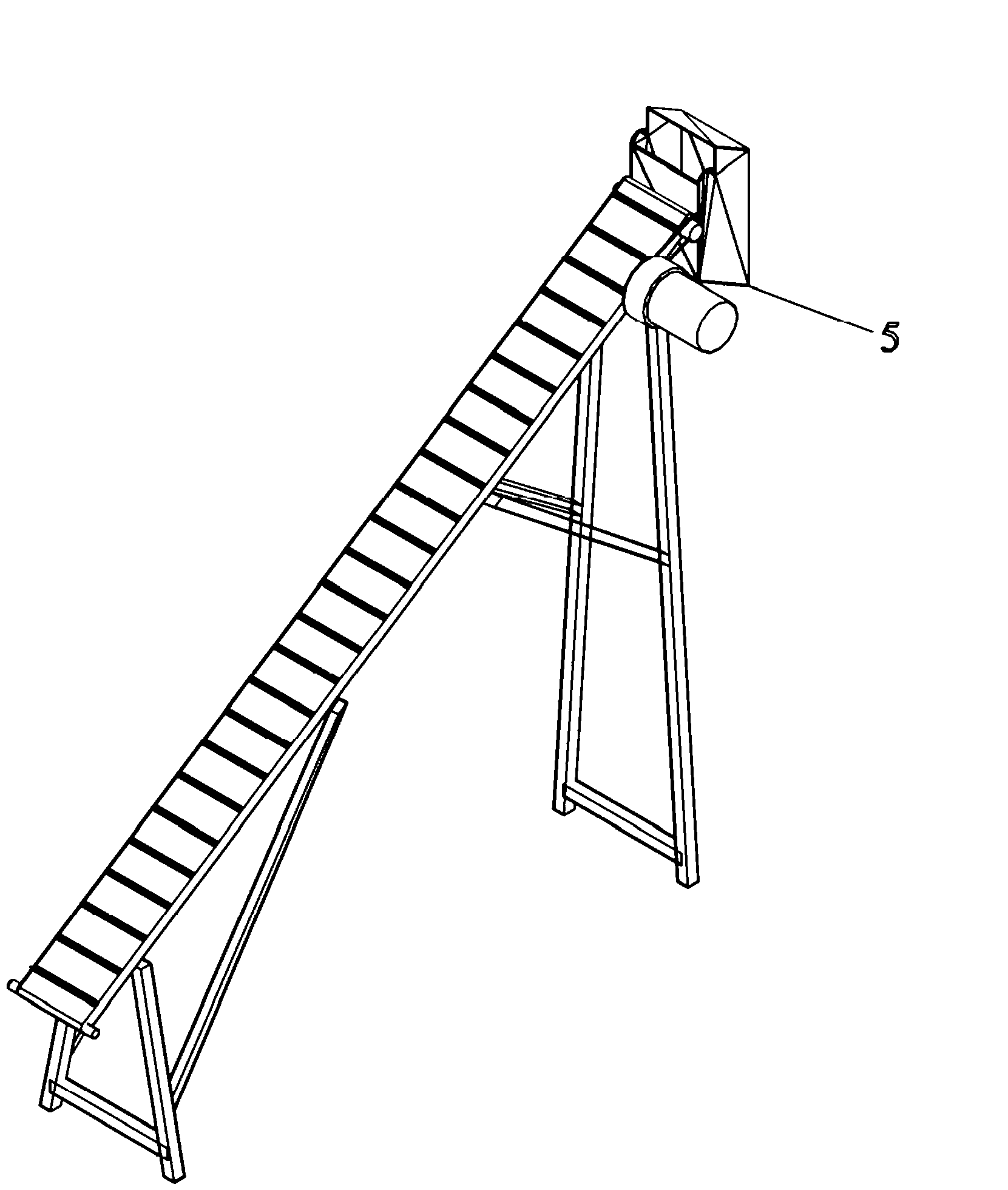

[0023] Such as figure 2 As shown, the hoist 1 is a belt conveying device for obliquely upwardly transporting poultry gizzard material. Shown in the figure is the arrangement of the blanking port 5 and the motor and the conveyor belt. When in use, artificially load materials on the lower side of the hoist.

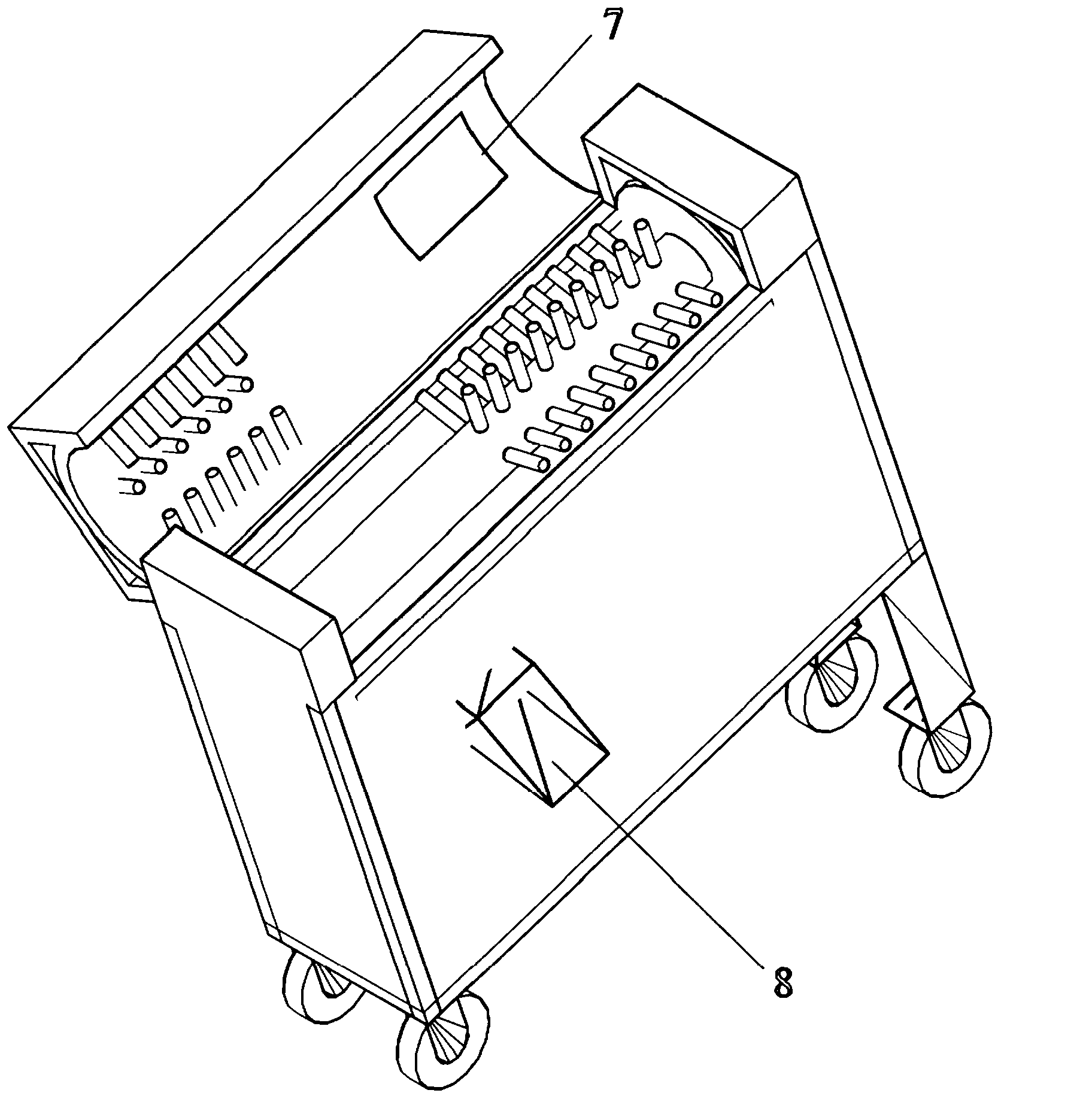

[0024] The deoiler 2 can use the poultry gizzard deoiler mentioned in the background of the present invention, only need to match the inlet and outlet with the equipment of the present invention. In the best way, use the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com