Conveying and transporting device for foundational detonator

A technology of basic detonators and conveying devices, which is applied in the direction of weapon accessories, blasting tubes, fuzes, etc., can solve the problems of large turnover stock, poor safety, and low level of operation technology on site, so as to reduce turnover stock, improve production efficiency and reliability, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

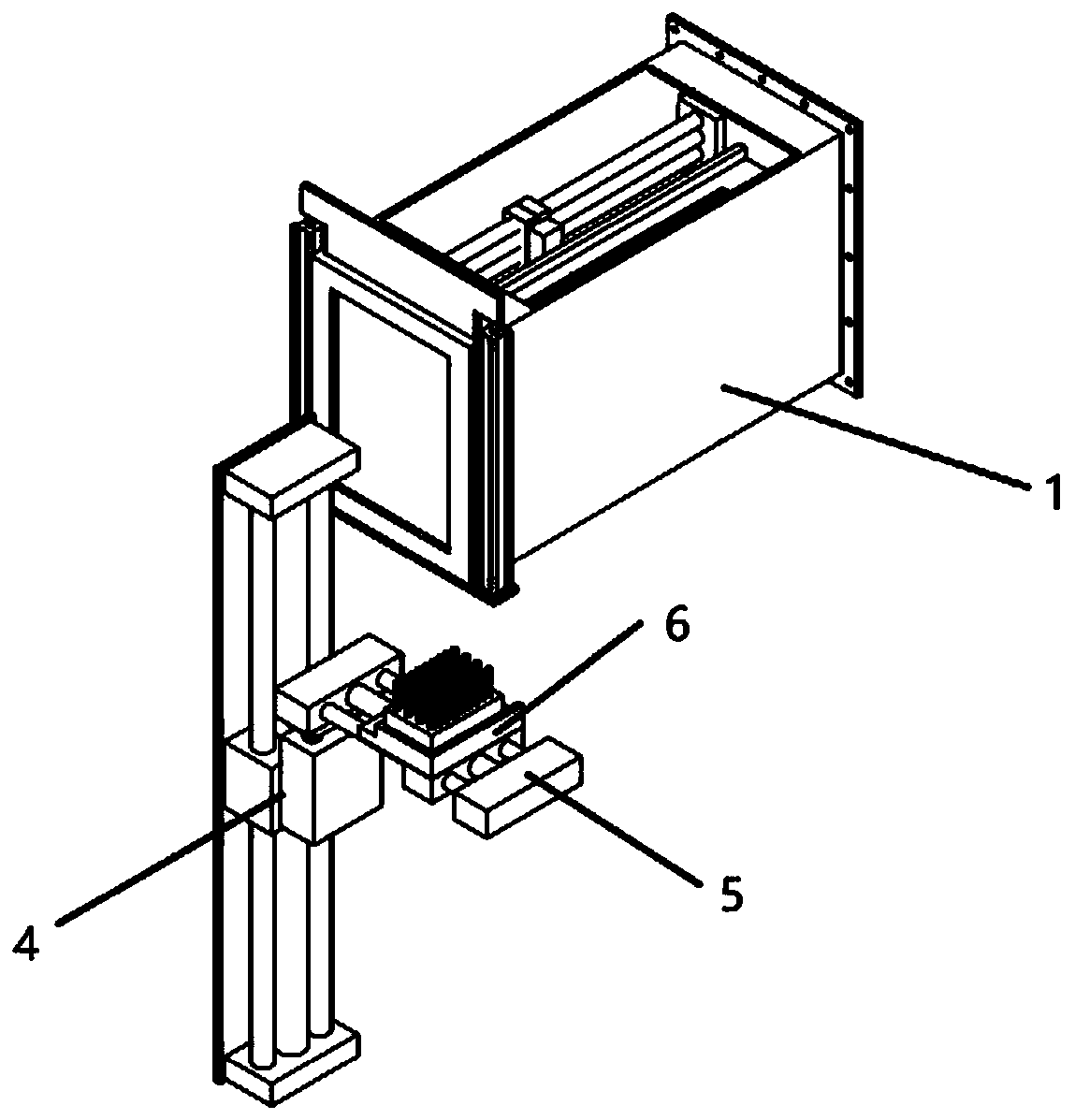

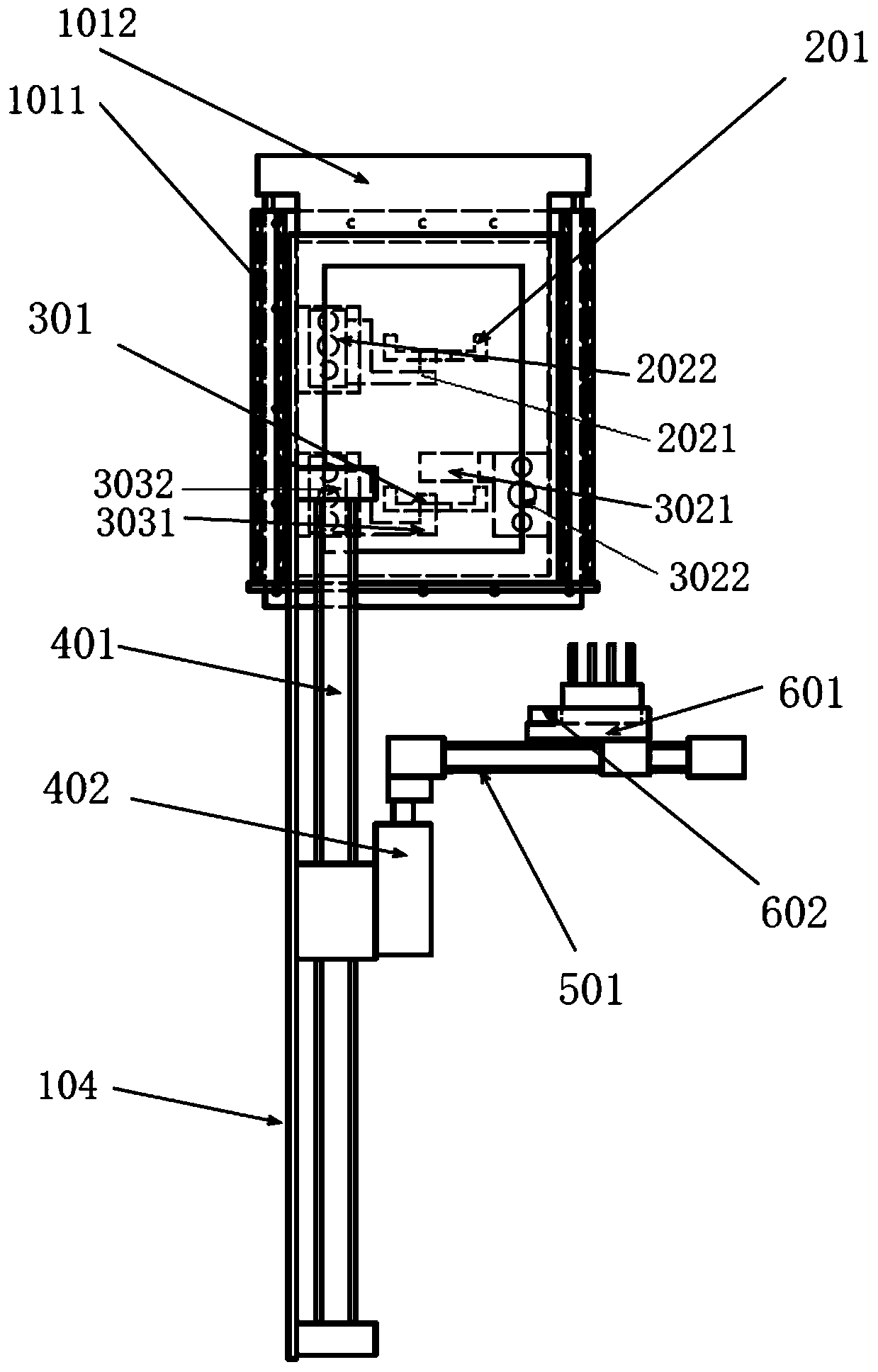

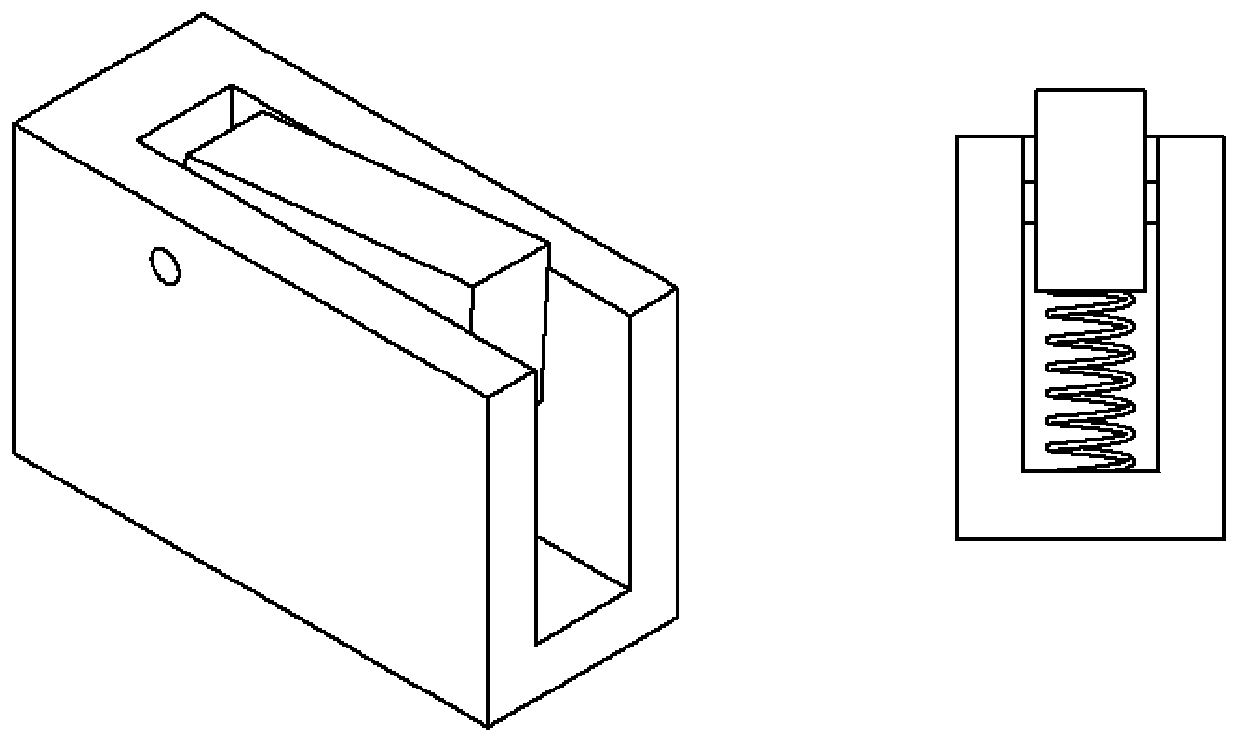

[0029] Such as Figure 1-5 As shown, a basic detonator delivery device includes an explosion-proof box 1, a feeding module, an ejection module, a lifting module 4, a translation module 5 and a positioning module 6; wherein, the explosion-proof box 1 includes a door opening cylinder 1011, an explosion-proof Damper 1012, explosion-proof plate 102, explosion vent 103, box extension plate 104; feeding module includes feeding slide rail 201, feeding pull block 2021, feeding pull block cylinder 2022; ejection module includes ejection slide rail 301, ejection hook 3021, ejection hook cylinder 3022, ejection block 3031, ejection block cylinder 3032; lift module 4 includes main lift cylinder 401, auxiliary lift cylinder 402; translation module 5 includes translation cylinder 501; The positioning module 6 includes a base detonator mold positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com