Intelligent grabbing robot system integration of toy motor assembling production line

A technology of assembly production line and robot system, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of poor quality, high price, imperfect system, etc., and achieve the effect of stable quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

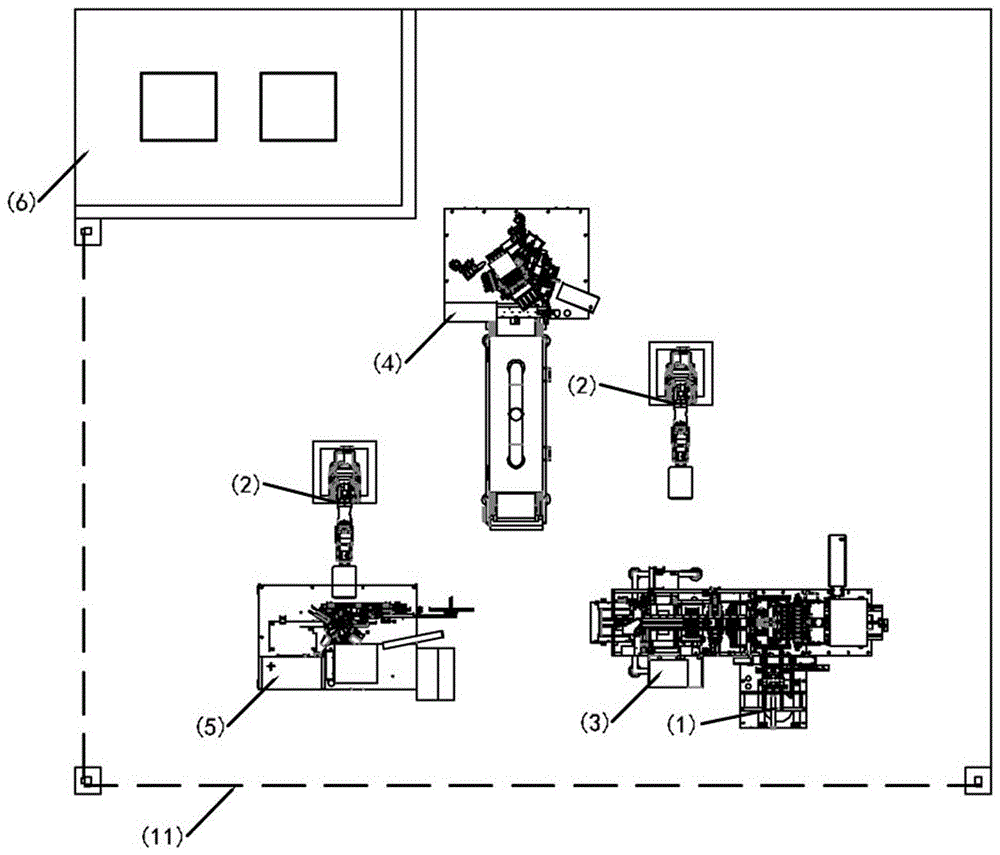

[0017] The working process of the present invention is as follows:

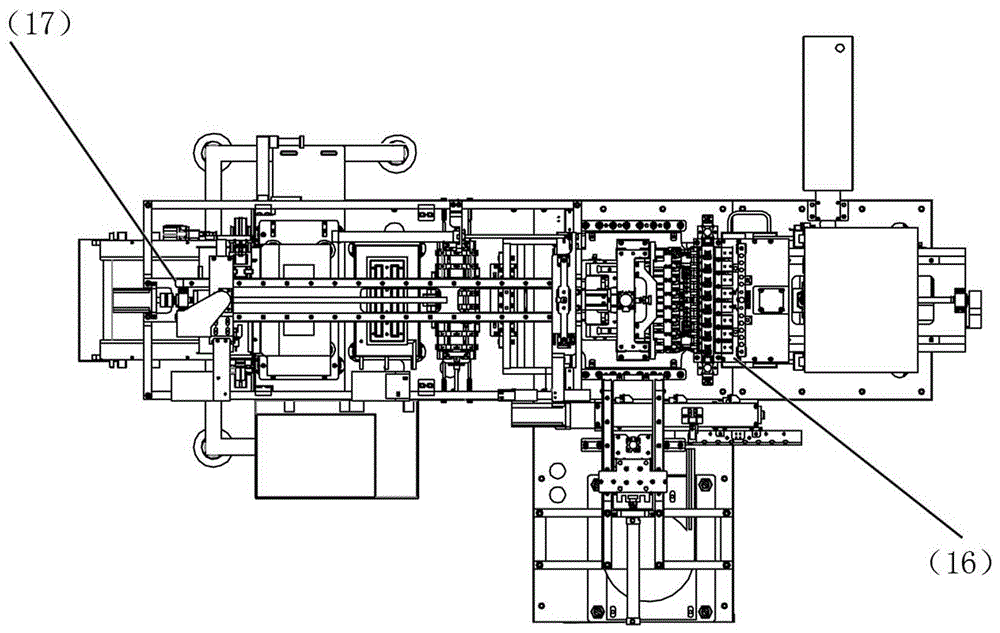

[0018] Before starting the machine, input the toy motor shell and the toy motor core into the assembly unit 3 respectively. After starting the machine, the toy motor shell and the toy motor core are respectively fixed by the clamps of the assembly machine 3 to realize the toy motor shell and the toy motor. Core position adjustment assembly.

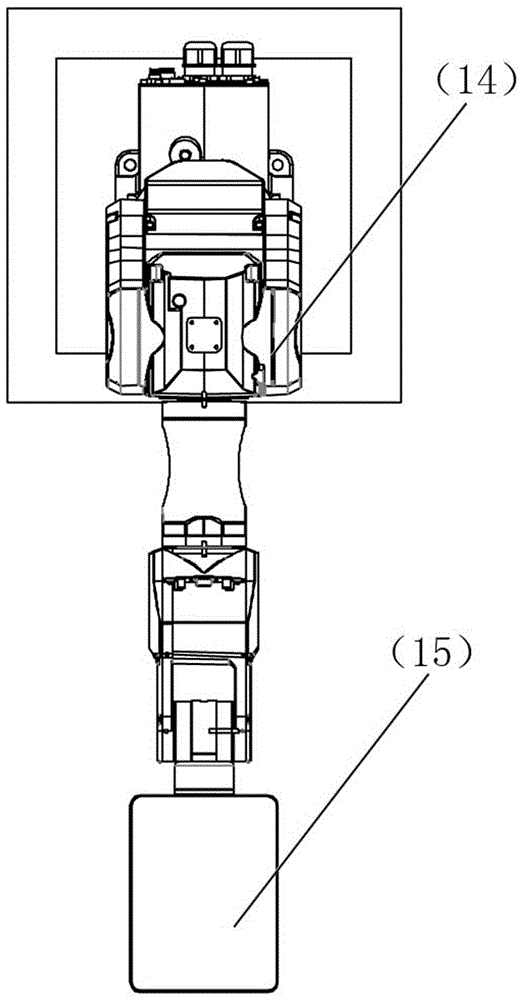

[0019] The clamp 15 at the front end of the robot 14 in the robot unit 2 grabs the toy motor from the assembly unit 3 and places it in the dispensing and curing unit to fix the toy motor by dispensing glue.

[0020] The gripper 15 at the front end of the robot 14 in the robot unit 2 realizes grabbing the toy motor from the dispensing and curing unit and placing it in the counting and packaging unit. This unit completes the functions of air cleaning, marking and counting and packaging the toy motor.

[0021] The monitoring system 6 is provided with a quality remote image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com