Fabricated concrete variable section T-shaped shear wall component and construction method thereof

A technology of variable cross-section and concrete, which is applied in the direction of building components, walls, building structures, etc. It can solve the problem of weak sleeve connection, difficulty in staggering horizontal steel bar joints, and failure of steel bar skeletons in T-shaped shear wall components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

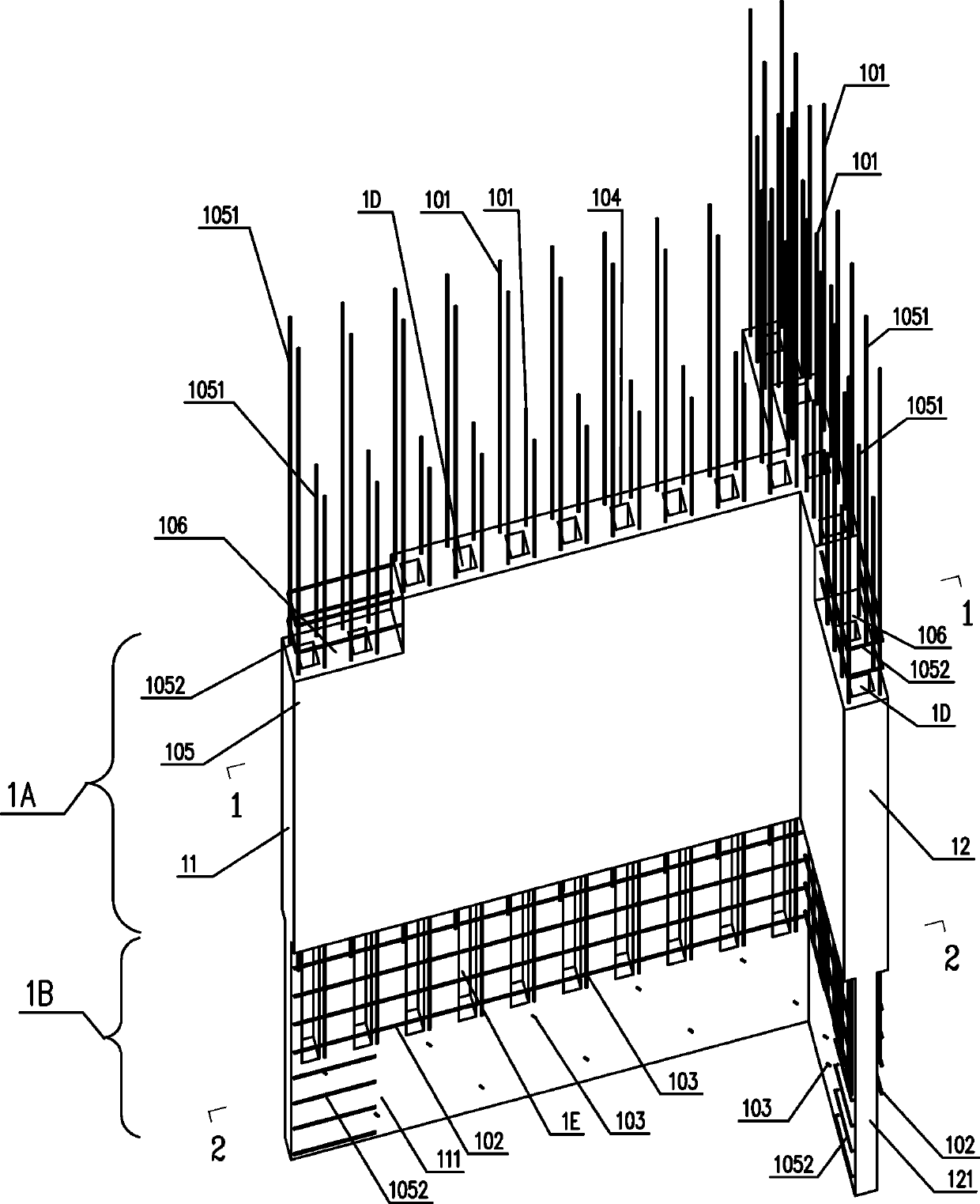

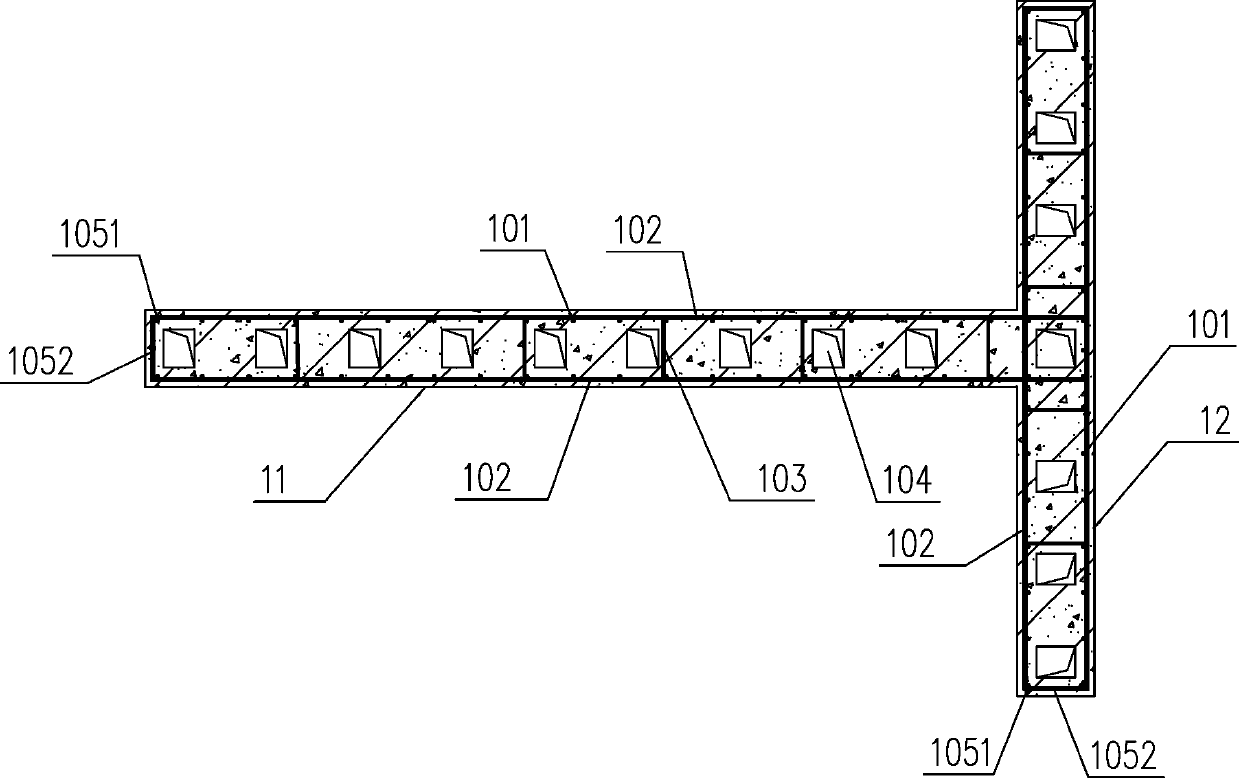

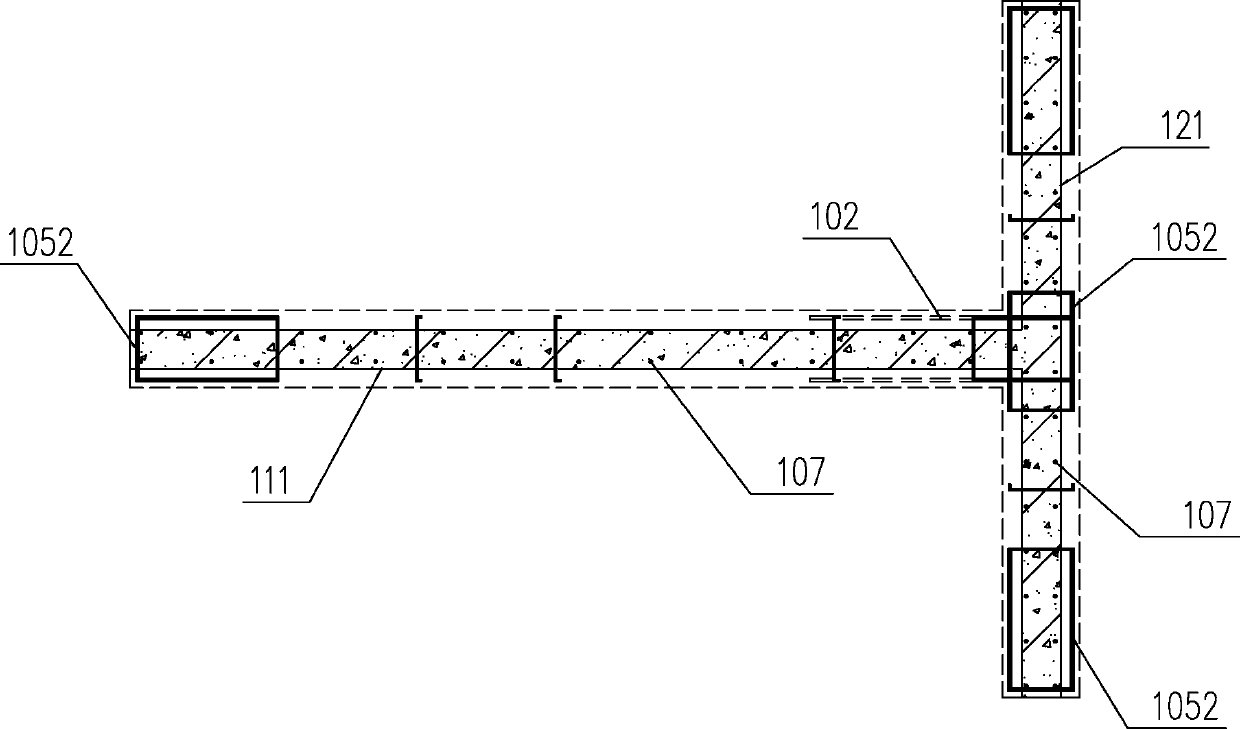

Embodiment 1

[0069] Such as Figure 1-3 As shown, a prefabricated concrete variable-section T-shaped shear wall member of the present invention includes an X-direction wall pier 11 and a Y-direction wall pier 12, and the X-direction wall pier 11 and the Y-direction wall pier 12 are wing walls, so The T-shaped shear wall member is divided into an upper part 1A of the member and a lower part 1B of the member formed by reducing the variable section, which is a whole formed by pouring concrete; the upper part 1A of the member is pre-embedded with vertical reinforcement 101, horizontal reinforcement 102 and tension Tie steel bars 103, the outer ends and intersections of the X-direction wall pier 11 and Y-direction wall pier 12 are provided with edge members 105, and the vertical reinforcement 101 in the edge member 105 is reinforced into the vertical reinforcement 1051 of the edge member, and installed There are stirrups 1052; the vertical reinforcement 101 and the edge member vertical reinforc...

Embodiment 2

[0071] Such as Figure 4-9 As shown, a manufacturing mold of a prefabricated concrete variable cross-section T-shaped shear wall member described in Example 1 of the present invention includes an X-direction wall pier mold 21, a Y-direction wall pier mold 22, and formwork diagonal supports 23 , pier 24 and Y-direction wall plinth oblique support 25; said X-direction wall pier mold 21 includes X-direction wall pier manufacturing platform 211, X-direction wall pier side formwork 212, X-direction wall pier top formwork 213, member lower section X-direction Wall core surface template 214, X-direction wall pier variable section baffle plate 215, X-direction wall pier bottom formwork 216, X-direction wall pier L-shaped connecting beam support template 217, vertical tunnel mold 201; the Y-direction wall pier The mold 22 includes a Y-direction wall pier making platform 221, a Y-direction wall pier side formwork 222, a Y-direction wall pier top formwork 223, a component lower section Y...

Embodiment 3

[0079] Such as Figure 4 with Figure 7As shown, a production mold of a prefabricated concrete variable-section T-shaped shear wall member described in Example 1 of the present invention is based on Example 2, on the Y-direction wall pier production platform 221 A movable rotating mechanism 203 with a clamping device is provided below. After the pouring process of the Y-direction wall 12 is completed and the mold is removed, the Y-direction wall 12 is fixed by the clamping device and moved to the maintenance process. Requirements, then move to the pouring process of the X-direction wall 11, rotate 90° along the X-direction wall 11, so that the X-direction wall 11 to be poured is in a horizontal state, and further erect the X-direction wall 11 related production molds, the X When the concrete part filled into the wall pier mold 21 communicates with the vertical tunnel 104 of the Y-direction wall pier 12, a vertical tunnel blocking formwork 204 is installed at the vertical tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com