A dry-wet two-step biogas fermentation device and method

A technology of biogas fermentation and wet fermentation, which is applied in the field of biogas fermentation equipment and dry-wet two-step biogas fermentation equipment, can solve the problems of reduced utilization rate of straw materials, increase of equipment construction cost, floating on the top of fermentation tank, etc. Adhesion and reproduction ability and activity, improving utilization rate, and avoiding the effect of floating crust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

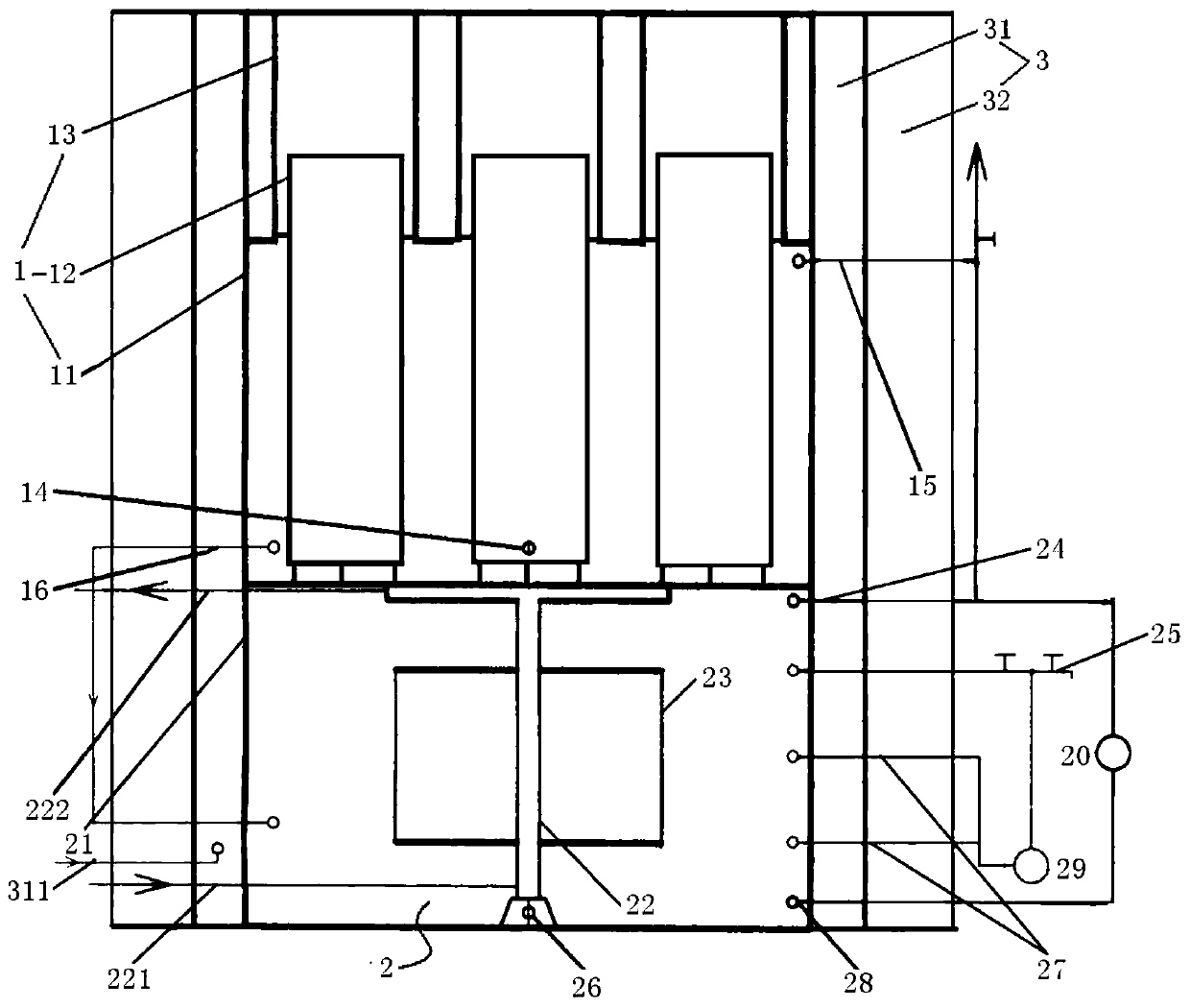

[0023] like figure 1 As shown, the wet and dry two-step biogas fermentation device provided by the present invention includes a primary dry fermentation mechanism 1 and a secondary wet fermentation mechanism 2 .

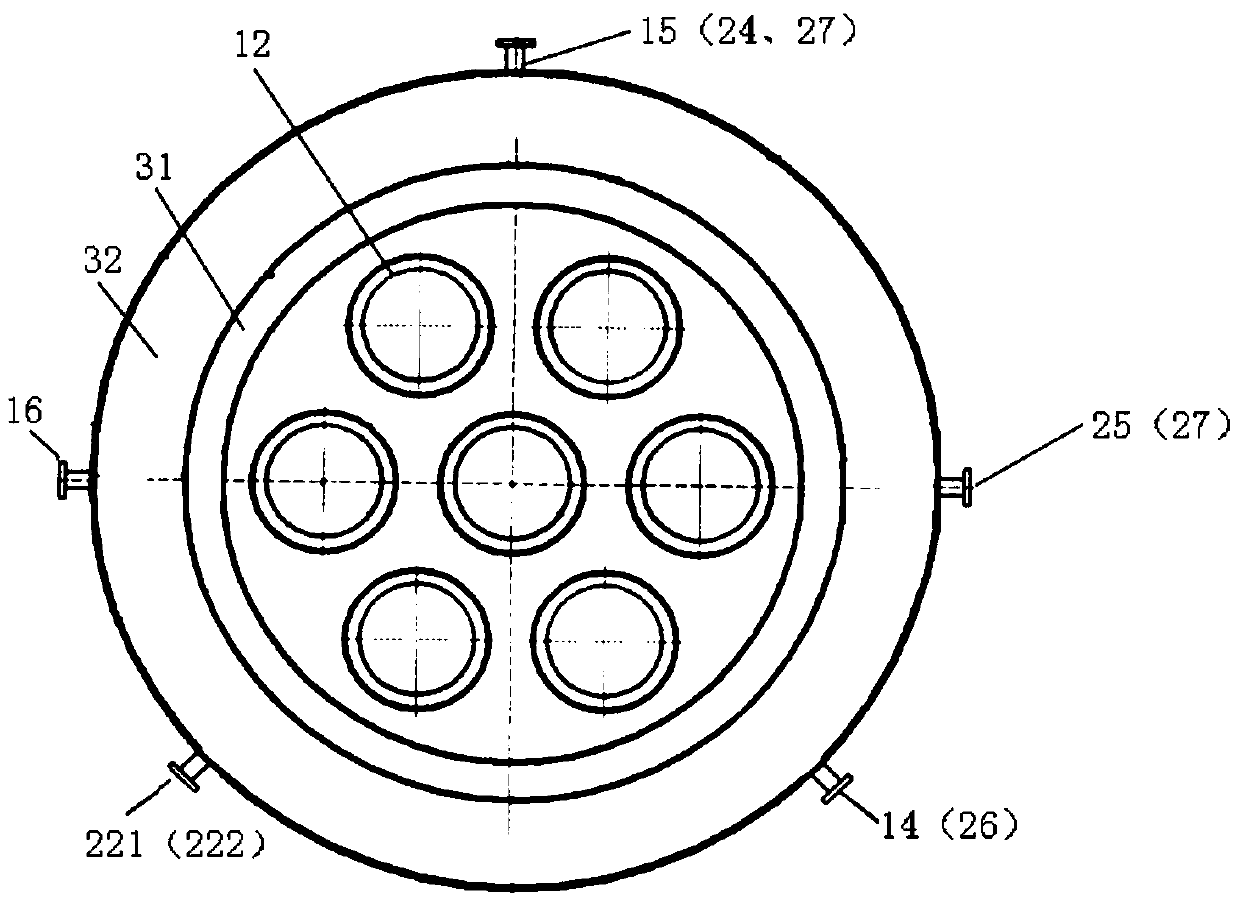

[0024] like figure 1 , figure 2 As shown, the primary dry fermentation mechanism 1 includes a dry fermentation tank 11 , several cages 12 and several water-sealed covers 13 . Wherein, the dry fermenter 11 is filled with material liquid, and the upper cover of the dry fermenter 11 is uniformly opened with several through holes. The cages 12 are filled with materials, and the cages 12 are soaked in the feed liquid in the dry fermentation tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com