High-solid-content anaerobic digestion reaction device and working method thereof

An anaerobic digestion and reaction device technology, which is applied in the field of high-concentration biomass anaerobic digestion, can solve the problems of VFAs accumulation, uneven contact between anaerobic microorganisms and substrates, etc., and achieve the effect of balanced gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

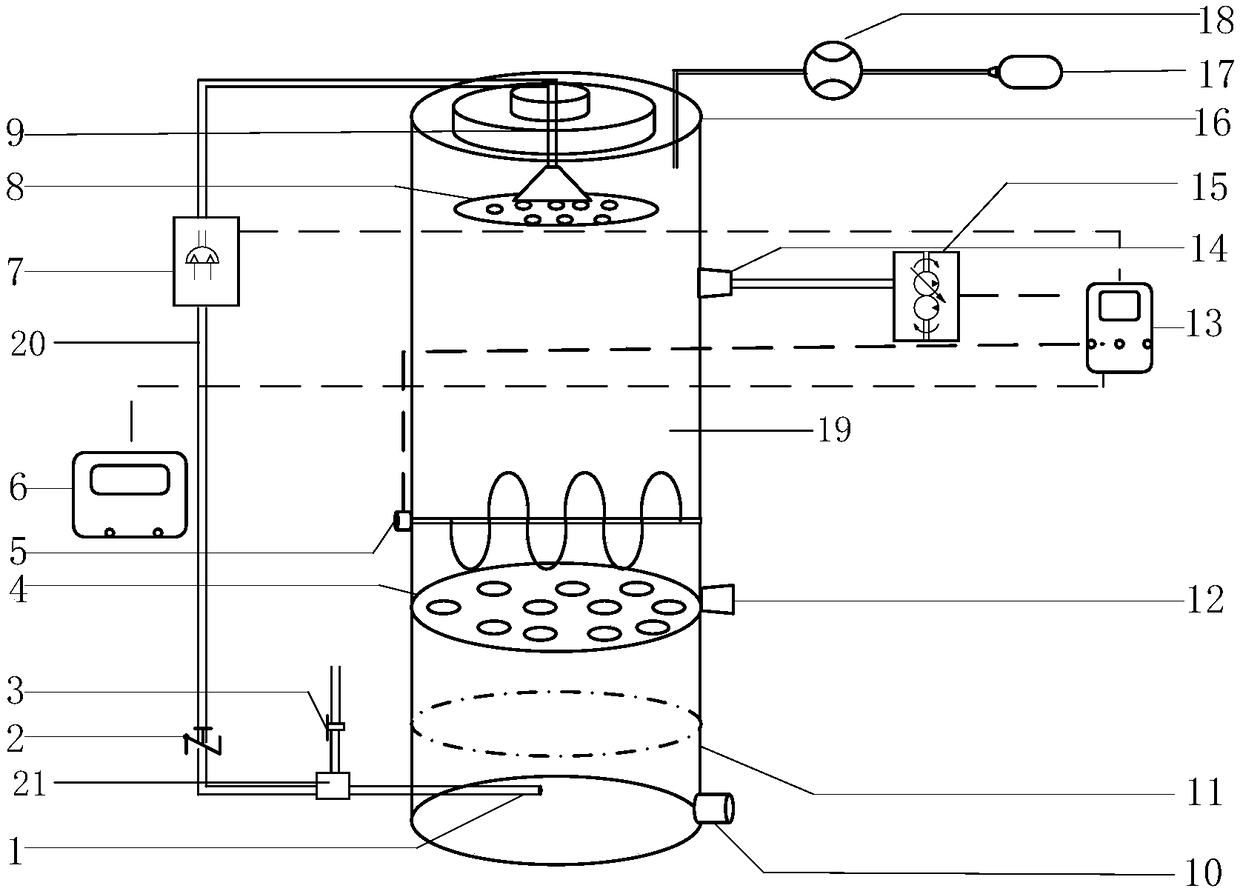

[0055] A high-solids anaerobic digestion reaction device, including a reactor 19, an anaerobic digestion system, a sampling system, a water circulation system, a gas collection system, and an on-line monitoring and control system. The bottom of the reactor 19 is provided with a water storage area 11;

[0056] The anaerobic digestion system includes a porous backing plate 4 arranged in the middle and lower part of the reactor 19 and a stirring device 5 above the porous backing plate 4. After adding anaerobic inoculated sludge and organic waste, the stirring is started by the PLC controller 13 Device 5, after fully mixing the organic waste and the anaerobic inoculated sludge, close the stirring device 5;

[0057] The water circulation system includes a water intake 1 inserted into the water storage area 11 and a water inlet 9 at the top of the reactor 19. The water intake 1 and the water inlet 9 are connected by a water circulation pipeline 20, and a peristaltic pump 7 is arrange...

Embodiment 2

[0060] A high-solids anaerobic digestion reaction device, the structure is as shown in embodiment 1, the difference is that the sampling system includes a sample inlet 14 and a screw pump 15 located in the upper part of the reactor 19, the screw pump 15 and PLC control Connected to the device 13, the PLC controller 13 controls the work of the screw pump 15 to transport the anaerobic inoculated sludge and organic waste.

Embodiment 3

[0062] A high-solids anaerobic digestion reaction device, the structure is as shown in Example 1, the difference is that the gas collection system includes a gas outlet 16 at the top of the reactor 19, and the gas outlet 16 is connected to a gas collection bag 17 through a ventilation pipeline , a gas volume flow meter 18 is arranged on the ventilation pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com