Method and device for producing sponge iron by using reducing gas prepared from coke oven gas

A technology of sponge iron and coke oven gas, applied in the direction of reducing gas emissions, can solve the problems of non-compliance with environmental protection requirements, failure to explain hydrogen sulfide, and inability to proceed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

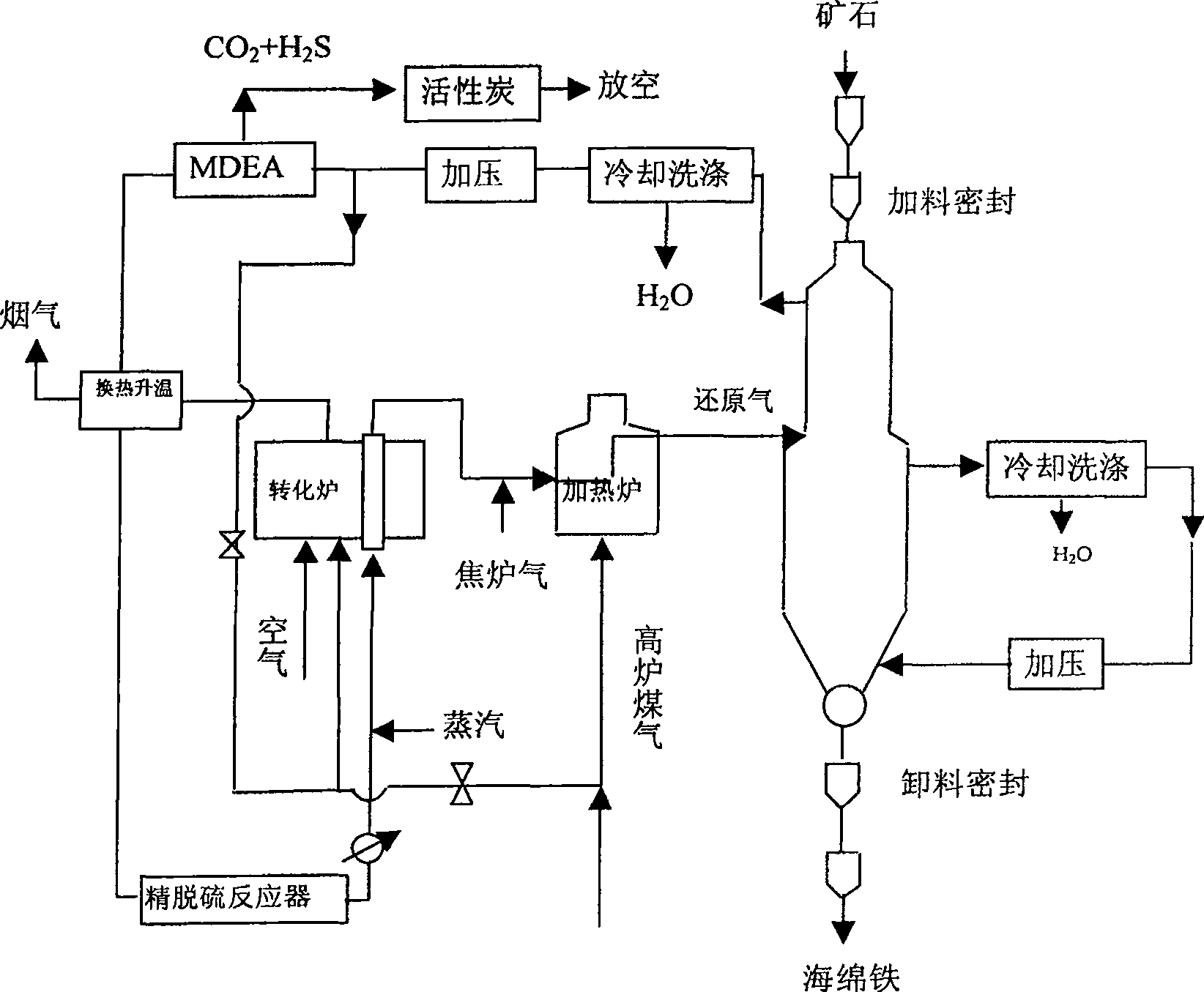

Embodiment 1

[0035] The coke oven gas is mixed with the reduction tail gas from the methane conversion furnace and enters the heating furnace. After being heated by the blast furnace gas to a temperature above 800°C, it enters the reduction zone of the moving bed reduction reactor. The complex organic sulfur in the coke oven gas is released in the reduction reactor. Most of it is converted into hydrogen sulfide or absorbed by DRI. After cooling, dedusting and dehydration, the reduction tail gas is pressurized to 0.5MPa, and enters the MDEA section to remove CO in the reduction tail gas. 2 and H 2 S and other acid gas, the released acid gas is removed by activated carbon desulfurizer to remove H 2 After S, it is emptied, and the purified reducing tail gas is preheated to 200°C by the reformer flue gas, and then enters the renewable conversion and absorption type fine desulfurization bed to remove the total sulfur to below 0.1ppm. The activity of the renewable conversion and absorption type ...

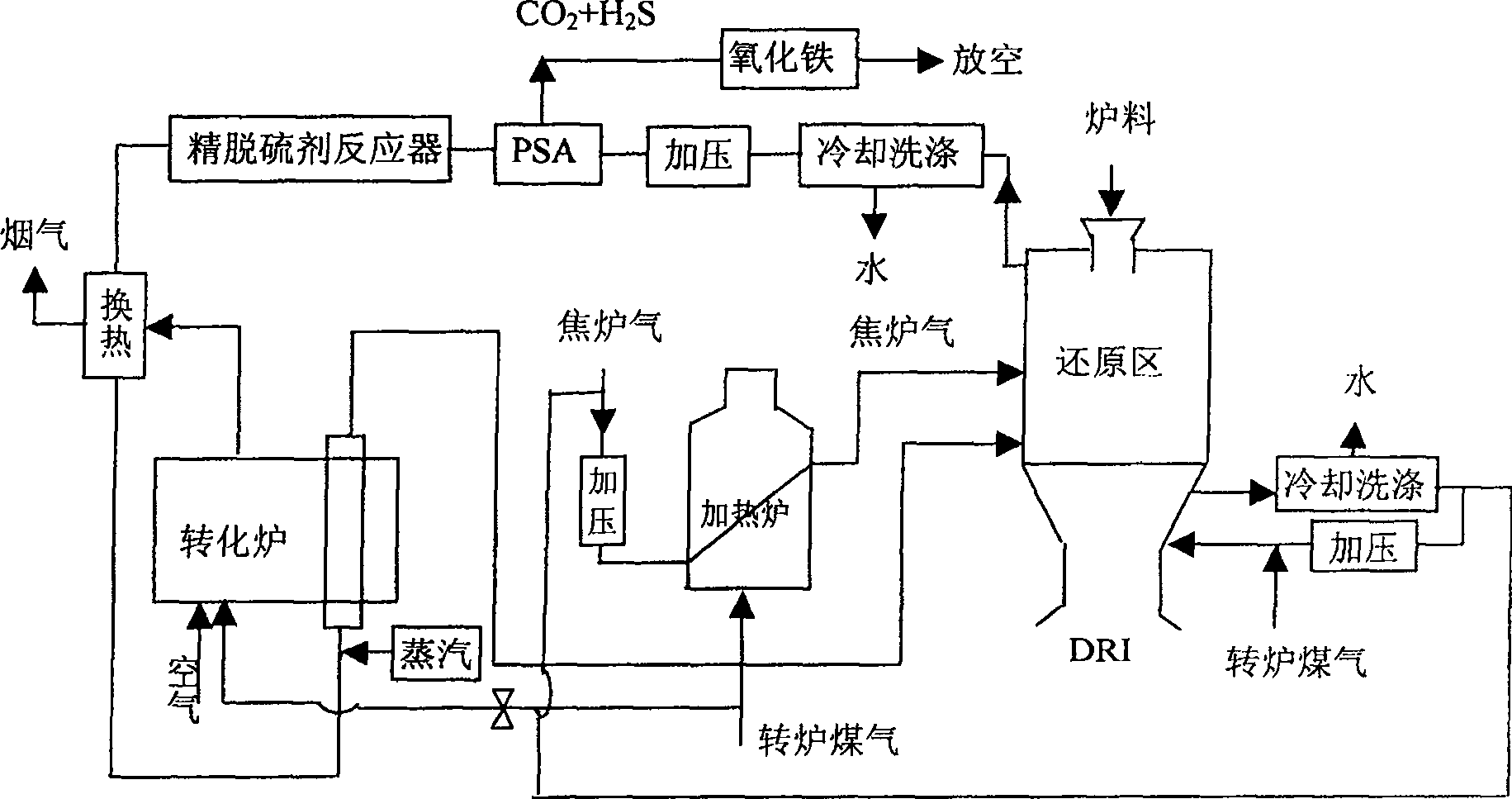

Embodiment 2

[0037] The reduction tail gas from the upper reduction zone of the DRI moving bed reactor is cooled, dedusted and dehydrated, then pressurized to 0.8MPa, enters the PSA device, and removes CO 2 、H 2 S and N 2 , the acid tail gas is vented after removing hydrogen sulfide with iron oxide desulfurizer, and the purified reduction tail gas enters the zinc oxide fine desulfurization reactor to remove the total sulfur to below 0.1ppm, and then enters methane steam reforming after heat exchange and heating of flue gas and adding steam Furnace, control steam / gas ratio 0.3:1, reformer outlet temperature 870°C, methane steam reforming catalyst Ni / α-Al 2 o 3 (Z412 / Z413 produced by the Research Institute of Qilu Petrochemical Company); the outlet methane content is less than 1%, and the converted reduction tail gas directly enters the moving bed DRI reduction furnace, and its position is higher than the position where the converted reduction gas enters the reduction furnace. The methane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com