Patents

Literature

48results about How to "Increase volumetric gas production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Home device and method for producing methane by dry-type fermentation of stalks

InactiveCN101338273AReduce handling difficultiesSmall footprintGas production bioreactorsWaste based fuelSludgeSlag

The invention relates to a device for producing biogas by straw dry type fermentation and a method, belongs to the agriculture environmental protection and biomass energy source utilization field. The straw is chopped. Nitrogen fertilizers are added. C / N is adjusted. The mixture is arranged in a column shaped biogas digester built underground after the mixture is composted. Anaerobic fermentation outcomes are inoculated and sealed with red-sludge plastic. The biogas is produced in the process of anaerobic fermentation. When the biogas production is lowered, the straw is processed eluviation by biogas liquid which is pumped by manual pumping device. When the biogas production is obviously reduced, the new materials should be changed. The straw dry typed anaerobic biogas can be realized. The technical requirements that the straw is substituted the animal manure as the main raw materials are achieved. The straw dry typed fermentation technology is used, which can reduce the difficulties in treating biogas liquid and biogas slag of the wet typed anaerobic fermentation biogas. At the same time, the volumetric biogas production of the biogas digester is improved, and the biogas digester building cost is lowered and the biogas digester occupied area is reduced. The designed biogas fluid backflow system solves the difficulty of the exchange of mass flows and substances in the straw dry typed fermentation.

Owner:JIANGSU ACAD OF AGRI SCI

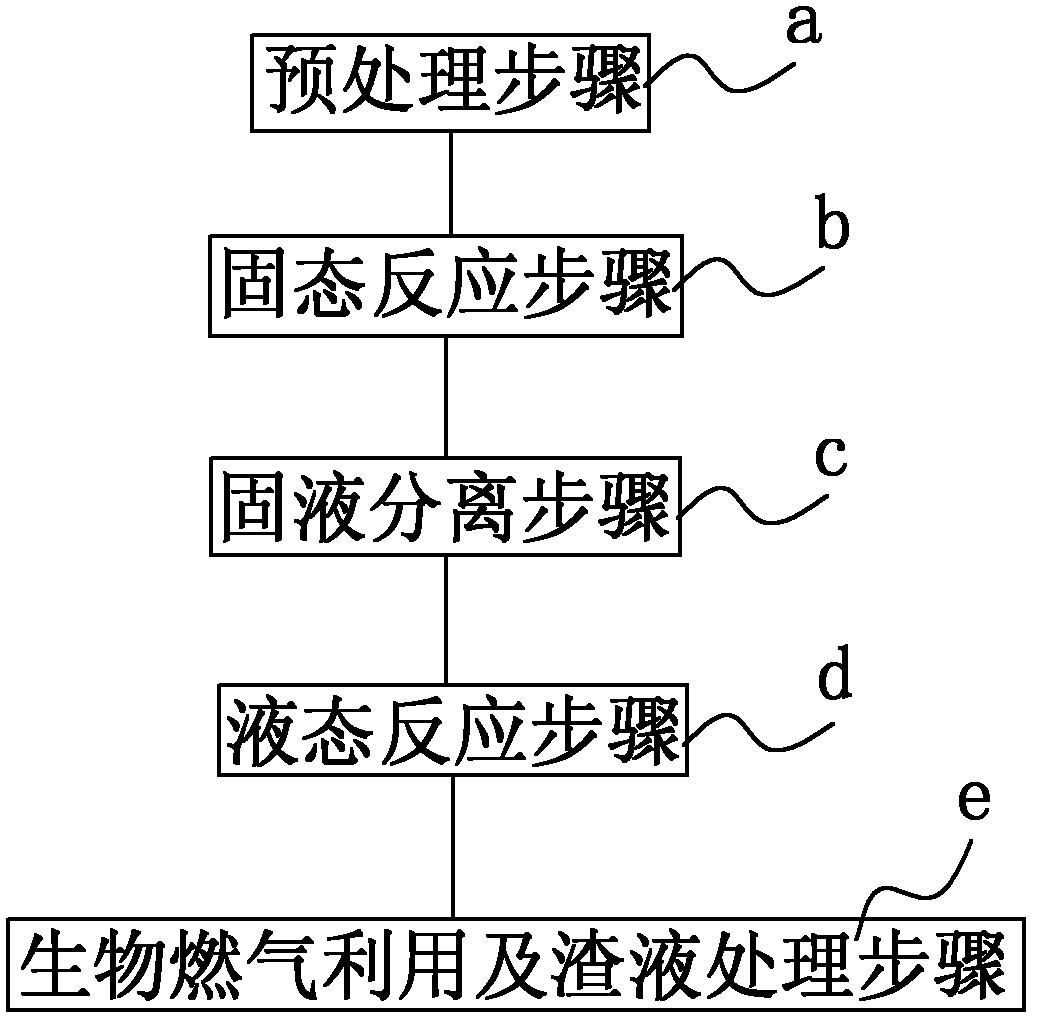

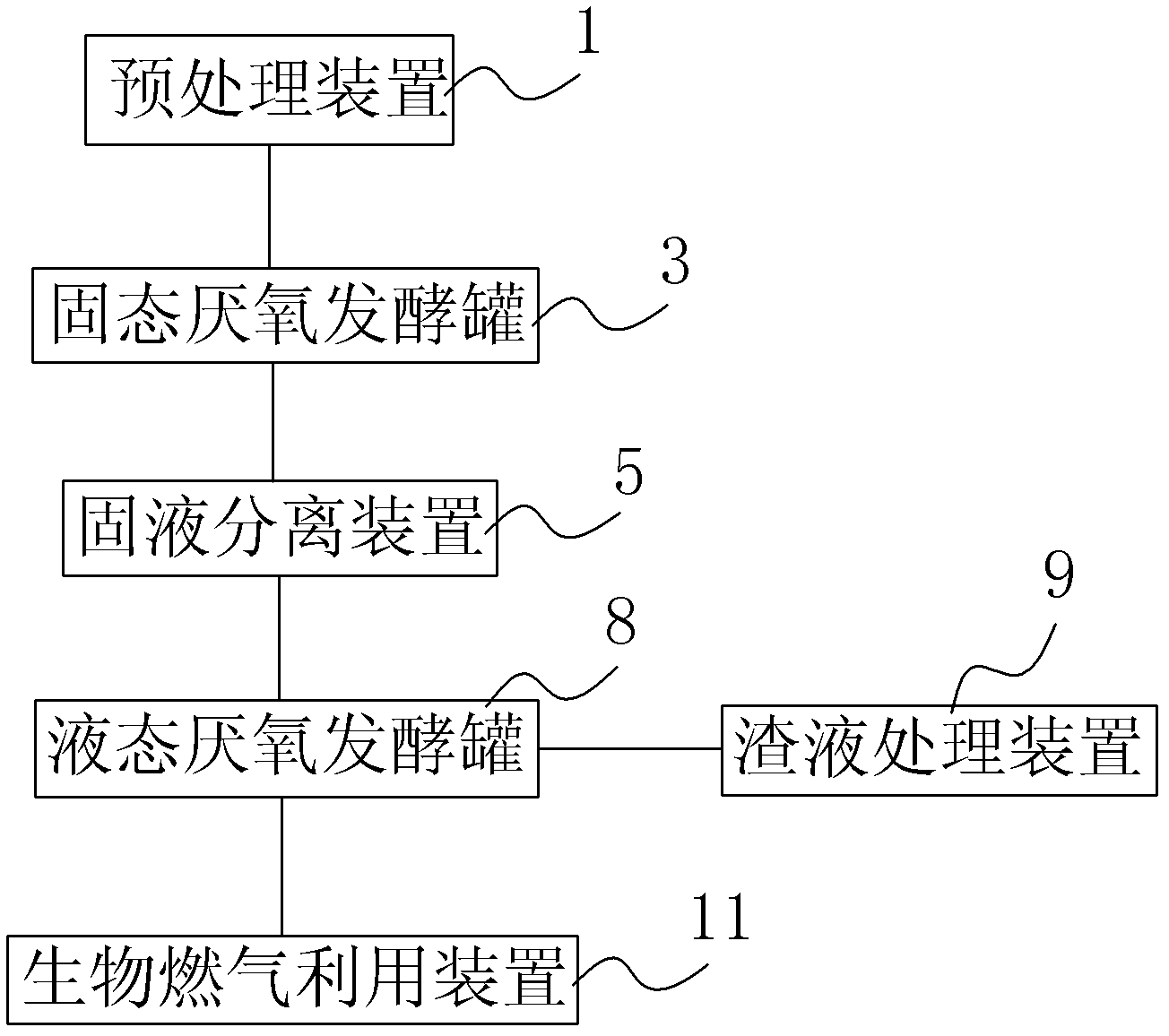

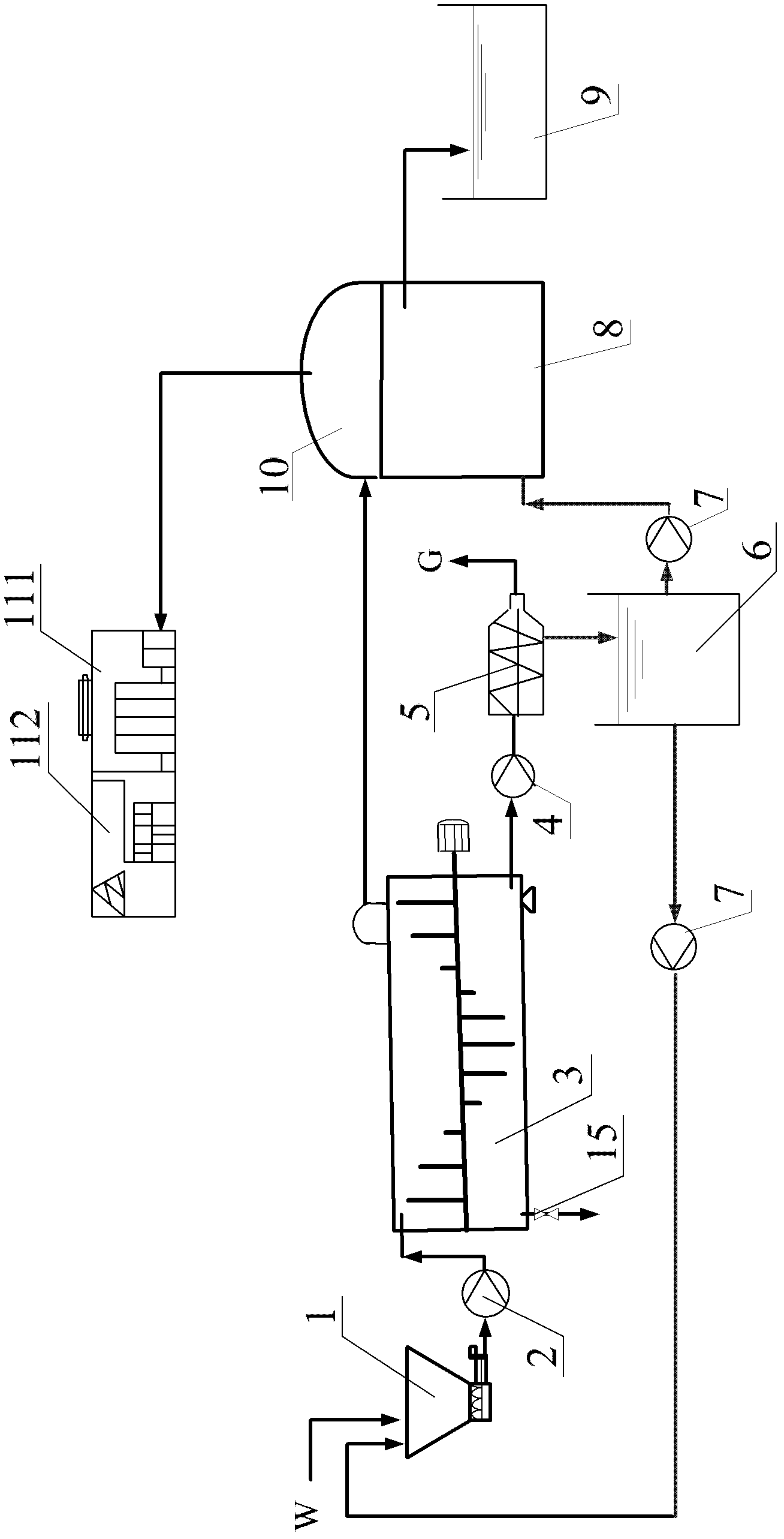

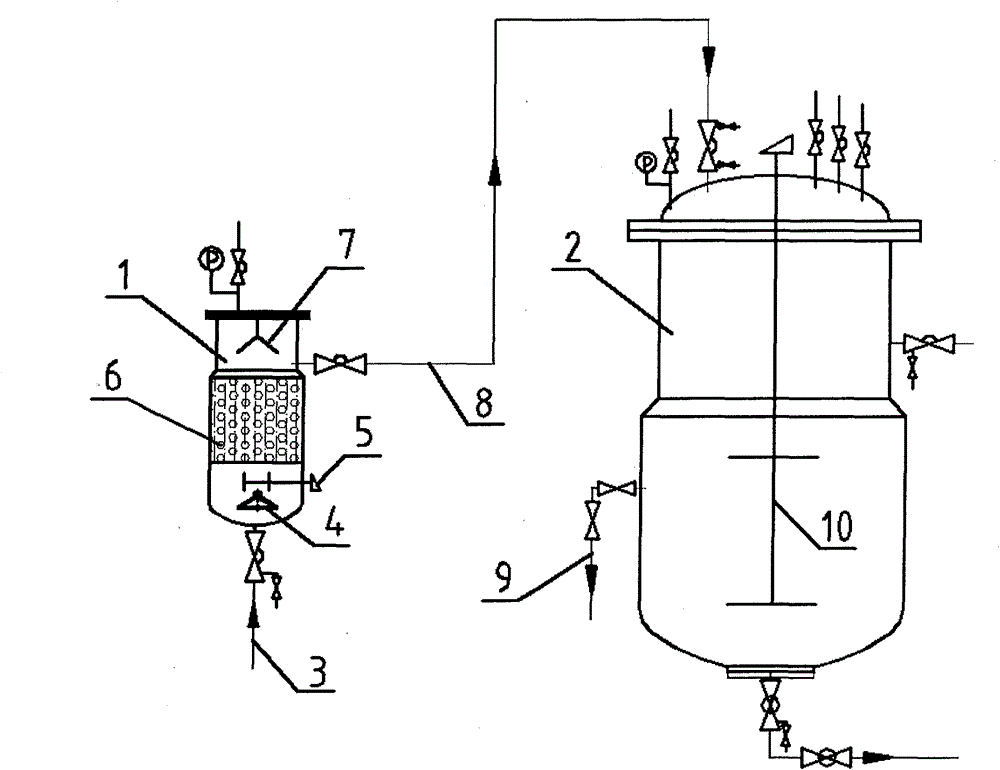

Method and device for producing bio-gas by organic waste

ActiveCN102321675AImprove processing efficiencyImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsReduction treatmentSlag

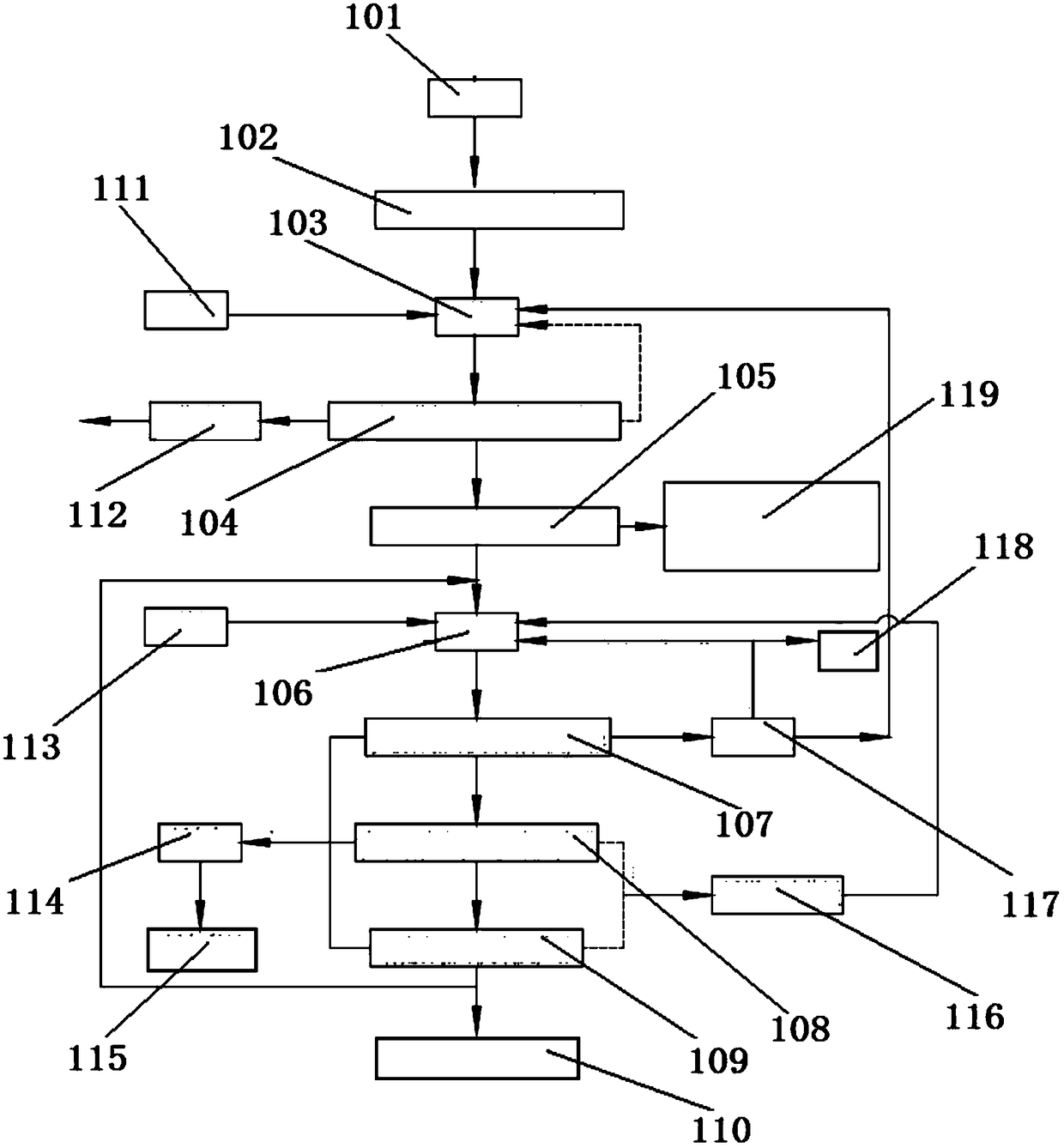

The invention provides a method and a device for producing bio-gas by organic waste. The method comprises a pretreatment step, a solid state reaction step, a solid-liquid separation step, a liquid state reaction step, a bio-gas utilization and slag liquid processing step; the device comprises a pretreatment apparatus, a solid state anaerobic fermentation cylinder, a solid-liquid separator, a liquid state anaerobic fermentation cylinder, a bio-gas utilization apparatus and a slag liquid processing apparatus. The solid state anaerobic fermentation cylinder is respectively connected with the pretreatment apparatus and the solid-liquid separator, the solid-liquid separator is connected with the liquid state anaerobic fermentation cylinder, and the liquid state anaerobic fermentation cylinder is respectively connected with the bio-gas utilization apparatus and the slag liquid processing apparatus. According to the invention, the organic waste can be processed with solid-liquid two-stage diphasic anaerobic digestion, so that the method is capable of realizing the harmlessness of organic waste, quantitative reduction treatment and resourceful utilization, acquiring the renewable cleaning energy and satisfying the urgent requirements of energy saving, emission reduction and environmental protection.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

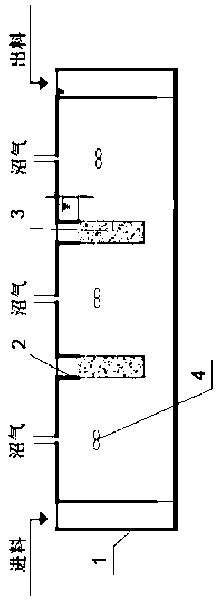

Biomass gasification system

The invention provides a biomass gasification system. The biomass gasification system comprises a multi-section fixed bed biomass gasification furnace, wherein the multi-section fixed bed biomass gasification furnace comprises a furnace body which is arranged in the longitudinal direction, the furnace body comprises a conical-hopper tail ash section which is arranged on the bottom and at least two gas production sections which are arranged on the tail ash section, the two gas production sections are arranged in the longitudinal direction and connected with each other in an end-to-end manner, and a fire grate is arranged between the tail ash section and the gas production section on the bottom; the side part of each gas production section is provided with a gas outlet; each gas outlet is connected with a gas branch pipeline, and a plurality of gas branch pipelines are connected to a gas main pipeline; the bottom of the tail ash section is provided with a slag outlet, and the side part of the tail ash section is provided with an air inlet; the upper side surface or the top end of the gas production section on the top is provided with a fuel inlet. The gasification furnace is compact in structure; the biomass raw material moisture applicability is high, and the strict requirement of the conventional gasification furnace on the moisture can be broken through; the produced gas is controllable in nature, and the appropriate biomass gas can be adjusted according to different requirements of the user; the biomass gasification system is applicable to the multi-section gas production process, so that the gasification efficiency is higher than that of the conventional gasification furnace.

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

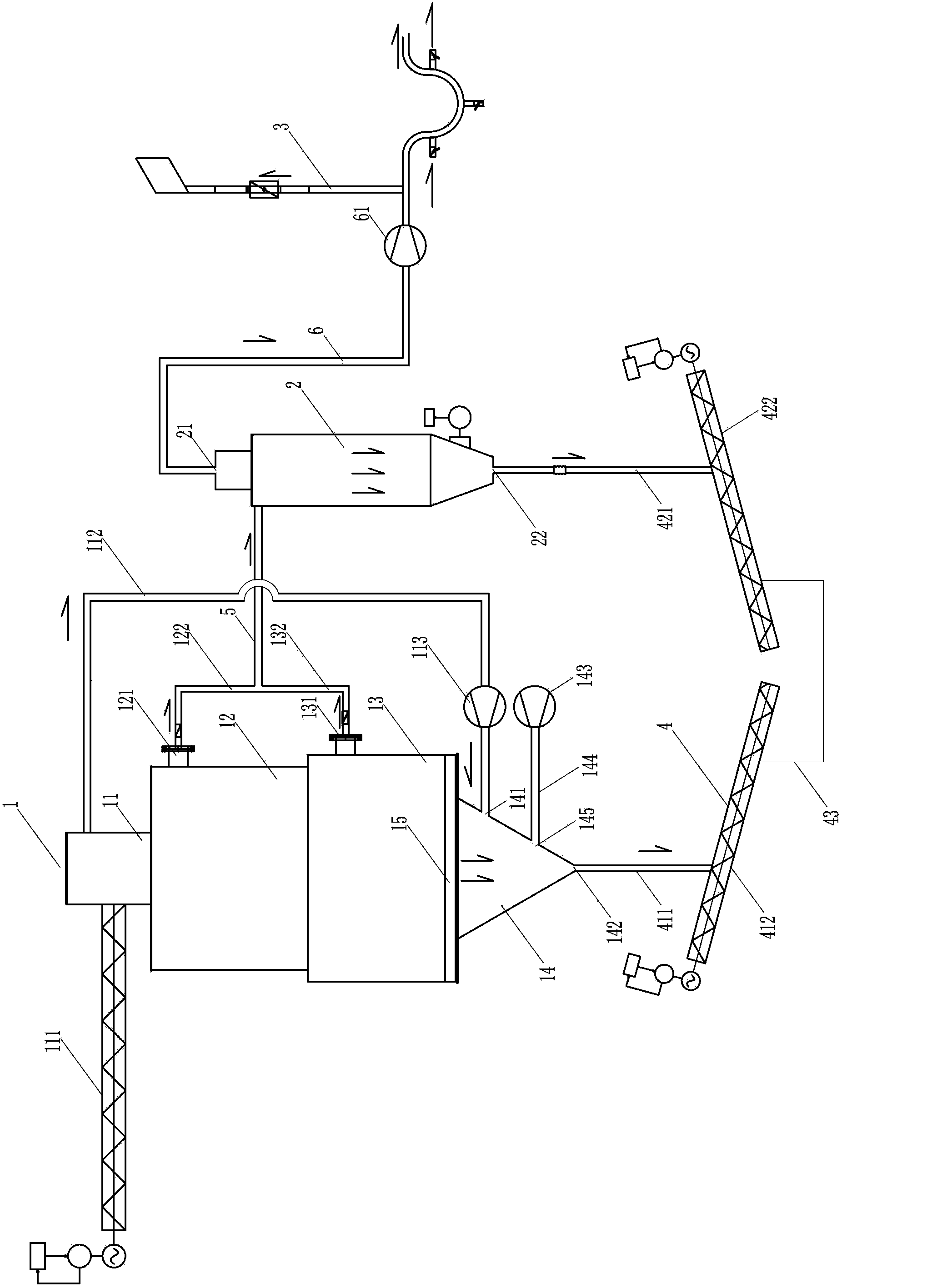

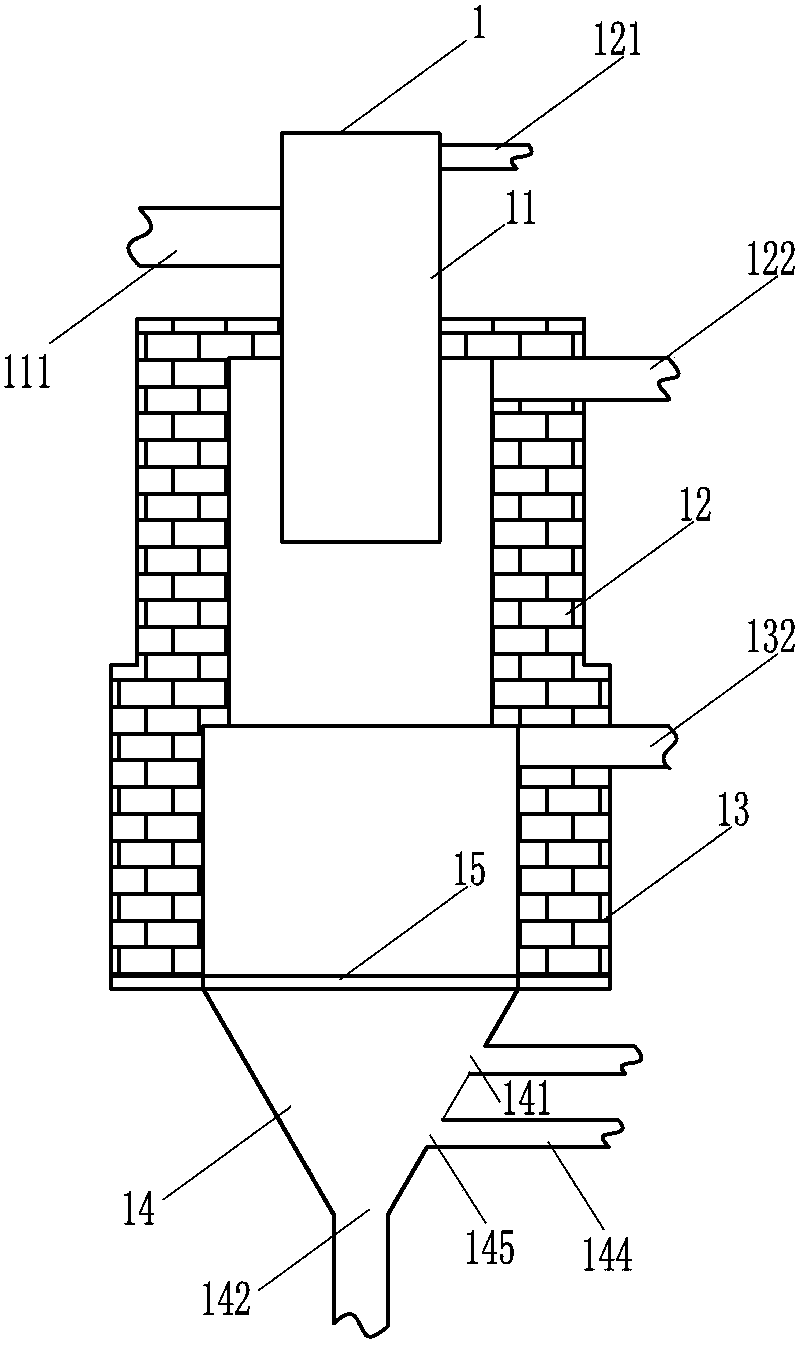

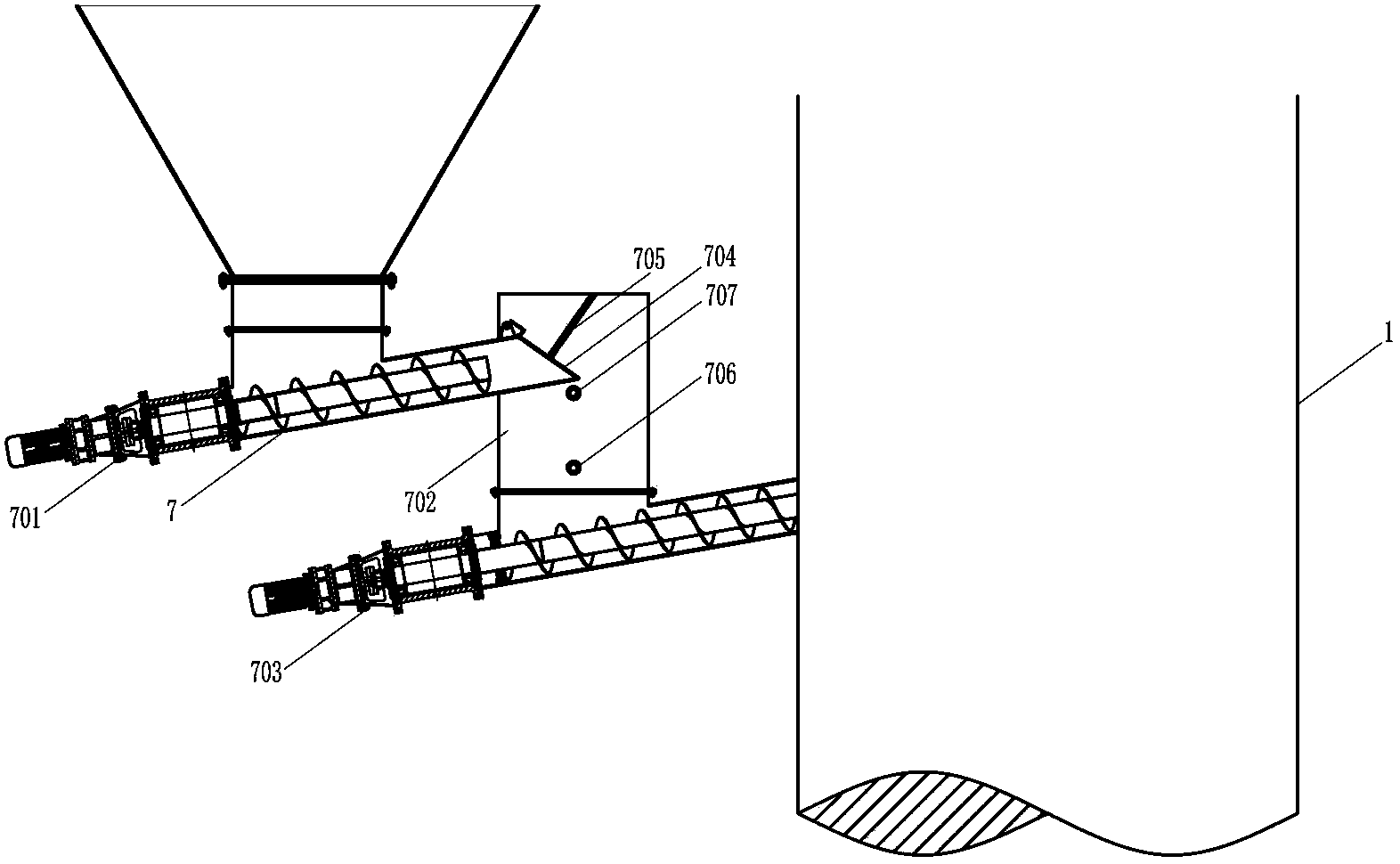

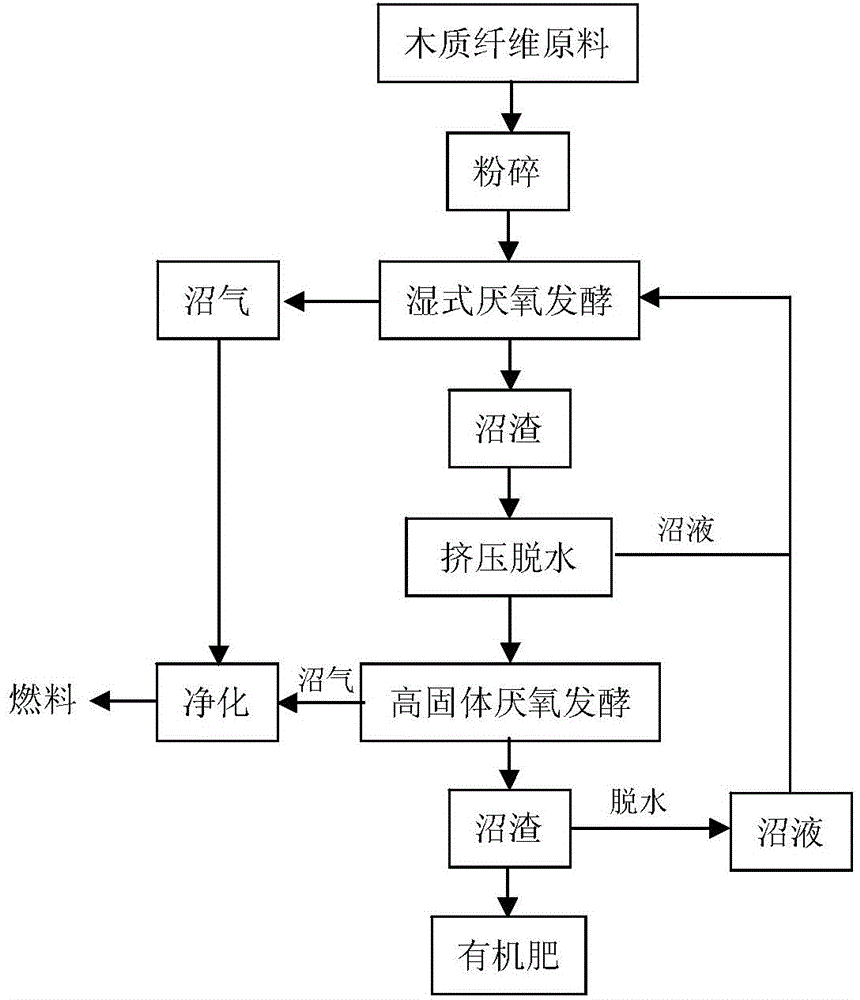

Method for producing biogas by virtue of large-scale anaerobic fermentation of wood fiber raw materials

InactiveCN104357488AEasy to handleLow investment costWaste based fuelFermentationFiberPulp and paper industry

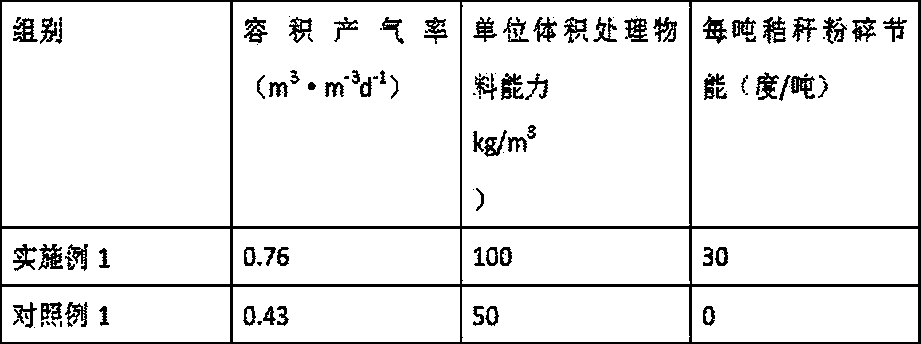

The invention discloses a method for producing biogas by virtue of large-scale anaerobic fermentation of wood fiber raw materials. The method comprises the following steps: crushing the wood fiber raw materials to be below 5.0cm and then adding an inoculum, regulating by use of water or biogas slurry and evenly mixing; adding the mixture to a continuous stirring reactor for wet anaerobic fermentation to produce biogas, wherein the stay time of the raw materials in the continuous stirring reactor is controlled to be within 15-20 days; immediately dehydrating biogas residue discharged by the continuous stirring reactor each day until the moisture content of the biogas residue is 75%-85%; directly feeding the dehydrated biogas residue into a semi-continuous feeding high-solid anaerobic reactor for further anaerobic fermentation to produce biogas. The method for producing the biogas by virtue of large-scale anaerobic fermentation of the wood fiber raw materials has the advantages that the processing capacity and the volumetric gas production rate of the anaerobic reactor are greatly improved, the volumetric gas production rate of the reactor is increased by more than 45% and more than 66% in contrast with a single CSTR process and a single high-solid anaerobic fermentation process, respectively, the unit volume capability of the reactor in processing the wood fiber raw materials is increased by more than one time, and good economic benefit can be produced.

Owner:JIANGSU ACAD OF AGRI SCI

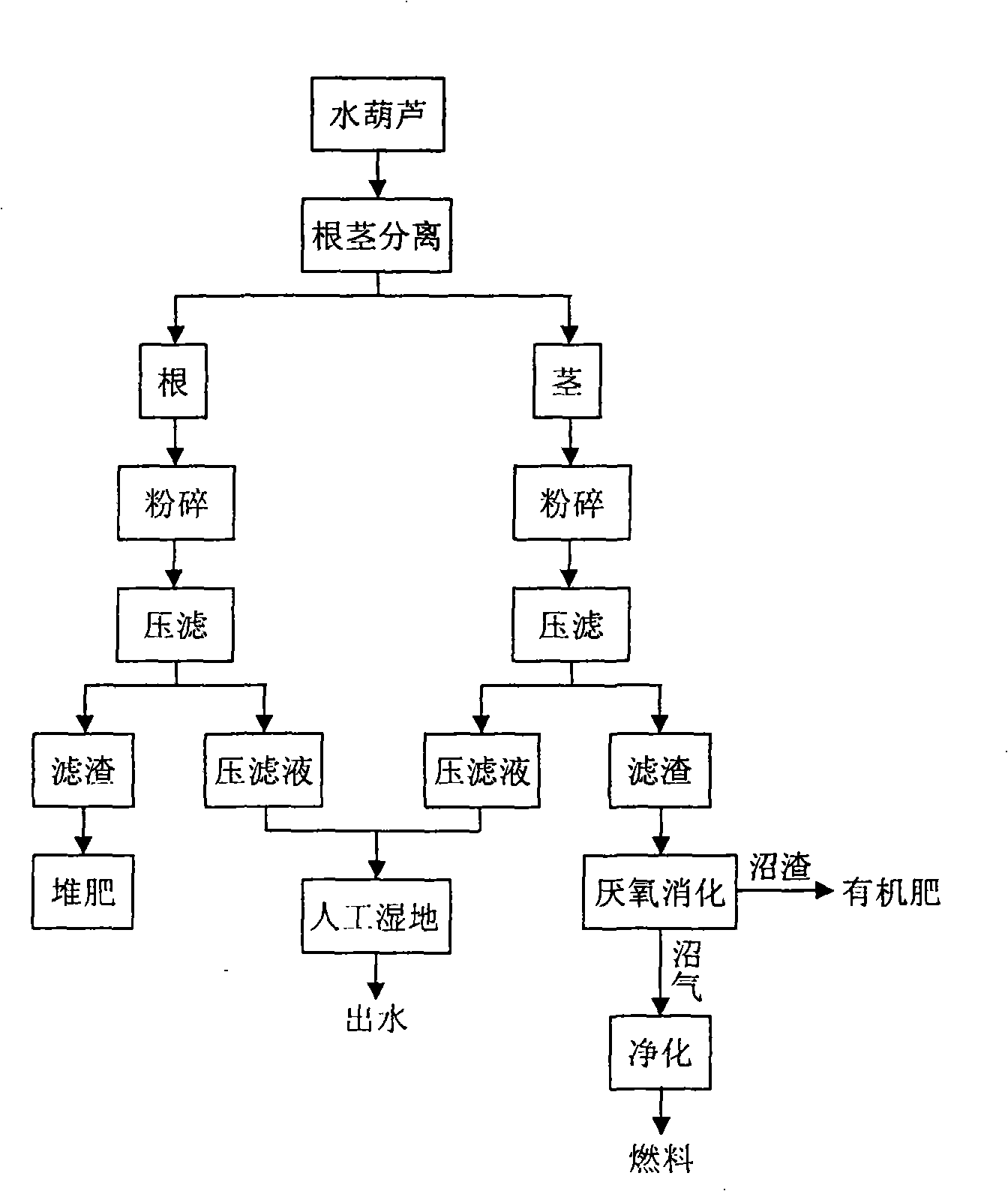

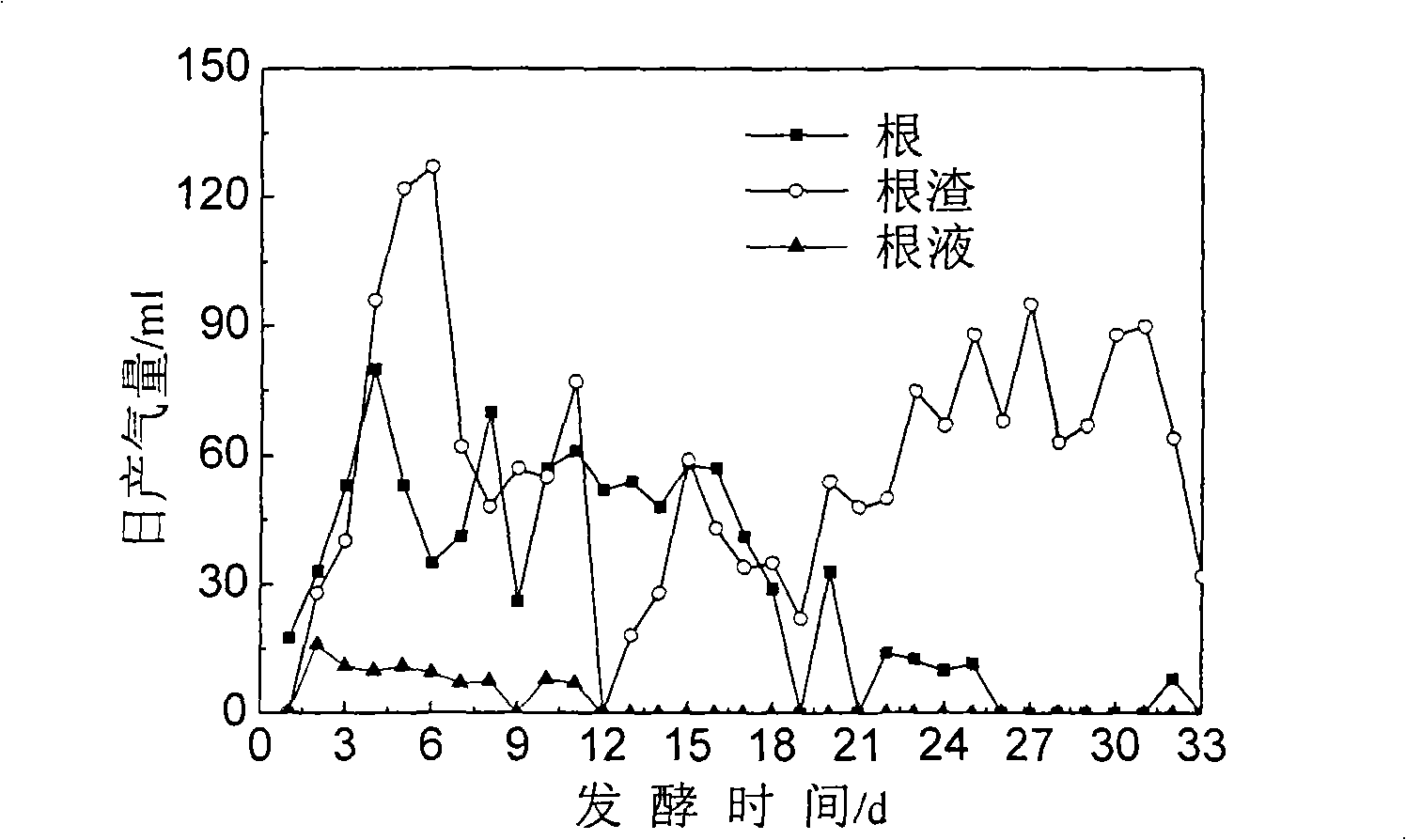

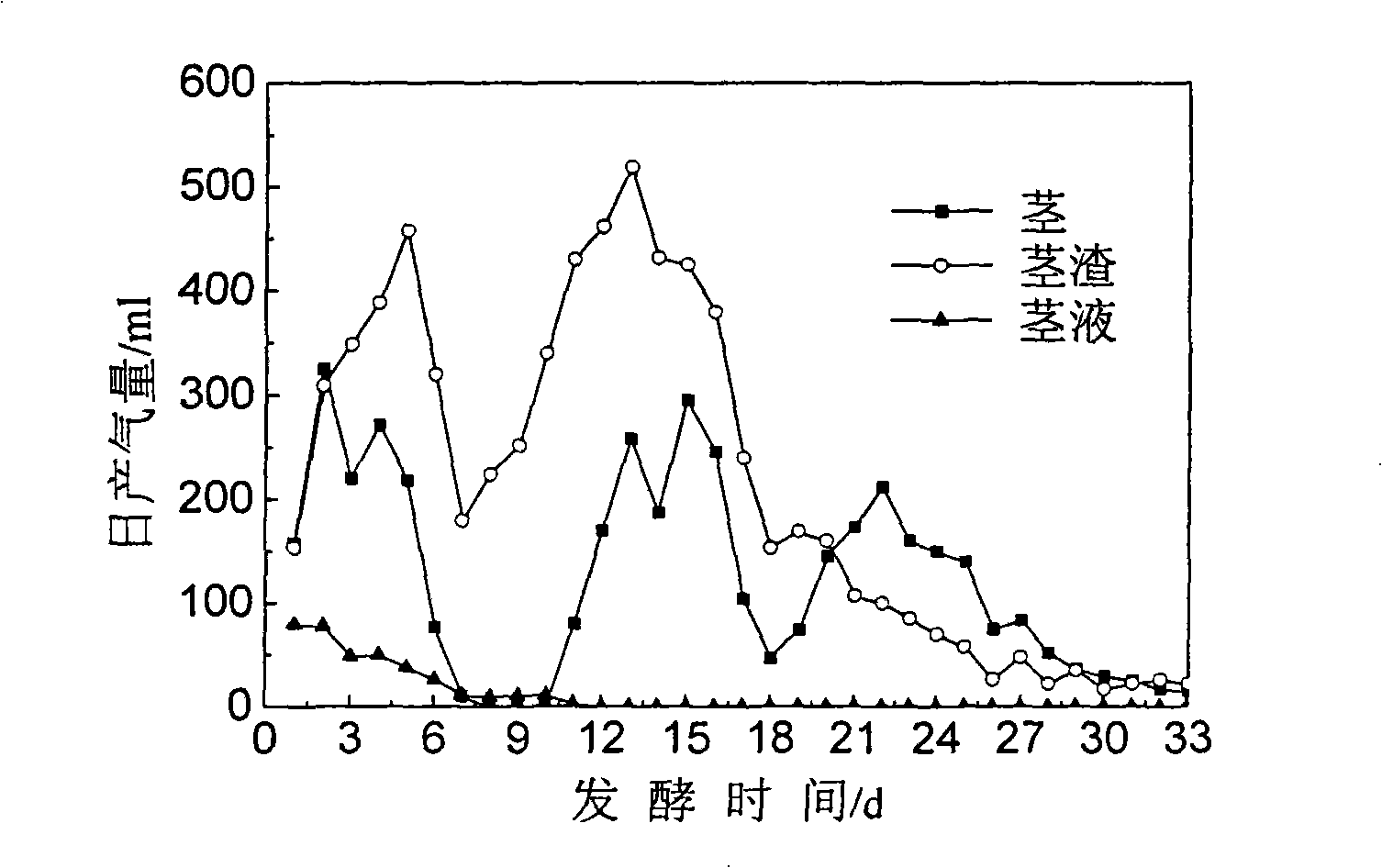

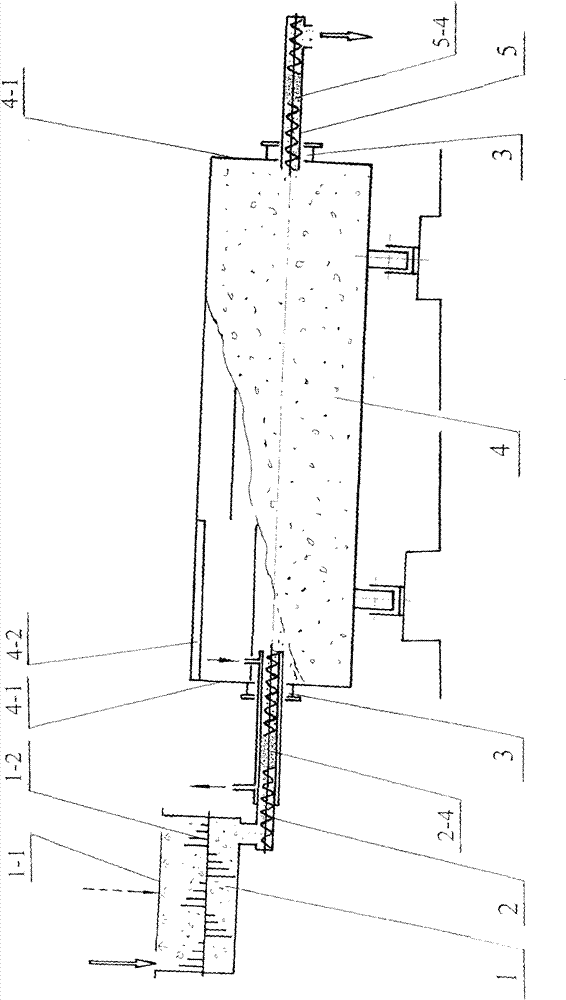

Novel technique for hyacinth resource utilization

The invention discloses a novel technique for hyacinth resource utilization, which comprises the following steps: collected roots and stems of hyacinth are separated and respectively pulverized into thick slurry states; the thick slurries are respectively pressed and filtered to obtain stem filtration residue, root filtration residue and root-stem filtration liquid; the root-stem filtration liquid is treated by a constructed wetland system and discharged; anaerobic fermentation inoculum is added into the stem filtration residue to generate marsh gas through anaerobic fermentation, wherein the load of an anaerobic reactor TS is 2.0 to 6.0 percent; and the water ratio of the root filtration residue is adjusted to 55 to 77 percent with straws, the C / N is adjusted to 25 to 35 percent, and aerobic compost is carried out. Because the roots and the stems of hyacinth are respectively filtered after being separated, and the filtered roots and stems are respectively carried out resource utilization in the anaerobic fermentation mode and the aerobic compost mode, thereby the gas generation performance of hyacinth is improved, the amount of gas generation is increased by 45.99 percent, the treating capability of the anaerobic reactor is improved by times, high-quality compost products are obtained simultaneously, and the invention has good economic benefit and environmental benefit.

Owner:NANJING UNIV

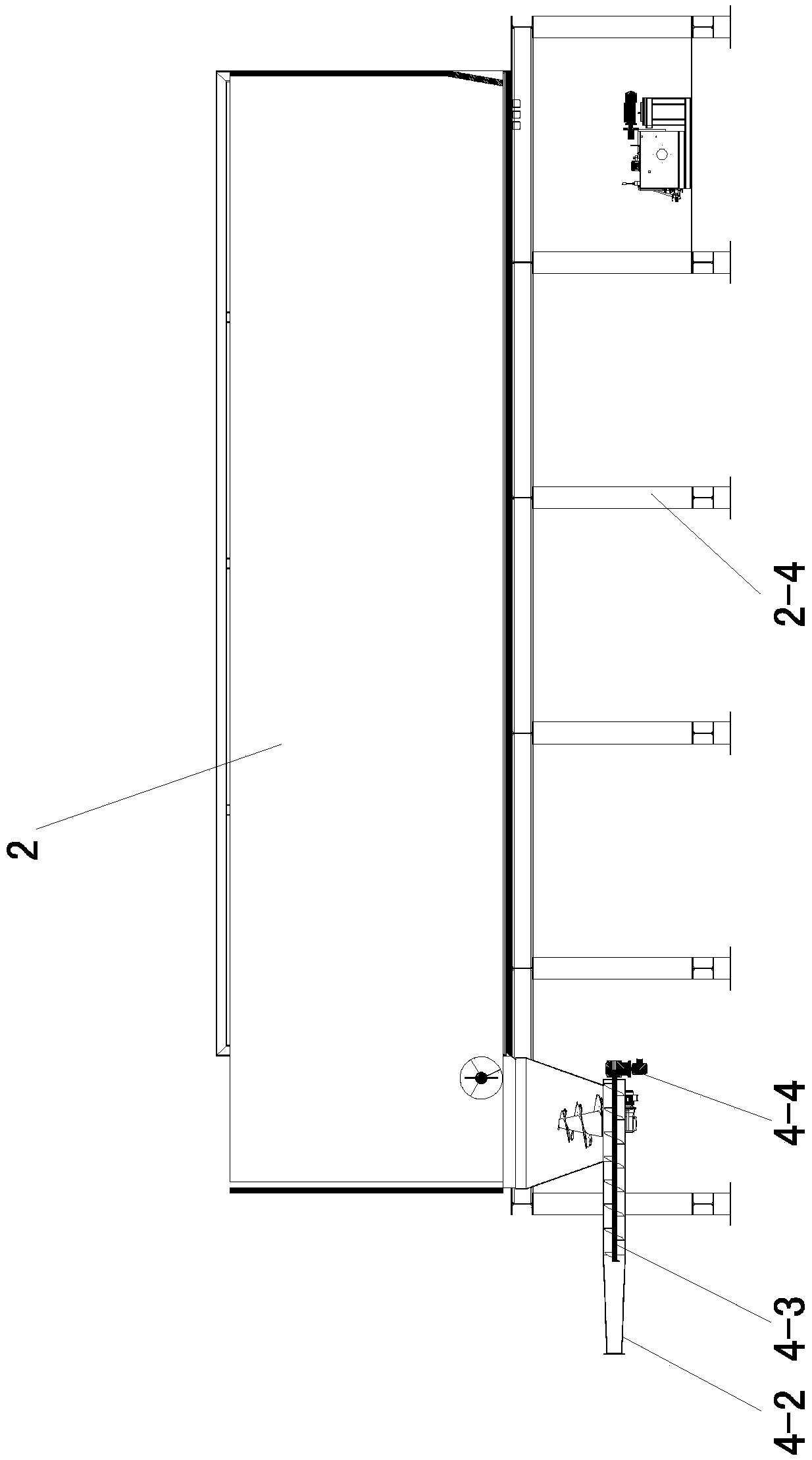

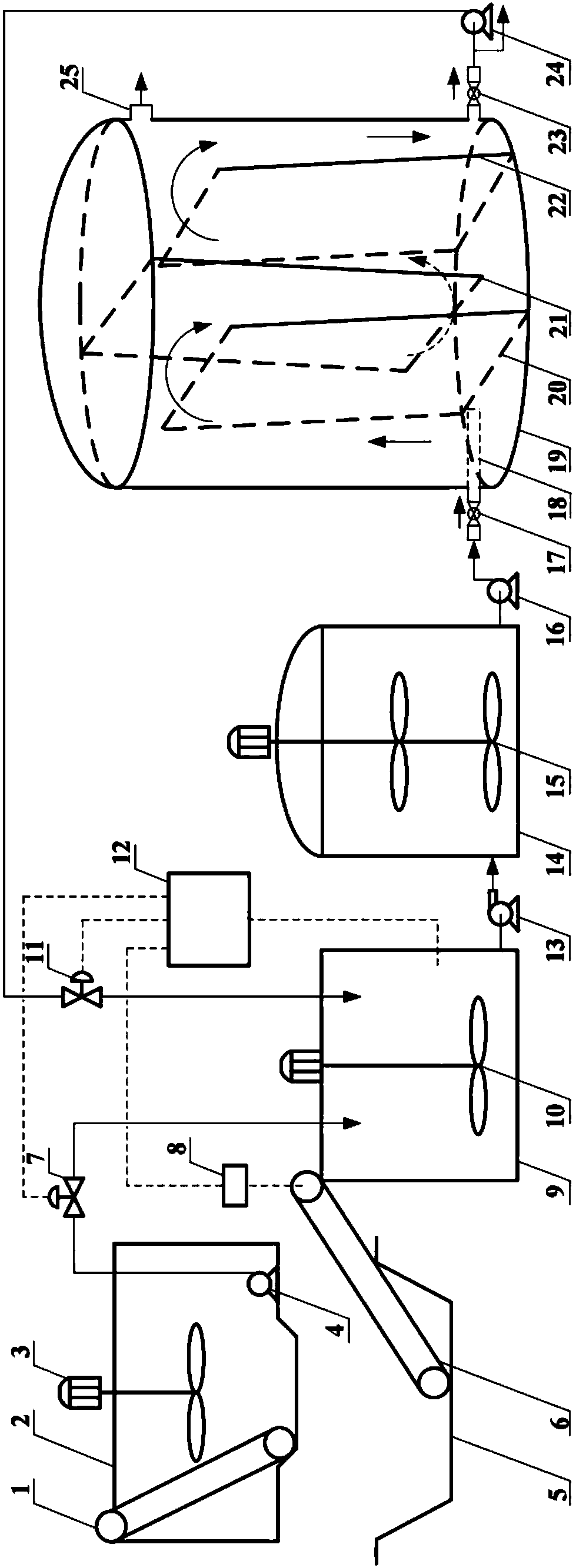

Continuously feeding and discharging dynamic dry method anaerobic fermentation apparatus and method thereof

InactiveCN102776121ASuitable for industrializationThere is no secondary pollution problemBioreactor/fermenter combinationsBio-organic fraction processingBiogasWater content

The invention relates to a continuously feeding and discharging dynamic dry method anaerobic fermentation apparatus and a method thereof. The apparatus is characterized in that a horizontal type rotating-drum silo accommodating anaerobic fermentation materials can be remained sealed and continuously fed and discharged when rotating. Adjustments of anaerobic fermentation parameters such as premixing of raw materials and anaerobic fermentation inoculums, temperature, water content, pH value, etc. are finished at the same time. When being used in producing biogas, the apparatus is advantaged in that secondary pollution problems are not existed because of no biogas slurry; anaerobic fermentation parameters are easy to control; and that the apparatus produces the biogas uniformly and is suitable for industrialization of the biogas; Materials are remixed continuously in a reactor and in a dynamic anaerobic fermentation state, so that the apparatus has high gas yield and occupies small area.

Owner:韩迪 +1

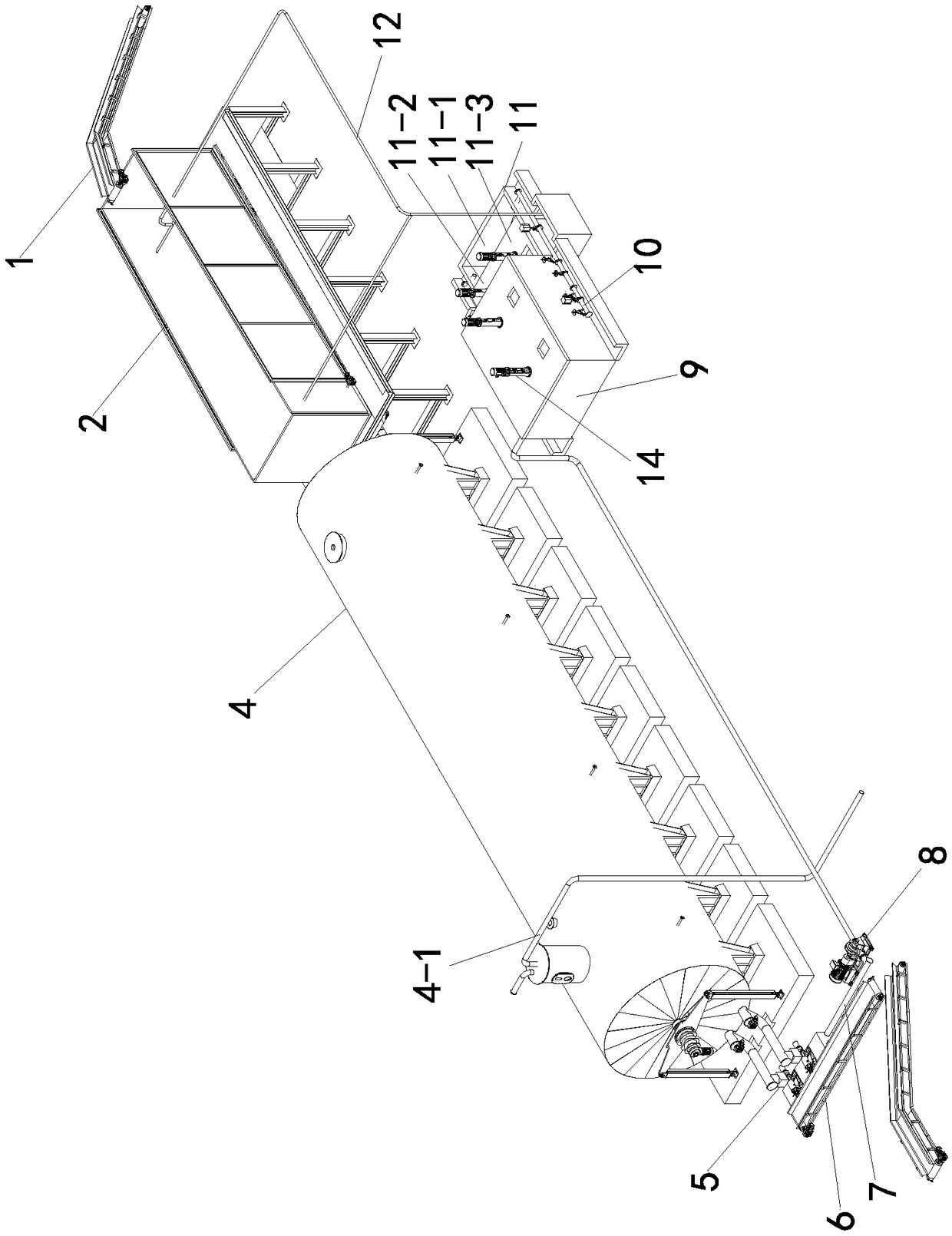

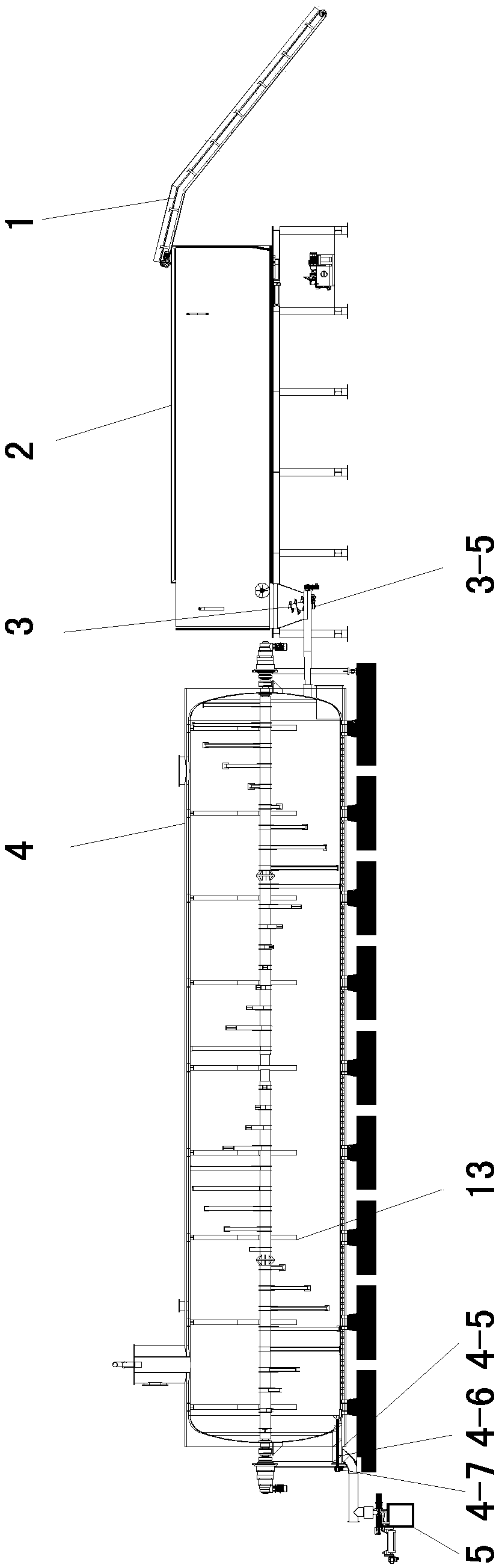

Horizontal push-flow anaerobic dry fermentation device and process for organic waste

PendingCN108660075AReduce heat consumptionIncrease gas production rateBioreactor/fermenter combinationsBiological substance pretreatmentsDry matterBiogas

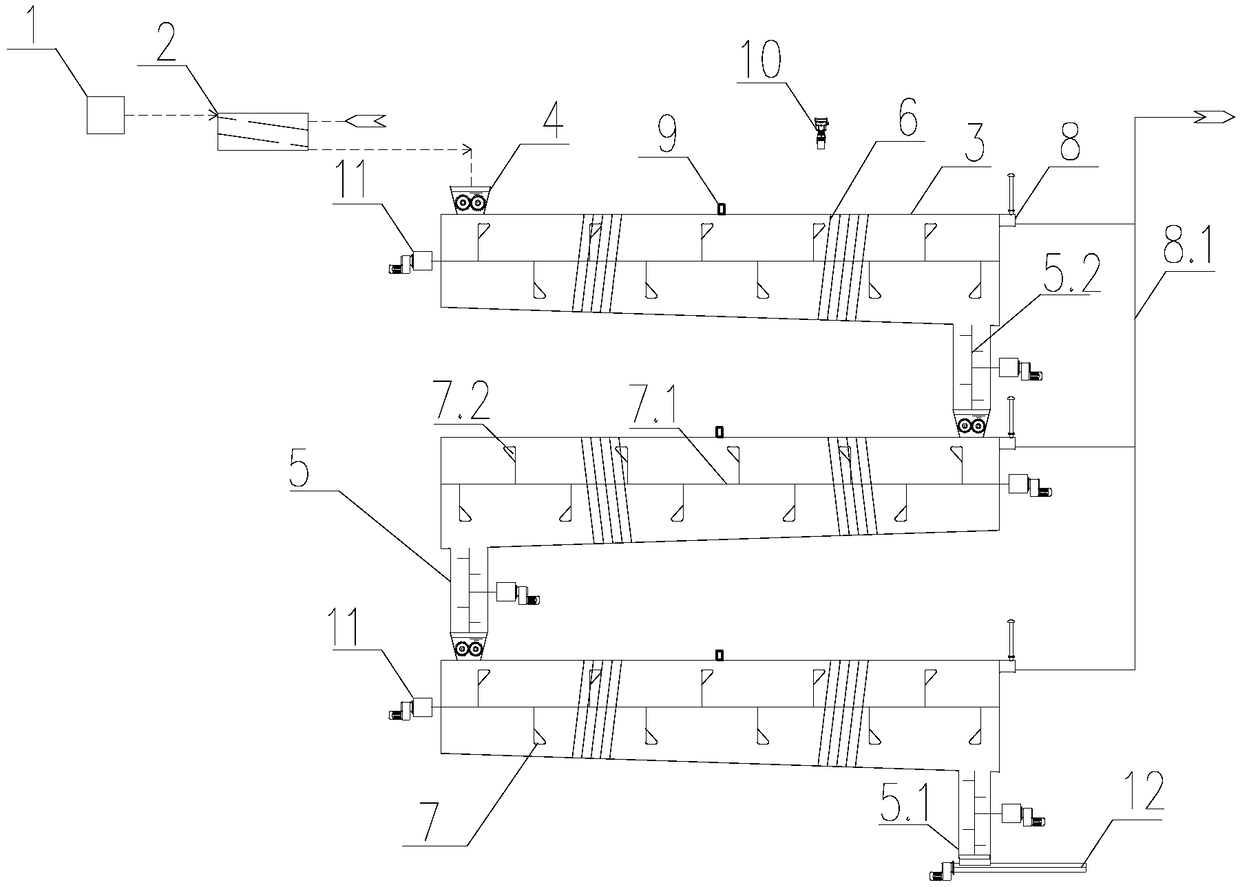

The invention relates to a horizontal push-flow anaerobic dry fermentation device and process for organic waste, and belongs to the technical field of anaerobic fermentation. The concentration of drymatter in a tank can be increased to 30%-60%, heat consumption is effectively reduced, and gas production rate is increased. Water spraying pipes are arranged at a feed end and a discharge end of a pretreatment pool, a feeder is arranged at the discharge end of the pretreatment pool and communicated with feed ports of an anaerobic fermentation tank, discharge ports of the anaerobic fermentation tank are communicated with inlets of pressers, a conveyor belt II is arranged in the position of the pressers and conveys biogas residues discharged from solid outlets of the pressers outwards, a biogasslurry tank conveys biogas slurry into a cow dung tank through a conveying pipe, the cow dung tank is communicated with inlets of the water spraying pipes, and a push-flow stirring shaft is arrangedin the anaerobic fermentation tank. The concentration of the dry matter inside can be increased to 30%-60% by the anaerobic fermentation tank, heat consumption is effectively reduced, the gas production rate is increased and the yield is increased.

Owner:黑龙江乾进能源科技有限公司

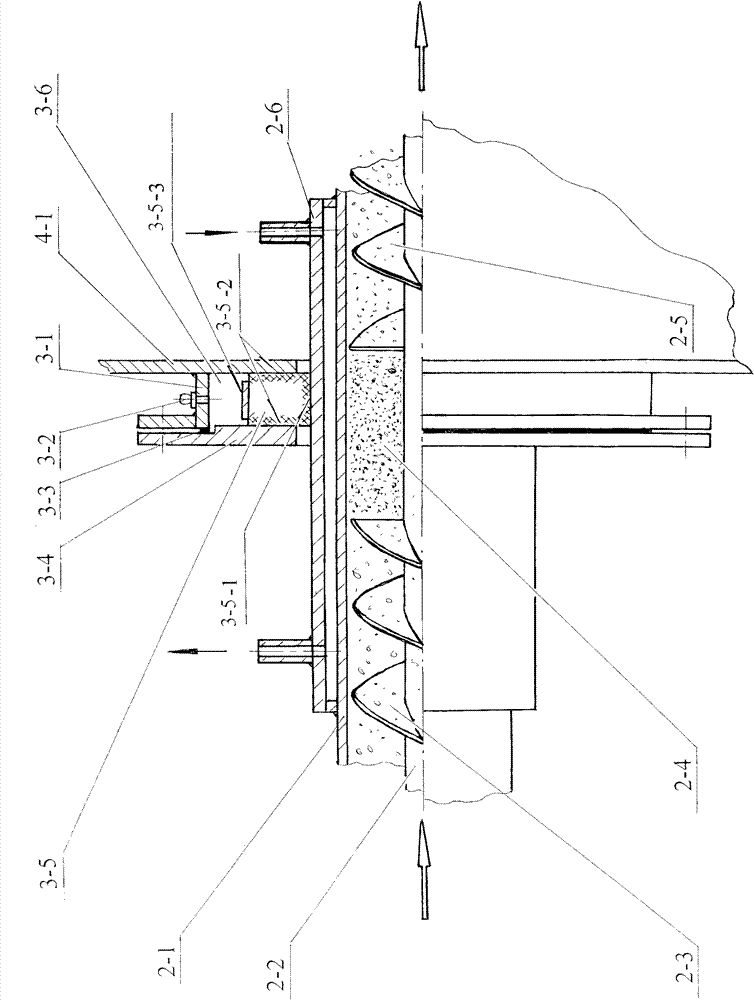

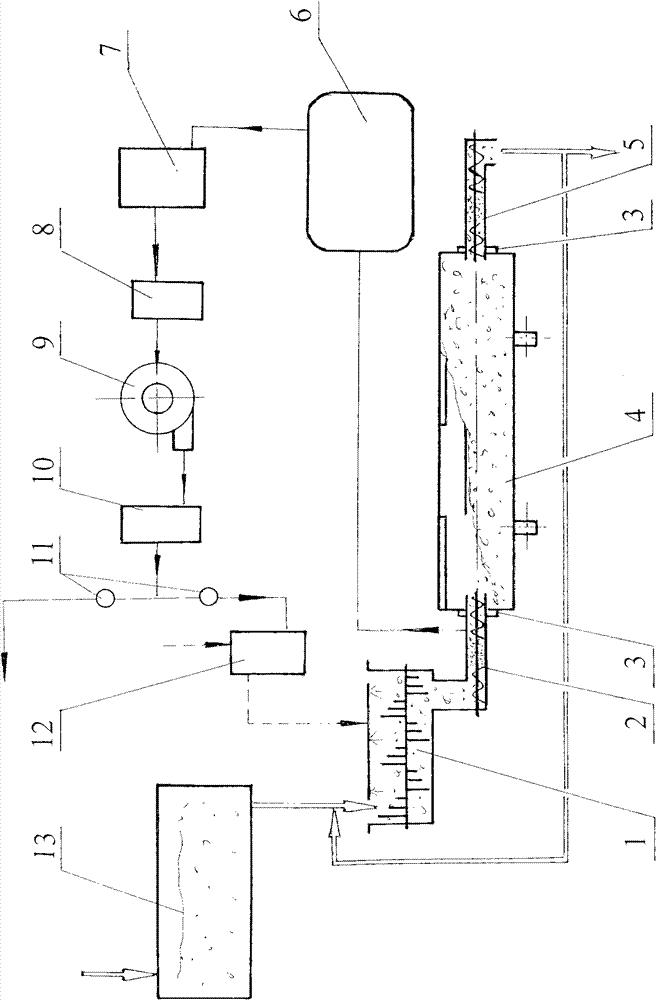

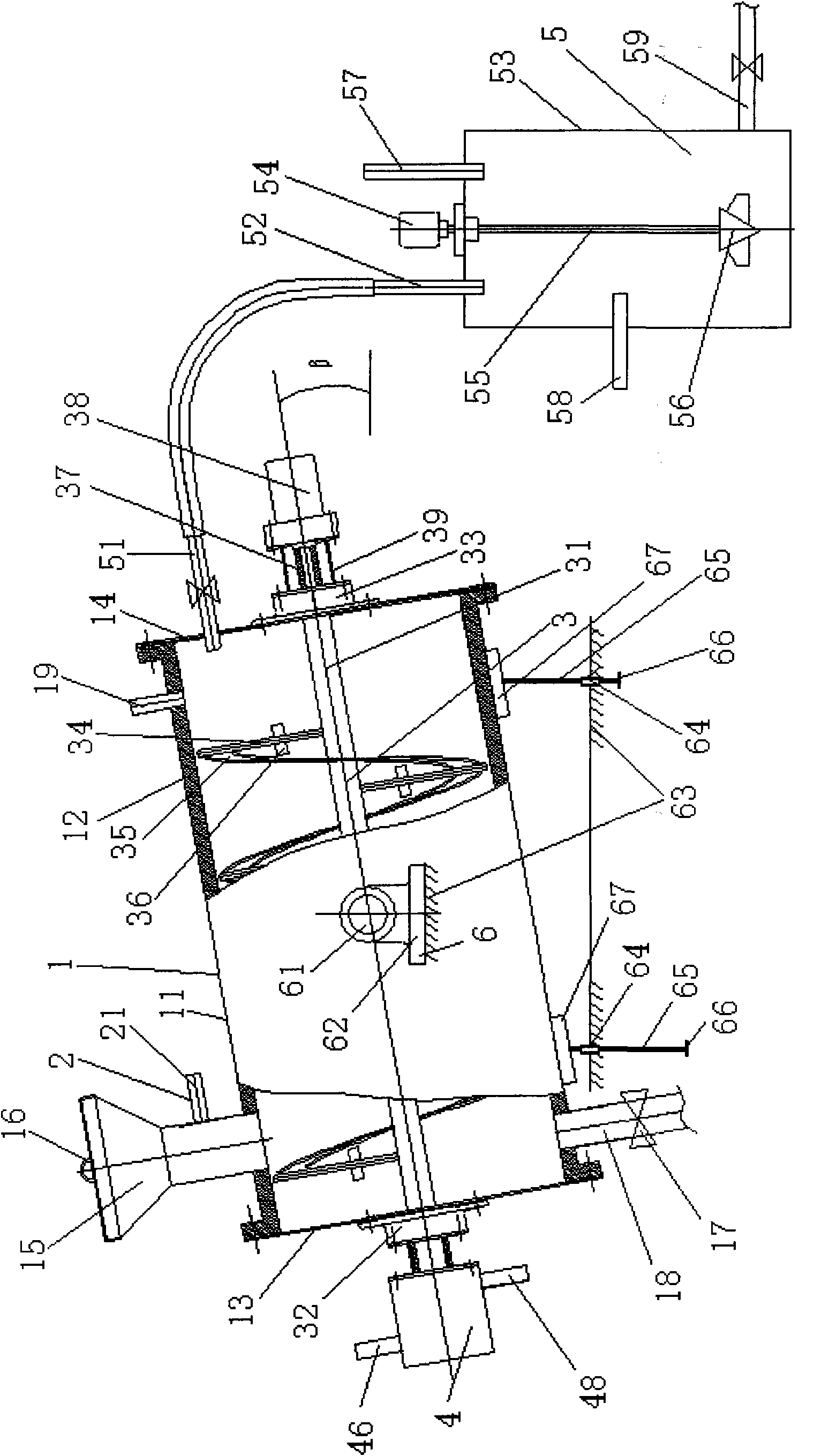

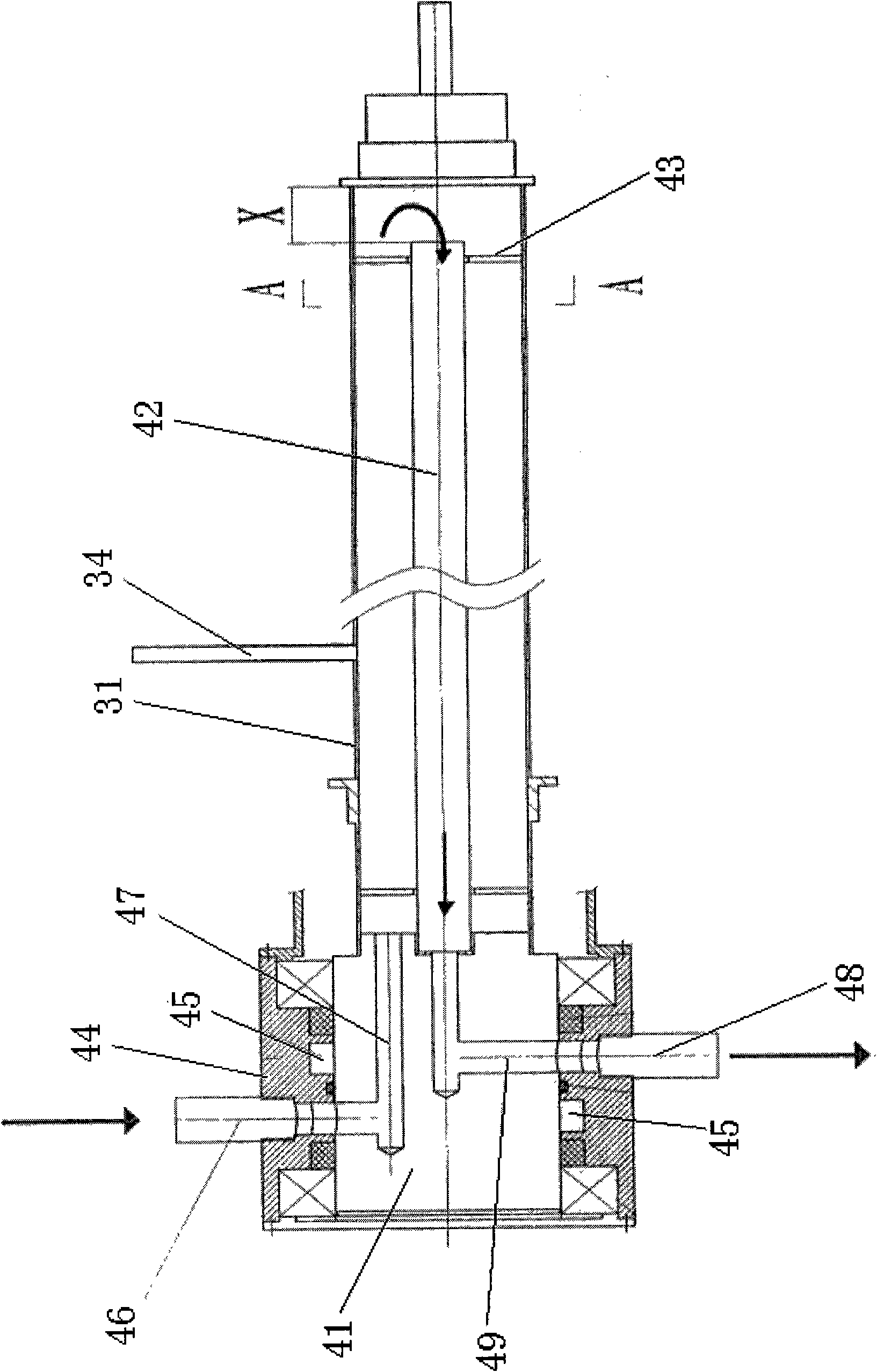

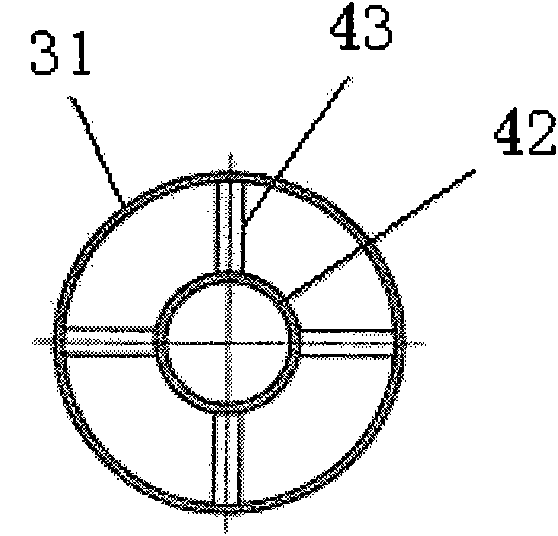

Acidification device and method of high-solid content dry livestock and poultry manure

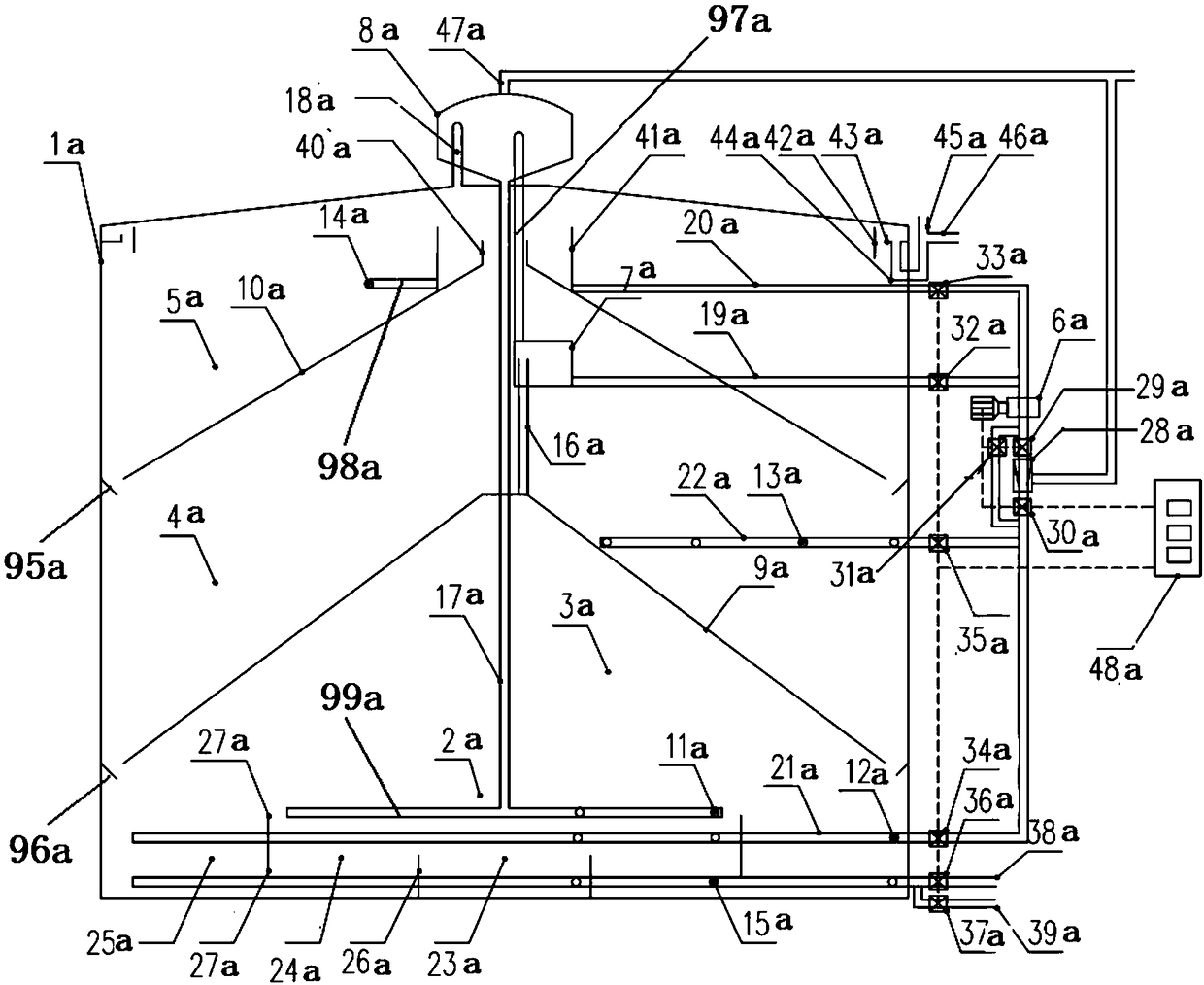

The invention discloses an acidification device and method of high-solid content dry livestock and poultry manure. The acidification device is characterized by comprising a hydrolysis acidification reactor, a biogas slurry refluxing and washing organic acid liquor device, a stirring and acid-squeezing mechanism, a hot water circulation heat transfer system, an acid solution collecting and blending system and an acidification tank angle-regulating mechanism, wherein the inside of the hydrolysis acidification reactor is provided with the stirring and acid-squeezing mechanism; one end of the hollow rotation shaft of the stirring and acid-squeezing mechanism is driven by a reducer motor, the other end of the hollow rotation shaft of the stirring and acid-squeezing mechanism is connected with the hot water circulation heat transfer system; the biogas slurry refluxing and washing organic acid liquor device is connected with the feed hopper of the hydrolysis acidification reactor; the hot water circulation heat transfer system is communicated with the hollow rotation shaft of the stirring and acid-squeezing mechanism, the parts in the hydrolysis acidification reactor perform heat transfer through the stirring and acid-squeezing mechanism; the acid solution collecting and blending system is connected with the hydrolysis acidification reactor, and the spindle heads on both sides of the hydrolysis acidification reactor is used to support the tank angle-regulating mechanism on the rack through a bearing seat. The acidification device disclosed by the invention can be widely used in the acidification treatment process of the livestock and poultry manure.

Owner:CHINA AGRI UNIV

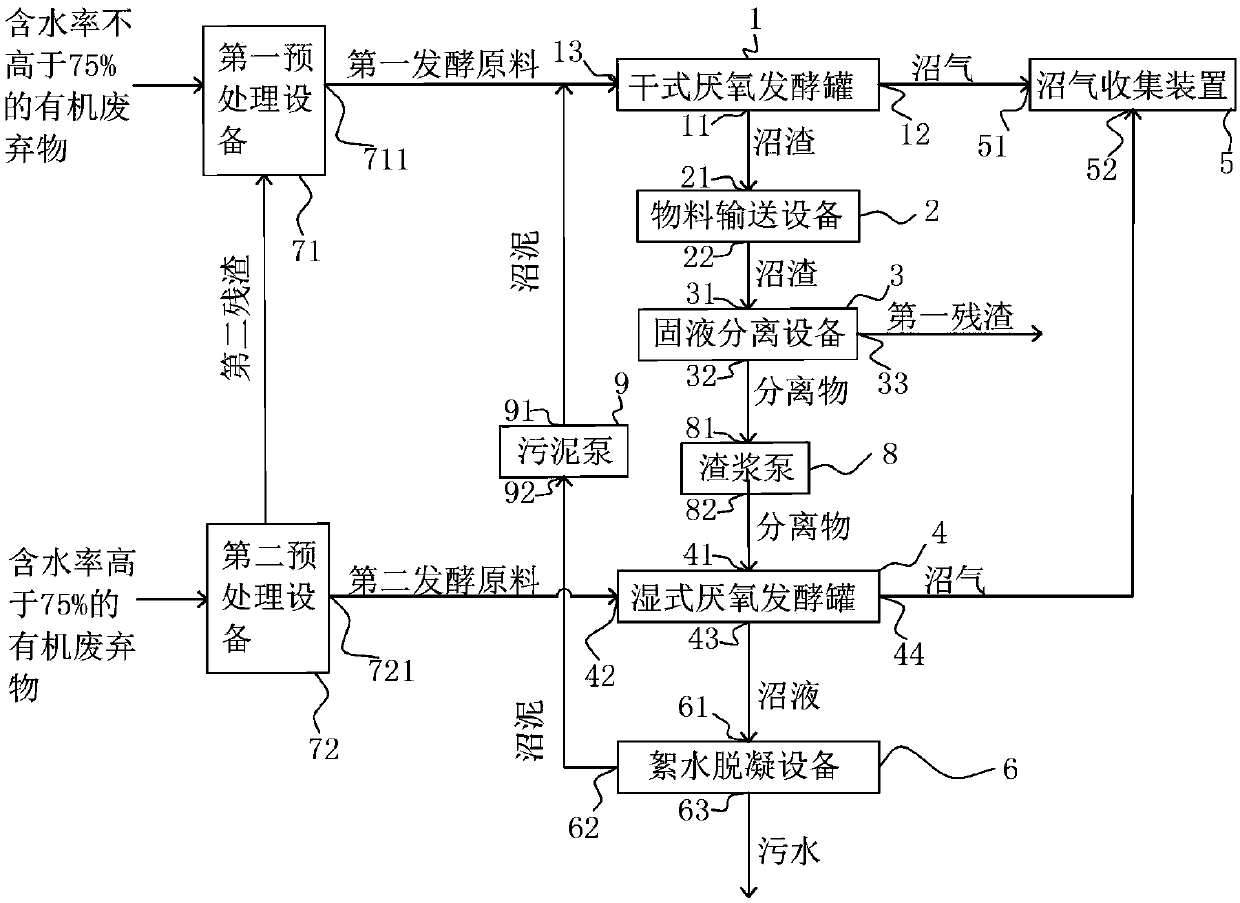

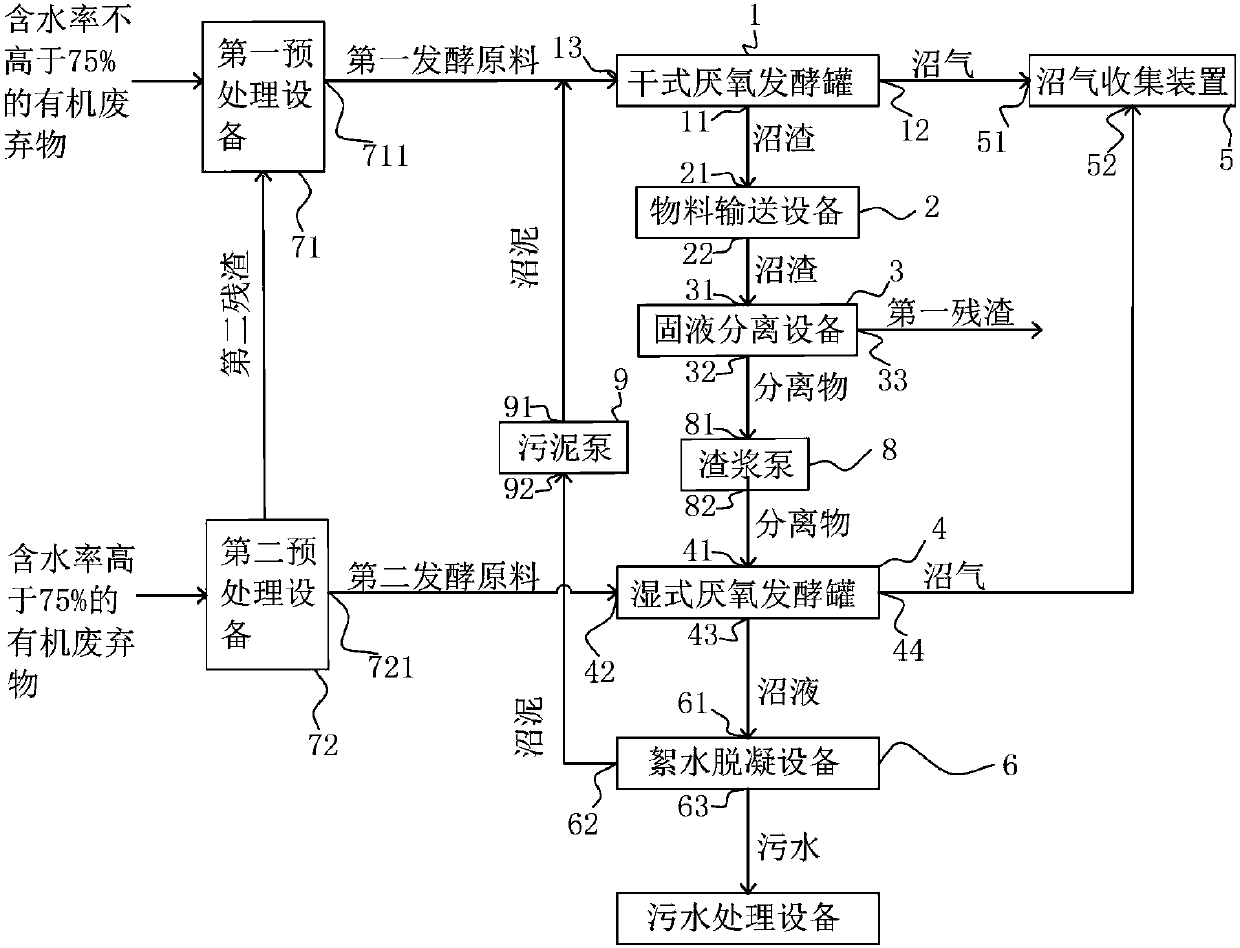

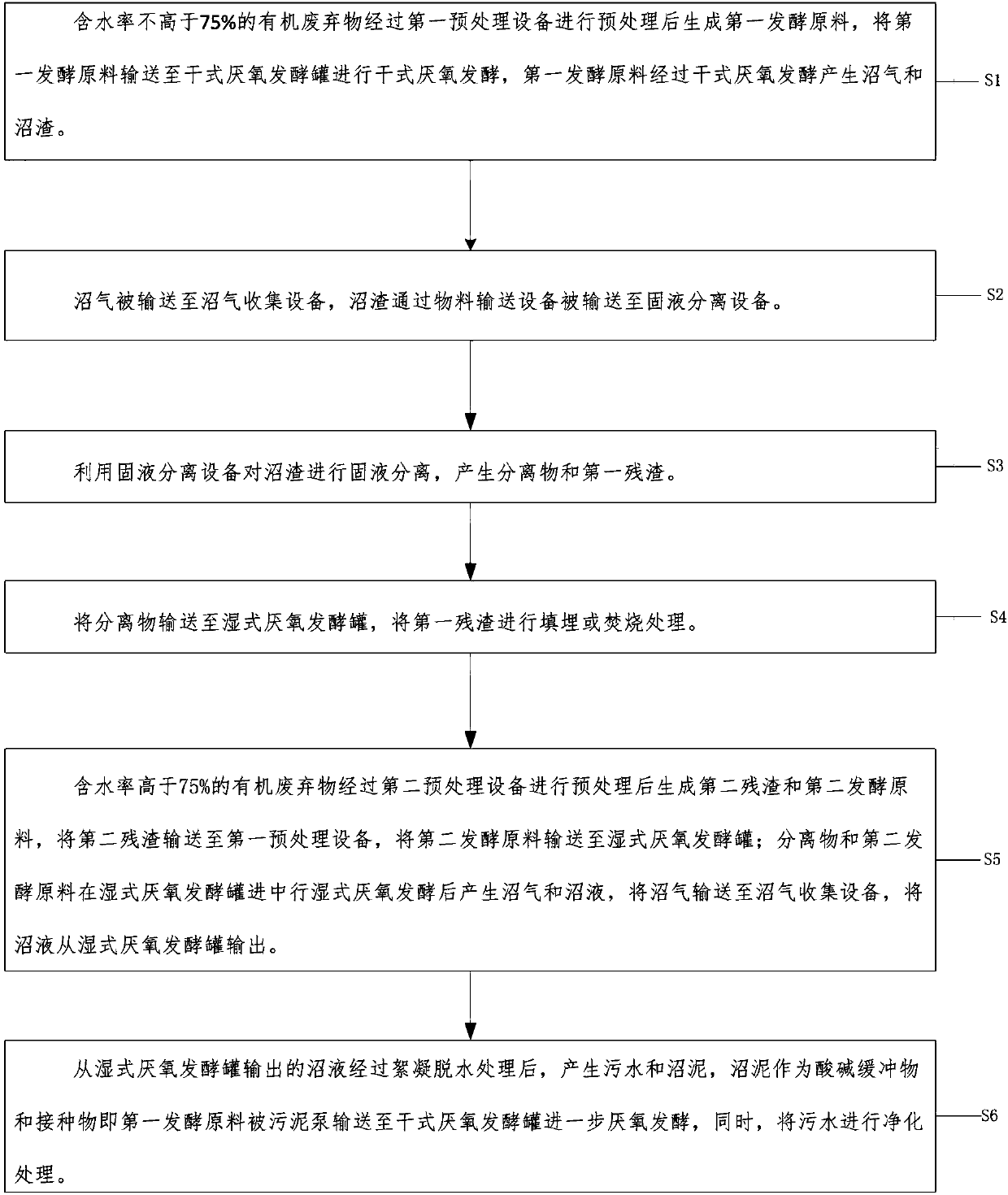

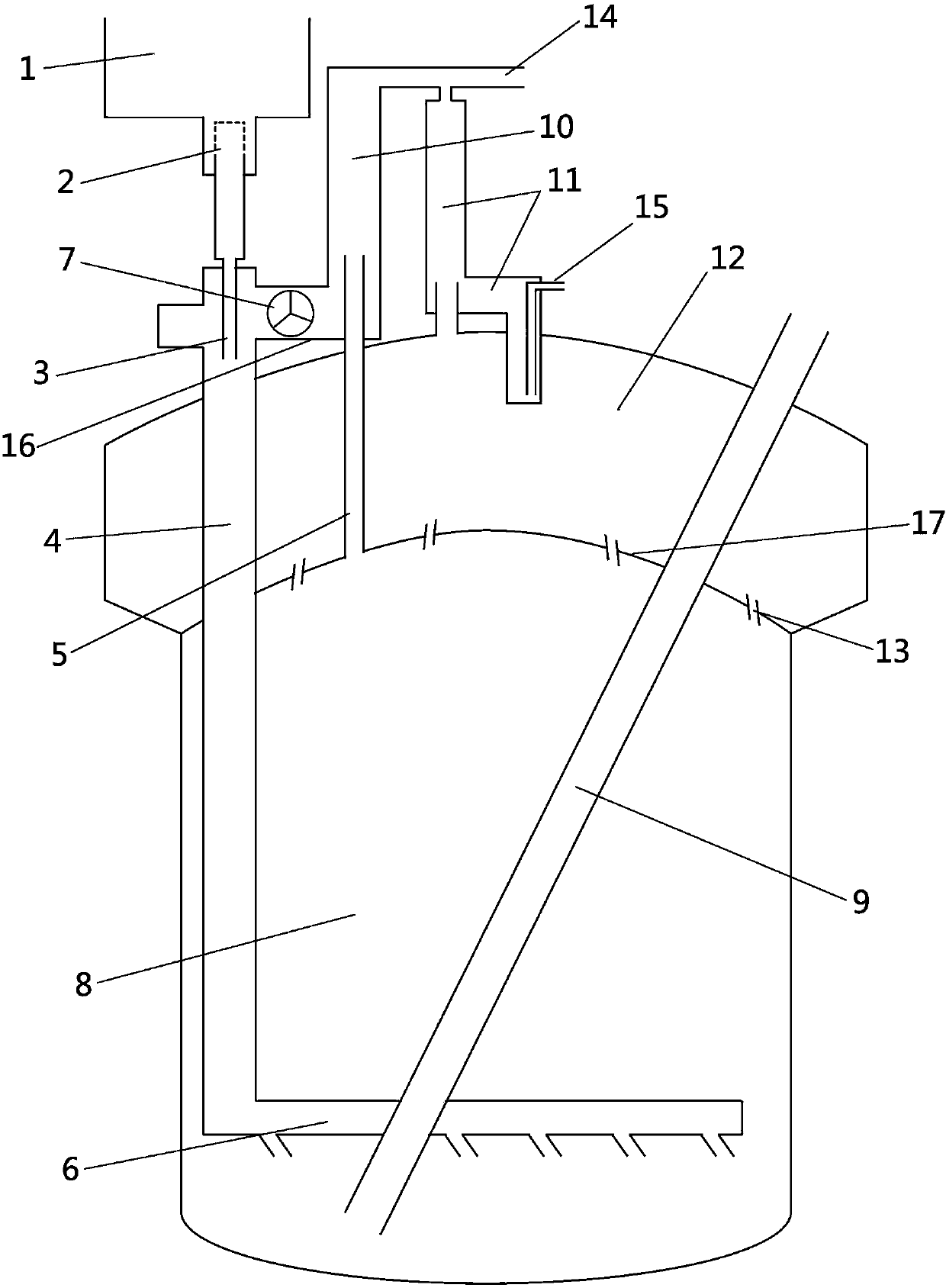

Device and method for dry-wet combined anaerobic fermentation for producing biogas

PendingCN107760589AHigh energy conversion rateEmission reductionBiological substance pretreatmentsGas production bioreactorsFlocculationGeneration rate

The invention discloses a device and a method for dry-wet combined anaerobic fermentation for producing a biogas. The device for dry-wet combined anaerobic fermentation for producing the biogas comprises first pretreatment equipment, a dry-type anaerobic fermentation tank, biogas collection equipment, material conveying equipment, solid-liquid separation equipment, second pretreatment equipment, awet-type anaerobic fermentation tank, flocculation dehydration equipment and a sludge pump, wherein biogas dregs generated from the dry-type anaerobic fermentation tank are subjected to solid-liquidseparation and are fed into the wet-type anaerobic fermentation tank; and biogas slurry generated from the wet-type anaerobic fermentation tank is subjected to flocculation dehydration and is flown back to the dry-type anaerobic fermentation tank. The device for dry-wet combined anaerobic fermentation for producing the biogas, which is disclosed by the invention, is reasonable in design, simple instructure, relatively high in organic matter conversion rate, relatively high in volume gas generation rate, relatively good in material impact resistance and wide in application range.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

STAIC high-efficiency anaerobic reactor

InactiveCN103387286AAvoid cloggingIncreased resistance to outburst loadsWaste based fuelTreatment with anaerobic digestion processesSlurryService efficiency

The invention discloses an STAIC high-efficiency anaerobic reactor. The STAIC high-efficiency anaerobic reactor is characterized in that the heights and diameters of two superposed reaction chambers are different from the height and the diameter of a TAIC anaerobic reactor, the diameter ratio of an upper tank to a lower tank is 5:4, the height ratio of the upper tank to the lower tank is 1:4, the height of the whole reactor ranges from 12 to 30 meters, and the high-diameter ratio of the whole reactor is 3 to 6; an adjustable speed circulating pump is arranged on a sludge return pipe; an automatic traction backflow circulator is arranged on a feed pipe; a protective cover is arranged at a feed pipe orifice; a biogas slurry and biogas residue overflow pipe is higher than the return pipe; a back washing switch is arranged on the feed pipe. The STAIC high-efficiency anaerobic reactor has the advantages that the volumetric gas production rate is high, the fermentation rate of the STAIC high-efficiency anaerobic reactor can be twice of that of the TAIC reactor, the area occupied by the STAIC high-efficiency anaerobic reactor is less than that occupied by the TAIC reactor, the capital investment is substantially reduced, the adaptability is widened, as a feed liquid in a backflow tank can be automatically dragged, the blockage of the feed liquid in the pipeline is effectively avoided, the service efficiency is improved, and more importantly, the anti-rush-out load of the tanks is increased.

Owner:秦家运

Methane fermentation device for straw

ActiveCN103103117BPrevent floating crustsIncrease concentrationBiological substance pretreatmentsGas production bioreactorsLiquid slagCircular cone

Owner:四川中沼生物能源检测有限责任公司

Method for improving efficiency of producing methane through kitchen waste high-concentration anaerobic digestion

ActiveCN105400825AImprove the efficiency of anaerobic digestionIncrease productionWaste based fuelSludge processingHigh concentrationAlkalinity

The invention discloses a method for improving efficiency of producing methane through kitchen waste high-concentration anaerobic digestion and belongs to the technical field of kitchen waste treatment. According to the method, pretreated kitchen waste is smashed and then mixed with anaerobic activated sludge to cultivate enterobacter cloacae and obtain bacterial liquid, the solid concentration and alkalinity of the mixture of the kitchen waste and the anaerobic activated sludge are blended, and enterobacter cloacae liquid is added and mixed uniformly to carry out anaerobic digestion. The method can ensure that the kitchen waste can ferment on the high-concentration condition, and meanwhile the high volume gas production rate can be obtained.

Owner:TSINGHUA UNIV

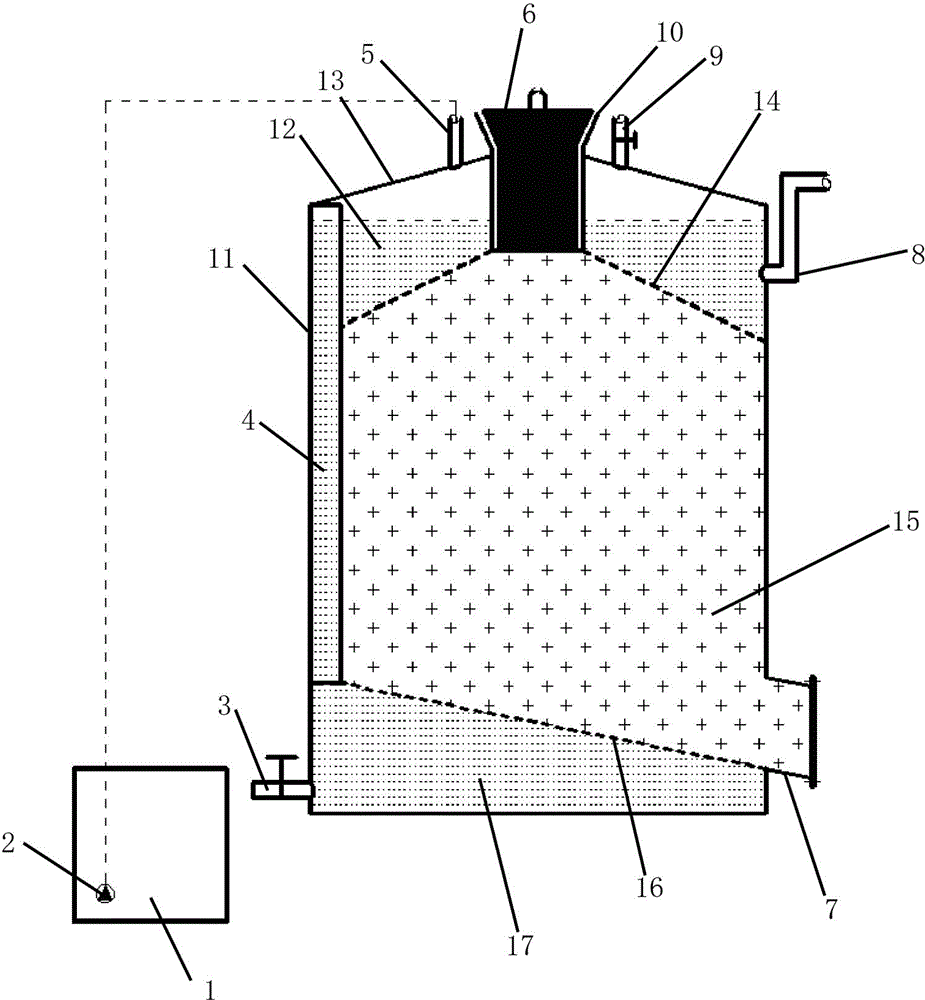

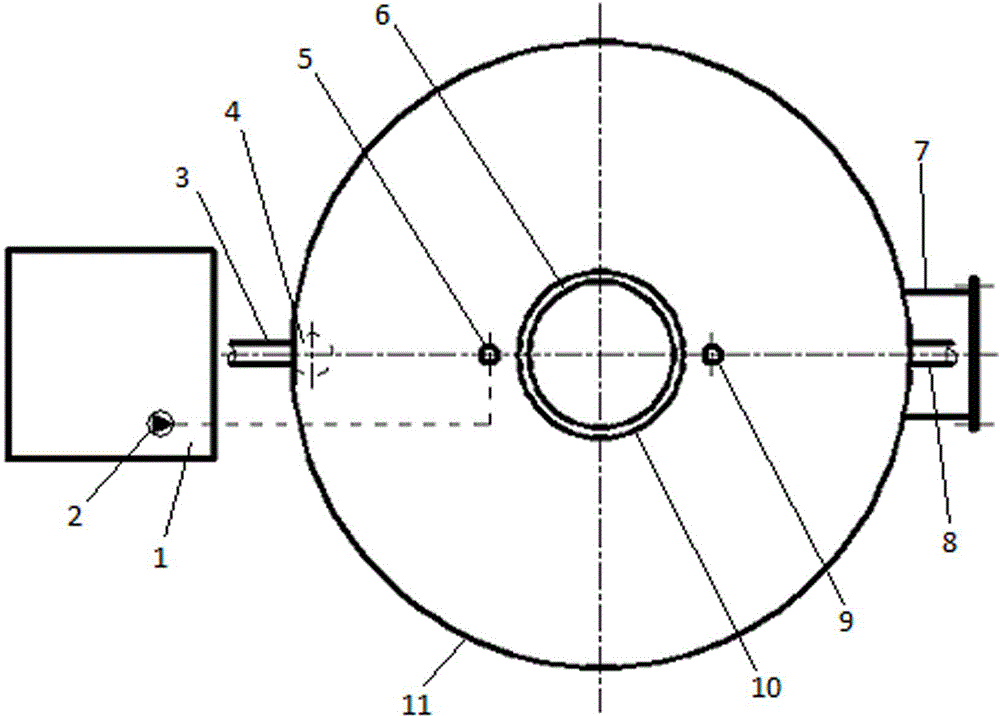

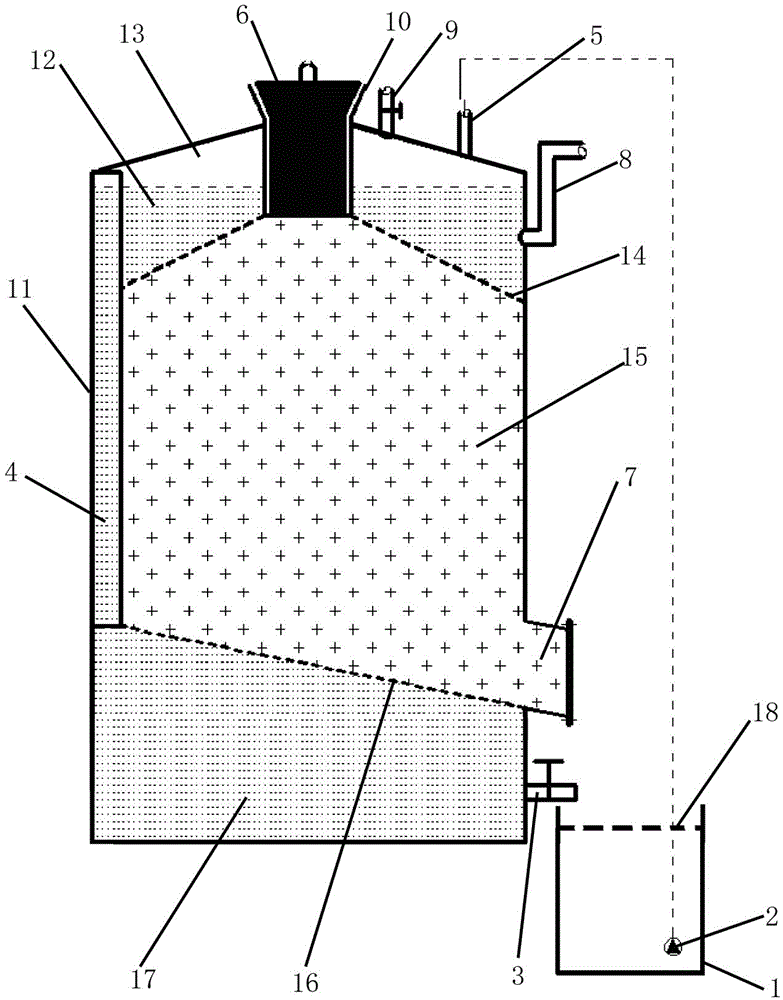

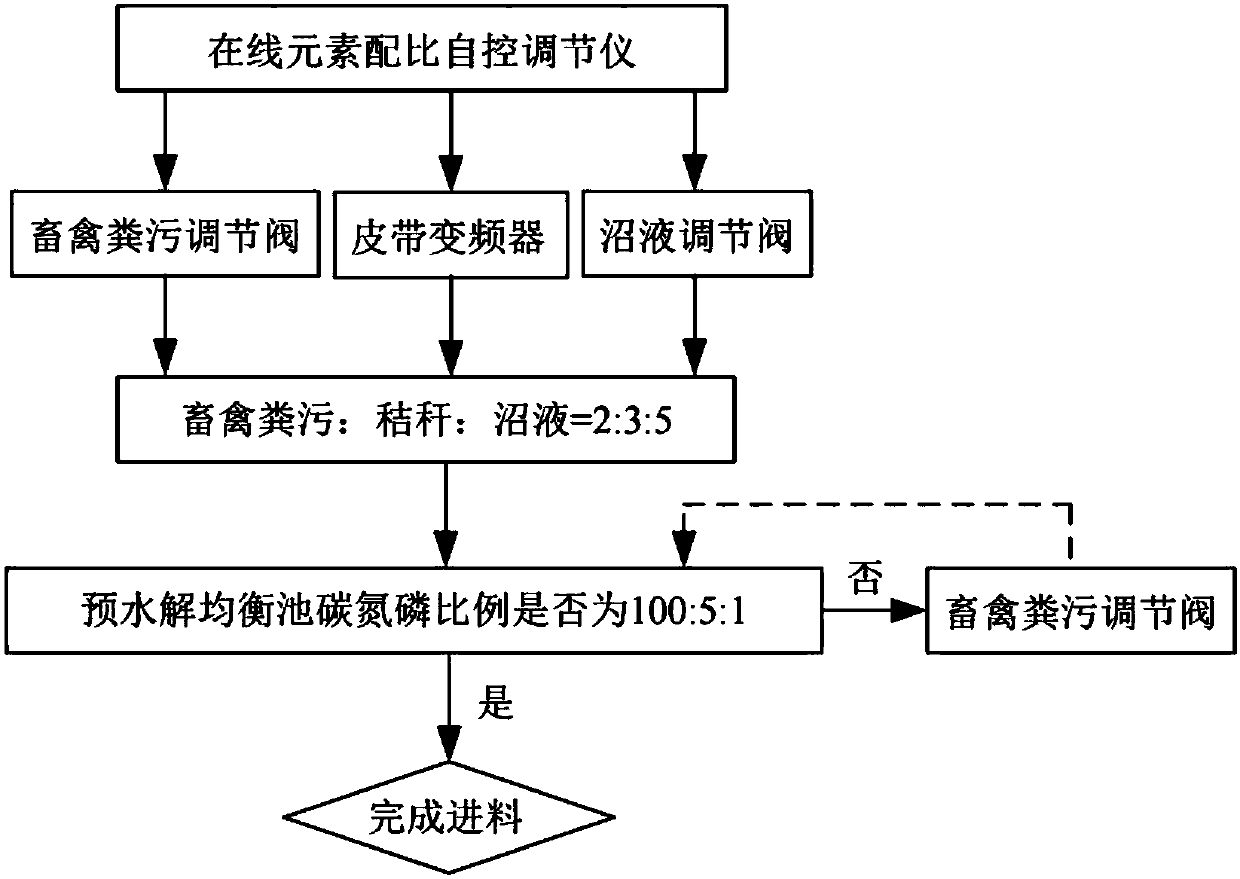

Device for preparing biogas by continuous treatment of straw and livestock and poultry feces and biogas preparation method

PendingCN107841457ASolve pollutionSolve environmental problemsBioreactor/fermenter combinationsBiological substance pretreatmentsAnimal fecesBiogas production

The invention discloses a device for preparing biogas by continuous treatment of straw and livestock and poultry feces and a biogas preparation method. The device comprises a sedimentation desanding pool, a straw silage pool, a pre-hydrolysis balancing pool, a feed buffer tank and an anaerobic fermentation tank. The sedimentation desanding pool and the straw silage pool are connected to the pre-hydrolysis balancing pool; the pre-hydrolysis balancing pool is connected to the feed buffer tank; the feed buffer tank is connected to a feeding port of the anaerobic fermentation tank, a discharging port at the bottom of the anaerobic fermentation tank is connected to the pre-hydrolysis balancing pool, and the top of the anaerobic fermentation tank is provided with a biogas outlet; the anaerobic fermentation tank is equally divided into 4 small compartments by inclined accelerating guide plates. The device for preparing the biogas by continuous treatment of the straw and livestock and poultryfeces cooperates with the biogas preparation method; after the straw and the livestock and poultry feces with backflow biogas slurry are subjected to reasonable carbon, nitrogen and phosphorus proportioning, the volume biogas production rate is high, the methane content of the biogas is high, and the biogas slurry treatment load is reduced.

Owner:山东恒力新能源工程有限公司

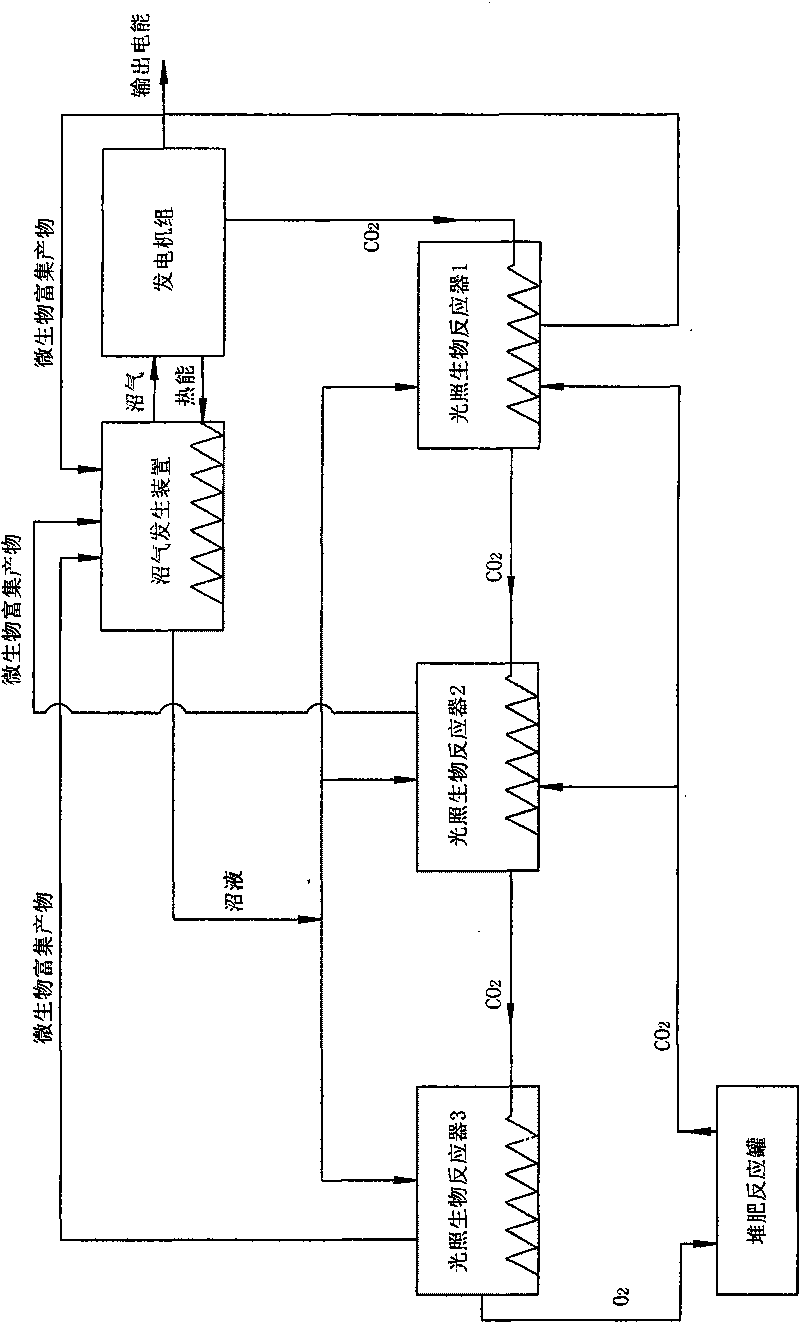

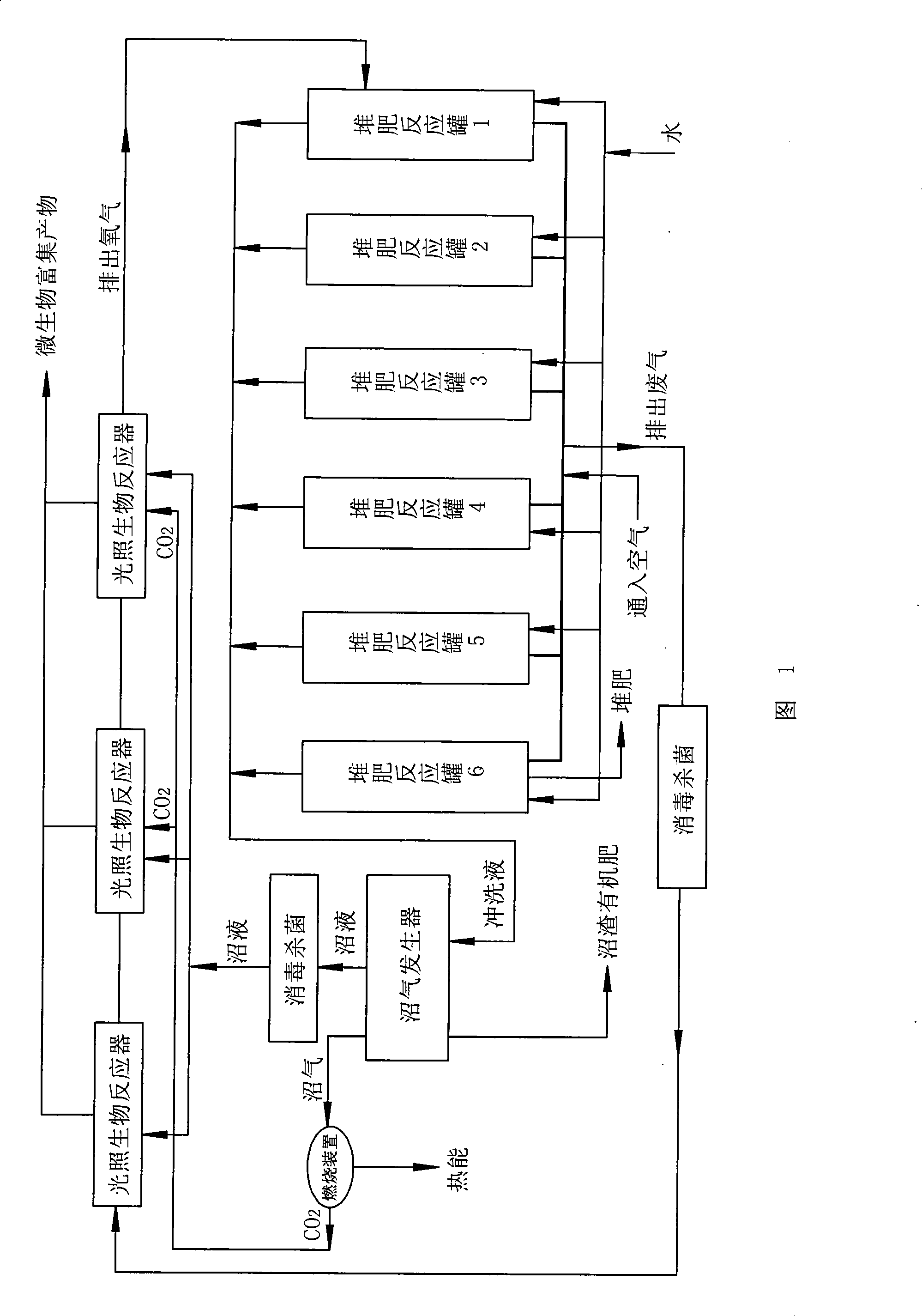

Microorganism power generating method by utilizing carbon source in a recycling way

InactiveCN101749106AGood breeding conditionsFull of nutritionInternal combustion piston enginesWaste based fuelNutrient solutionInternal combustion engine

The invention discloses a microorganism power generating method by utilizing carbon source in a recycling way, comprising the following steps: a) nutritional type microorganisms of light are placed in an illumination bioreactor, liquid nutrient solution is added, carbon dioxide gas is introduced, the microorganism enrichment products at the upper part of the floating illumination bioreactor are output; b) the microorganism enrichment products are input in a methane generator, the generated methane liquid is input in the illumination bioreactor, and the generated methane is input in a combustion motor in a generator set for burning; c) the output carbon dioxide gas is input to the illumination bioreactor. In the method, the luminous energy nutritional type microorganisms are used as primary material for marsh gas power generation, non-renewable resources are not consumed, and harmful gas is not exhausted. By adopting the way of circulating utilization, all products in the process flow can be used.

Owner:刘爱平

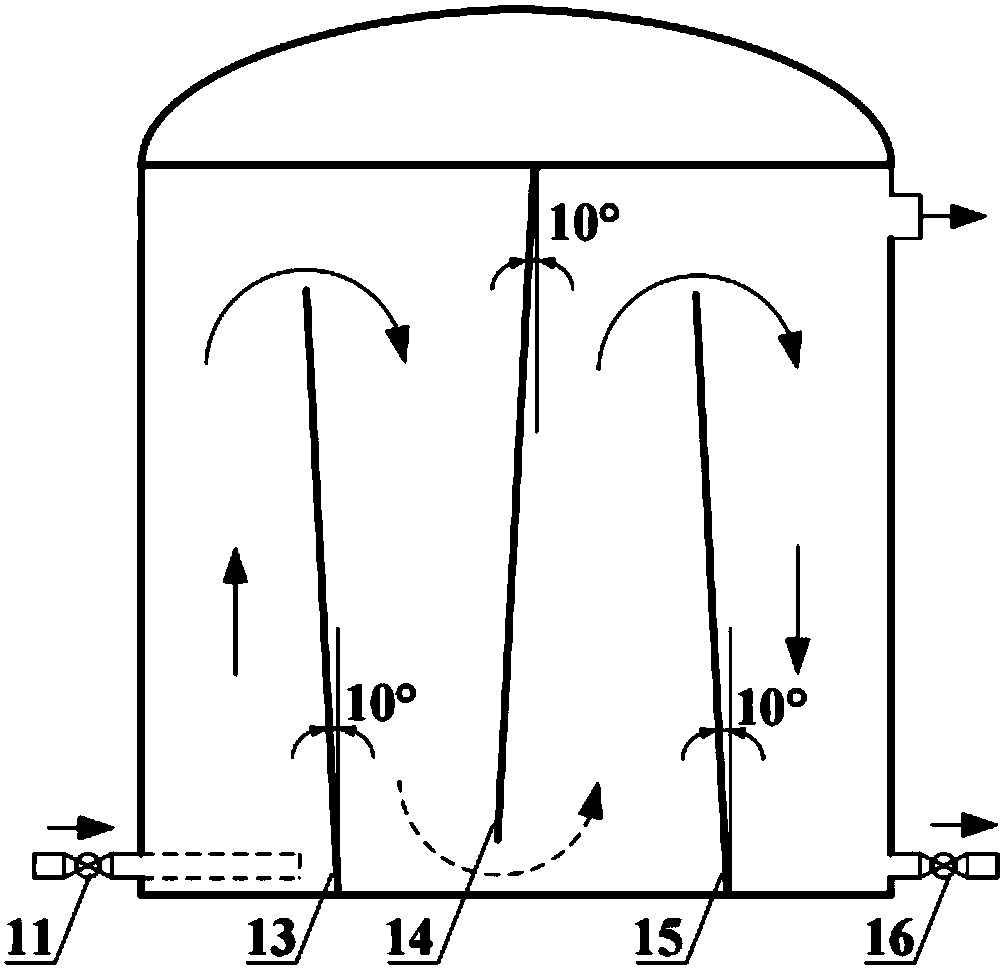

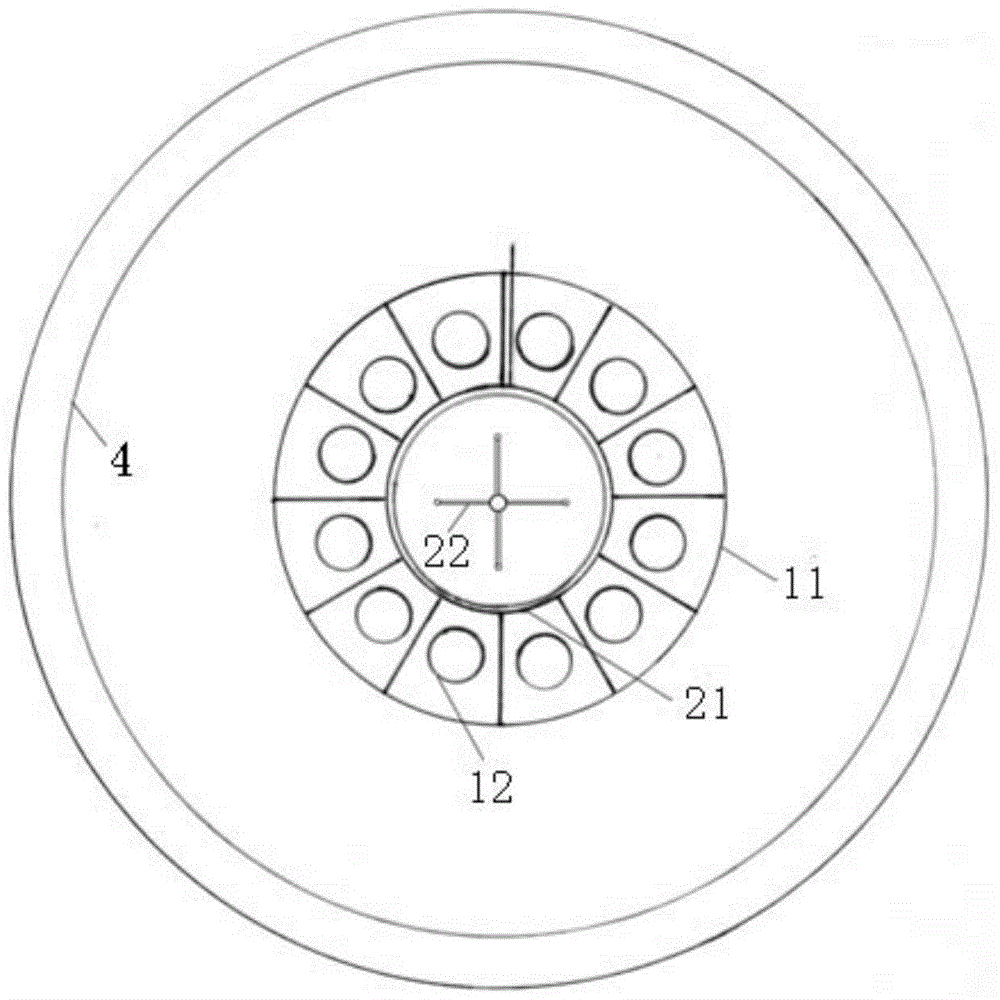

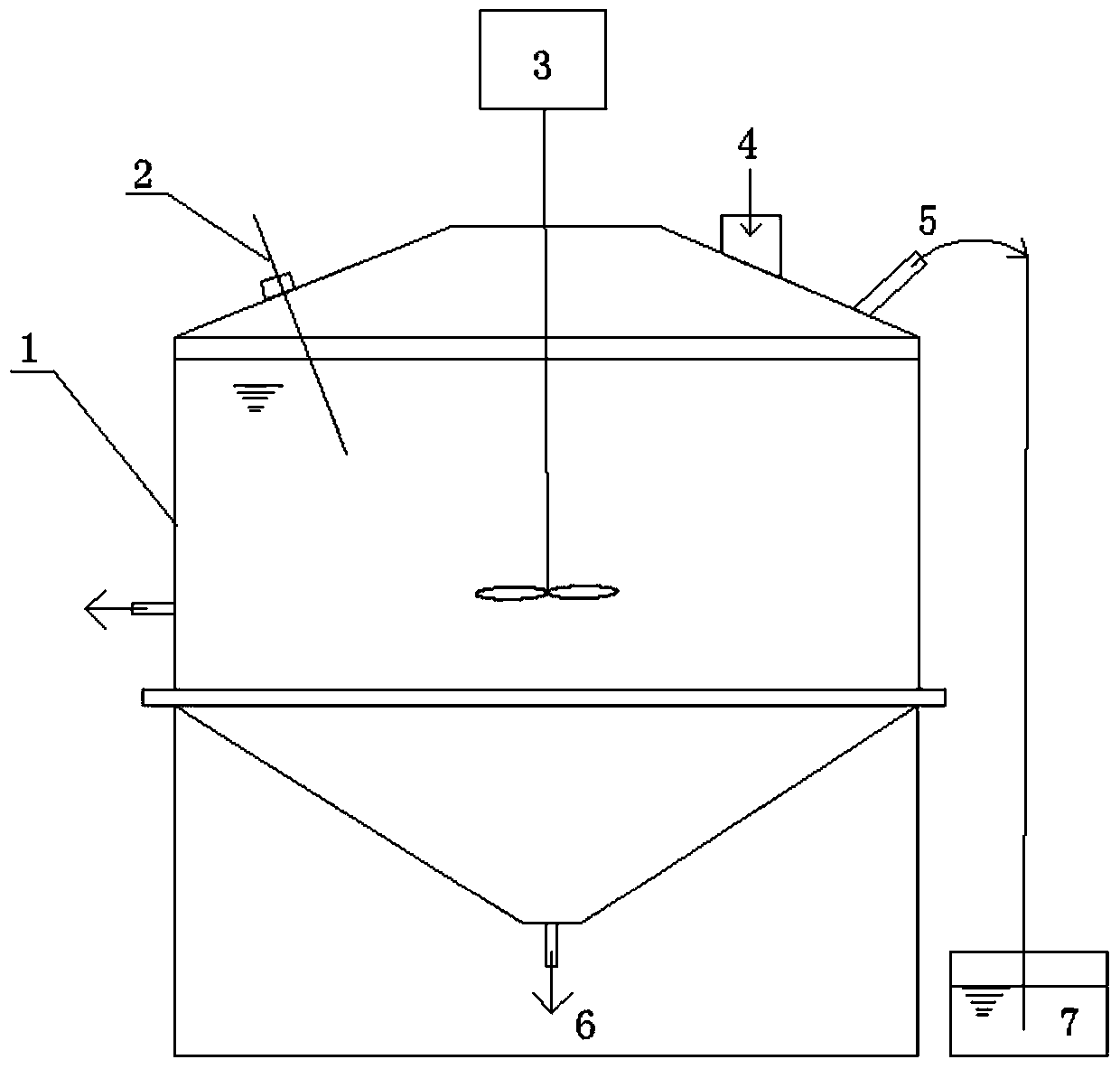

High-concentration liquid multi-component raw material anaerobic bacterium-rich fermentation apparatus and technology thereof

InactiveCN104611195AIncrease volumetric organic loading ratioHigh activityGas production bioreactorsWaste based fuelBiotechnologyHigh concentration

The invention discloses a high-concentration liquid multi-component raw material anaerobic bacterium-rich fermentation apparatus and a technology thereof, and belongs to the biotechnical field. The apparatus is composed of an anaerobic bacterium enrichment tank and an anaerobic reactor. The anaerobic bacterium enrichment tank is divided into a complete mixing zone, a strain enrichment zone and a settling zone from bottom to top, wherein the complete mixing zone is provided with a cyclone water distributor and a lateral stirrer, the strain enrichment zone is provided with a filler, and the settling zone is provided with a three-phase separator and a sludge discharging tube. The filler can effectively improve the concentration of flora as a microbial carrier; the lateral stirrer induces water flow disturbance, and allows excess microbes attached on the filler to be washed down and to be fully mixed with a fermentation raw material in order to promote the degradation of the fermentation raw material; the three-phase separator is used to separate biogas, a fermentation liquid and granular sludge; and the sludge discharging tube is used for conveying high concentration anaerobic bacteria to the anaerobic reactor. The anaerobic bacterium enrichment tank is constructed in the invention in order to improve the concentration and activity of the florae, widen the adaptability of the fermentation raw material, promote the degradation of the fermentation raw material and increase the volumetric organic load and the volumetric gas productivity.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

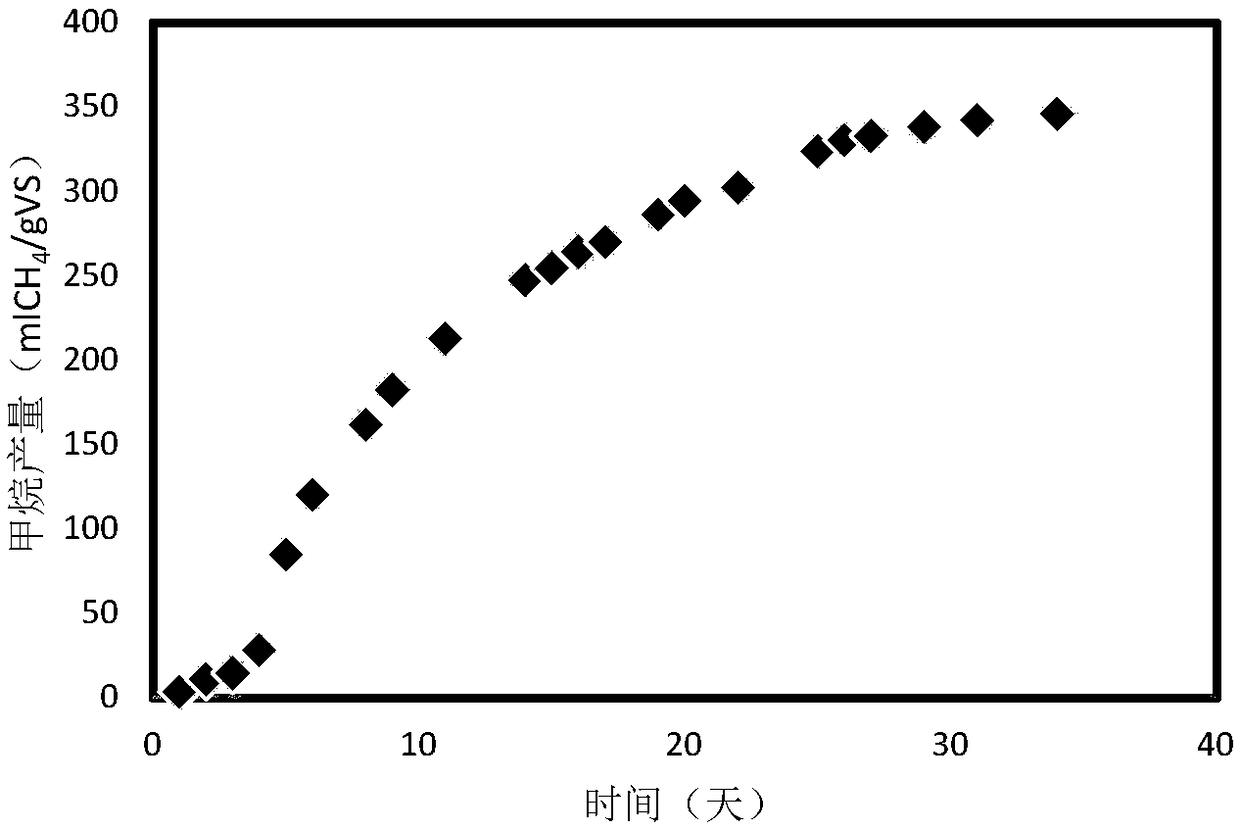

Method for improving anaerobic digestion gas-production performance of maize straws through directional acidification pretreatment

ActiveCN104593430AHigh activityPromote degradationWaste based fuelFermentationMethanationResource utilization

The invention discloses a method for improving the anaerobic digestion gas-production performance of maize straws through directional acidification pretreatment, and belongs to the field of efficient resource utilization of maize straws. The method comprises the following steps: carrying out pretreatment on maize straws by using sodium hydroxide; acidifying the maize straws, and adding activated sludge into the pretreated maize straws, wherein relatively, 10-50 g of TS activated sludge is added into 52 g of TS maize straws; adding tap water until the tap water accounts for 80% of the total volume of a reaction container, mixing the obtained object, filling nitrogen into the reaction container, and hermetically fixing the container in a shaking table, wherein the temperature of the shaking table is kept at 40+ / -2 DEG C; measuring the pH value by using a pH meter every time, and when the pH value is less than 5.5, stopping acidifying; and after methanation startup is completed, by taking an acidified discharged material as a raw material, carrying out feeding and discharging once a day, wherein a fed material and the discharged material are same in volume, and the HRT (hydraulic retention time) is 40 days. According to the invention, the separation of an acidification stage and a methanation stage in biological sciences is realized, and the effects of acidification bacteria groups and methane-producing bacteria groups in respective stage are enhanced, thereby facilitating the stable and efficient operation of an acidification phase and a methane-producing phase, and greatly improving the biodegradability and gas production performance of maize straws.

Owner:BEIJING UNIV OF CHEM TECH

High-ammonia-nitrogen organic waste dry biogas fermentation device and fermentation method thereof

PendingCN108913541ALess investmentEasy to operateGas production bioreactorsWaste based fuelHigh concentrationSemi solid

The invention discloses a high-ammonia-nitrogen organic waste dry biogas fermentation device and a fermentation method thereof. The dry biogas fermentation device comprises a horizontal fermentation tank body. A feeding channel, a fermentation chamber and a discharging channel are arranged in the horizontal fermentation tank body. The bottom portions of the feeding channel and the discharging channel separately communicate with the fermentation chamber; a plurality of storage and placing mechanisms for placing additives are fixedly arranged at the top of the fermentation chamber in the lengthdirection of the fermentation chamber; and the top of the fermentation chamber communicates with a biogas pipe. After the high-ammonia-nitrogen organic waste dry biogas fermentation device and the fermentation method thereof are adopted, solid and semi-solid organic wastes are directly fermented by biogas without water dilution or pretreatment and sand removal. Tolerance to high concentration ammonia nitrogen and high gas production efficiency under high ammonia nitrogen are achieved. Less heat is needed for heating, and odor emission is low.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Four-in-one biogas fermentation device and method

ActiveCN104694374AIncrease profitShorten degradation timeBioreactor/fermenter combinationsBiological substance pretreatmentsFiberSludge

The invention relates to a four-in-one biogas fermentation device and method. The device comprises a first-stage dry fermentation mechanism, a second-stage wet fermentation mechanism, a folding gas storage bag, a sunlight greenhouse and a solar water heater, wherein the first-stage dry fermentation mechanism comprises an annular dry fermentation tank which is filled with a feed liquid and is arranged in the sunlight greenhouse, a net box which is filled with a material and is soaked in the feed liquid, and a water seal cover which is hermetically arranged at the top of the net box; the second-stage wet fermentation mechanism comprises a wet fermentation tank which is communicated with the dry fermentation tank, a heat exchanger which is arranged in the wet fermentation tank, and a biological membrane which is fixed in the wet fermentation tank; a gas guide pipe is arranged at the top part of the wet fermentation tank; the folding gas storage bag is arranged at the top part of the wet fermentation tank and is communicated with the gas guide pipe; and the solar water heater is arranged at the top part of the sunlight greenhouse and is used for supplying circulating hot water to the heat exchanger. By using the four-in-one biogas fermentation device and the method provided by the invention, the problem that a sludge pump is blocked easily is solved, and by combining the use of solar energy and the sunlight greenhouse, energy sources are saved, the degradation time of a fiber material is shortened, the utilization ratio of a fermentation raw material is improved, the content of methane in biogas is improved, and the comprehensive utilization ratio of biogas residues and biogas slurry is increased.

Owner:李世峰 +2

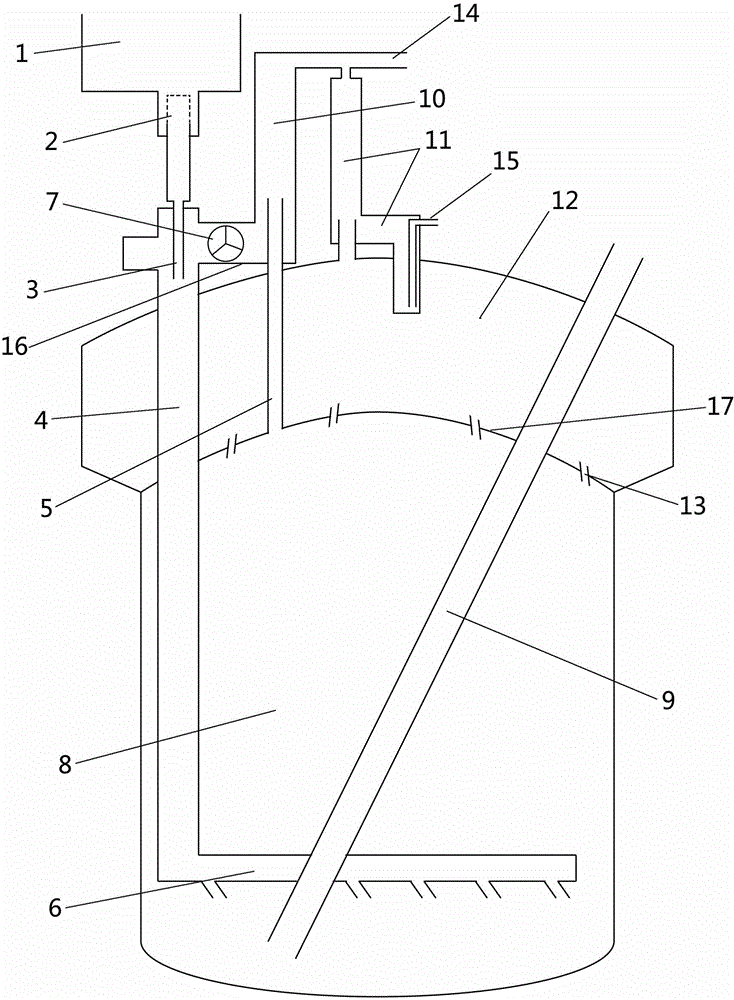

Straw and excrement mixed anaerobic fermentation reactor and biogas fermentation process thereof

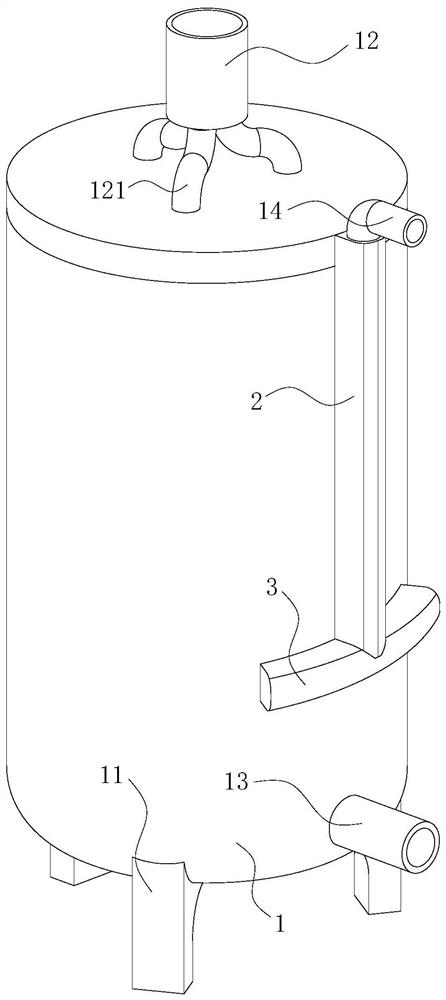

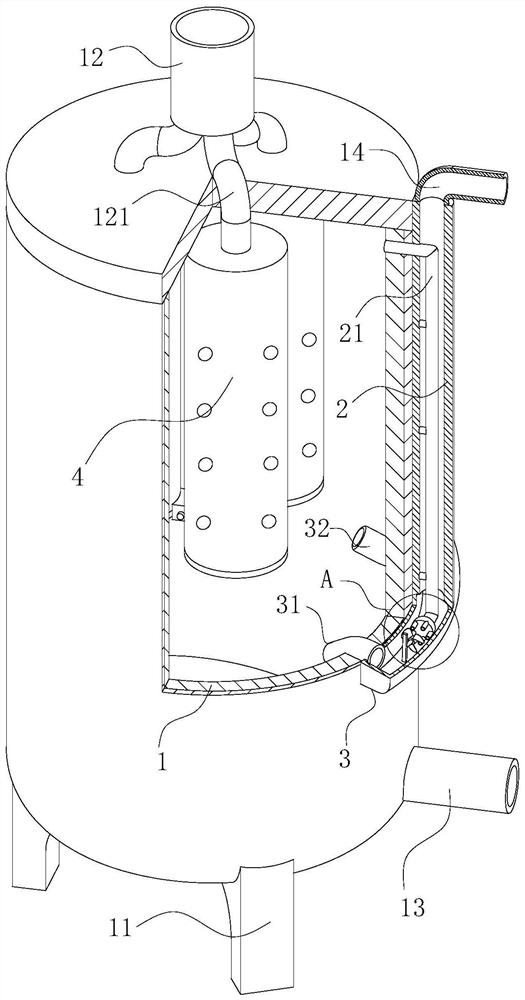

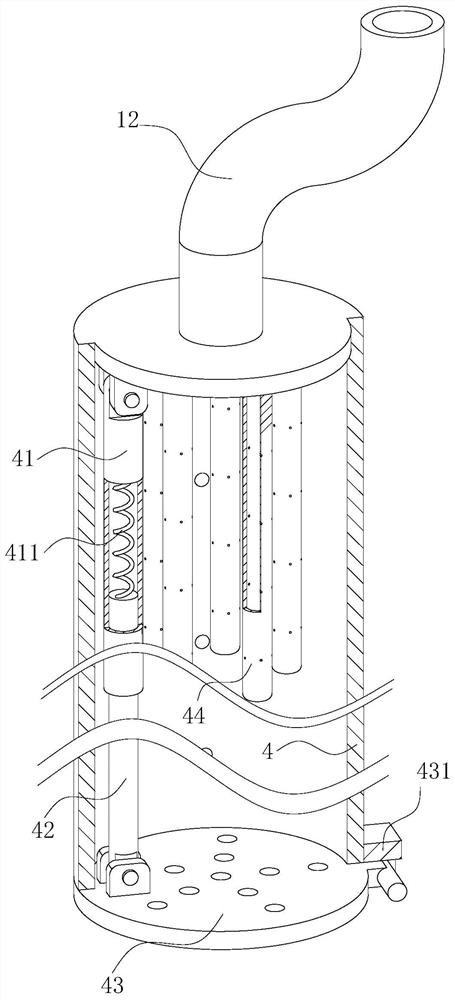

InactiveCN113174314AReduce layeringEnhance heat and mass transferBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFermentation

The invention belongs to the technical field of anaerobic fermentation, and particularly relates to a straw and excrement mixed anaerobic fermentation reactor and a biogas fermentation process thereof. The reactor comprises a tank body and supporting legs; the supporting legs are fixedly mounted on the lower surface of the tank body; a feeding hole is fixedly formed in the upper surface of the tank body; a discharge hole is fixedly formed in the side surface of the tank body; a vertical pipe and a transverse pipe are fixedly mounted on the side surface of the tank body; the lower end of the vertical pipe is fixedly connected with the transverse pipe, and the vertical pipe and the transverse pipe communicate with each other; an air guide pipe is fixedly mounted in the vertical pipe through a bracket; the lower end of the air guide pipe extends into the transverse pipe, and the upper end of the air guide pipe enters the tank body; the two ends of the transverse pipe are communicated with the inner space of the tank body; and an air outlet is fixedly formed in the upper surface of the vertical pipe. The reactor is simple in structure, the biogas slurry in the tank body is stirred in the biogas discharging process, energy consumption is reduced, and meanwhile, the fermentation efficiency is improved and the volume gas production rate is increased through dry and wet two-step fermentation.

Owner:巢湖市鑫兴农能源环保有限公司

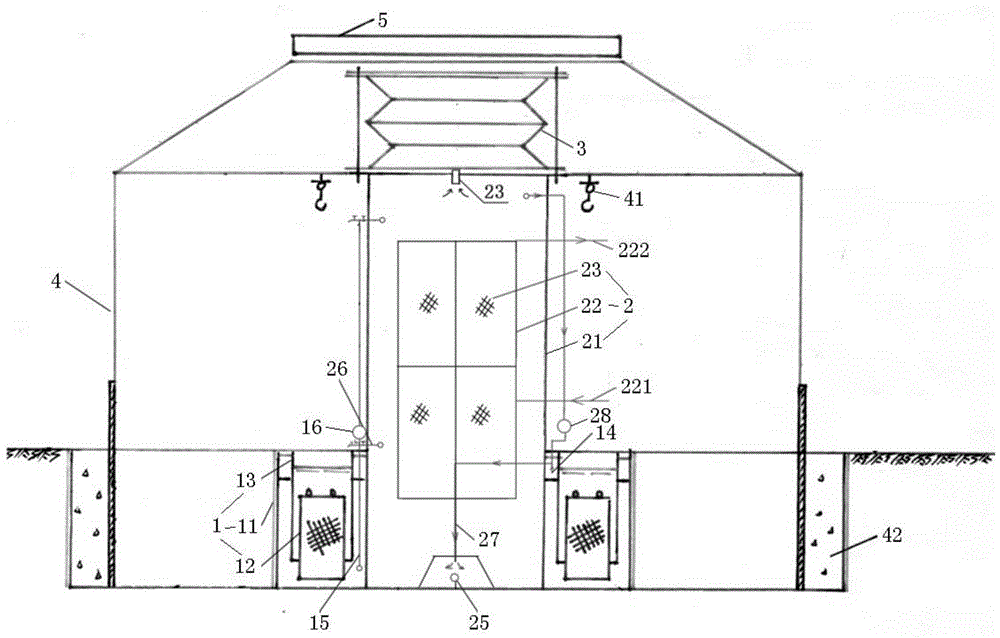

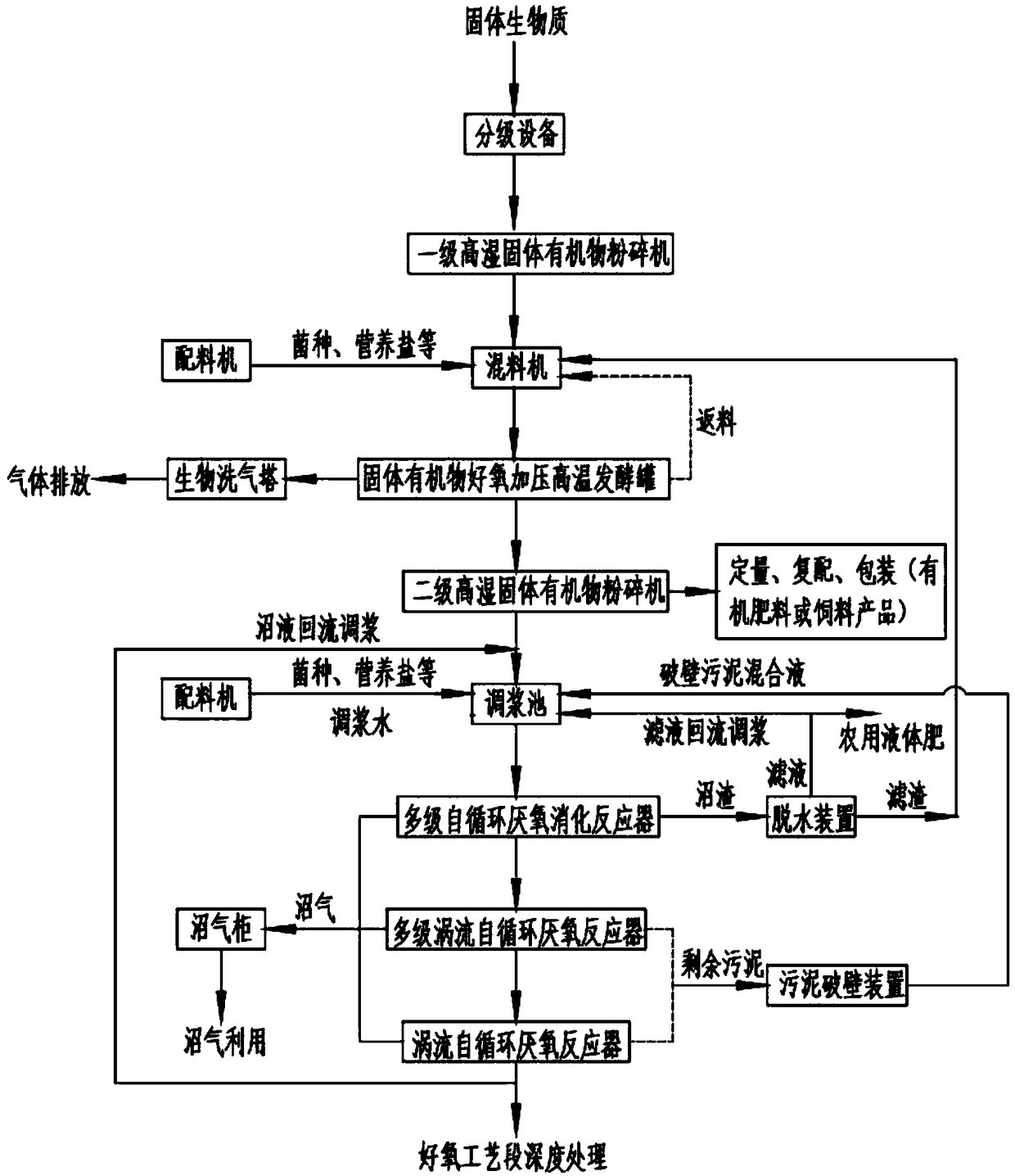

Device and method for preparing biogas and organic fertilizer from biomass through coupling of aerobic fermentation and anaerobic digestion

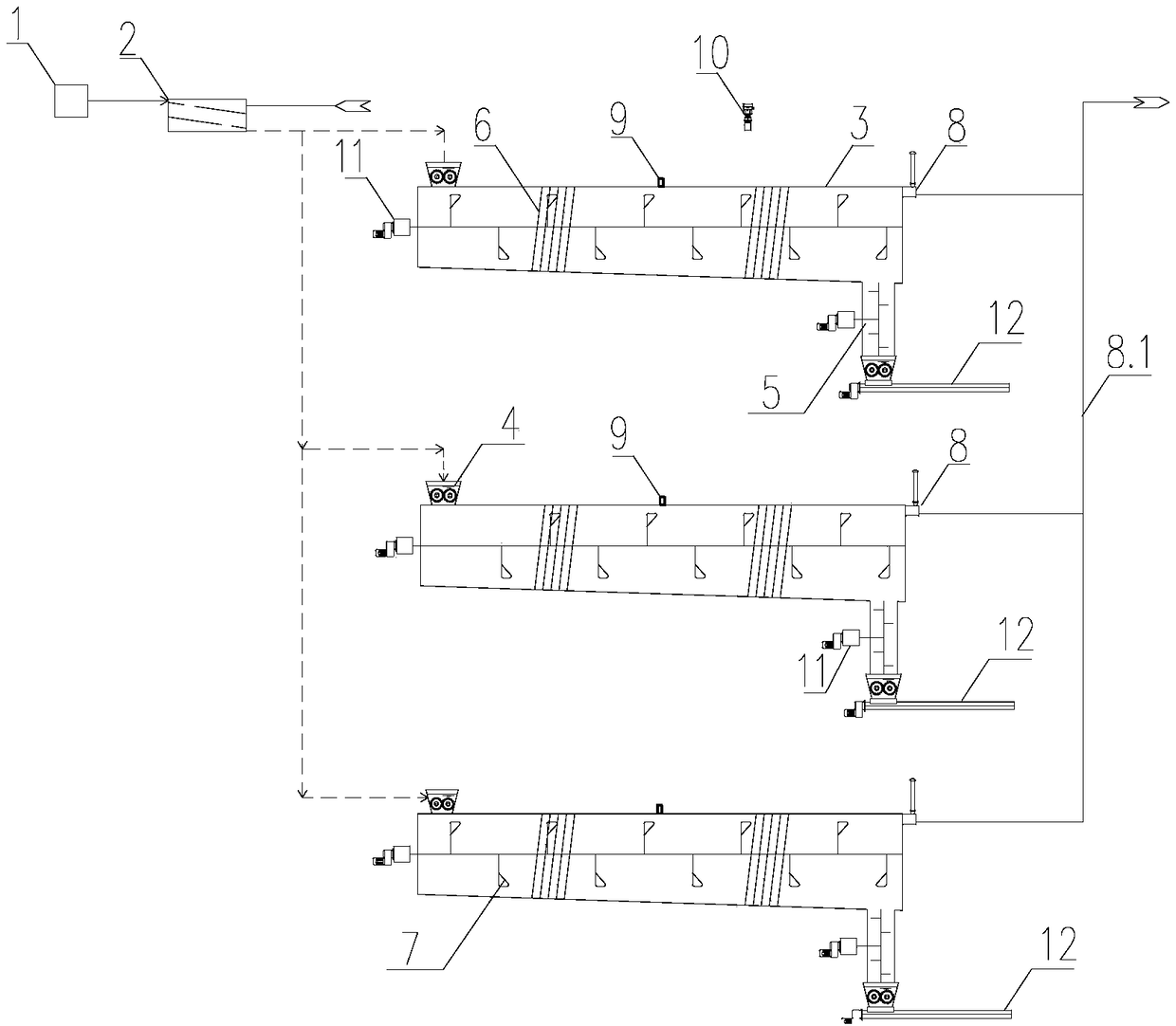

PendingCN108441521AIncrease temperatureImprove conversion rateBio-organic fraction processingProductsFiberAerobic digestion

The invention discloses a device and a method for preparing biogas and organic fertilizer from biomass through coupling of aerobic fermentation and anaerobic digestion. The method comprises the stepsas follows: solid biomass is classified by classification equipment, long fibers are crushed and then enter a mixer, aerobic composting fermentation treatment is performed after the long fibers are mixed uniformly in the mixer, and an aerobic fermented product is obtained; the aerobic fermented product is crushed, then put in a size mixing tank to be uniformly mixed and pumped in a multi-stage self-circulating anaerobic digestion reactor, effluent enters a multi-stage vortex self-circulating anaerobic reactor and a vortex self-circulating anaerobic reactor step by step to be subjected to anaerobic fermentation for production of biogas, and finally, the biogas is sent to an aerobic process section for deep treatment. As for the characteristic that high-humidity and long fibers exist in biomass materials, crushing pretreatment is performed firstly, high-temperature composting treatment is performed, the higher material temperature can be obtained without heating, no chemical decomposition agents are added, organic fertilizer can be quickly prepared through high-temperature fermentation, and the conversion rate of the materials can be higher in the following multi-stage anaerobic biogas preparation devices.

Owner:南宁绿智环保科技有限公司

Dry anaerobic system for treating high-concentration organic wastes

PendingCN109136073ASolve the problem that cannot be fully utilizedSolutions for small, mass transferBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationEconomic benefits

The invention discloses a dry anaerobic system for treating high-concentration organic wastes. The dry anaerobic system sequentially comprises an anaerobic feeder and an anaerobic inoculator, whereinthe anaerobic inoculator is connected with a plurality of dry anaerobic reactors in parallel or is serially connected with a plurality of dry anaerobic reactors end to end; each dry anaerobic reactorcomprises an anaerobic fermentation chamber; anaerobic feeding hoppers are arranged on the upper parts of the anaerobic fermentation chambers; the other ends of the anaerobic feeding hoppers are sequentially connected with the anaerobic inoculator through pipes; anaerobic discharging devices are arranged on the lower parts of the anaerobic fermentation chambers; the inner walls of the anaerobic fermentation chambers are wound with heating and heat-insulating devices; horizontal plow-shaped stirrers hinged to the two ends of the anaerobic fermentation chambers are arranged inside the anaerobicfermentation chambers; biogas collecting devices are mounted on the outer walls of the other ends of the anaerobic fermentation chambers; each biogas collecting device is connected with a connecting pipe. In a process technology from pollution to recycling, the efficiency of converting organic matters into inorganic matters is improved, the yield of biomass gas is increased, economic benefits areincreased, and the difficulty of difficult elimination in the process of returning a biogas slurry to a field is overcome.

Owner:湖北农谷能源建设有限公司 +1

STAIC efficient anaerobic reactor

InactiveCN104341042ASpeed up the flowReduce running timeWaste based fuelTreatment with anaerobic digestion processesSlurryAnaerobic reactor

The invention discloses an STAIC high-efficiency anaerobic reactor. The STAIC high-efficiency anaerobic reactor is characterized in that the heights and diameters of two superposed reaction chambers are different from the height and the diameter of a TAIC anaerobic reactor, the diameter ratio of an upper tank to a lower tank is 5:4, the height ratio of the upper tank to the lower tank is 1:4, the height of the whole reactor ranges from 12 to 30 meters, and the high-diameter ratio of the whole reactor is 3 to 6; an adjustable speed circulating pump is arranged on a sludge return pipe; an automatic traction backflow circulator is arranged on a feed pipe; a protective cover is arranged at a feed pipe orifice; a biogas slurry and biogas residue overflow pipe is higher than the return pipe; a back washing switch is arranged on the feed pipe. The STAIC high-efficiency anaerobic reactor has the advantages that the volumetric gas production rate is high, the fermentation rate of the STAIC high-efficiency anaerobic reactor can be twice of that of the TAIC reactor, the area occupied by the STAIC high-efficiency anaerobic reactor is less than that occupied by the TAIC reactor, the capital investment is substantially reduced, the adaptability is widened, as a feed liquid in a backflow tank can be automatically dragged, the blockage of the feed liquid in the pipeline is effectively avoided, the service efficiency is improved, and more importantly, the anti-rush-out load of the tanks is increased.

Owner:秦家运

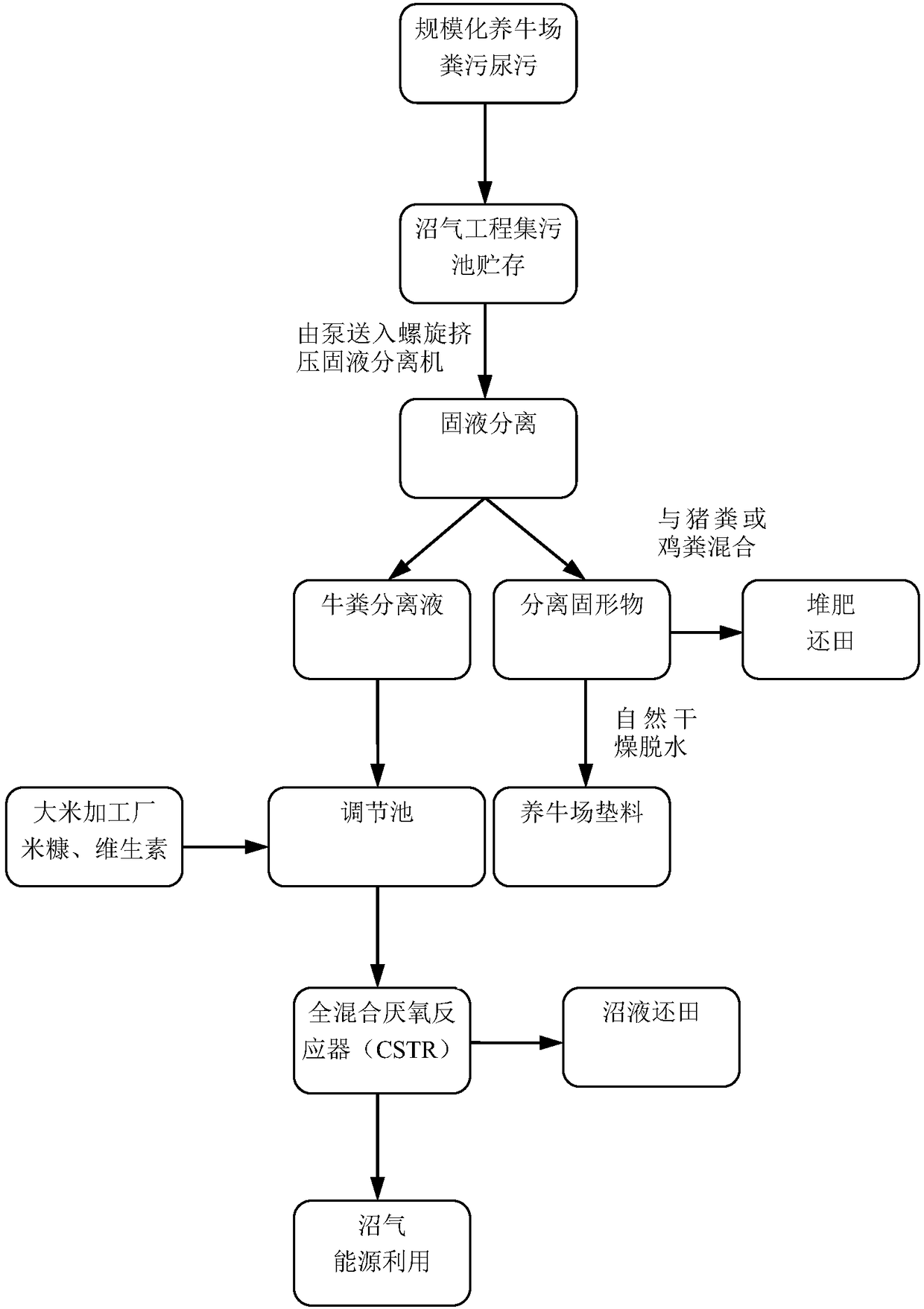

Resource utilization method for cow-dung separating liquid

InactiveCN108298794AFull utilization of resourcesReduce moisture contentSludge treatment by de-watering/drying/thickeningClimate change adaptationTotal solid contentResource utilization

The invention relates to a resource utilization method for cow-dung separating liquid. The resource utilization method includes the following specific steps that (1) cultivated-cow dung urine pollution is collected, solid-liquid separation is carried out, and the cow-dung separating liquid with the total solid content of 5% to 6% is obtained; (2) the cow-dung separating liquid and rice bran are evenly stirred to form a mixed raw material; (3) the mixed raw material is fed into a full-mixing anaerobic fermentation reactor and subjected to medium-temperature anaerobic fermentation, marsh gas generated through anaerobic fermentation is collected, biogas slurry generated after reacting is used for returning to the field. According to the resource utilization method, the resource utilization efficiency of single large-scale cultivated-cow dung pollution is high, water resources required by mixing anaerobic fermentation treatment are saved, and the generated biogas slurry is also easily treated.

Owner:SOUTHWEST UNIV

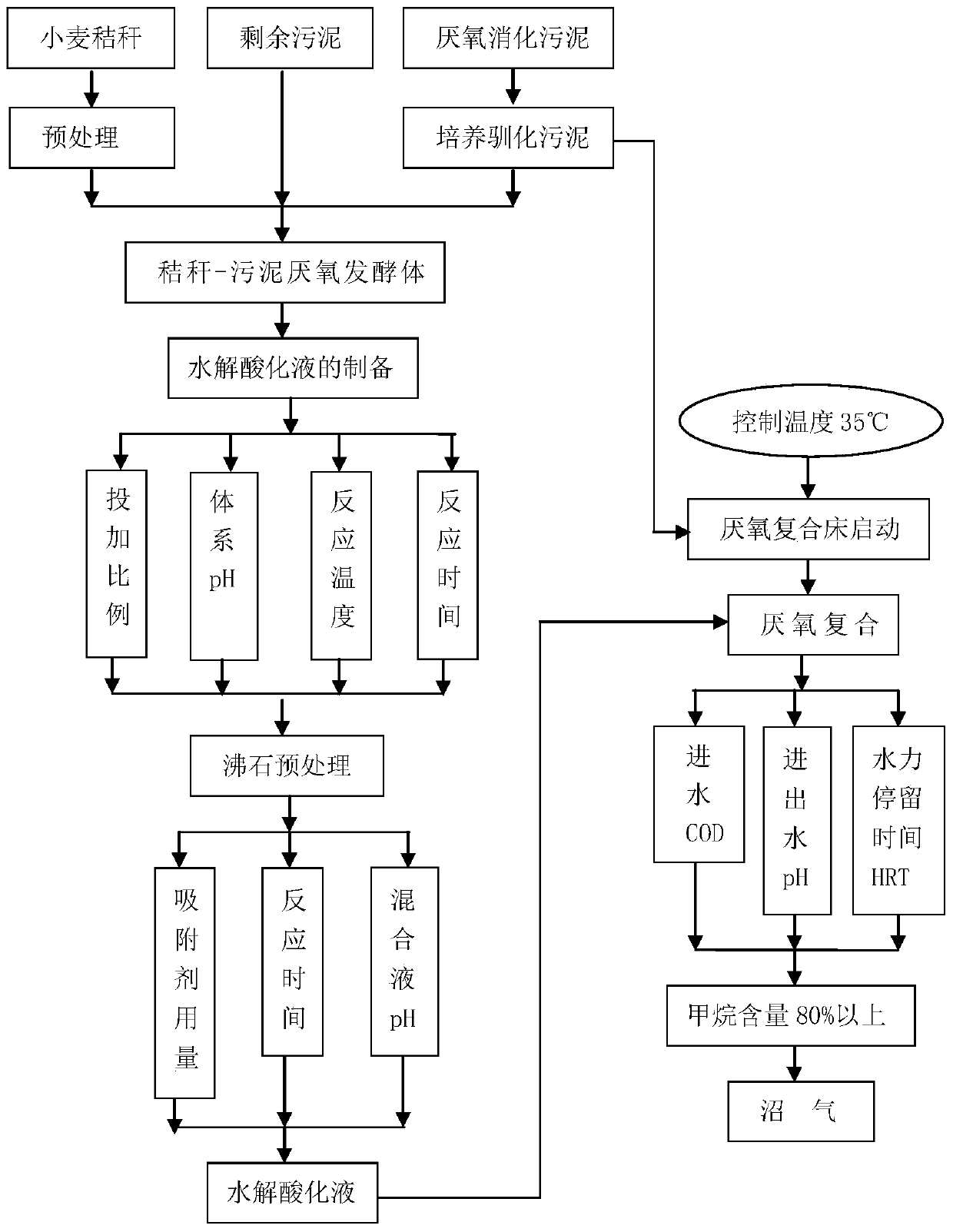

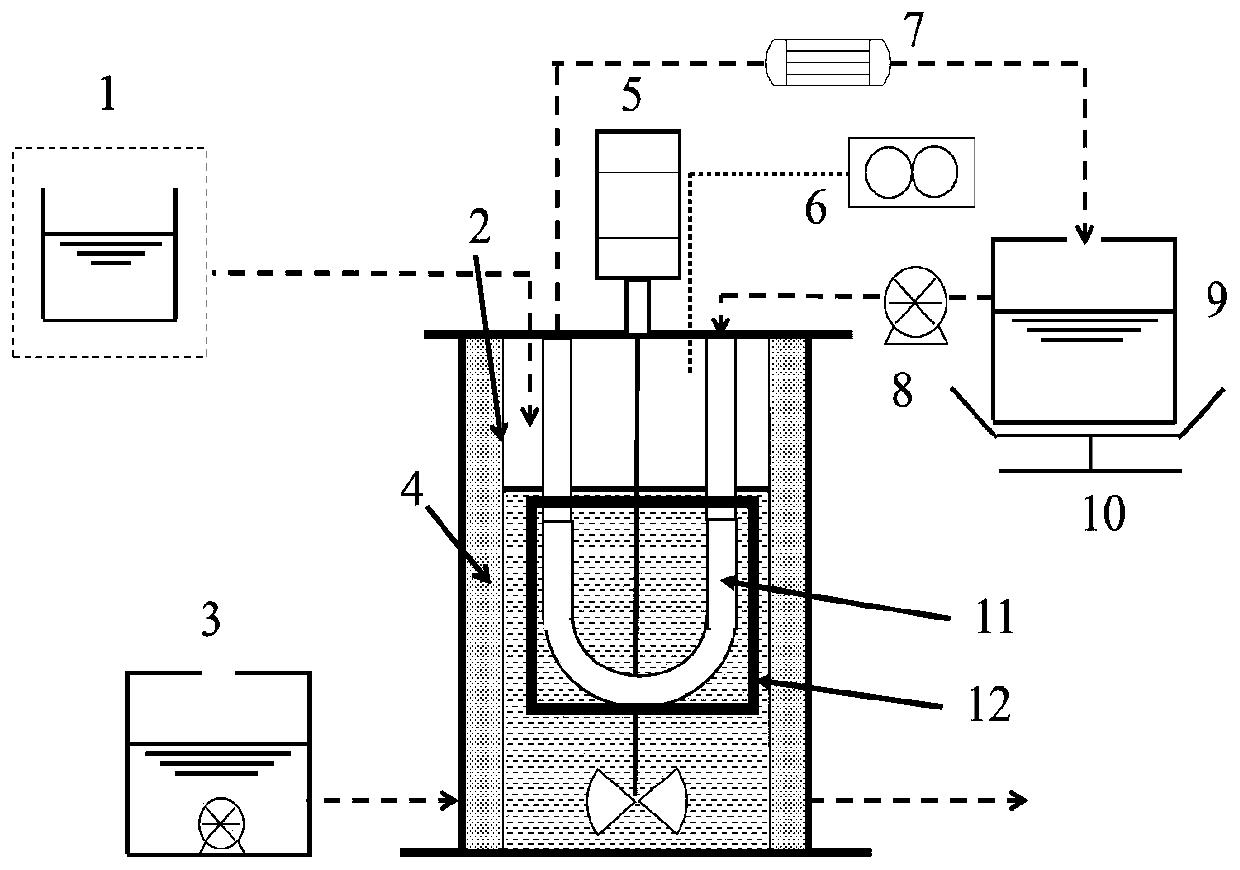

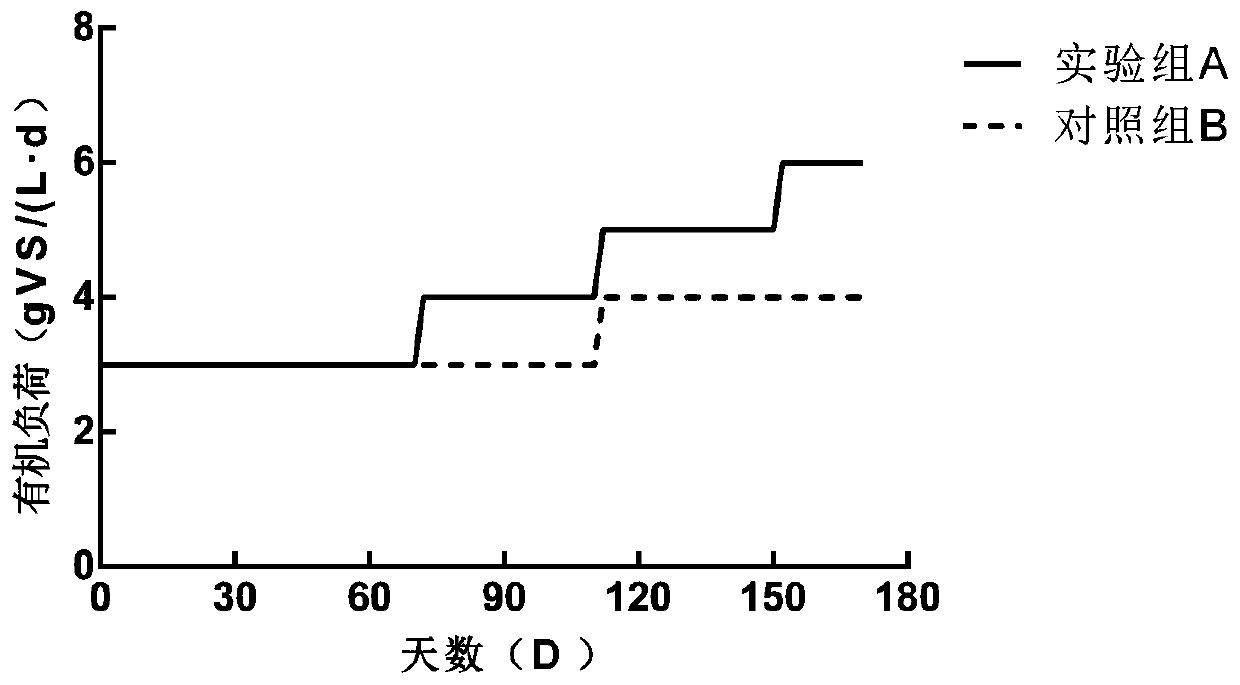

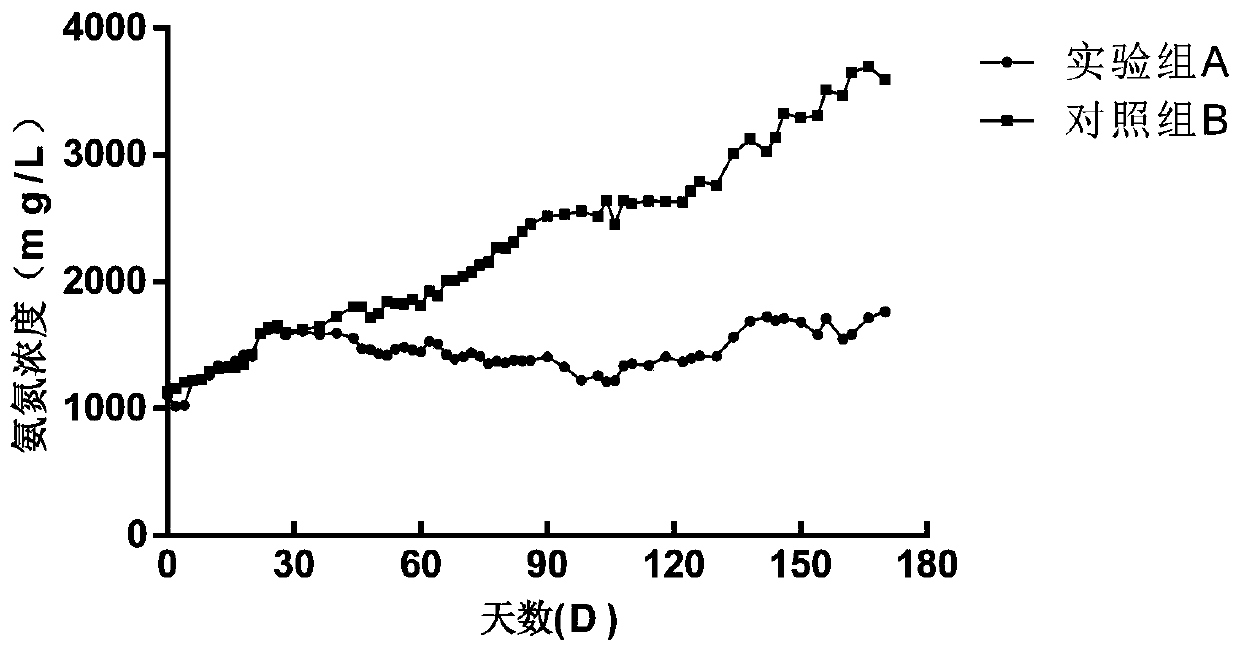

A method for preparing biogas by using straw combined with excess sludge

ActiveCN105969809BReduce loss rateAvoid secondary pollutionWaste based fuelSludge processingSorbentHydrolysis

Owner:XIAN HUINING PAPER

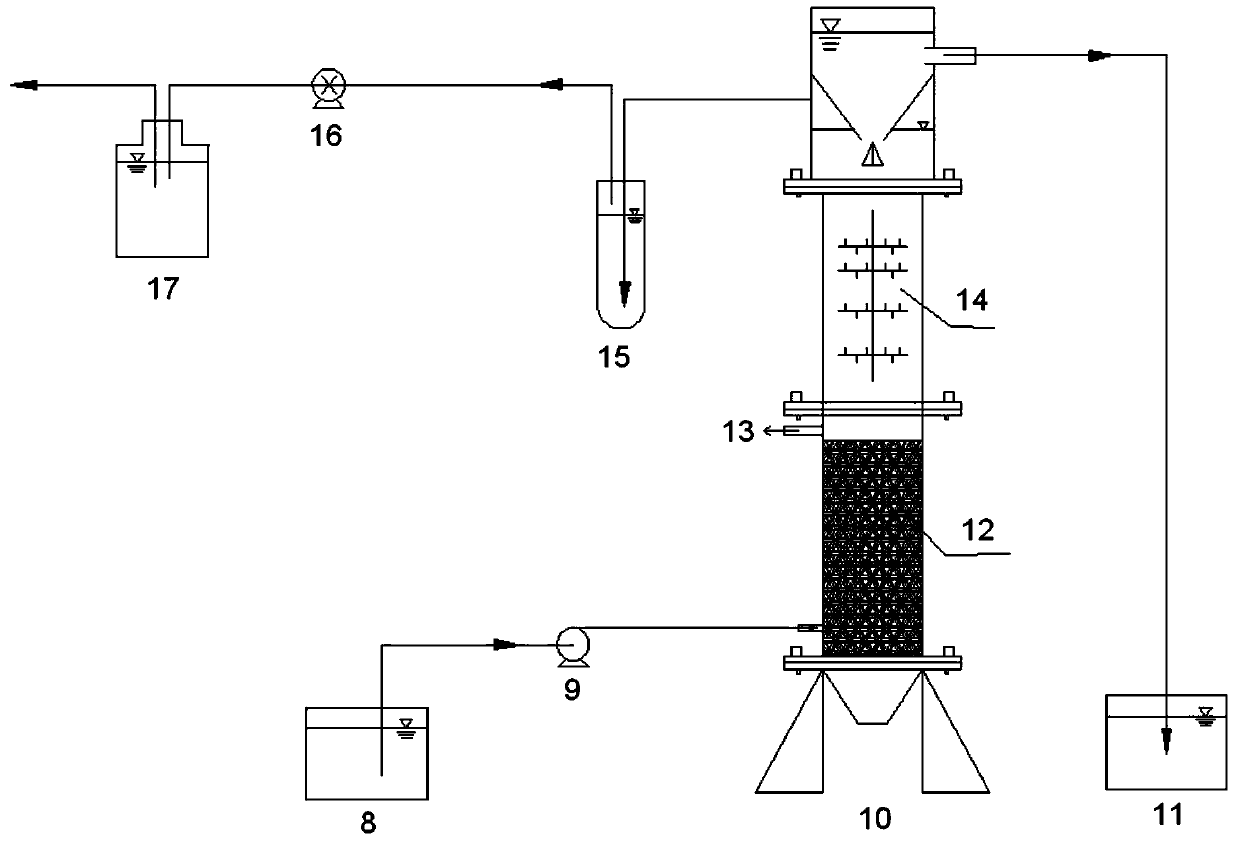

Device and method for in-situ removal of ammonia nitrogen in anaerobic digestion system

ActiveCN108246051BReduce inhibitionEasy to handleGas treatmentDispersed particle separationAmmoniacal nitrogenPeristaltic pump

The invention provides an in-situ device for removing ammonia nitrogen in an anaerobic digestion system, which includes an ammonia removal anaerobic digestion tank and an ammonia absorption-circulation system, and the ammonia absorption-circulation system includes a separation membrane module, an acid An absorption liquid storage bottle and a peristaltic pump, the separation membrane assembly includes a separation membrane and a membrane protection layer arranged outside the separation membrane, the separation membrane assembly is arranged inside the anaerobic digestion tank for ammonia removal; The ammonia anaerobic digestion tank is used to hold the anaerobic digestion feed liquid. The device provided by the invention can realize the in-situ removal of ammonia nitrogen in the anaerobic digestion system, remove ammonia nitrogen while performing anaerobic digestion, reduce the inhibitory effect of ammonia nitrogen, and recover ammonia nitrogen.

Owner:TSINGHUA UNIV

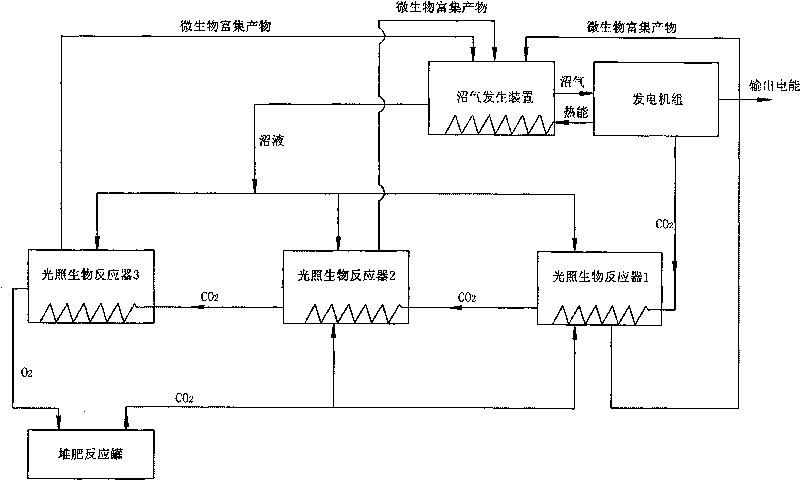

Method for efficiently and cleanly disposing solid organic wastes

InactiveCN101747098BGood growth and reproduction conditionsFull of nutritionBio-organic fraction processingClimate change adaptationMicroorganismLight energy

The invention discloses a method for efficiently and cleanly disposing solid organic wastes, which comprises following steps: a, crashing the solid organic wastes into granular materials, adding auxiliary materials in the granular materials, adjusting ratio of carbon to nitrogen, composting and fermenting the mixture; b, placing light-energy nutritional microorganisms in a photobioreactor, addingliquid culturing solution in the photobioreactor and culturing the microorganisms; and c, delivering gas discharged from a compost reactor to the photobioreactor, and generating the enriched productsof the microorganisms. In the process of disposing the solid organic wastes, the invention cannot only recover and utilize all the wastes in a technological process, but also produce a plurality of by-products with economic use values.

Owner:刘爱平

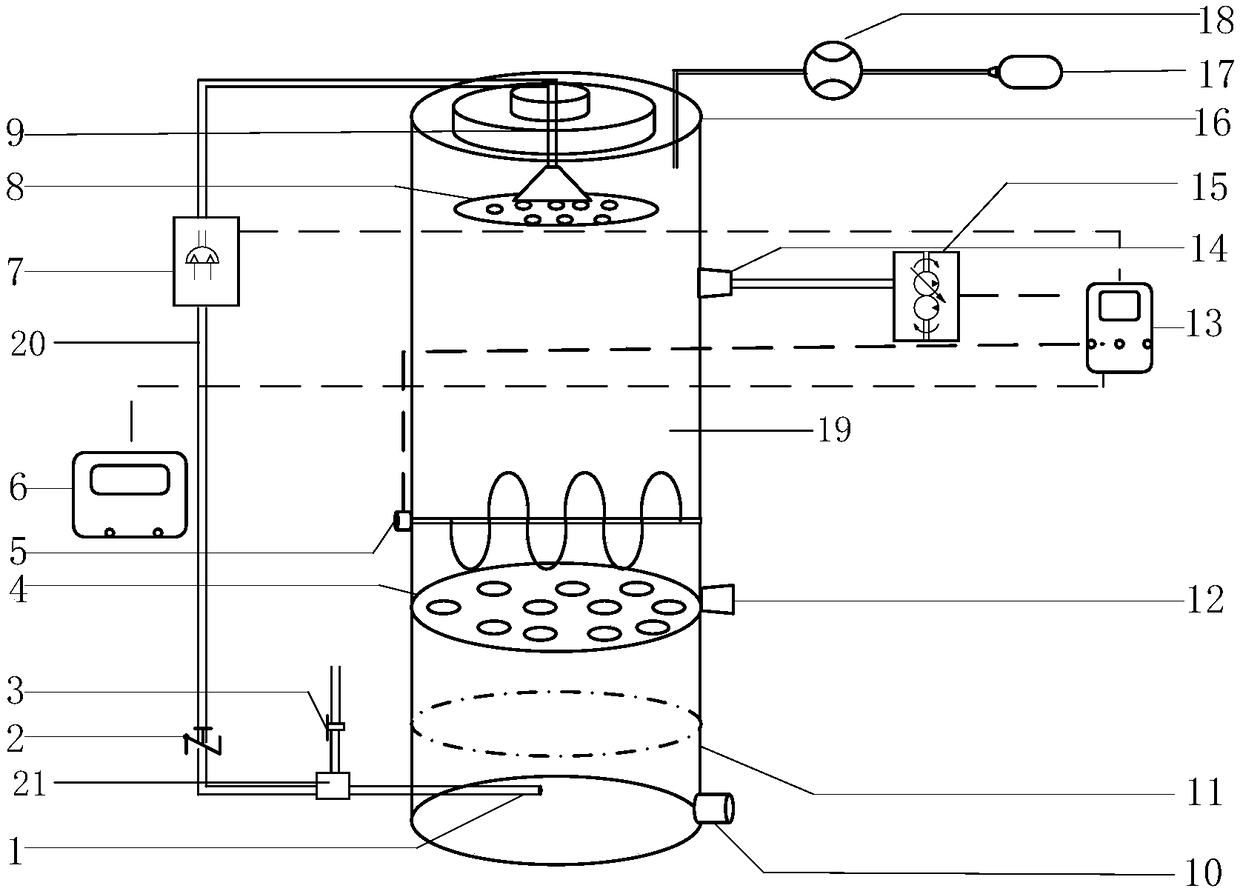

High-solid-content anaerobic digestion reaction device and working method thereof

ActiveCN109384363AEliminate poisonSolve the dilemmaBiological sludge treatmentPeristaltic pumpHigh concentration

The invention relates to a high-solid-content anaerobic digestion reaction device and a working method thereof, and belongs to the field of high-concentration biomass anaerobic digestion. The device comprises a reactor, an anaerobic digestion system, a sample introduction system, a water circulation system, a gas collection system and an on-line monitoring and regulation system, wherein a water storage area is arranged at the bottom of the reactor; the anaerobic digestion system comprises a porous backing plate and a stirring device located above the porous backing plate; the water circulationsystem comprises a water intake and a water inlet; a peristaltic pump is arranged on a water circulation pipeline; the on-line monitoring and regulation system comprises a PLC (programmable logic controller), an on-line monitor and a regulation standby pipeline; and the stirring device, the peristaltic pump and the on-line monitor are connected with the PLC. The device effectively solves the problems of heterogeneity, nonuniform contact between anaerobic microorganisms and substrates, and local VFAs (volatile fatty acids) accumulation, and effectively improves organic waste treatment efficiency and methane productivity by monitoring reaction process indicators and timely regulating an anaerobic digestion process.

Owner:SHANDONG UNIV

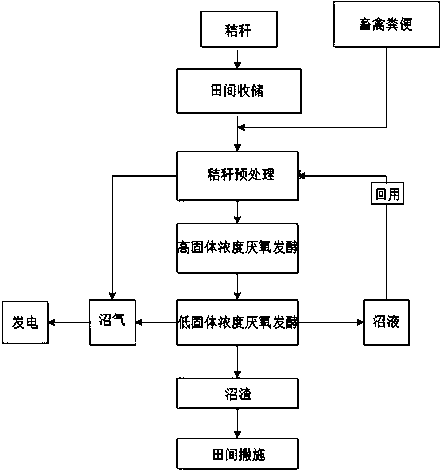

A method of combining baled straw and livestock and poultry manure to produce biogas

ActiveCN105755056BSimple processSuitable for large-scale processingWaste based fuelSludge processingBiotechnologyLivestock manure

The invention discloses a method for generating methane jointly through bundled straw and livestock and poultry manure.The method specifically includes the steps that A, after being harvested, straw is inoculated with a methane fermenting agent, the bundled straw is piled in a reactor in an overlapped mode, the livestock and poultry manure is injected, and aerobiotic placement is conducted; B, the reactor is sealed, biogas slurry inoculation is conducted, and fermentation is conducted for 30-35 days; C, the biogas slurry is injected, and fermentation is conducted for 15-20 days.The methane is generated jointly through the large-scale bundled straw and the livestock and poultry manure, the problem that cellulose raw materials cannot be directly treated in an energy conversion mode after mechanical harvesting and storage in the prior art is solved, energy consumption is reduced, cost is reduced, the volume gas generation rate of the anaerobic reactor is increased, and compared with a traditional fermentation process, the cumulative gas generation amount of the whole fermentation process is increased by 50% or above.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

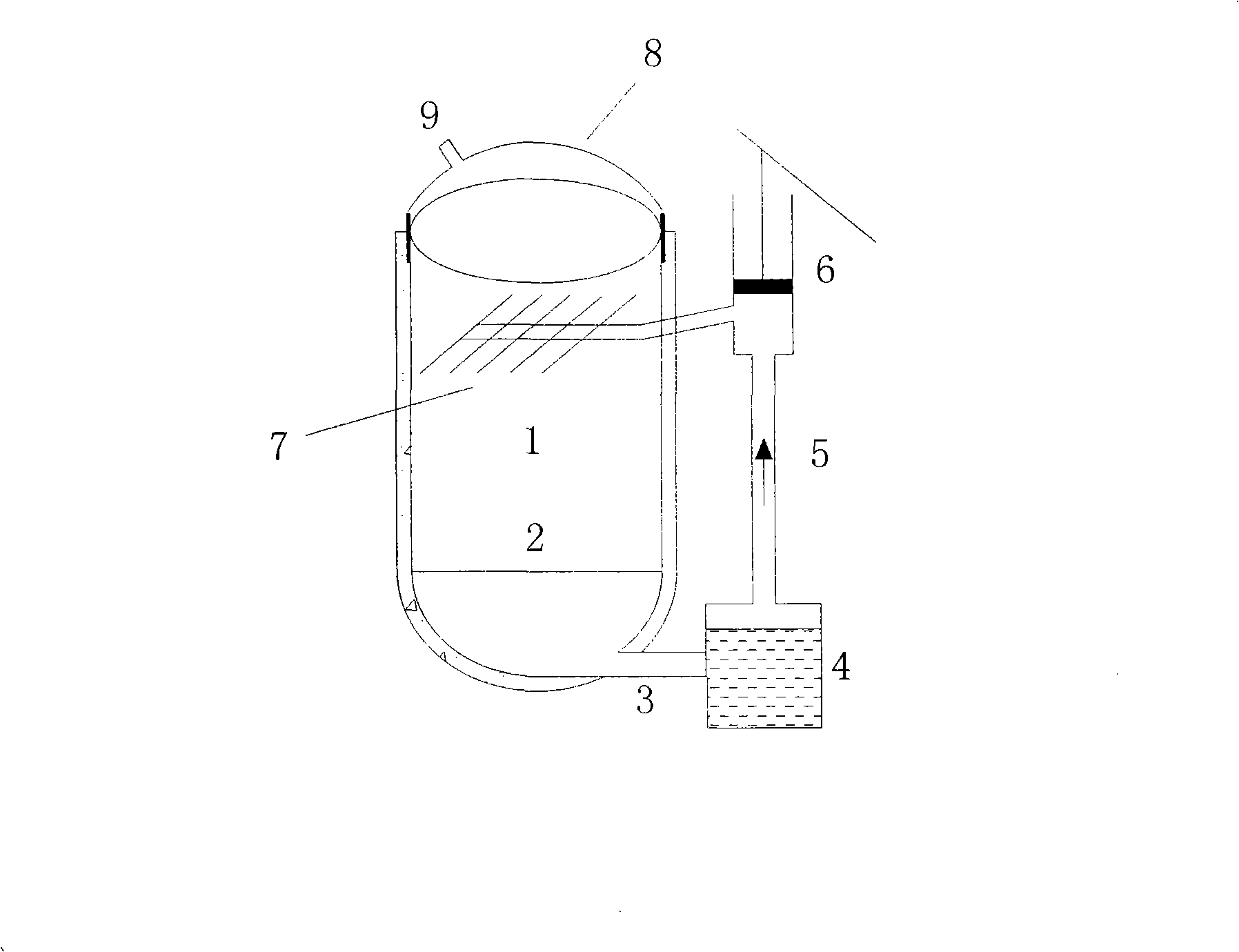

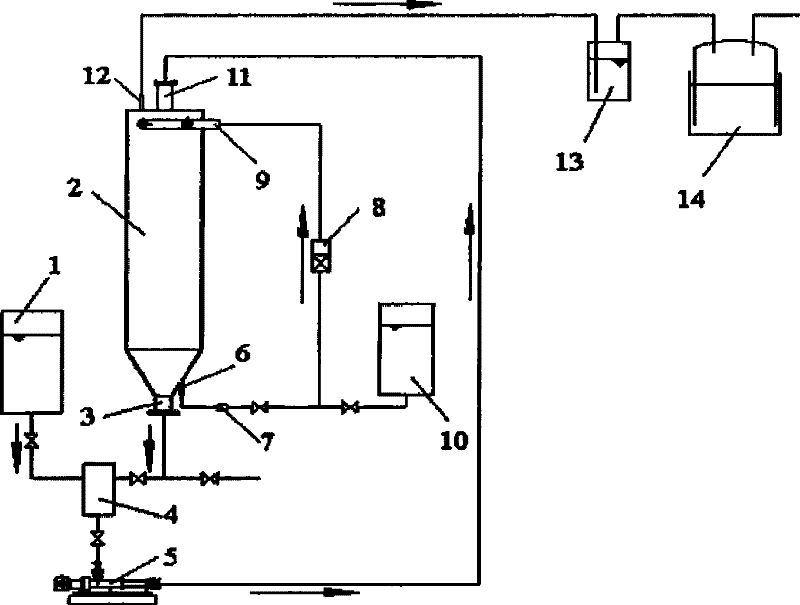

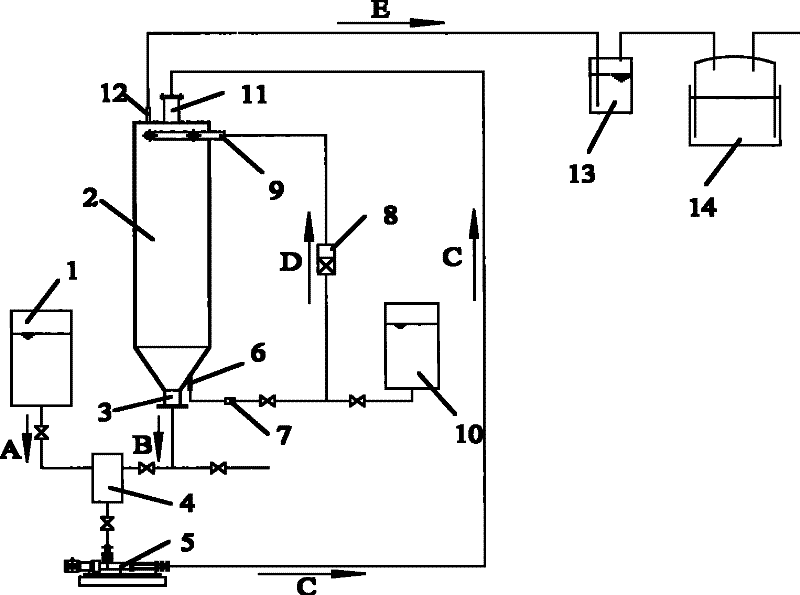

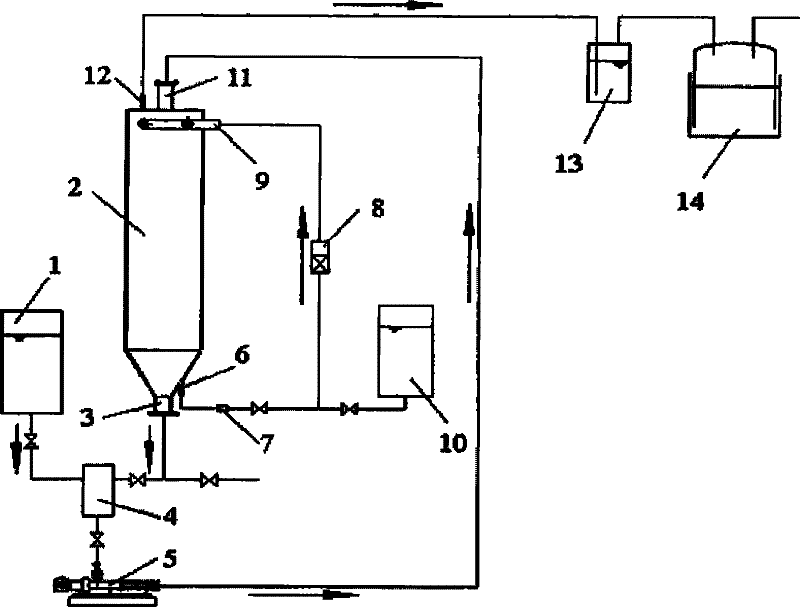

Vertical non-stirred organic waste dry-type anaerobic digestion processing equipment and method

InactiveCN101381674BIncrease volumetric gas production rateSmall footprintBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxSlurry

The invention discloses vertical equipment for treating organic waste by dry anaerobic digestion without stirring and a method thereof. The equipment comprises that a feed port and an air outlet are arranged on the vertical digester; a discharge port is arranged on the bottom of the vertical digester; a feeding storage tank is connected with the discharge port of the vertical digester through a pipeline, an inoculation mixing tank and a delivery pump; the discharge port of the vertical digester is connected with the inoculation mixing tank through a control valve; a biogas slurry discharge pipe is arranged on the lower part of the vertical digester, and is connected with a spraying device arranged on the upper part of the vertical digester through a pH value on-line monitor, a reflux pumpsequentially; and an alkali solution storage tank is connected with the reflux pump through the pipeline and the control valve. The vertical equipment for treating organic waste by dry anaerobic digestion without stirring and the method thereof overcome the defects of difficult isotrope mixing, easy isotrope acidification and the like of the prior dry anaerobic digestion system, and is applicableto treatment on household organic garbage, kitchen garbage, excrement of fowls and livestocks, agricultural waste, garden garbage, sewage sludge and other organic waste.

Owner:SOUNDGRP CO LTD

Directional acidification pretreatment method to improve gas production performance of anaerobic digestion of corn straw

ActiveCN104593430BHigh activityPromote degradationWaste based fuelFermentationMethanationResource utilization

The invention discloses a method for improving the anaerobic digestion gas-production performance of maize straws through directional acidification pretreatment, and belongs to the field of efficient resource utilization of maize straws. The method comprises the following steps: carrying out pretreatment on maize straws by using sodium hydroxide; acidifying the maize straws, and adding activated sludge into the pretreated maize straws, wherein relatively, 10-50 g of TS activated sludge is added into 52 g of TS maize straws; adding tap water until the tap water accounts for 80% of the total volume of a reaction container, mixing the obtained object, filling nitrogen into the reaction container, and hermetically fixing the container in a shaking table, wherein the temperature of the shaking table is kept at 40+ / -2 DEG C; measuring the pH value by using a pH meter every time, and when the pH value is less than 5.5, stopping acidifying; and after methanation startup is completed, by taking an acidified discharged material as a raw material, carrying out feeding and discharging once a day, wherein a fed material and the discharged material are same in volume, and the HRT (hydraulic retention time) is 40 days. According to the invention, the separation of an acidification stage and a methanation stage in biological sciences is realized, and the effects of acidification bacteria groups and methane-producing bacteria groups in respective stage are enhanced, thereby facilitating the stable and efficient operation of an acidification phase and a methane-producing phase, and greatly improving the biodegradability and gas production performance of maize straws.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com