Device and method for preparing biogas and organic fertilizer from biomass through coupling of aerobic fermentation and anaerobic digestion

A technology of anaerobic digestion and aerobic fermentation, which is applied in the field of fertilizer and biomass energy, and can solve the problems of secondary pollution of odor, low gas production rate, single resource utilization mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

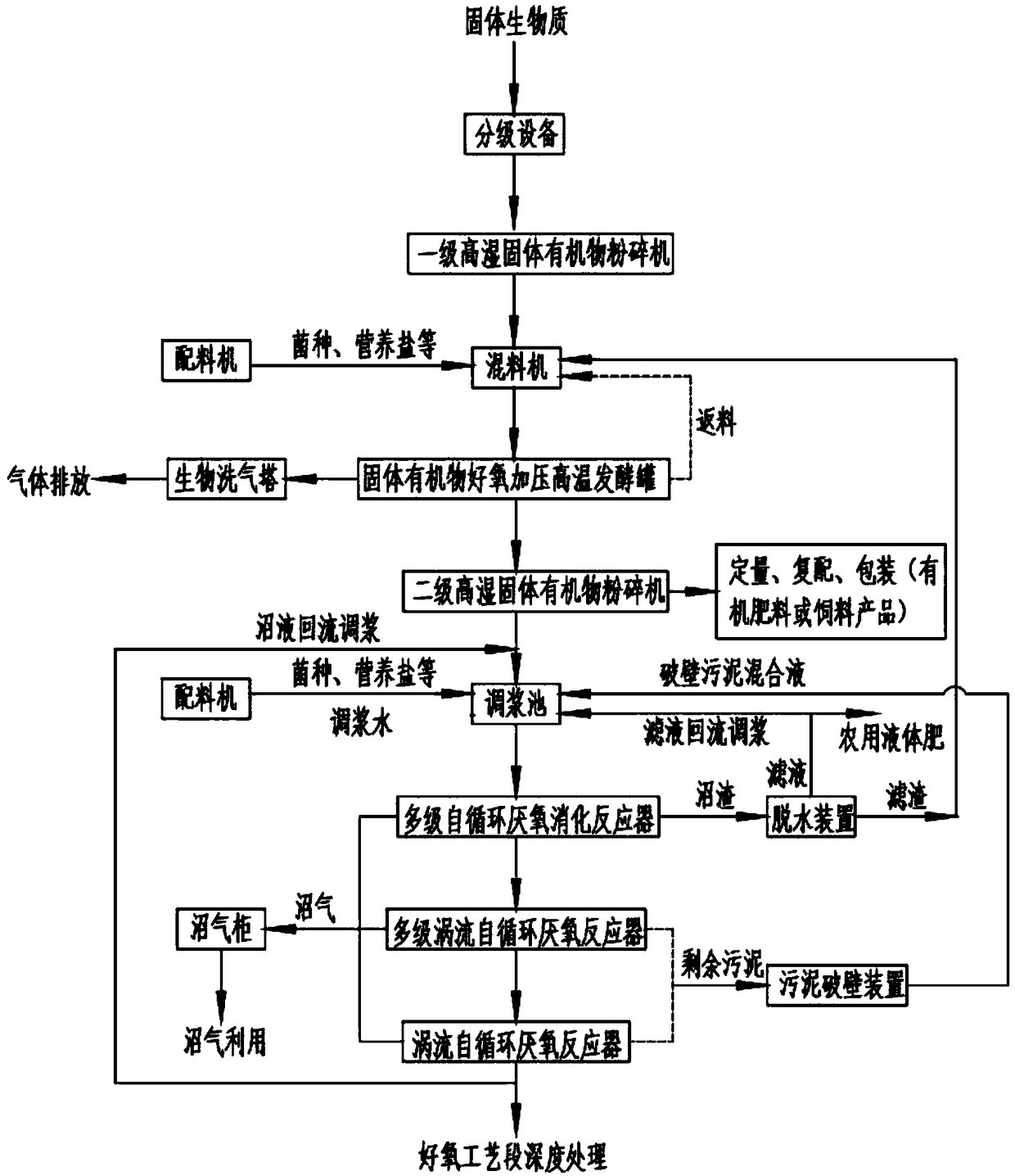

[0067](1) Chinese herbal medicine residues are classified by grading equipment, and the long fibers enter the first-level high-humidity solid organic matter pulverizer for first-level pulverization treatment to 40-60 mesh, and then enter the blender, and the aerobic fermentation agent (yeast) is added from the batcher , Bacillus licheniformis, Brevibacillus sporogenes, Bacillus amyloliquefaciens, Trichoderma composite bacterial agent), nutrient salts (N, P, K), evenly mixed with filter residue and returned materials, and then sent to solid organic matter for aerobic pressurized high-temperature fermentation The tank is subjected to aerobic fermentation and fermentation treatment, and the aerobic fermentation product enters the secondary high-humidity solid organic matter pulverizer for crushing treatment to 20-30 mesh and then puts it into the slurry mixing tank, and the batching machine adds anaerobic fermentation bacteria agent (cellulolytic bacteria, semi Cellulolytic bacter...

Embodiment 2

[0078] A method for aerobic fermentation coupled with anaerobic digestion of biomass to prepare biogas and organic fertilizer, the method steps are: solid biomass is classified by a classification device, and long fibers enter a first-level high-humidity solid organic matter pulverizer for crushing and then enter Mixer, at the same time, add aerobic fermentation bacteria and nutrient salts including N, P and K to the mixer from the first batcher, and send them into the aerobic pressurized high-temperature fermenter for solid organic matter after being uniform in the mixer Carry out aerobic decomposing and fermentation treatment to obtain aerobic fermentation products; aerobic fermentation products enter the secondary high-humidity solid organic matter pulverizer for crushing treatment and then put into the mixing tank, and at the same time add mixing water into the mixing tank by the second batching machine , anaerobic fermentation bacteria agent, and nutrient salts including N...

Embodiment 3

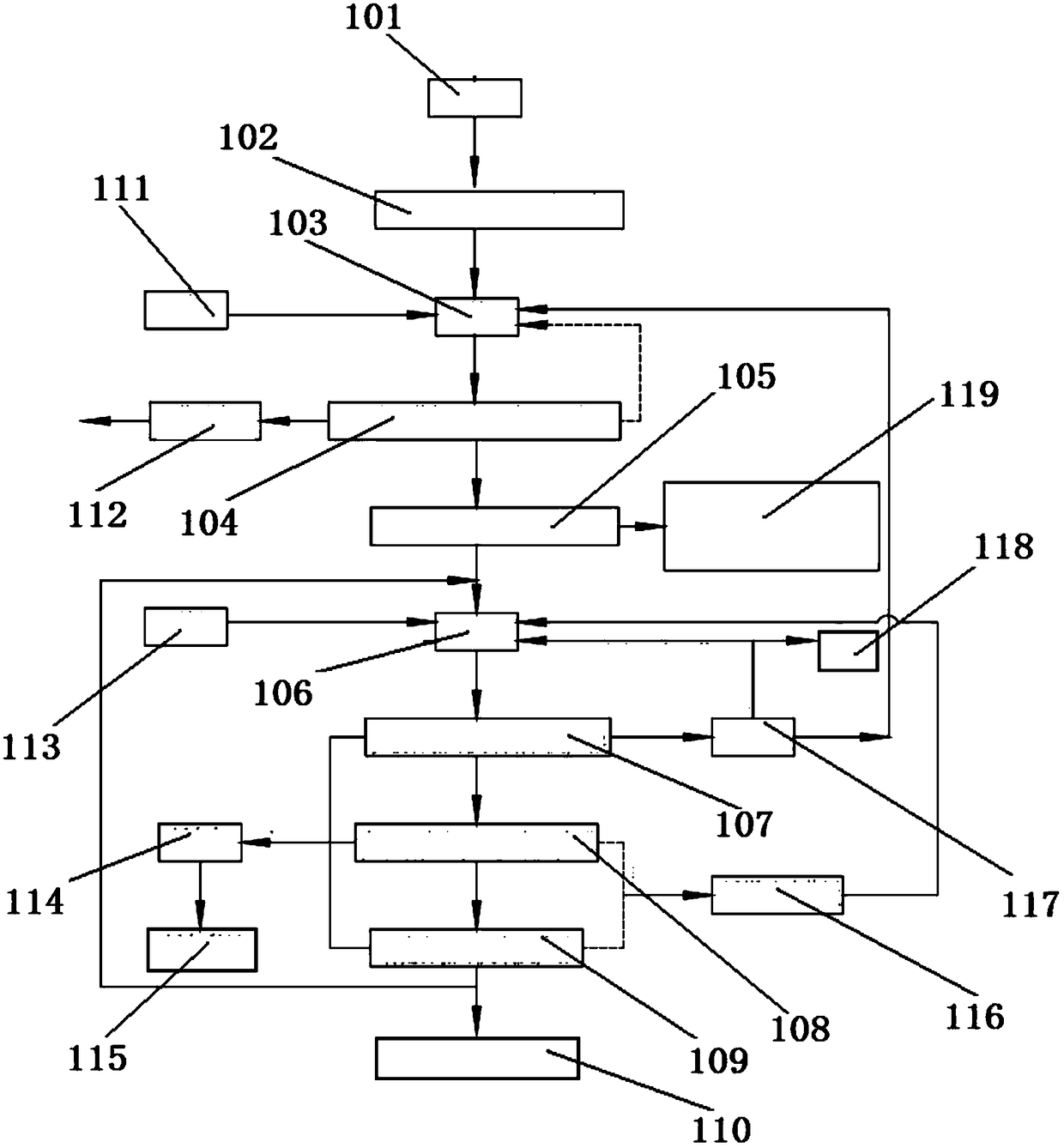

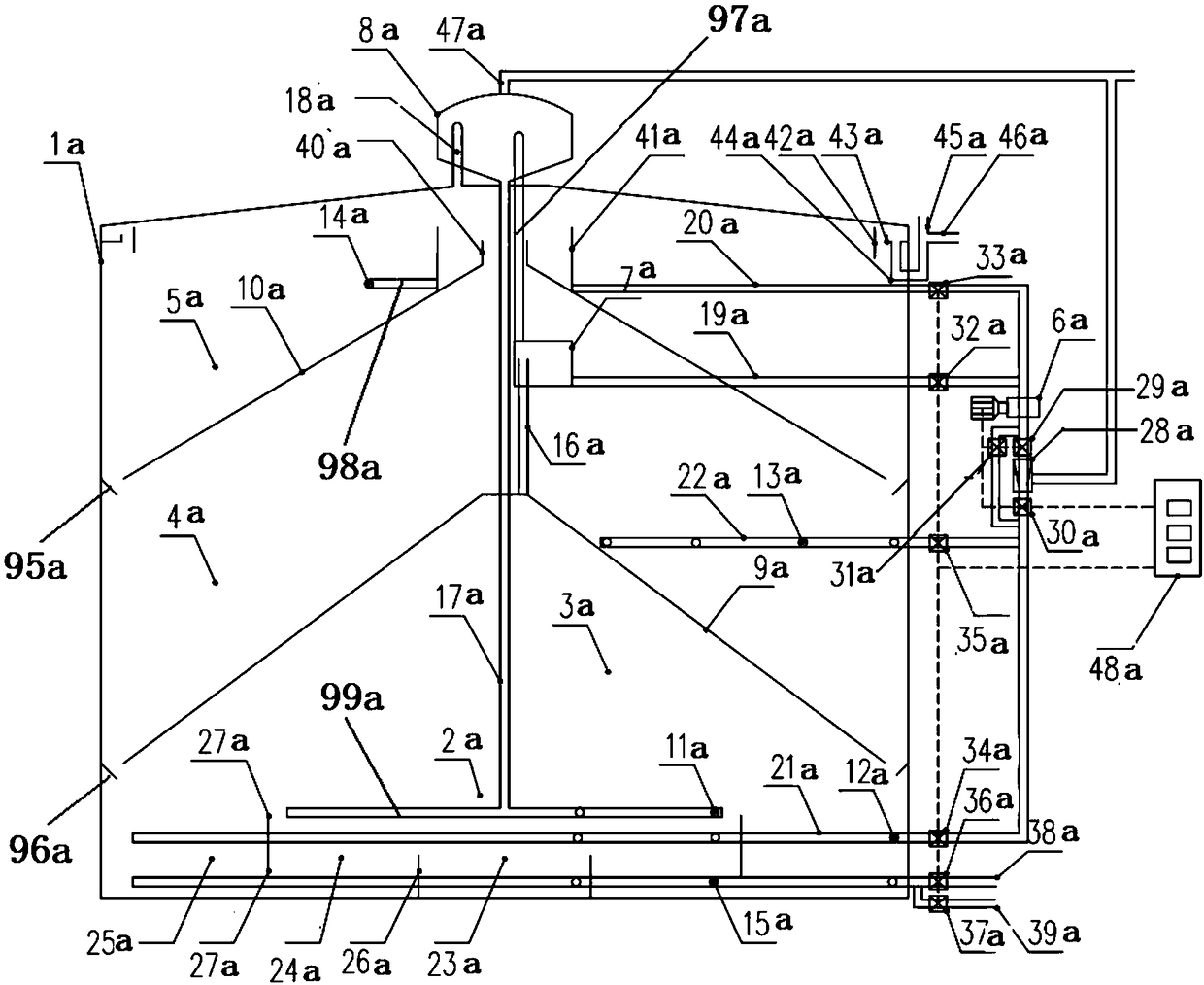

[0089] A device for preparing biogas and organic fertilizer by coupling aerobic fermentation with anaerobic digestion of biomass, including a classification device 101, a first-stage high-humidity solid organic matter pulverizer 102, a mixer 103, an aerobic pressurized high-temperature fermenter for solid organic matter 104, Secondary high-humidity solid organic pulverizer 105, mixing tank 106, multi-stage self-circulating anaerobic digestion reactor 107, multi-stage vortex self-circulating anaerobic reactor 108 and vortex self-circulating anaerobic reactor 109,

[0090] The long fiber discharge port of the classification device 101 is connected to the feed port of the primary high-humidity solid organic pulverizer 102, and the discharge port of the primary high-humidity solid organic pulverizer 102 is connected to the feed port of the mixer 103. The discharge port of the mixer 103 is connected to the feed port of the solid organic matter aerobic pressurized high-temperature fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com