Resource utilization method for cow-dung separating liquid

A technology for separating liquid and recycling it is applied in the field of resource utilization of cow dung separation liquid, which can solve the problems of wasting water and difficult to handle biogas liquid, and achieve the effects of not easy clogging, low moisture content and high fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

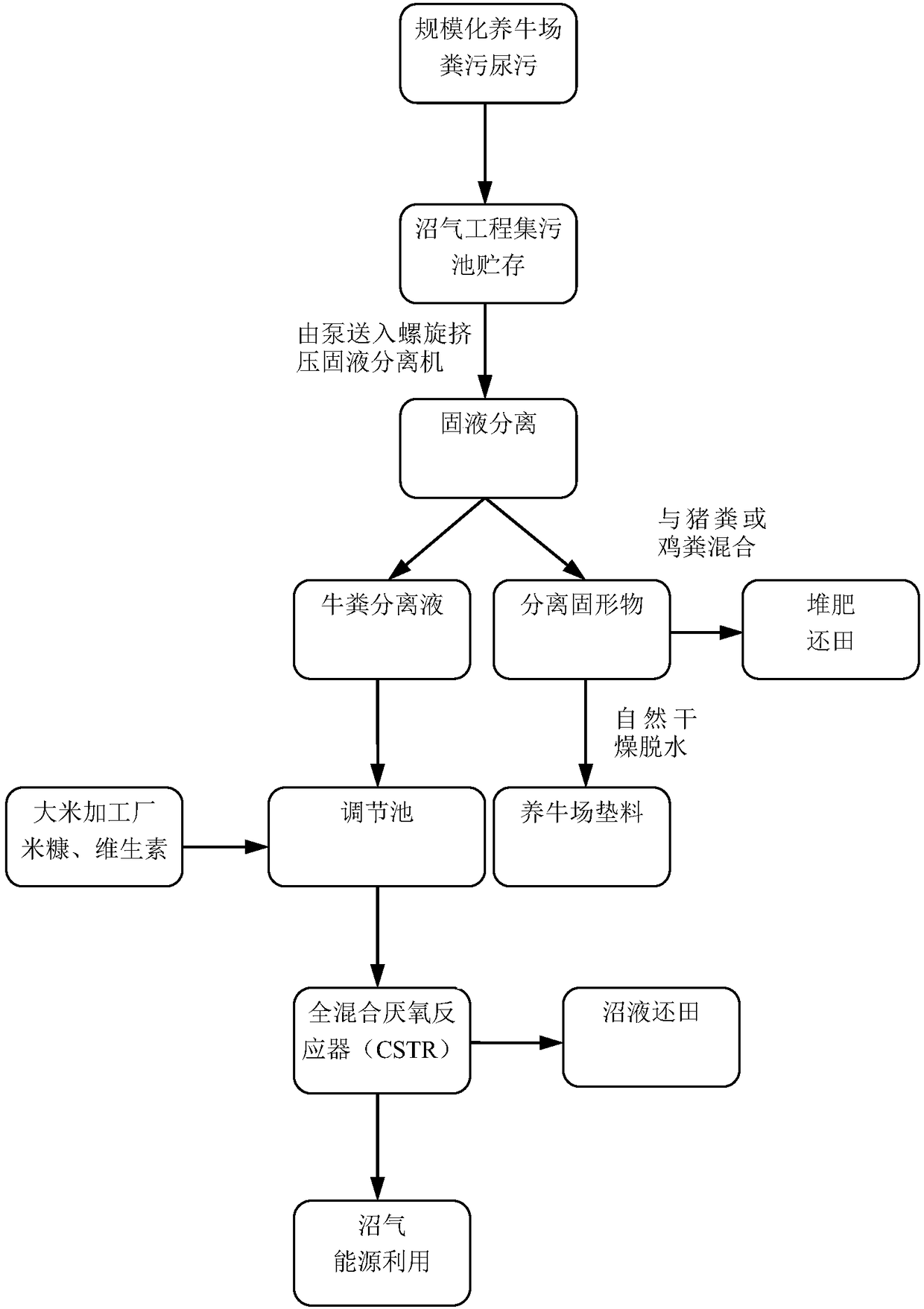

[0022] A method for resource utilization of cow dung separation liquid, specifically comprising the following steps:

[0023] (1) Collect the feces and urine from large-scale cattle farms with a sewage suction truck and send them to the sewage collection tank of the biogas factory, and transport them to the variable pitch and variable shaft diameter screw extrusion solid-liquid separator through the action of the screw pump for solid-liquid separation. Separating, respectively obtaining a cow dung separation liquid with a total solid content (TS) of 5%, and an isolated solid with a moisture content of 41% by mass; wherein, the obtained isolated solid is used as a bedding material for cattle bedding after natural drying;

[0024] (2) Mix the obtained cow dung separation liquid with the rice bran obtained from rice processing and production according to the dry matter mass ratio of 1:1.5, and stir evenly to form a mixed raw material;

[0025] (3) Use a pump to send the obtained ...

Embodiment 2

[0028] A method for resource utilization of cow dung separation liquid, specifically comprising the following steps:

[0029] (1) Collect the feces and urine from large-scale cattle farms with a sewage suction truck and send them to the sewage collection tank of the biogas factory, and transport them to the variable pitch and variable shaft diameter screw extrusion solid-liquid separator through the action of the screw pump for solid-liquid separation. Separation, to obtain the cow dung separation liquid with a total solid content (TS) of 6%, and the separation solid with a moisture content of 40% by mass; wherein, the obtained separation solid is directly mixed with pig manure or chicken manure after natural drying Mix compost, adjust the moisture and carbon-nitrogen ratio (C / N) of the compost, and improve the compost effect;

[0030] (2) Mix the obtained cow dung separation liquid with the rice bran obtained from rice processing and production according to the dry matter mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com