Dry anaerobic system for treating high-concentration organic wastes

An organic waste and dry anaerobic technology, which is applied in the field of high-concentration organic waste treatment, disposal, and resource utilization, can solve the problems of incomplete resource utilization of discharged biogas slurry, large reactor sediments and scum, and volumetric production. Low gas rate and other problems, to achieve the effect of fewer types of applicable materials, expanding economic benefits, and low volumetric gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

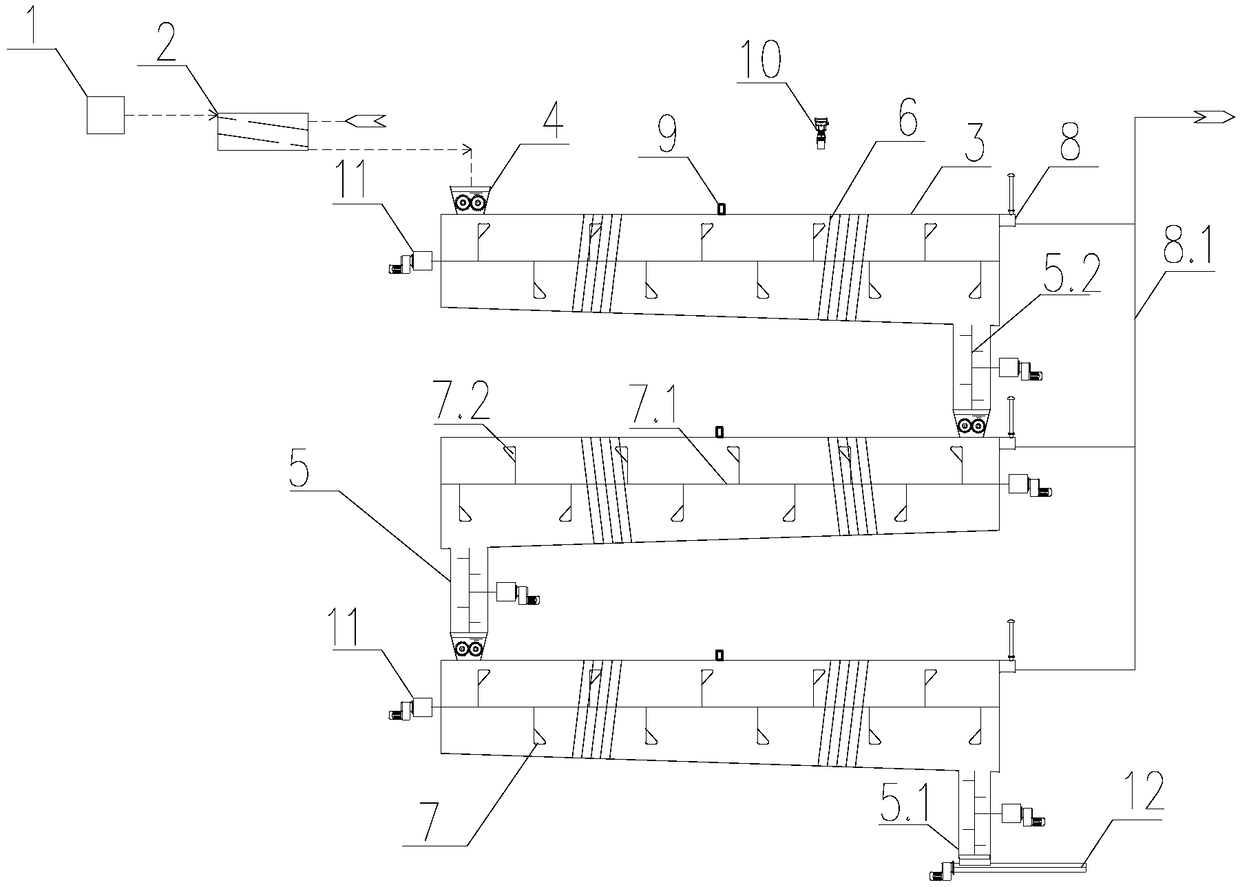

[0034] Such as figure 1 The series-type high-concentration organic waste dry-type anaerobic system shown includes anaerobic feeder 1 and anaerobic inoculator 2 in turn, anaerobic inoculator 2 and three dry anaerobic reactors in series. Connect, the dry anaerobic reactor comprises anaerobic fermentation chamber 3, and the section of anaerobic fermentation chamber 3 is rectangular trapezoidal,

[0035] The anaerobic fermentation chamber 3 provides a physical and chemical environment for mesophilic or high-temperature anaerobic microorganisms, and the reaction chamber is closely connected with multiple auxiliary devices and works together. The operating pressure of the reaction chamber is 0-3500Pa, the residence time is 10-30d, and the volumetric gas production rate is 1-4m 3 / m 3 d. The temperature of medium-temperature fermentation is 35-38°C, and the temperature of high-temperature fermentation is 50-55°C. The reaction chamber is a horizontal steel structure, and the bottom...

Embodiment 2

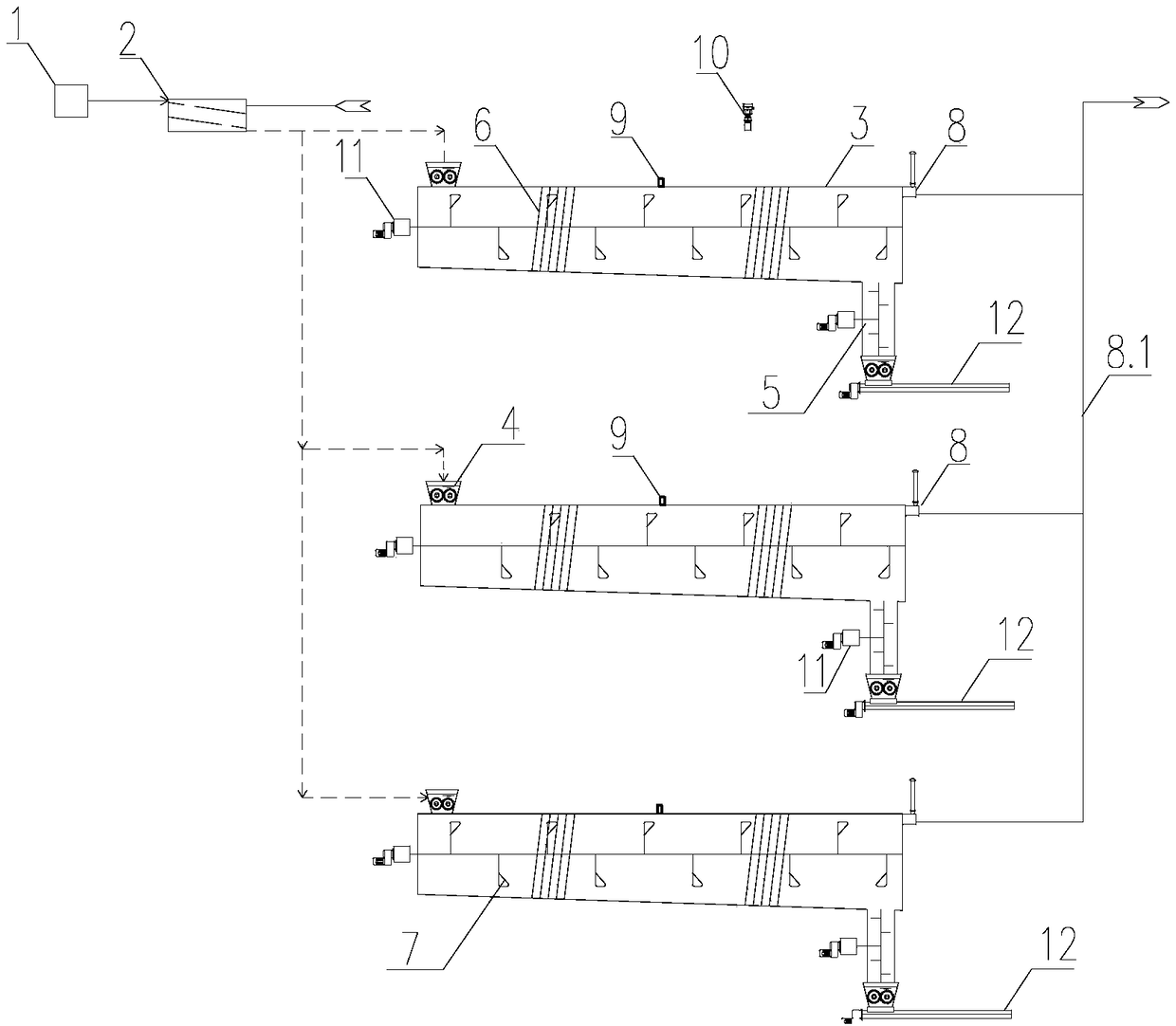

[0042] Such as figure 2 The parallel high-concentration organic waste dry anaerobic system shown is basically the same as the structure, the difference is:

[0043] The connection between the anaerobic inoculator 2 and three parallel dry anaerobic reactors; the bottom of the discharge pipe 5.1 of each dry anaerobic reactor is provided with a discharge conveyor 12 .

[0044] According to the actual situation, the pretreated material enters the anaerobic fermentation chamber 3 of different dry anaerobic reactors through the anaerobic feed funnel 4 after being inoculated by the anaerobic inoculator 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com