Continuously feeding and discharging dynamic dry method anaerobic fermentation apparatus and method thereof

A dry anaerobic and fermentation equipment technology, applied in biochemical equipment and methods, biological material sampling methods, bioreactors/fermenters for specific purposes, etc. Difficulties, the level of industrialization needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

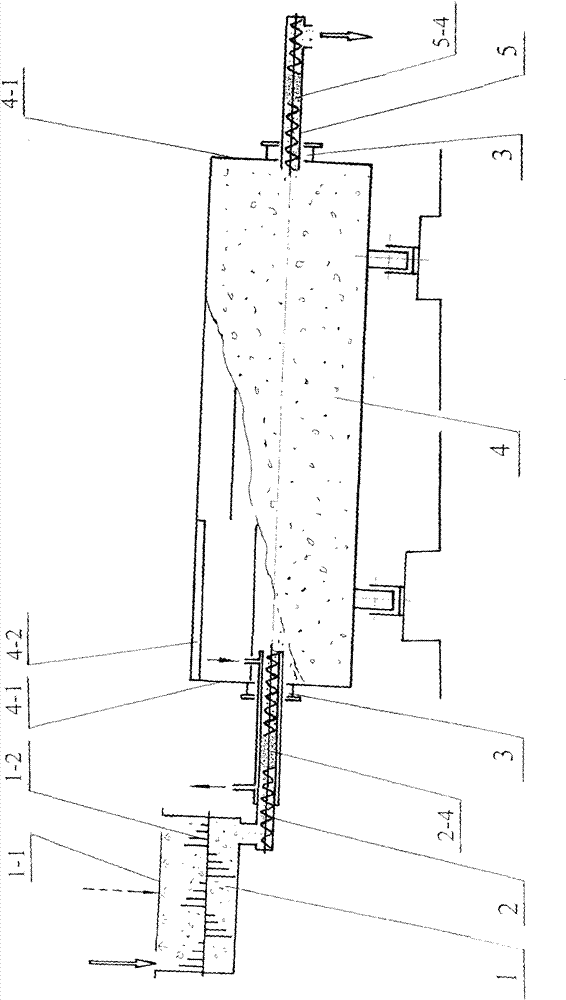

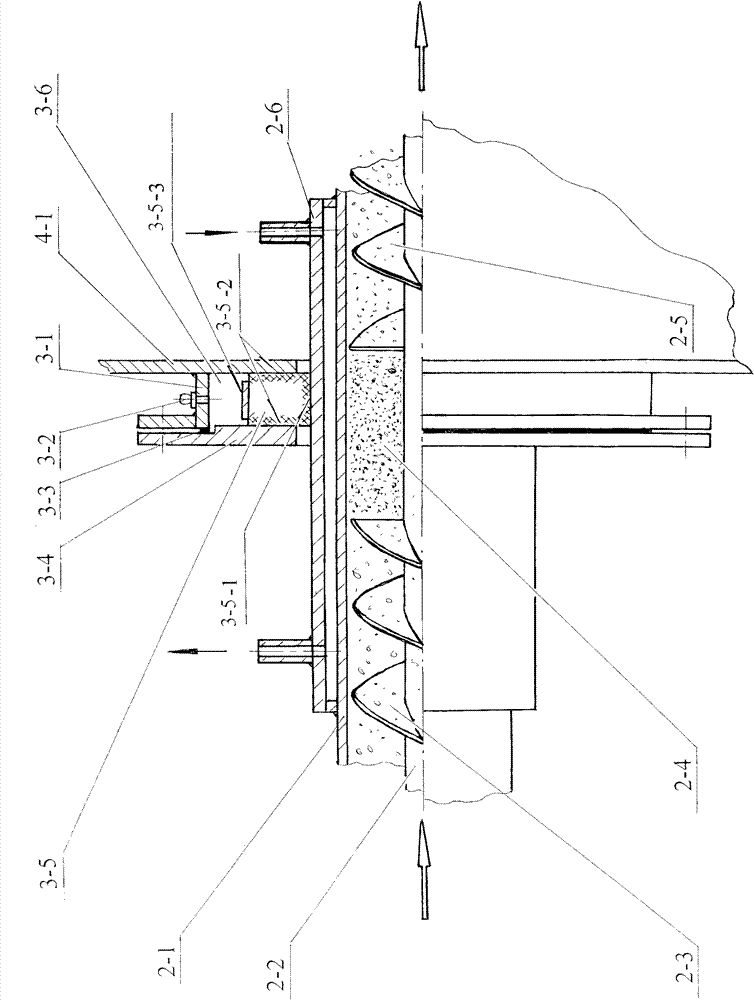

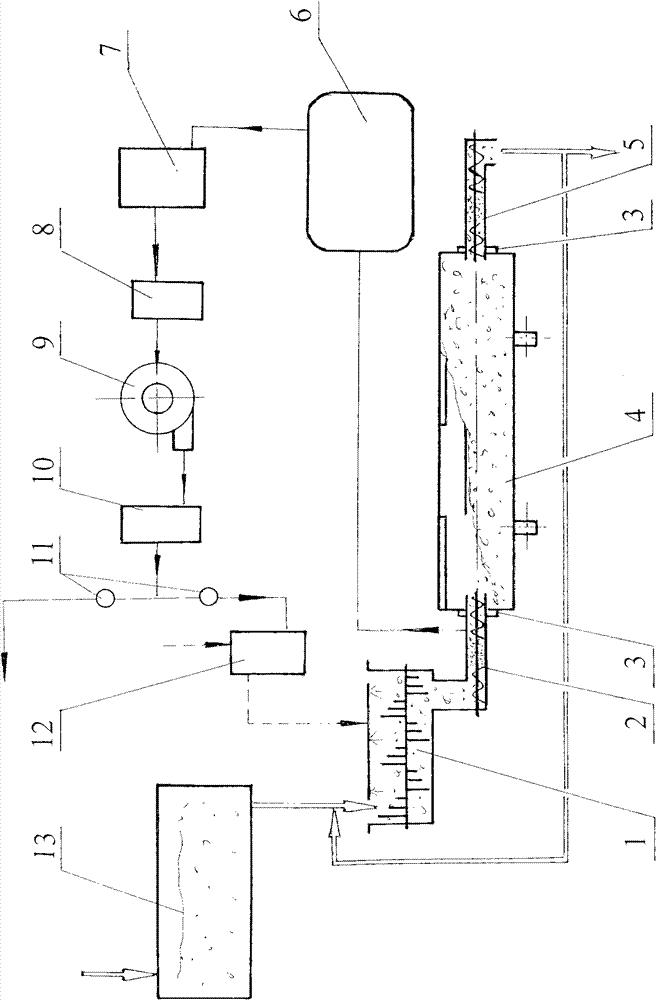

[0017] One has a diameter of 3m, a length of 15m, and a volume of 106m 3 The horizontal rotary silo with a rotation speed of 4rpm, an anaerobic fermentation hydraulic retention period of 21 days, and a biogas production capacity of 100m 3 / d.

[0018] 1800kg of aerobically fermented cow dung and corn stalk powder mixture and 450kg of biogas fermentation inoculum are required every day. The total weight of the mixture of the two is 2250kg, the water content is about 60%, and the temperature is about 50°C.

[0019] When the water temperature is 0°C in winter, the material should be adjusted to the moisture content (70%) and temperature (42°C) suitable for mesophilic anaerobic fermentation when feeding. It is necessary to add a temperature of 18°C to the raw material premixing and adjustment device. 750kg of water at ℃, the amount of biogas recycled by the biogas boiler is 6m 3 / d or so.

[0020] reference sign

[0021] 1——Raw material premixing and adjustment device

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com