Preparation method of lithium nickel cobalt manganate composite material coated with lithium iron phosphate on surface

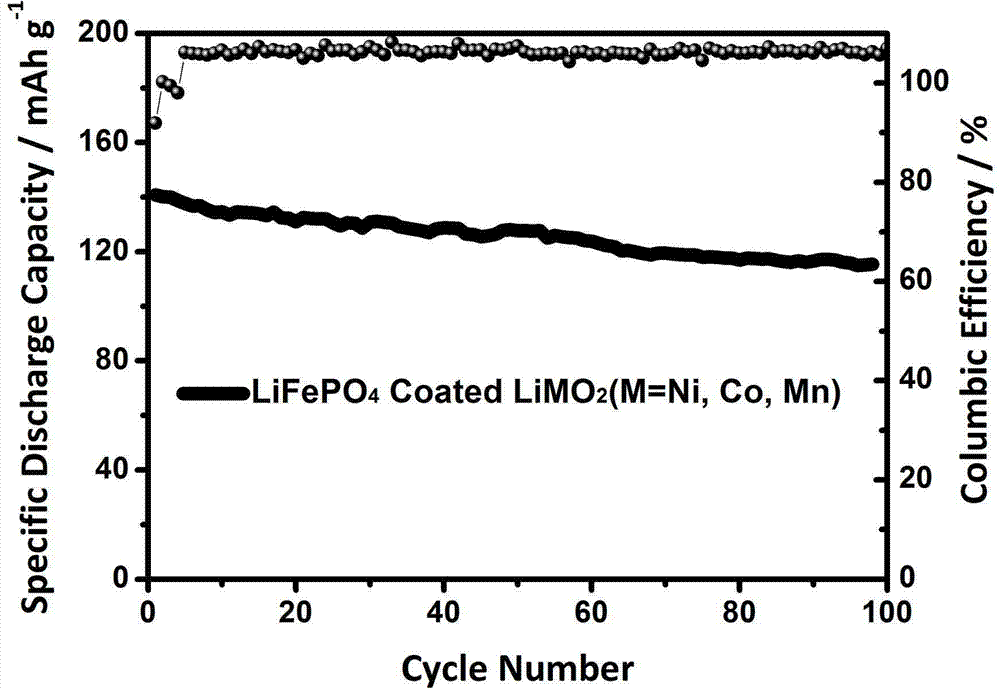

A surface-coated technology of lithium iron phosphate and nickel-cobalt lithium manganese oxide, which is applied in the field of new energy material preparation, can solve problems such as poor cycle performance, poor safety, and poor material stability, and achieve improved safety and high capacity. , good cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

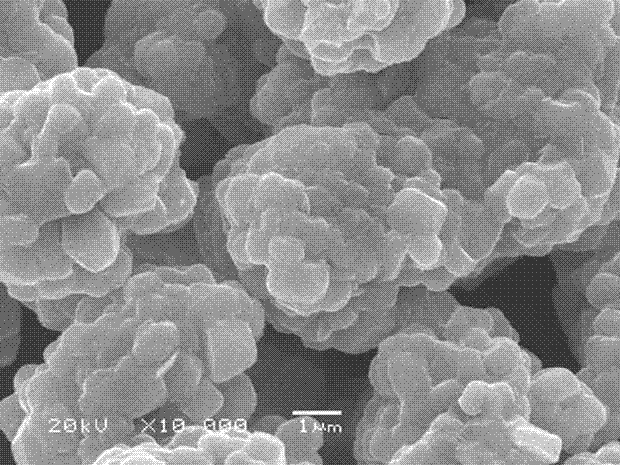

[0025] Example 1 3%LiFePO? Surface coated nickel cobalt manganic acid composite material

[0026] Weigh 0.0771g of LiOH·H?O with a purity of 98%, dissolve it with 40ml of distilled water, add 3g of nickel-cobalt lithium manganate ternary material and 10ml of ethanol to form a mixed solution A and stir at a speed of 300r / min About 20min. Then weigh 0.0692g of H?PO? with a concentration of 85% and add 20ml of distilled water to stir evenly. Add the H?PO? Then weigh 0.1668g of FeSO? 7H?O and add 10ml of distilled water, add the completely dissolved FeSO? Stir for a while. A certain amount of ethanol is added to the stirred material and put into a reaction kettle and put into an oven for hydrothermal reaction, and the temperature is 150° C. for 20 hours. The reacted material was dried under a nitrogen atmosphere at 500° C. for 2 hours after suction filtration and drying. The obtained material was uniformly mixed with acetylene black and PDFE to prepare a positive electrode, an...

example 2

[0027] Example 2 5%LiFePO? surface coated nickel cobalt lithium manganate composite material

[0028] Weigh 0.1285g of LiOH·H?O with a purity of 98%, dissolve it with 40ml of distilled water, add 3g of nickel-cobalt lithium manganate ternary material and 10ml of ethanol to form a mixed solution A and stir at a speed of 400r / min for 10min about. Then weigh 0.1153g of 85% H?PO?, add 20ml of distilled water and stir evenly, add the H?PO? Then weigh 0.2780g of FeSO? 7H?O and add 10ml of distilled water, add the completely dissolved FeSO? Stir for a while. The stirred material is replenished with a certain amount of ethanol and packed into a reactor and put into an oven for hydrothermal reaction, and the temperature is 180° C. for 5 hours. Other processes are identical to Example 1.

example 3

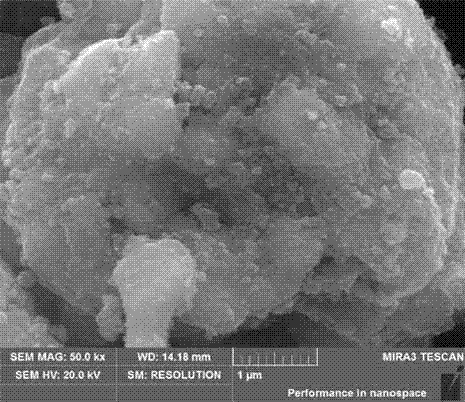

[0029] Example 3 10%LiFePO? surface coated nickel cobalt lithium manganate composite material

[0030] Weigh 0.2576g of LiOH·H?O with a purity of 98%, dissolve it with 40ml of distilled water, add 3g of nickel-cobalt lithium manganate ternary material and 10ml of ethanol to form a mixed solution A and stir at a speed of 400r / min for 10min about. Then weigh 0.2306g of H?PO? with a concentration of 85% and add 20ml of distilled water to stir evenly. Add the H?PO? Then weigh 0.5560g of FeSO? 7H?O and add 10ml of distilled water, add the completely dissolved FeSO? Stir for a while. The stirred material is replenished with a certain amount of ethanol and packed into a reactor and put into an oven for hydrothermal reaction, and the temperature is 180° C. for 5 hours. After the reacted material was suction filtered and dried, it was baked at 500° C. for 2 hours under a nitrogen atmosphere. Other processes are identical to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com