Total-nutrient water-retaining degradable mechanically-applied coated fertilizer

A full-nutrient fertilizer and water-retaining technology, applied in fertilization methods, organic fertilizers, inorganic fertilizers, etc., can solve the problems of poor compression resistance of the fertilizer core, affecting the soil environment, easy powder removal, etc., achieve high toughness and plasticity, and improve soil Structure, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of full nutrient fertilizer core:

[0038] The amount of raw materials is recorded by the quality of one thousand finished products.

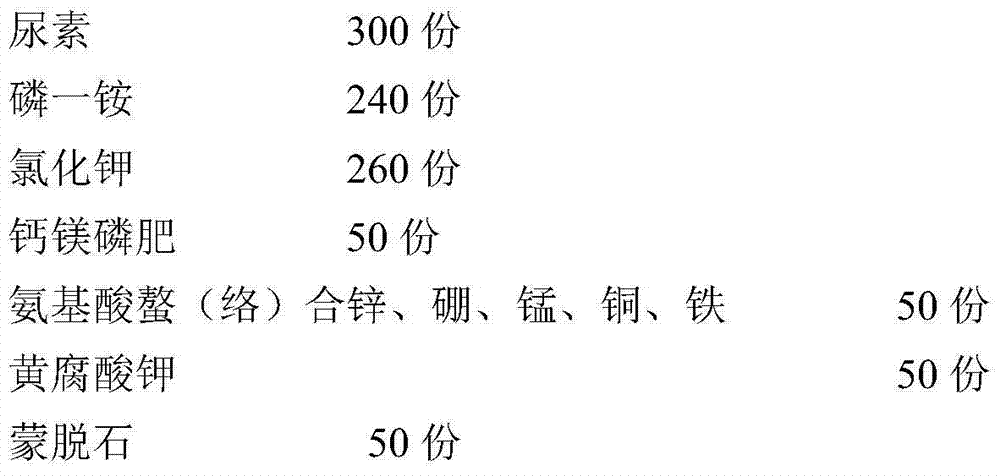

[0039]

[0040] Among them, the particle size of the montmorillonite is 400 mesh, and the above-mentioned raw materials are fully mixed to obtain a full-nutrient fertilizer core through a high-tower granulation process.

[0041] (2) Preparation of water-retaining degradable coating solution:

[0042] Based on the mass of 100 parts of the coating solution, 40g of sulfur was completely melted in a high-speed shear mixer at 120°C, and 40g of melamine formaldehyde resin and 10g of polyvinyl acetate were added in sequence, and the heating was continued at 120°C. Stirring speed of rev / min, stirring for 5 minutes, then adding 5g of diatomaceous earth and 5g of polyacrylic acid, stirring for 5 minutes at a stirring speed of 200 rev / min, to form a stable coating solution;

[0043] (3) Preheating and coating:

[0044] Put 50k...

Embodiment 2

[0050] With example 1, difference is: replace 50 parts of potassium fulvate in embodiment 1 with each 25 parts of alginic acid and potassium fulvate, replace the montmorillonite in embodiment 1 with each 25 parts of diatomite 50 parts of destoned, wherein the particle size of montmorillonite is 200 mesh, the cold water insoluble nitrogen content of melamine formaldehyde resin is 40%, and the free aldehyde is less than 0.5%.

[0051] The fully nutrient and water-retaining degradable machine-applied coated fertilizer (marked as 16-12-15) prepared in Example 2 was tested according to the industry standard for controlled-release fertilizers (HG / T3931-2007), and the nutrient release period was found to be 70 days .

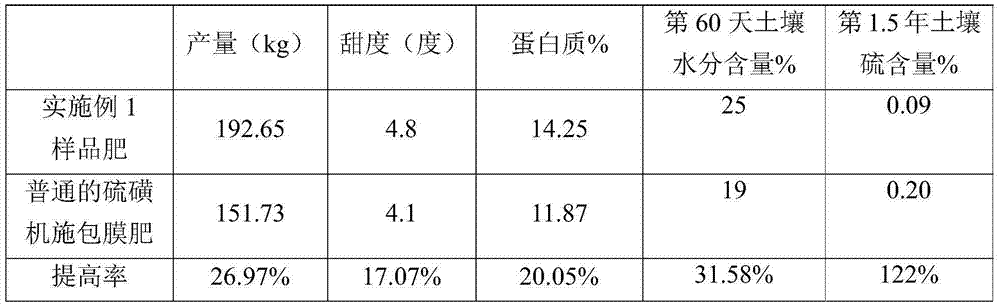

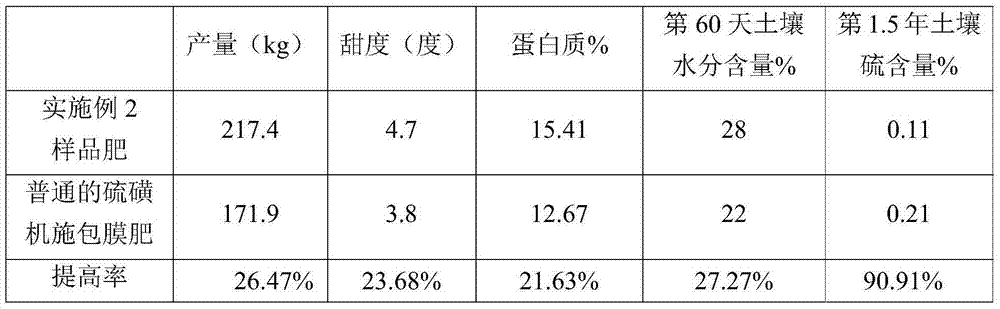

[0052] Contrast the sample fertilizer (16-12-15) prepared in Example 2 with the common sulfur machine-applied coating fertilizer with NPKS nutrients, corn is planted in the plot, and each plot area is 100m 2 , apply 8kg to each plot, adopt the method of mechanical app...

Embodiment 3

[0056] With example 1, difference is: replace 50 parts of potassium fulvate in embodiment 1 with each 25 parts of humic acid and potassium fulvate, replace the montmorillonite in embodiment 1 with each 25 parts of kaolin and diatomaceous earth Stone 50 parts.

[0057] The full nutrient and water-retaining degradable machine-applied coated fertilizer prepared in Example 3 was tested according to the industry standard for controlled-release fertilizers (HG / T3931-2007), and the nutrient release period was found to be 57 days.

[0058] Contrast the sample fertilizer (16-12-15) prepared in Example 3 with the common sulfur machine-applied coating fertilizer with NPKS nutrient, and the corn is planted in the plot, and each plot area is 100m 2 , apply 8kg to each plot, adopt the method of mechanical application, and pour the same amount of water each time, collect 20cm soil samples for analysis, and the results of the agrochemical test are as follows:

[0059]

[0060] On the whol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com