Toughening and waterproof starch plastic and preparation method thereof

A technology of starch plastics and water resistance, which is applied in the field of polylactic acid/thermoplastic starch/thermoplastic polyurethane blended starch plastics and its preparation, which can solve the problems of unsuitability for large-scale industrial production, easy migration of polyethylene glycol, and complicated starch treatment process and other issues, to achieve the effect of improving material toughness and water resistance, reducing material cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

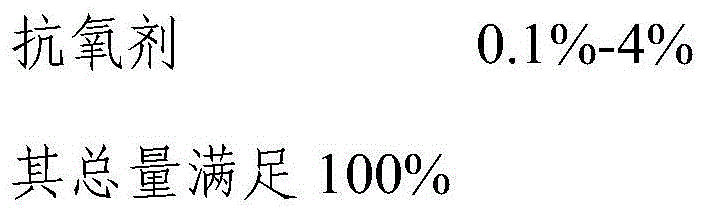

Embodiment 1

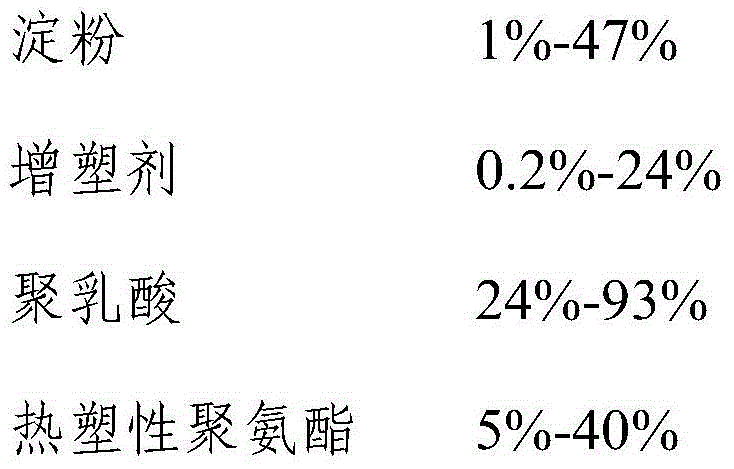

[0026] In this embodiment, the formula component of toughened water-resistant starch plastic weight percent of the present invention is as follows:

[0027] Starch 4% (produced by Gansu Shengdafangzhou Potato Modified Starch Co., Ltd., industrial grade, cassava starch), polylactic acid 87% (produced by Natureworks in the United States, brand: 2003D), thermoplastic polyurethane 7% (produced in Dadong, Taiwan, polyester type, Shore hardness is 65A), glycerin 1.5% (produced by Shanghai Shenbo Chemical Co., Ltd., analytically pure), antioxidant 0.5% (Jiangsu Feixiang Chemical Binhai Co., Ltd., model: 1010)

[0028] The preparation method of the above-mentioned toughened water-resistant starch plastic is as follows:

[0029] (1) Dry starch, polylactic acid, and thermoplastic polyurethane at 80°C for 6 hours, and then accurately weigh each component according to the above-mentioned formula for toughening water-resistant starch plastic;

[0030] (2) Put starch and glycerin in propor...

Embodiment 2

[0033] In this embodiment, the formula component of toughened water-resistant starch plastic weight percent of the present invention is as follows:

[0034] Starch 20% (produced by Gansu Shengda Fangzhou Potato Modified Starch Co., Ltd., industrial grade, cassava starch), polylactic acid 58.5% (produced by Natureworks in the United States, brand: 2003D), thermoplastic polyurethane 15% (produced in Dadong, Taiwan, polyester type, Shore hardness is 65A), glycerin 6% (produced by Shanghai Shenbo Chemical Co., Ltd., analytically pure), antioxidant 0.5% (Jiangsu Feixiang Chemical Binhai Co., Ltd., model: 1010)

[0035] The preparation method of the above-mentioned toughened water-resistant starch plastic is as follows:

[0036] (1) Dry starch, polylactic acid, and thermoplastic polyurethane at 80°C for 6 hours, and then accurately weigh each component according to the above-mentioned formula for toughening water-resistant starch plastic;

[0037] (2) Put starch and glycerin in pro...

Embodiment 3

[0040] In this embodiment, the formula component of toughened water-resistant starch plastic weight percent of the present invention is as follows:

[0041] Starch 29% (produced by Gansu Shengdafangzhou Potato Modified Starch Co., Ltd., industrial grade, cassava starch), polylactic acid 40.5% (produced by Natureworks in the United States, brand: 2003D), thermoplastic polyurethane 20% (produced by Dadong, Taiwan, polyester type, Shore hardness is 65A), glycerin 10% (produced by Shanghai Shenbo Chemical Co., Ltd., analytically pure), antioxidant 0.5% (Jiangsu Feixiang Chemical Binhai Co., Ltd., model: 1010)

[0042] The preparation method of the above-mentioned toughened water-resistant starch plastic is as follows:

[0043] (1) Dry starch, polylactic acid, and thermoplastic polyurethane at 80°C for 6 hours, and then accurately weigh each component according to the above-mentioned formula for toughening water-resistant starch plastic;

[0044] (2) Put starch and glycerin in pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com