Straw and excrement mixed anaerobic fermentation reactor and biogas fermentation process thereof

An anaerobic fermentation and reactor technology, applied in the direction of solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of power consumption and increased energy consumption , to achieve the effect of increasing gas production rate, reducing the possibility of stratification, and improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

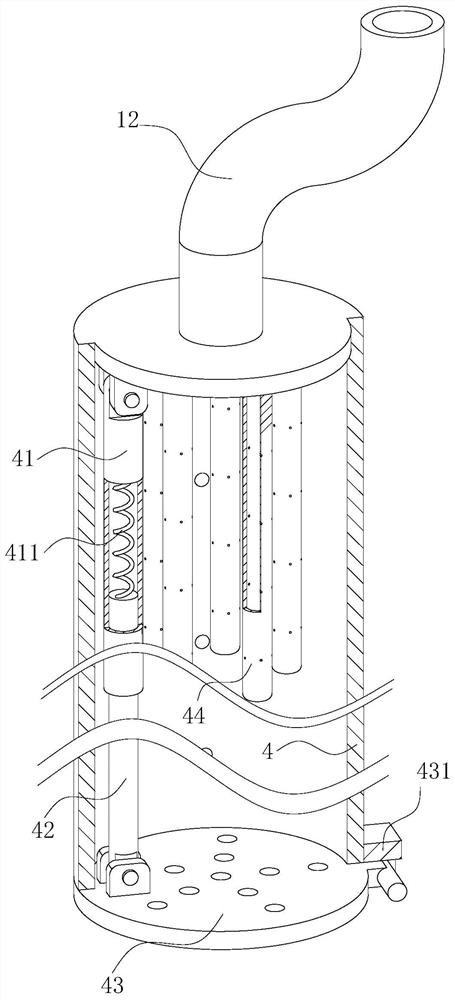

[0050] As an embodiment of the present invention, a mounting frame 33 is fixedly installed in the horizontal pipe 3; a rotating shaft 331 is installed on the side of the mounting frame 33 facing the vertical pipe 2; the end of the rotating shaft 331 is away from the mounting frame 33 An impeller 332 is fixedly installed on it; the impeller 332 does not contact the inner wall of the transverse tube 3;

[0051] The lower end of the air guide tube 21 is fixedly equipped with a connecting pipe 341, and the two are connected to each other; The distance between them is equal; the connecting pipe 341 is fixedly installed with a dispersing pipe 34 away from the end of the air guide pipe 21, and the two communicate with each other; The ones communicate with each other; the ejection pipes 342 have a plurality of them, which are evenly distributed around the central line of the dispersion pipe 34;

[0052] The diameter of the ejection pipe 342 is smaller than the diameter of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com