A method for preparing biogas by using straw combined with excess sludge

A technology of excess sludge and inoculated sludge, applied in sludge treatment, biological sludge treatment, fermentation and other directions, can solve the problem of low content of carbohydrates, etc., and achieve low production cost, shortened anaerobic reaction cycle, and economic benefits. considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

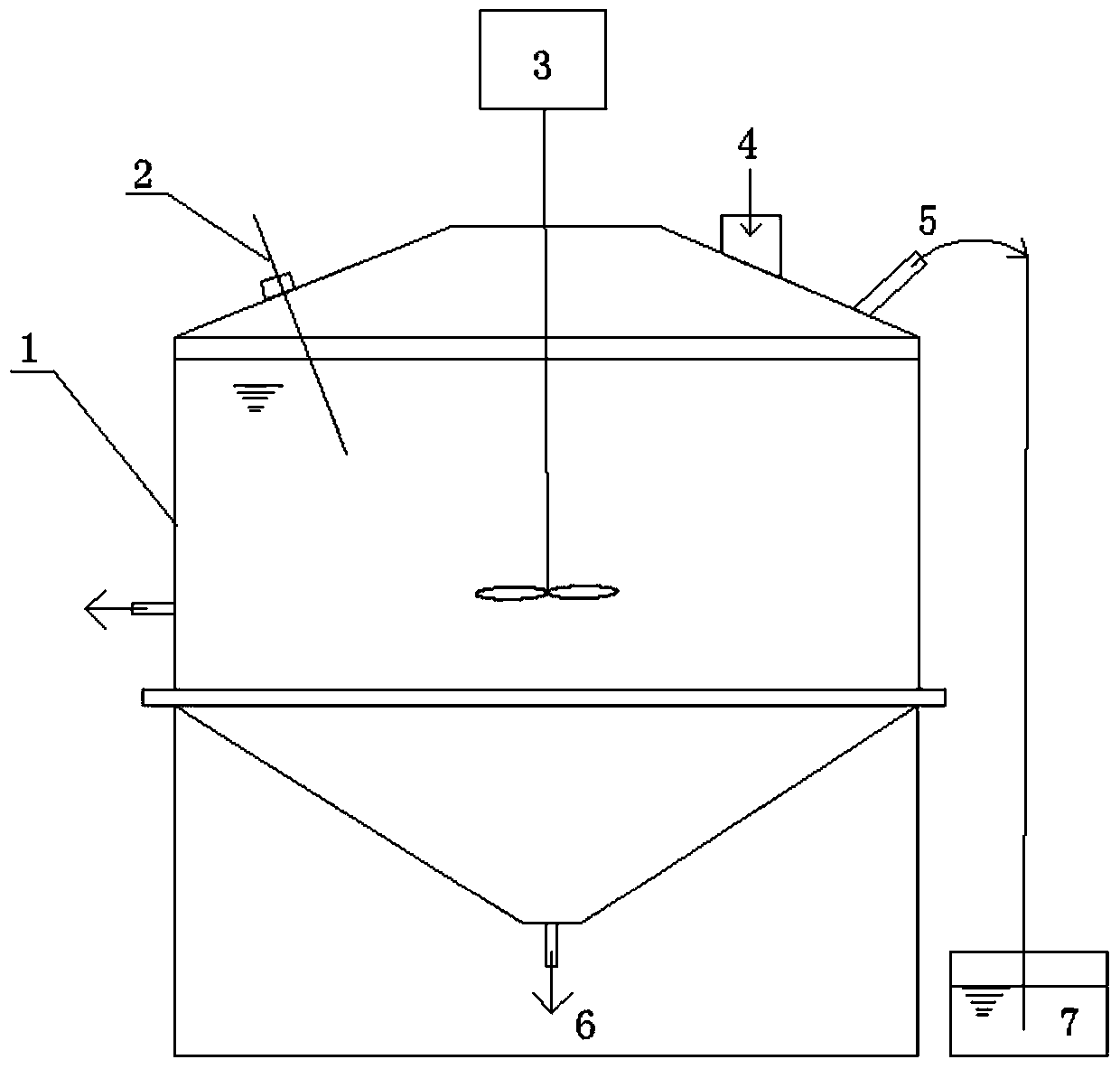

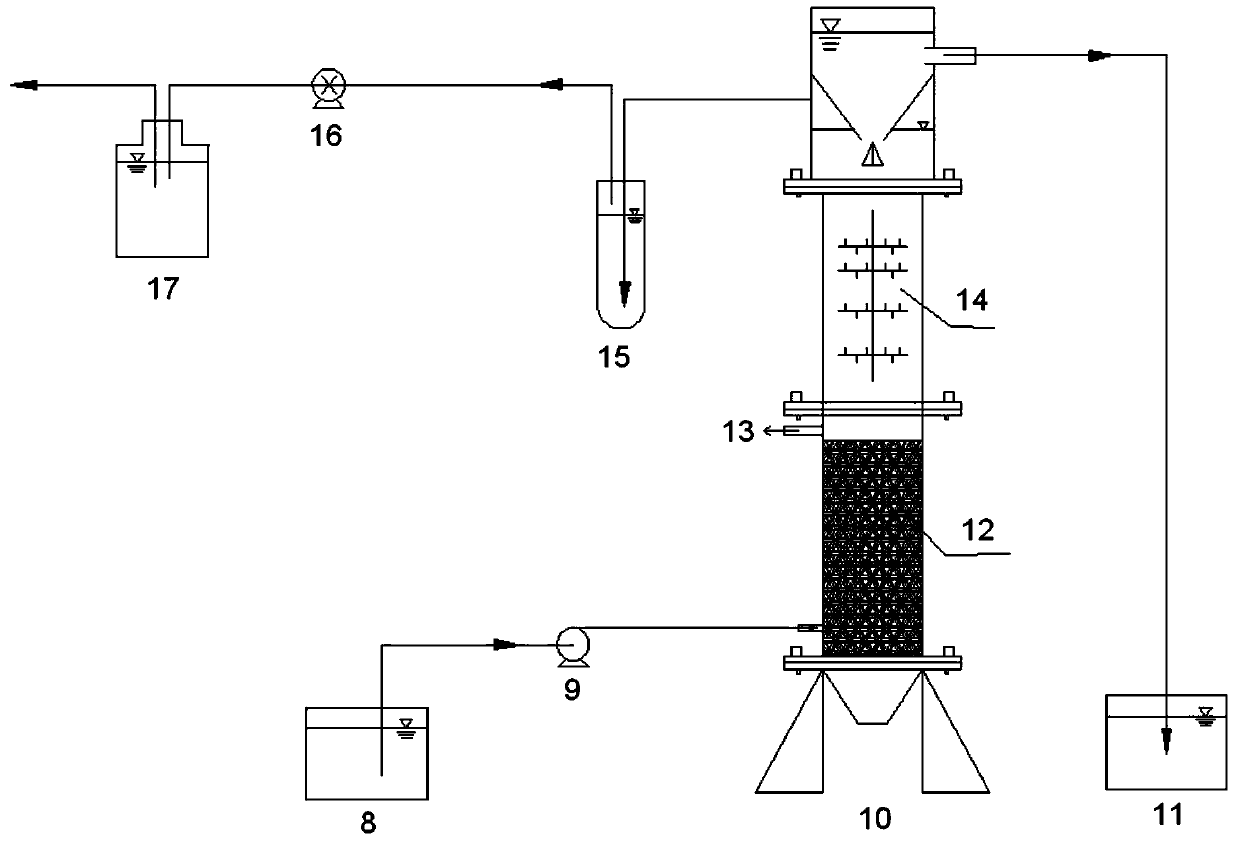

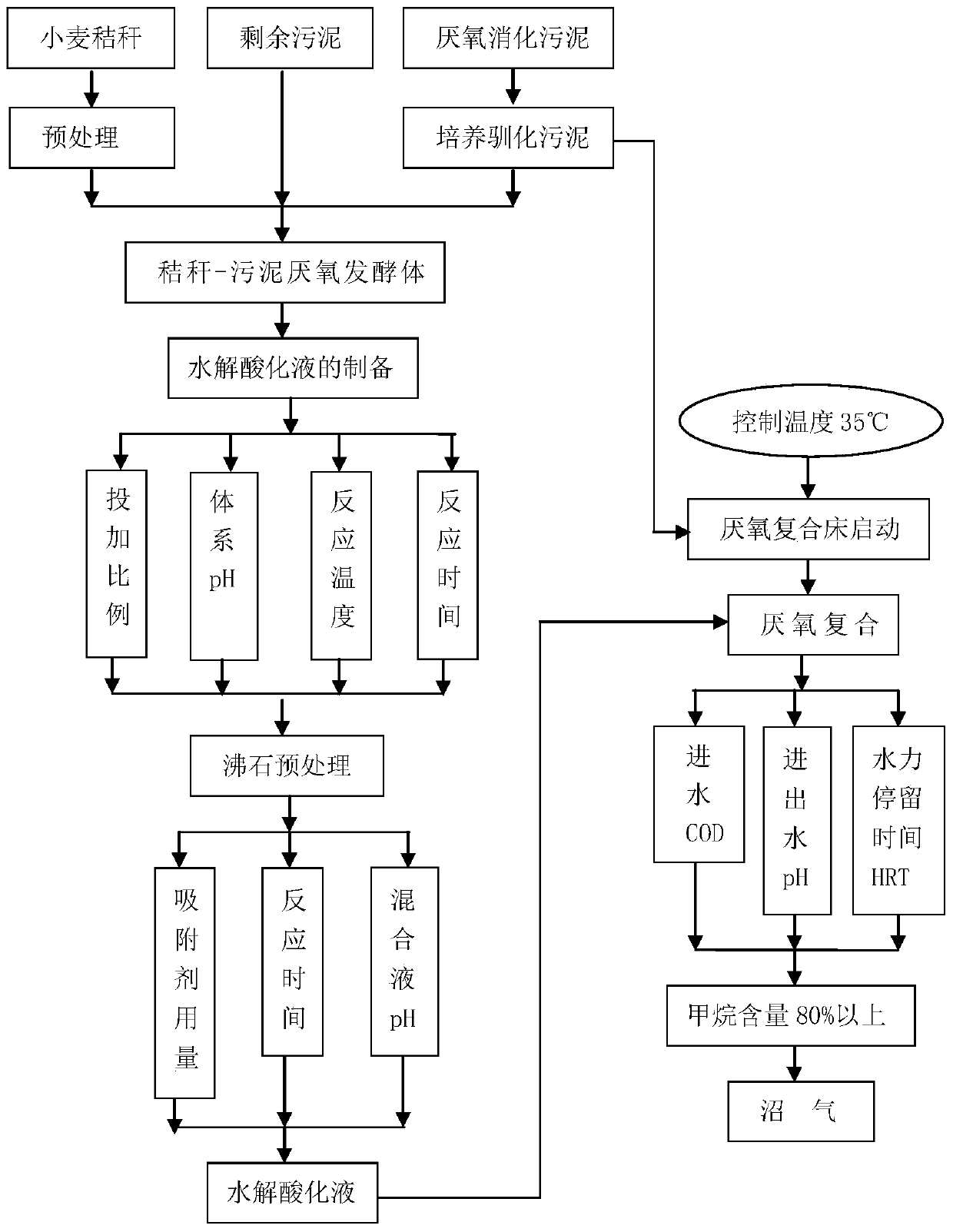

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Test the main indicators of the straw, cut it through a 60-mesh sieve, add a 10% sodium hydroxide solution to the straw at a solid-to-liquid ratio of 1:1, and pretreat it at 50°C for 30 minutes to obtain the pretreated straw. Treat the straw, measure its water content after pretreatment and save it for later use;

[0047] Step 2: Take back the excess sludge obtained from the treatment workshop of the domestic sewage plant, remove larger impurities, seal and keep the water in reserve, and test the components of the excess sludge and its supernatant.

[0048] Step 3: Use the anaerobic digestion sludge from the sewage treatment plant as the inoculation sludge. The inoculation sludge has an oval appearance, dark gray color and good performance. The dissolved organic matter in the anaerobic digestion sludge digestion liquid is used as the carbon source , after 7 days of aerated culture to improve the activity of hydrolytic acidification bacteria, then added to the hy...

Embodiment 2

[0053] Step 1: Test the main indicators of the straw, cut it through a 60-mesh sieve, add a 10% sodium hydroxide solution to the straw at a solid-to-liquid ratio of 1:1, and pretreat it at 50°C for 30 minutes to obtain the pretreated straw. Treat the straw, measure its water content after pretreatment and save it for later use;

[0054] Step 2: Take back the excess sludge obtained from the treatment workshop of the domestic sewage plant, remove larger impurities, seal and keep the water in reserve, and test the components of the excess sludge and its supernatant.

[0055] Step 3: The anaerobic digestion sludge taken from the sewage treatment plant is used as the inoculation sludge. The inoculation sludge has an oval appearance, dark gray color and good performance. Using dissolved organic matter in the digested liquid of anaerobic digested sludge as carbon source, aerated for 7 days to increase the activity of hydrolytic acidification bacteria, and then added to the hydrolytic...

Embodiment 3

[0060] Step 1: Test the main indicators of the straw, cut it through a 60-mesh sieve, add a 10% sodium hydroxide solution to the straw according to a solid-to-liquid ratio of 1:1, and pretreat the straw at 50°C for 30 minutes to obtain the pretreated straw. Treat the straw, measure its water content after pretreatment and save it for later use;

[0061] Step 2: Take back the excess sludge obtained from the treatment workshop of the domestic sewage plant, remove larger impurities, seal and keep the water in reserve, and test the components of the excess sludge and its supernatant.

[0062] Step 3: The anaerobic digestion sludge taken from the sewage treatment plant is used as the inoculation sludge. The inoculation sludge has an oval appearance, dark gray color and good performance. The dissolved organic matter in the digested liquid of anaerobic digested sludge was used as the carbon source, aerated for 7 days to increase the activity of the hydrolytic acidification bacteria, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com