Four-in-one biogas fermentation device and method

A biogas fermentation and biogas technology, which is applied in biochemical cleaning devices, biochemical equipment and methods, fermentation, etc., can solve the problems of reduced utilization rate of straw materials, floating on the top of the fermentation tank, and increased device construction costs. The effect of increasing the volume gas production rate, reducing the low residue of pesticides and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

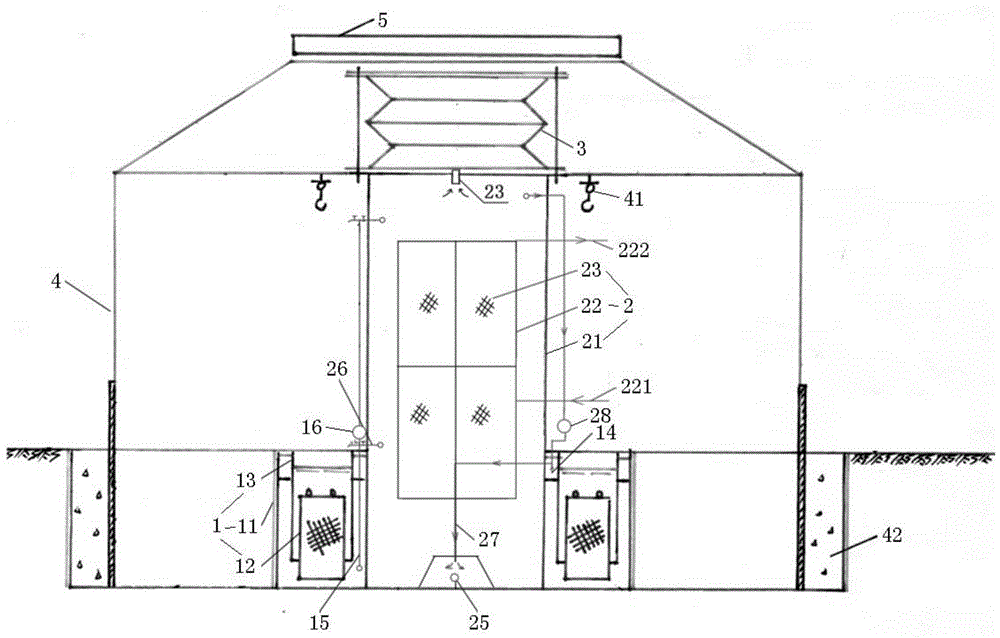

[0024] Such as figure 1 As shown, the four-in-one biogas fermentation device provided by the present invention includes a primary dry fermentation mechanism 1, a secondary wet fermentation mechanism 2, a foldable air storage bag 3, a solar greenhouse 4 and a sun-dried solar water heater 5.

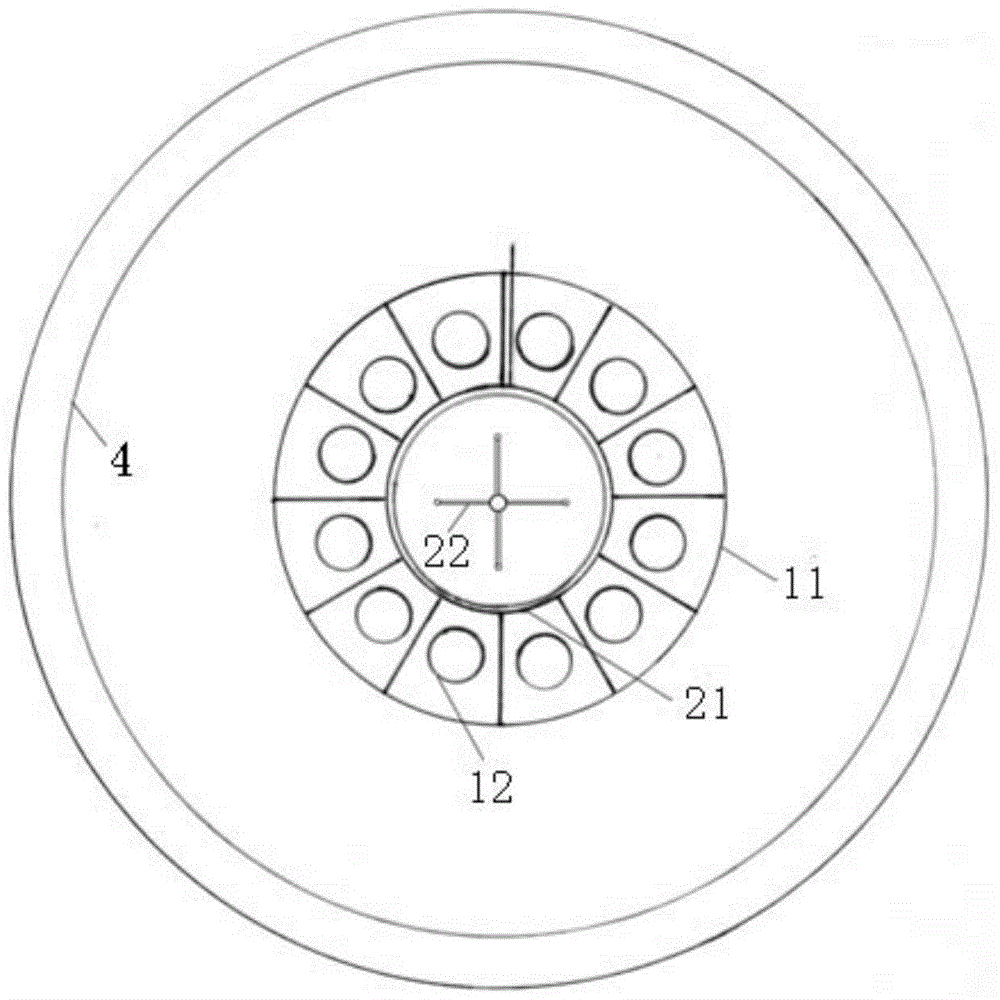

[0025] Such as figure 1 , figure 2 As shown, the primary dry fermentation mechanism 1 includes a dry fermentation tank 11 , several cages 12 and several water-sealed covers 13 . The dry fermenter 11 has a ring structure and is arranged in the solar greenhouse 4. The dry fermenter 11 is filled with feed liquid, and the upper cover of the dry fermenter 11 is unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com