High-ammonia-nitrogen organic waste dry biogas fermentation device and fermentation method thereof

A technology of organic waste and biogas fermentation, which is applied in the field of treatment and utilization, can solve the problems of the limitation of fermentation substrate and microbial communication, dry biogas fermentation cannot be carried out normally, and the content of dry matter in the feed is low, so as to eliminate electron transfer Effects of barrier, less odor, and less nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

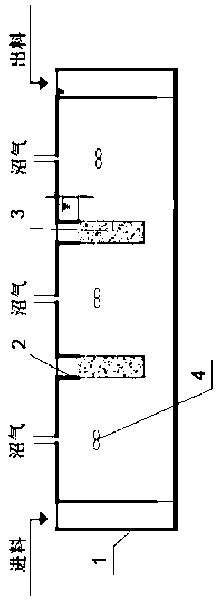

[0028] A dry-type biogas fermentation device for high ammonia nitrogen organic waste, comprising a horizontal fermentation tank body. The horizontal fermentation tank body is provided with a feed channel, a fermentation chamber and a discharge channel. The bottoms of the feed channel and the discharge channel are respectively connected to the fermentation tank. The chambers are connected. On the top of the fermentation chamber, a plurality of loading mechanisms for placing additives are fixed along the length direction of the fermentation chamber. The top of the fermentation chamber is connected with a biogas pipe.

[0029] The loading and unloading mechanism is a frame for containing additives, and the frame is arranged at intervals of 2000-5000 mm along the length of the fermentation chamber, the width of the frame is 200-500 mm, the length of the frame is 500-1000 mm less than the width of the fermentation chamber, and the height of the frame is lower than Chamber depth at l...

Embodiment 2

[0040] This embodiment further describes the device and method of the present invention in conjunction with the accompanying drawings.

[0041] The horizontal fermentation tank body 1 of the dry biogas fermentation device adopts a horizontal form, and the solid and semi-solid organic wastes with high ammonia nitrogen directly enter the dry biogas fermentation device through the feeding device.

[0042] Frames 2 for containing additives are arranged at intervals of 2000 to 5000 mm in the length direction of the biogas fermentation device. The frames are made of steel plates with a width of 200 to 500 mm. The depth of the chamber is at least 600~1200mm; the upper part of the frame is welded with the top plate of the tank of the biogas fermentation device, suspended in the biogas fermentation device, and there are holes or gaps in the middle, lower part and bottom of the frame 300~500mm below the liquid level in the biogas fermentation device , Aperture or slit width 20~50mm, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com