STAIC efficient anaerobic reactor

An anaerobic reactor and anaerobic reaction tank technology, applied in the field of STAIC high-efficiency anaerobic reactor, can solve the problems of high effluent water level, increased pressure resistance coefficient, long start-up time, etc., achieve high volume gas production rate, improve Degradation rate, effect of shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

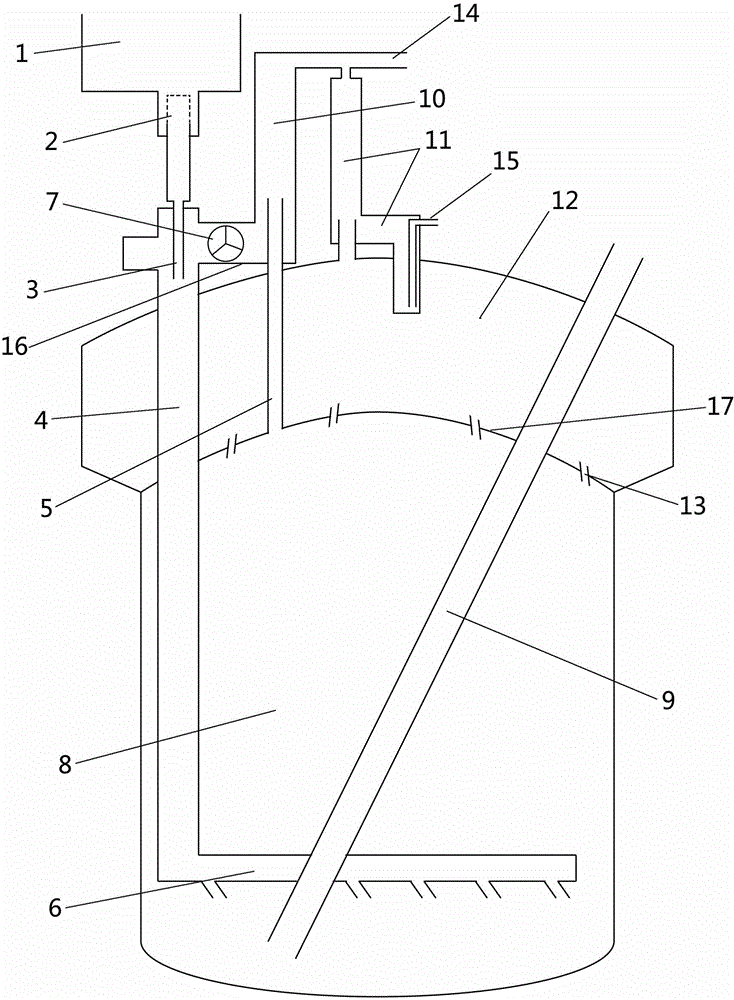

[0016] refer to figure 1 , the present invention consists of an automatic pressure-regulating feeding pool 1, a protective cover 2, an automatic traction reflux circulator 3, a feeding pipe 4, an upward reflux pipe 5, a material distribution system 6, an adjustable speed circulating pump 7, a lower reaction pool 8, and a discharge Slag pipe 9, lower reaction tank gas-liquid separator 10, upper reaction tank gas-liquid separator 11, upper reaction tank 12, inclined connecting pipe 13, gas delivery pipe 14, liquid slag overflow pipe 15, return pipe 16, three-phase separation Device 17 is composed. The upper reaction tank 12 is superimposed on the lower reaction tank 8, the three-phase separator and the inclined connecting pipe are arranged on both sides of the top of the lower reaction tank 8, the speed-adjustable circulation pump 7 is arranged on the return pipe 16, and the lower reaction tank 8 is respectively connected to the upper and lower reaction tanks. The return pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com