Home device and method for producing methane by dry-type fermentation of stalks

A biogas production and dry fermentation technology, applied in fermentation, gas production bioreactors, waste fuels, etc., can solve the problems of no biogas slurry reflux system, difficult biogas slurry treatment, and inconvenient cleaning of straw residues, etc., to reduce the difficulty of treatment , The effect of increasing the volumetric gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

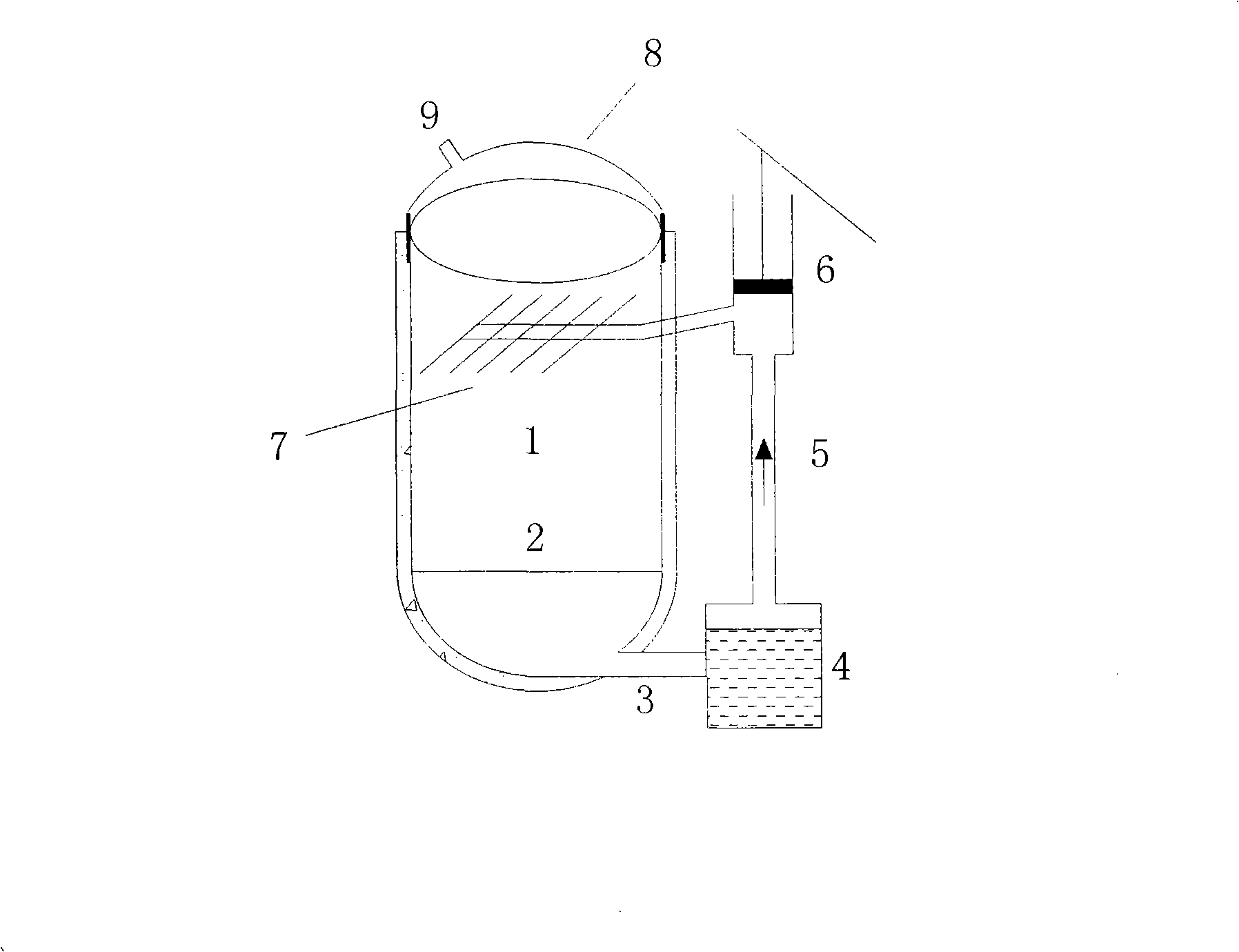

[0020] Taking a family of three as an example, according to the technical performance of biogas produced by dry anaerobic fermentation of straw and the needs of the residents for the amount of biogas for cooking and boiling water, design and build a 6m2 3 Biogas digester (see attached drawing 1 for the design drawing). Biogas pool 1 is a water-proof pool cast in brick or concrete. The biogas pool is cylindrical, and the bottom of the pool is conical downward. The bottom of the cone has a pipe 3 connected to the outside of the biogas digester. The pipe is connected to the collection pond 4 built on one side of the biogas digester. Through the pipe 3, the water leached from the biogas digester can be discharged into the collection pond. The collection pond is lower than the biogas There is a shaft 5 above the collection pool, and a pumping device 6 is installed in the shaft to pump the biogas slurry in the collection pool into the biogas digester through the backflow plastic pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com