A kind of coated decorative base paper based on gravure printing and its manufacturing method

A technology for decorative base paper and gravure printing, applied in special paper, papermaking, coating, etc., can solve problems such as unsatisfactory effect, and achieve the effect of solving the problem of excessive filler and powder drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

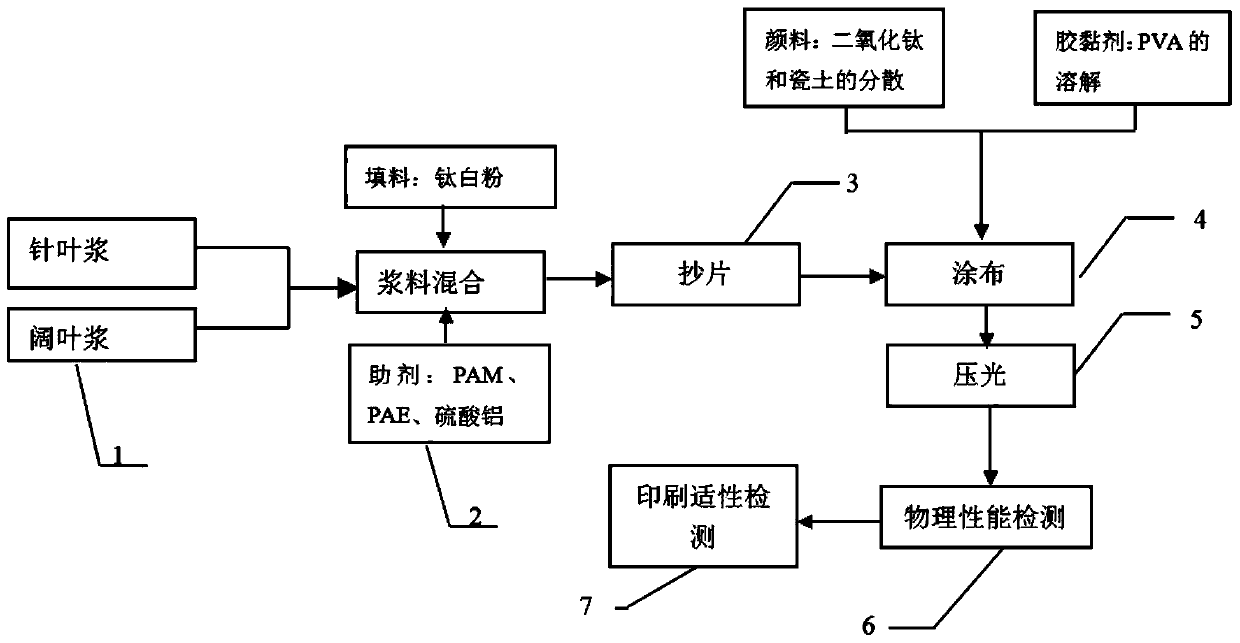

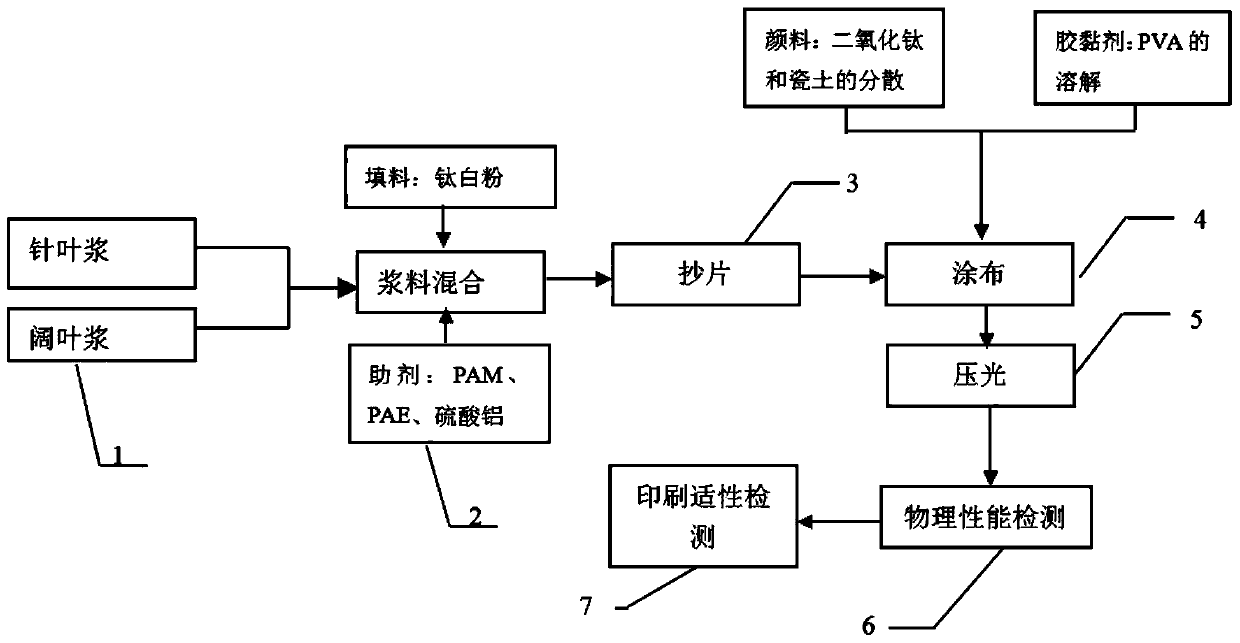

Method used

Image

Examples

preparation example Construction

[0035] (2) Preparation of filler: Pour the weighed water and titanium dioxide into the frosted disperser, and add the dispersant sodium hexametaphosphate. The amount of the dispersant added is 0.4%-1% of the mass of the titanium dioxide, the speed of the mixer is set at 20000-25000r / min, and the constant speed disperses for about 40-60min. Finally, a solution with a titanium dioxide concentration of 1%-10% is prepared.

[0036] ⑶Mixing of slurry: Firstly, the weighed pulp is fluffed, the speed of the standard fluffing machine is set to 10000-20000r / min, and the time is set to 5-10min. Stir the decomposed pulp under a constant speed mixer at a speed of 800-1500r / min, then add the filler titanium dioxide solution to the pulp solution for mixing, and add additives PAM, PAE and aluminum sulfate. The dry weight of the added titanium dioxide is 20%-40% of the dry weight of the pulp. After adding the filler, stir for 3-5 minutes. The dry weight of PAE is 1%-5% of the dry weight of t...

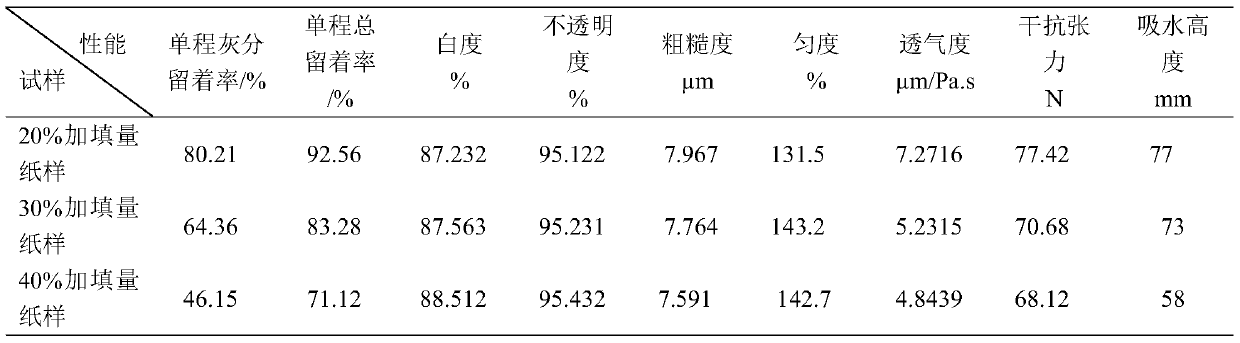

Embodiment 1

[0054] 1. Copying of decorative base paper

[0055] (1) Beating: Tear the coniferous pulp board and the broad-leaved pulp board into small pieces and soak them in water for 12 hours respectively, and beat the coniferous pulp and broad-leaved pulp separately with a trough-type beater. The beating degree of the coniferous pulp is 32° SR, the beating degree of hardwood pulp is 28°SR. Dry the beaten pulp and put it in a sealed bag to balance the moisture for 24 hours.

[0056] (2) Preparation of filler: Pour the weighed water and titanium dioxide into the frosted disperser, and add the dispersant sodium hexametaphosphate. The addition amount of the dispersant is 0.4% of the mass of titanium dioxide, the speed of the mixer is set to 20000r / min, and the stirring is carried out for 60min. Finally, a solution with a titania concentration of 1% was prepared.

[0057] ⑶ Mixing of slurry: First, the weighed pulp is deflagged, the speed of the standard deflaker is set to 15000r / min, an...

Embodiment 2

[0092] 1. Copying of decorative base paper

[0093] (1) Beating: Tear the coniferous pulp board and the broad-leaved pulp board into small pieces and soak them in water for 12 hours respectively, and beat the coniferous pulp and broad-leaved pulp separately with a trough-type beater. The beating degree of the coniferous pulp is 35° SR, the beating degree of hardwood pulp is 30°SR. Dry the beaten pulp and put it in a sealed bag to balance the moisture for 24 hours.

[0094] (2) Preparation of filler: Pour the weighed water and titanium dioxide into the frosted disperser, and add the dispersant sodium hexametaphosphate. The added amount of the dispersant is 0.6% of the mass of titanium dioxide, the speed of the disperser is set at 22000r / min, and the stirring is carried out for 60min. Finally, a solution with a titania concentration of 5% was prepared.

[0095] ⑶ Mixing of slurry: First, the weighed pulp is deflagged, the speed of the standard deflaker is set to 15000r / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com