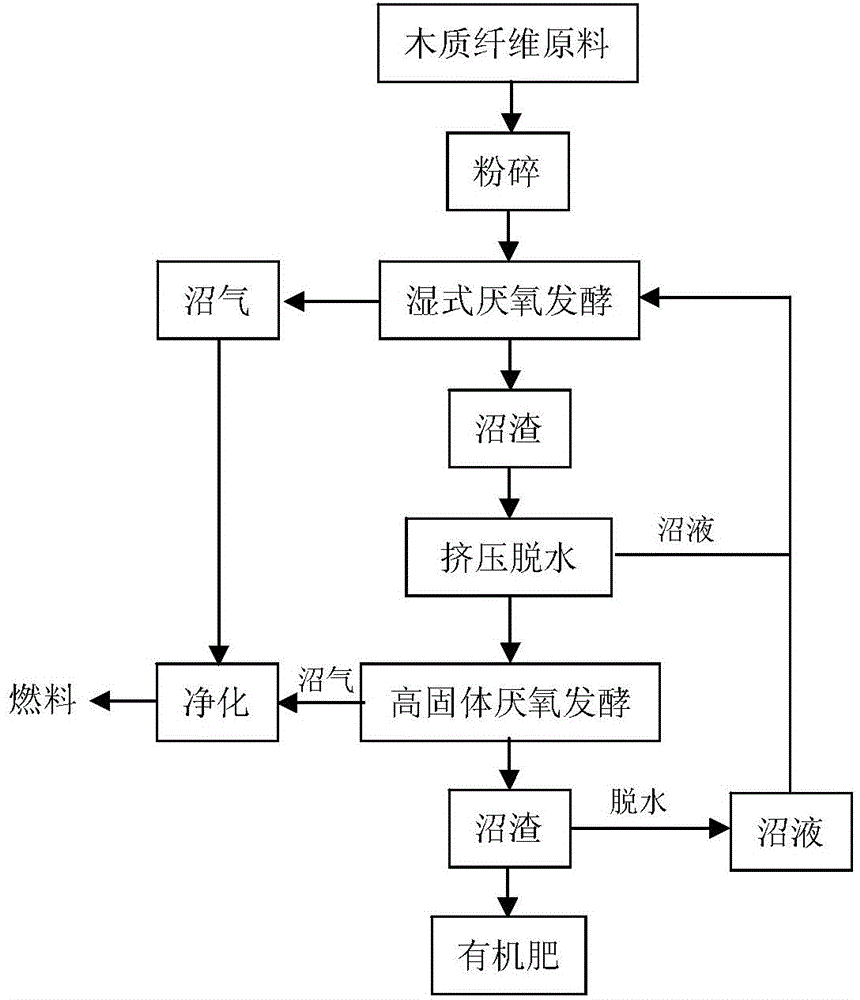

Method for producing biogas by virtue of large-scale anaerobic fermentation of wood fiber raw materials

A lignocellulosic raw material, anaerobic fermentation technology, applied in the direction of fermentation, waste fuel, etc., can solve the problems of low processing capacity of anaerobic reactor, high one-time investment, low volumetric gas production rate, etc., to improve processing capacity and volume The effect of gas production, reduced project investment cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The experiment was carried out in a CSTR reactor with an effective volume of 10L and a high-solids anaerobic reactor with an effective volume of 6L, and the fermentation temperature was 34-37°C. The collected wheat straw was naturally air-dried and mechanically crushed to below 5.0 cm.

[0029] Start-up of the CSTR reactor: add crushed wheat straw with a mass of 500 g of TS and 4 kg of inoculum (anaerobic digested sludge) with a mass fraction of TS of 2.5% into the CSTR reactor, adjust the C / N of the fermentation product to about 30 with urea, and use water to Adjust the TS concentration of wheat straw in the fermenter to 5%. After mixing, nitrogen gas is introduced for 2 minutes, and the experiment is started after sealing. Stir twice a day, each time for 15 minutes, at a speed of 15-20 r / min. After 15 days, mix well according to the mass ratio of wheat straw: biogas slurry 1:18, add 667g of the mixture to the CSTR reactor every day, and discharge the same amount of fe...

Embodiment 2

[0045] The experiment was carried out in a CSTR reactor with an effective volume of 10L and a high-solids anaerobic reactor with an effective volume of 6L, and the fermentation temperature was 34-37°C. The collected corn stalks were naturally air-dried and mechanically crushed to a size below 5.0 cm. Add 3% NaOH solution to the crushed corn stalks. The amount of NaOH solution added is the same as that of corn stalks TS. After mixing, it is pretreated at room temperature and used for anaerobic fermentation after 48 hours.

[0046] Start-up of the CSTR reactor: add TS 600g pretreated corn stalks and 4.8kg TS inoculum (old digester sludge) with a TS mass fraction of 2.5% to the CSTR reactor, and use urea to adjust the C / N of the fermentation product to 30 Use water to adjust the TS concentration of corn stalks in the fermenter to 6%. After mixing, inject nitrogen gas for 2 minutes, start the experiment after sealing, stir twice a day, each time for 15 minutes, and the speed is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com