Device and method for dry-wet combined anaerobic fermentation for producing biogas

A dry-type anaerobic fermentation and anaerobic fermentation technology, which is applied in the field of dry-wet combined anaerobic fermentation to produce biogas, can solve the problems of small application range and inability to take into account the conversion rate of organic matter and volumetric gas production rate of anaerobic fermentation at the same time , to achieve the effects of wide application range, improved energy conversion rate and high volumetric gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

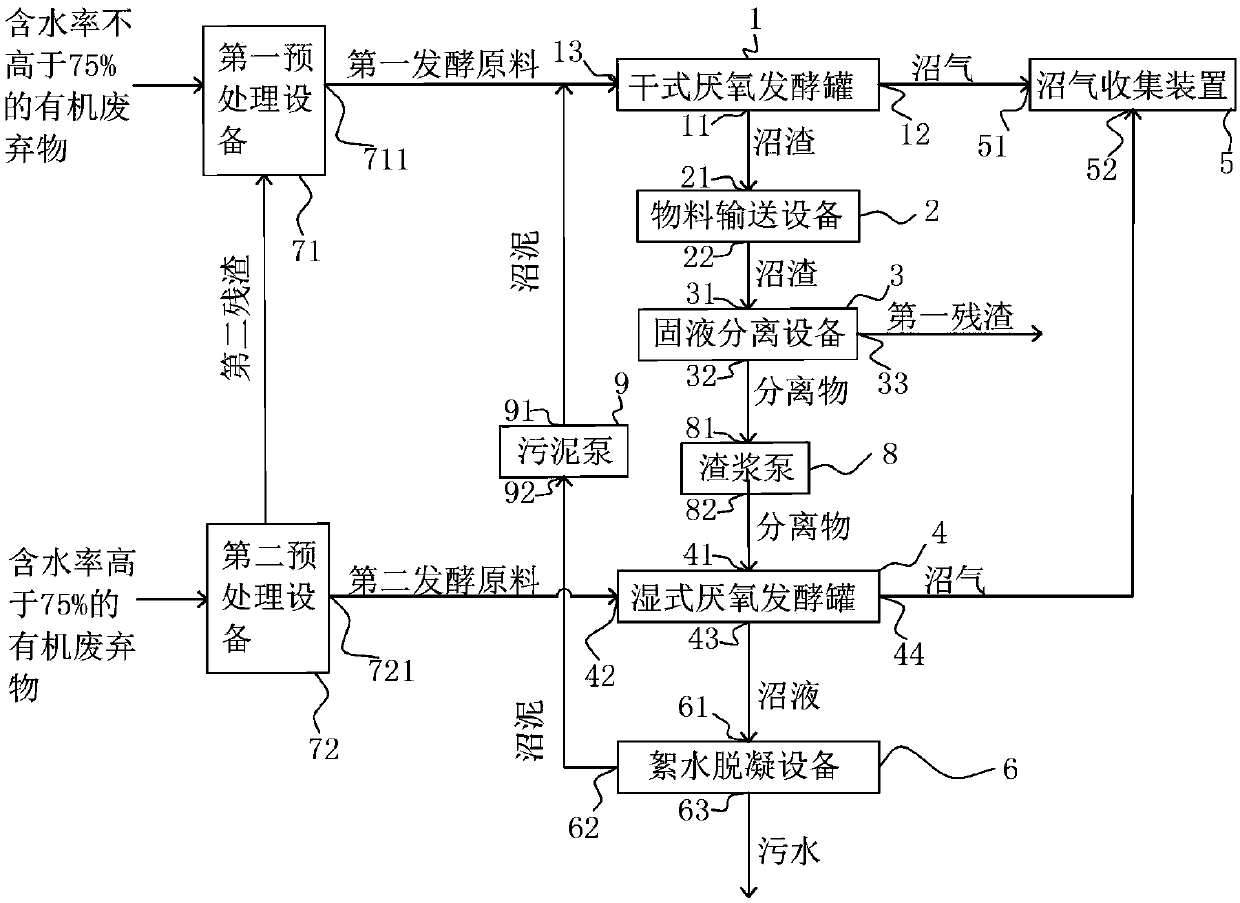

[0031] Such as figure 1As shown, this embodiment provides a device for producing biogas by combined dry-wet anaerobic fermentation, which includes a first pretreatment device 71, a dry anaerobic fermentation tank 1 and a biogas collection device 5, wherein the first pretreatment device 71 An output port 711 is provided, and the dry anaerobic fermentation tank 1 is provided with a feed port 13 , a gas output port 12 and a biogas residue output port 11 . The biogas collection device 5 is provided with a first gas input port 51 and a second gas input port 52. Preferably, the biogas collection device may be but not limited to a biogas cabinet. The output port 711 of the first pretreatment device 71 is connected to the feed port 13 of the dry anaerobic fermentation tank 1, and the gas output port 12 of the dry type anaerobic fermentation tank 1 communicates with the first gas input port 51 of the biogas collection device 5 . The device for producing biogas by combined dry-wet ana...

Embodiment 2

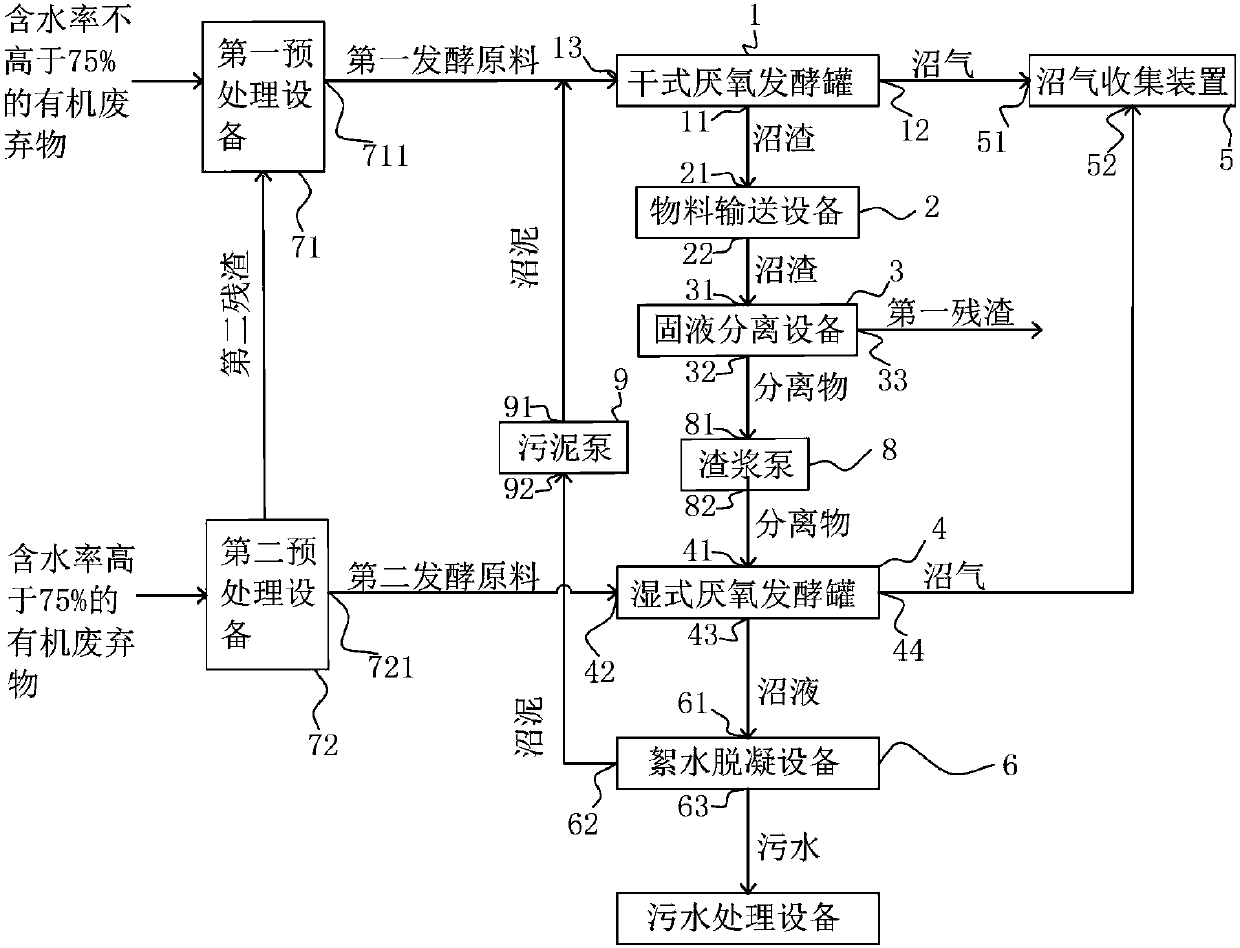

[0040] This embodiment provides another device for producing biogas by combined dry-wet anaerobic fermentation, the structure of which is basically the same as that of Embodiment 1, and only the different parts will be described below.

[0041] Such as figure 2 As shown, in this embodiment, the device for producing biogas by combined dry-wet anaerobic fermentation also includes a sewage treatment device 10 , and the sewage output port 63 of the flocculation decondensation device 6 is connected to the input port 101 of the sewage treatment device 10 . The sewage treated by the sewage treatment equipment 10 can be reused. The reuse of water resources in the anaerobic fermentation process not only saves a lot of water resources, but also reduces the environmental pollution caused by the anaerobic fermentation process, and better protects the environment.

Embodiment 3

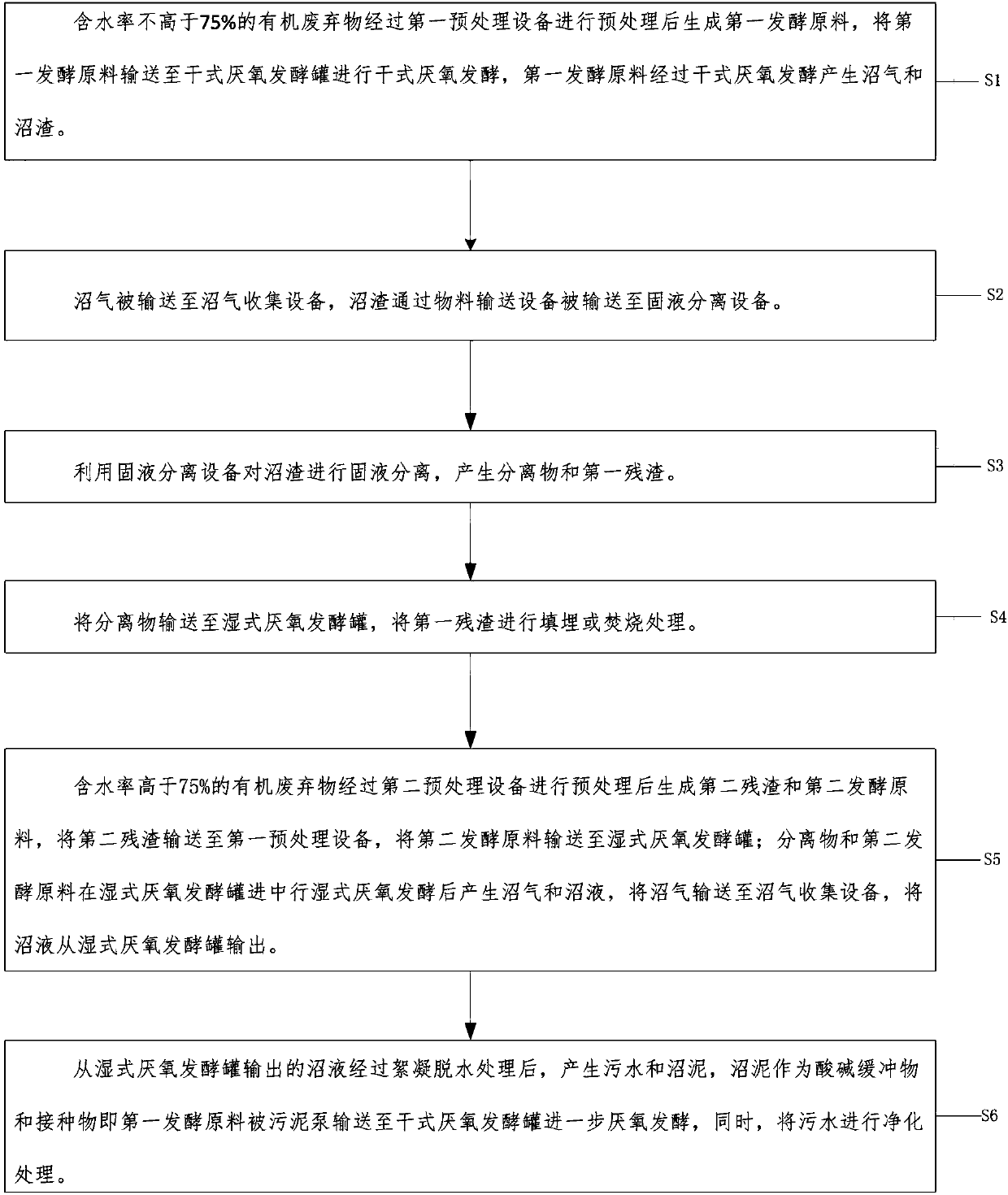

[0043] This example provides a method for producing biogas by combined dry-wet anaerobic fermentation. Such as image 3 Shown, the method for dry-wet combined anaerobic fermentation to produce biogas comprises the following steps:

[0044] Step S1, the organic waste with a moisture content not higher than 75% is pretreated by the first pretreatment device 71 to generate the first fermentation raw material, wherein the particle size of the first fermentation raw material is not larger than 30mm, and the moisture content is not higher than 75% , the ash content is not higher than 25% on a dry basis. The first fermentation raw material is transported to the dry anaerobic fermentation tank 1 for dry anaerobic fermentation. Preferably, the first fermentation raw material is transported to the dry fermentation reaction tank through a hydraulic plunger pump or a screw conveyor. The first fermentation raw material undergoes dry anaerobic fermentation to produce biogas and biogas re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com