Comprehensive utilization method of amorphous-silica-containing biomass

一种无定形二氧化硅、二氧化硅的技术,应用在二氧化硅、氧化硅、化学仪器和方法等方向,能够解决能耗大、环境污染、不能生物质利用等问题,达到能量转化率高、工艺设计巧妙简便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

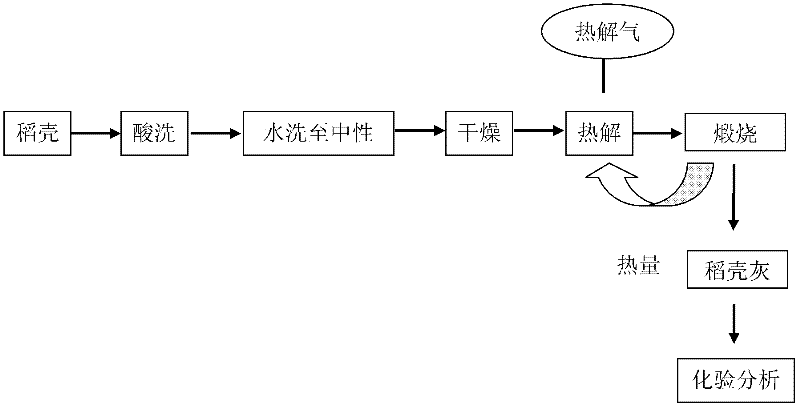

[0023] Such as figure 1 As shown, the rice husk is simply washed with water to remove impurities such as soil in the rice husk, soaked in hydrochloric acid with a mass concentration of 10% for 24 hours, and washed repeatedly until the pH of the washing solution is close to neutral; then put it in a drying box Dry at 100°C to constant weight.

[0024] The dried rice husk is conveyed to the pyrolysis furnace by the screw conveyor and pyrolyzed at 600°C in an oxygen-free environment, and the pyrolysis gas generated is sent to the subsequent purification treatment device for standby, or directly sent to the gasifier for gasification to produce Syngas is used for subsequent supply and demand, or sent to boilers for combustion and power generation.

[0025] The solid product after pyrolysis is sent to the calcination furnace, and the temperature of the calcination furnace is maintained at 650°C for calcination in an air atmosphere. The hot flue gas generated by calcination is passe...

Embodiment 2

[0029] The rice husk is simply washed with water to remove impurities such as soil in the rice husk, and then soaked in a nitric acid solution with a mass concentration of 5% for 24 hours, washed with water until neutral; then dried at 110°C until the water content is below 20%.

[0030] The dried rice husk is transported to the pyrolysis furnace by the screw conveyor and pyrolyzed at 800°C in an oxygen-free environment, and the pyrolysis gas generated is sent to the subsequent purification treatment device for standby, or directly sent to the gasifier for gasification to produce Syngas is used for subsequent supply and demand, or sent to boilers for combustion and power generation.

[0031] The solid product after pyrolysis is sent to the calciner, and the temperature of the calciner is controlled to maintain at 800°C for calcination in the air atmosphere. The hot flue gas generated by the calcination is passed into the pyrolysis furnace to provide heat for the pyrolysis furna...

Embodiment 3

[0035] The rice husk is simply washed with water to remove impurities such as soil in the rice husk, and then dried at 120°C until the water content is below 20%. The dried rice husk is conveyed to the pyrolysis furnace by the screw conveyor and pyrolyzed at 1000°C in an oxygen-free environment, and the pyrolysis gas generated is sent to the subsequent purification treatment device for standby, or directly sent to the gasifier for gasification to produce The synthesis gas is used for subsequent supply and demand, or the pyrolysis gas is directly sent to the boiler for combustion to generate electricity.

[0036] The pyrolyzed solid product was put into a sulfuric acid solution with a mass concentration of 5% and boiled for 4 hours; washed 3 times with water until the pH of the solution was close to neutral; and then dried in a drying oven at 102°C until the water content was below 30%.

[0037] Then it is sent to the calciner, and the temperature of the calciner is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com