Device and method for in-situ removal of ammonia nitrogen in anaerobic digestion system

A technology of anaerobic digestion and anaerobic digestion tank, which is applied in the field of biomass energy recovery, can solve problems such as the inability to directly reduce the concentration of ammonia nitrogen, unstable system operation, complex process routes, etc., achieve good economic utilization prospects, increase processing load and The effect of gas production efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

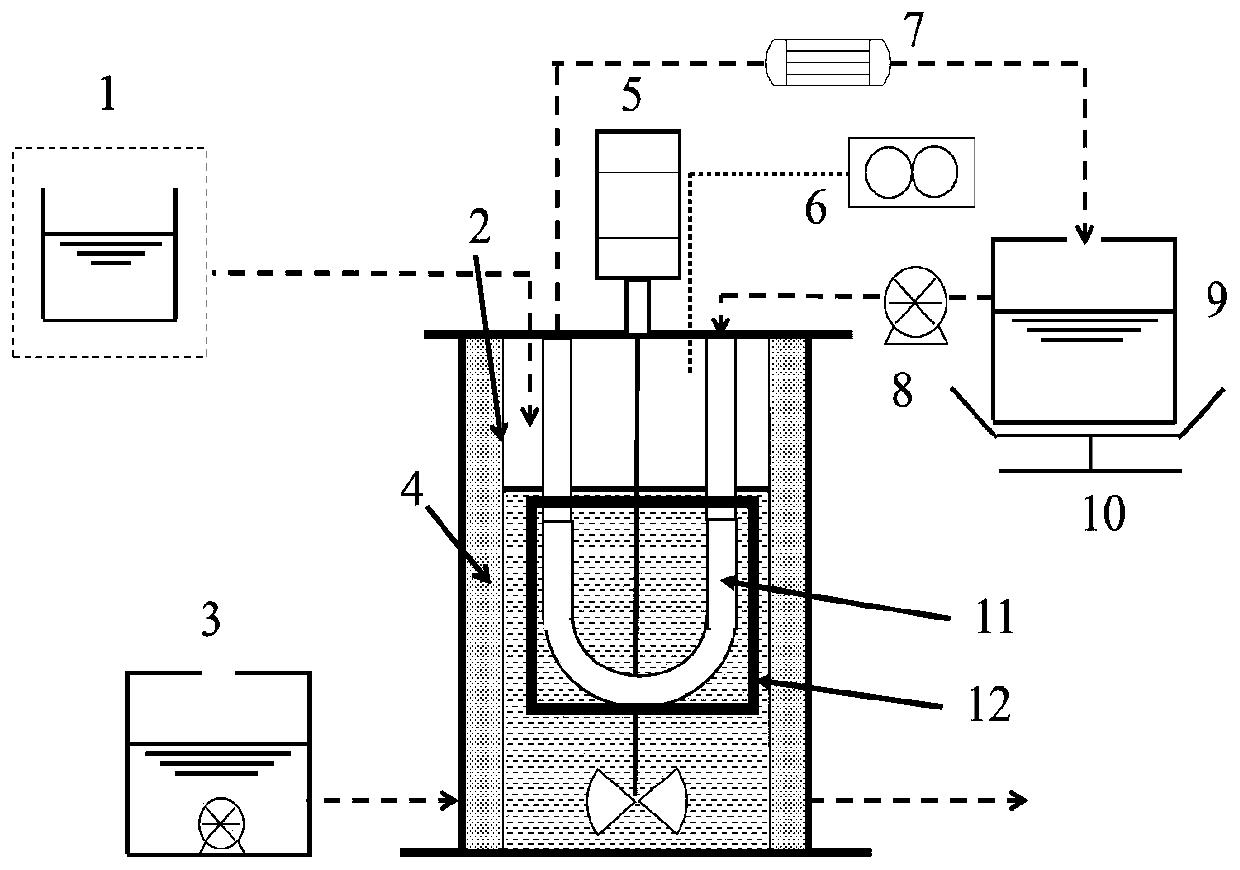

Method used

Image

Examples

Embodiment 1

[0039] Anaerobic digestion treatment is performed on the food waste material after sorting, crushing and deoiling pretreatment in a kitchen waste treatment plant in a northern city.

[0040] The basic properties of the used kitchen waste materials are shown in the table below:

[0041] Table 1 Main properties of food waste materials

[0042]

[0043] The total solid content (TS) of the seed sludge used for the anaerobic digestion treatment is (2.4±1.1)%, and the volatile solid content (VS) is (2.2±0.2)%.

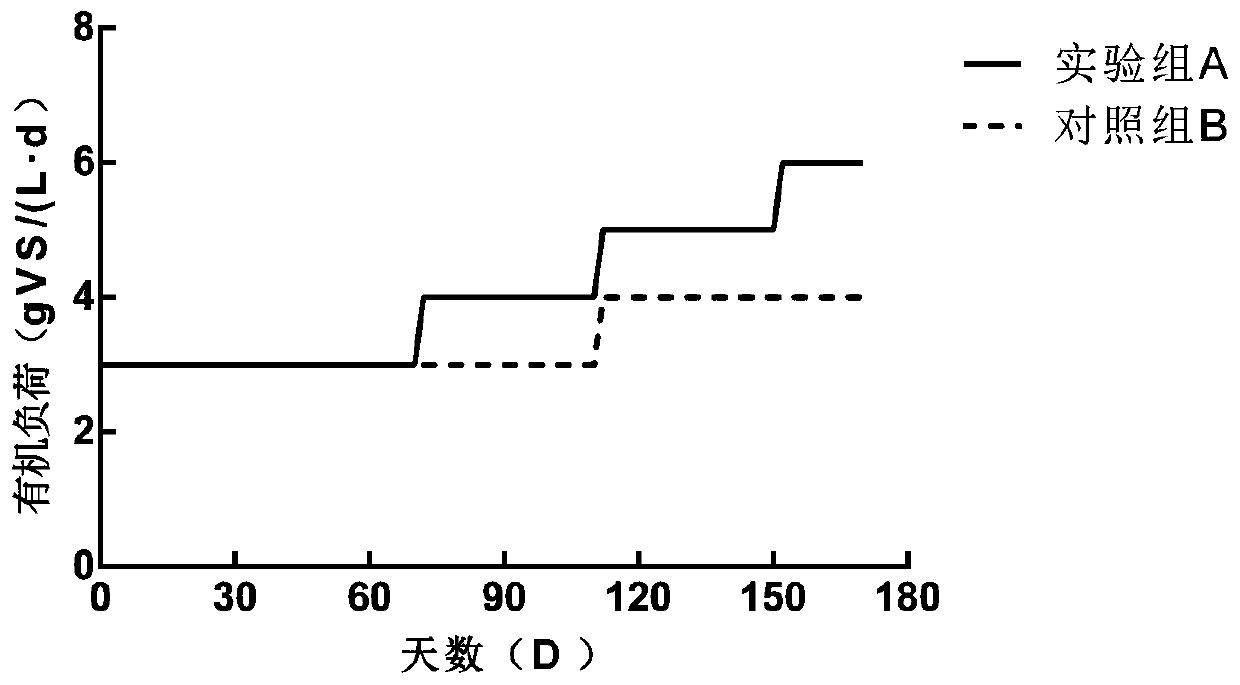

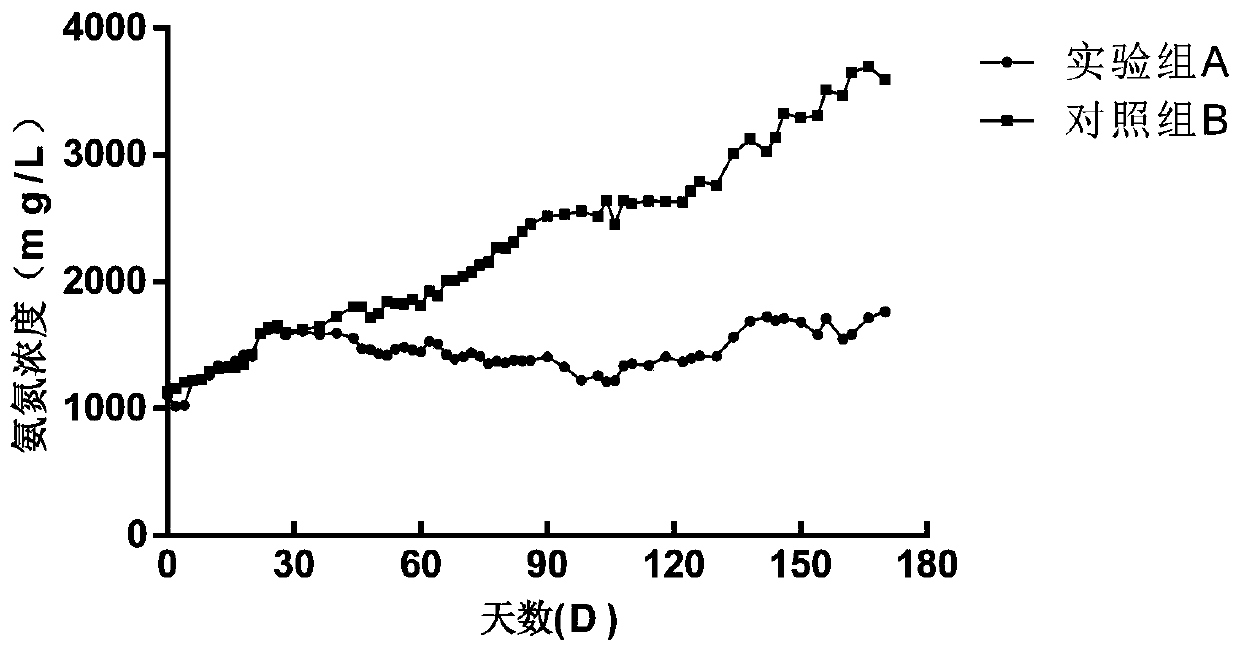

[0044] An experimental group (A) and a control group (B) are set up, the experimental group adopts the device for removing ammonia nitrogen in the anaerobic digestion system in situ provided by the present invention, and the control group adopts a traditional fully mixed anaerobic digestion tank. The other operating conditions of the two groups were the same. The total volume of the anaerobic digestion tank is 9L, and the effective volume is 5L. During the experiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com