Microorganism power generating method by utilizing carbon source in a recycling way

A microbial power generation and microbial technology, which is applied in biological sludge treatment, fermentation, waste fuel, etc., can solve the problems of large investment, geographical environment constraints, low efficiency of biogas combustion and power generation, etc., and achieves high volume gas production rate and strong fecundity. , the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The equipment used in this embodiment includes a photobioreactor, a biogas generator, a composting reactor, a heat exchanger, and a generator set.

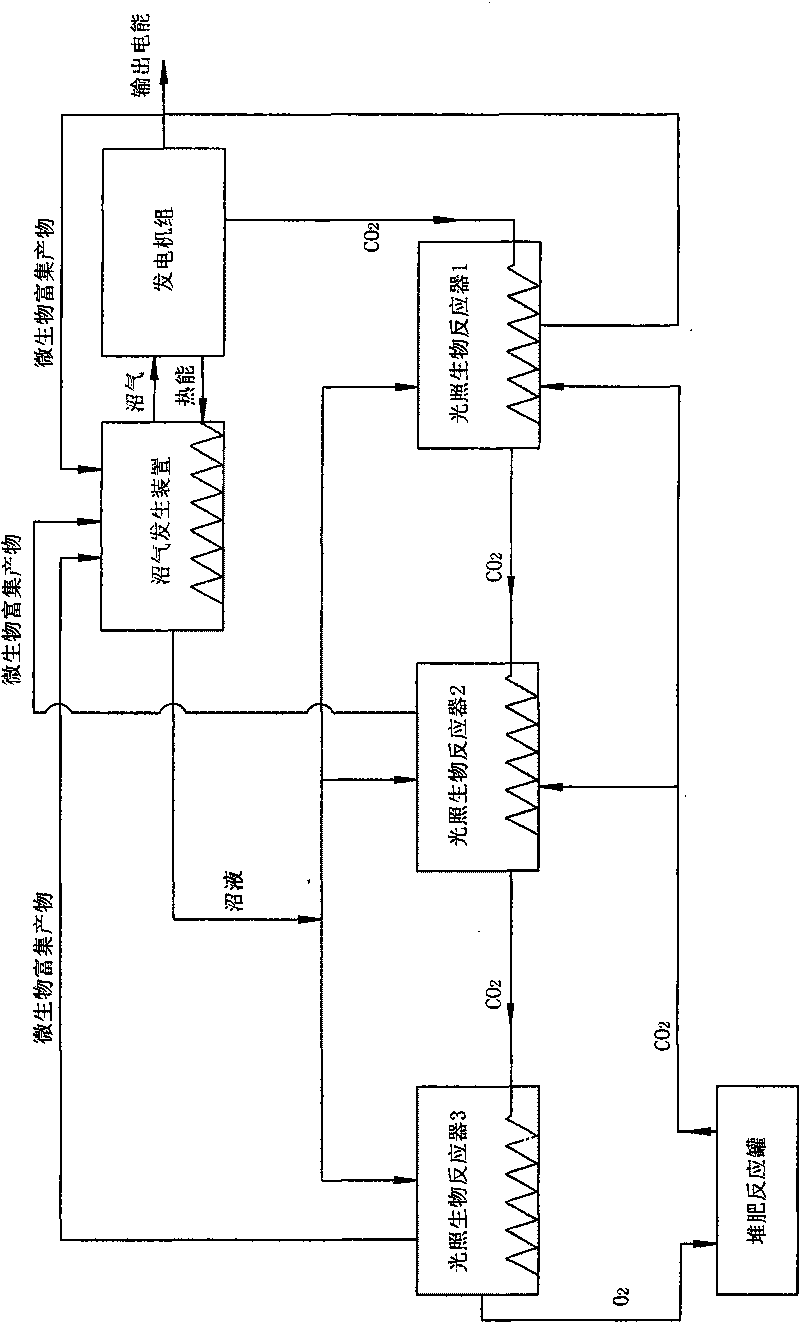

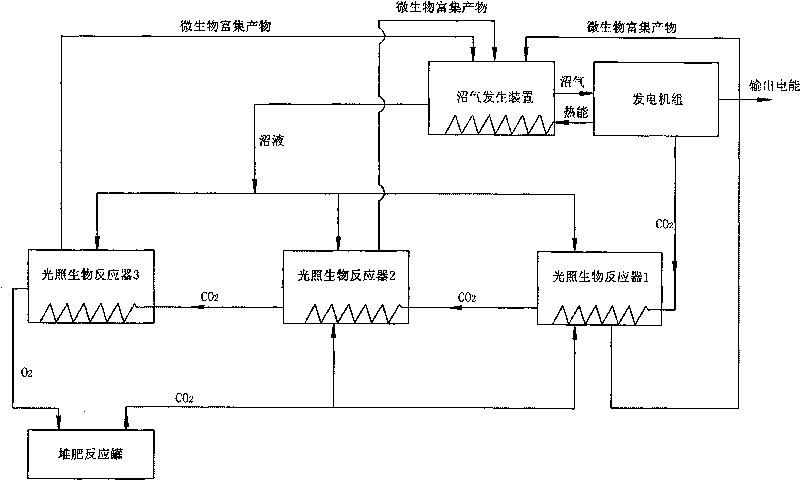

[0030] The technological process of this embodiment is as figure 1 As shown, the three photobioreactors in this embodiment are connected in series as one group. The carbon dioxide gas produced by the composting reactor is passed into the photobioreactor 1 and photobioreactor 2 respectively through the diversion pipe to provide the carbon dioxide gas required for the start of the photobioreactor; the microbial enrichment produced by the photobioreactor The product is input into the biogas generating device through the microbial discharge pipeline of the photobioreactor, and reacts with the anaerobic fermentation sludge in the biogas generating device to generate biogas. The biogas generating device feeds the generated biogas into the internal combustion engine in the generator set for combustion to generate electricity, and...

Embodiment 2

[0037] The equipment used in this embodiment includes a photobioreactor, a biogas generator, and a generator set. Its connection method and process can refer to figure 1 .

[0038] In this example, cyanobacteria and algae (dinoflagellates, chlorella, macroalgae) were used in the preparation of microbial enrichment products. Add 0.5% strains to the anaerobic sludge leachate according to the weight percentage, place it in a photobioreactor, and add an appropriate amount of water at a volume ratio of 1:1, control the water temperature at 25-26°C, and place it for 72 hours , into the carbon dioxide gas. It has been tested and determined that when the concentration of microbial dry matter is greater than 1g / L, the microbial enrichment product floating on the upper part of the photobioreactor is output to the biogas generating device to generate biogas and biogas slurry; the biogas slurry is input into the photobioreactor, The biogas is input into the internal combustion engine i...

Embodiment 3

[0044] The equipment used in this embodiment includes a photobioreactor, a biogas generator, and a generator set. Its connection method and process can refer to figure 1 .

[0045] In this example, Chlamydomonas was used when preparing the microbial enrichment product. Place Chlamydomonas in a photobioreactor, add nitrogen, phosphorus and potassium-containing culture solution (200 mg / L nitrogen, 40 mg / L phosphorus, 180 mg / L potassium), control the water temperature at 25-30 ° C, and place it for 60 hours , into the carbon dioxide gas, after inspection and determination, when the concentration of microbial dry matter is greater than 1g / L, filter the excess water from the microbial enrichment product floating on the upper part of the photobioreactor, and then put the concentrate into the biogas generating device , the remaining liquid is returned to the photobioreactor to further increase efficiency. After biogas and biogas slurry are generated, the biogas slurry is passed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com