Patents

Literature

83results about How to "Can be large or small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing porous starch and its application

InactiveCN1546529AHigh adsorption rateRaw materials are readily availableGlucose-Fructose SyrupPotato starch

The invention discloses a method for producing porous starch and its application by using starch, maize starch, tapioca starch, sweet potato starch and potato starch as raw material, and charging complex enzyme of saccharified enzymes and alpha-amylase possessing raw starch hydrolysis vitality under the temperature lower than gelatinization temperature, agitating continuously, reacting for a finite period of time at constant temperature, and obtaining porous starch product through centrifuging, scrubbing and drying.

Owner:JIANGNAN UNIV

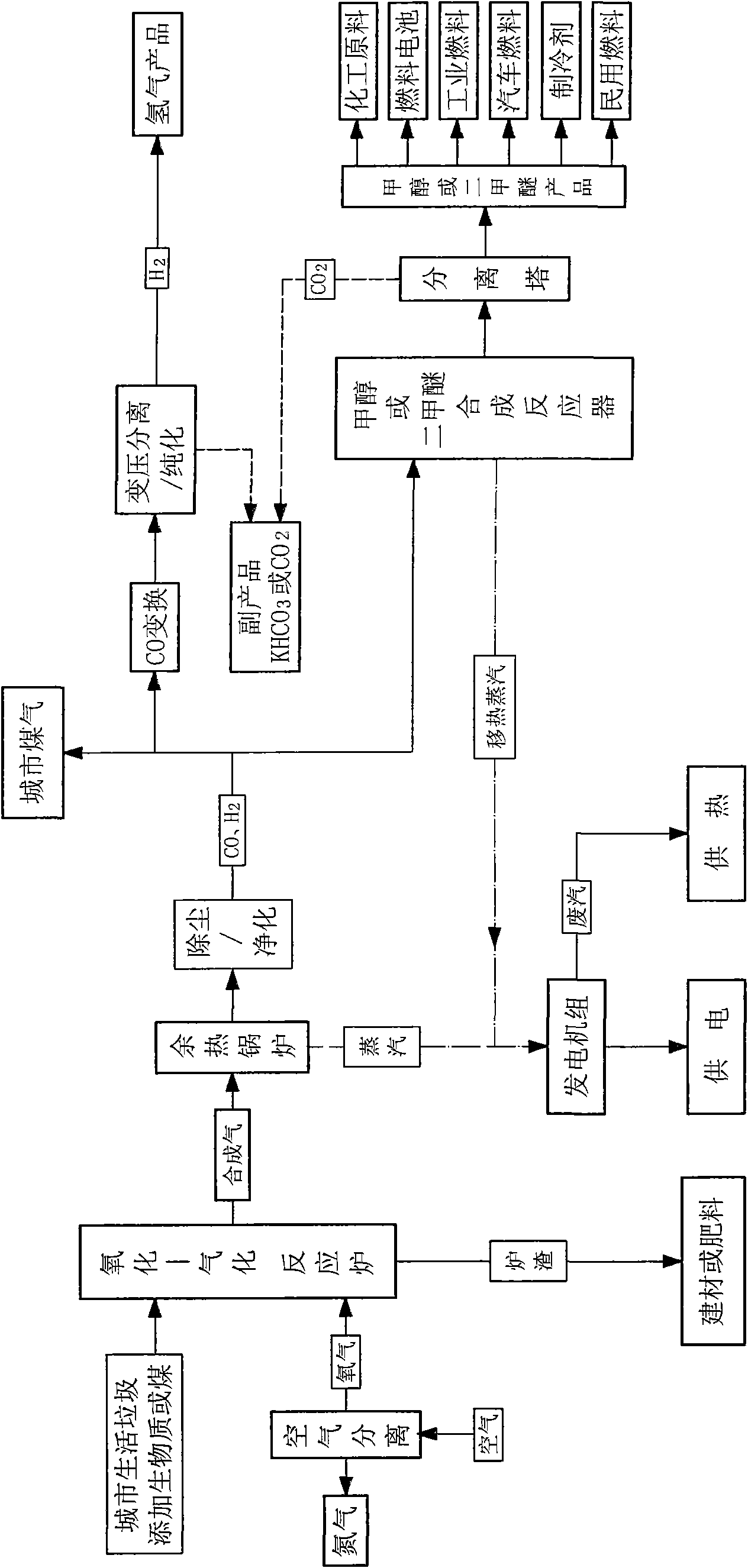

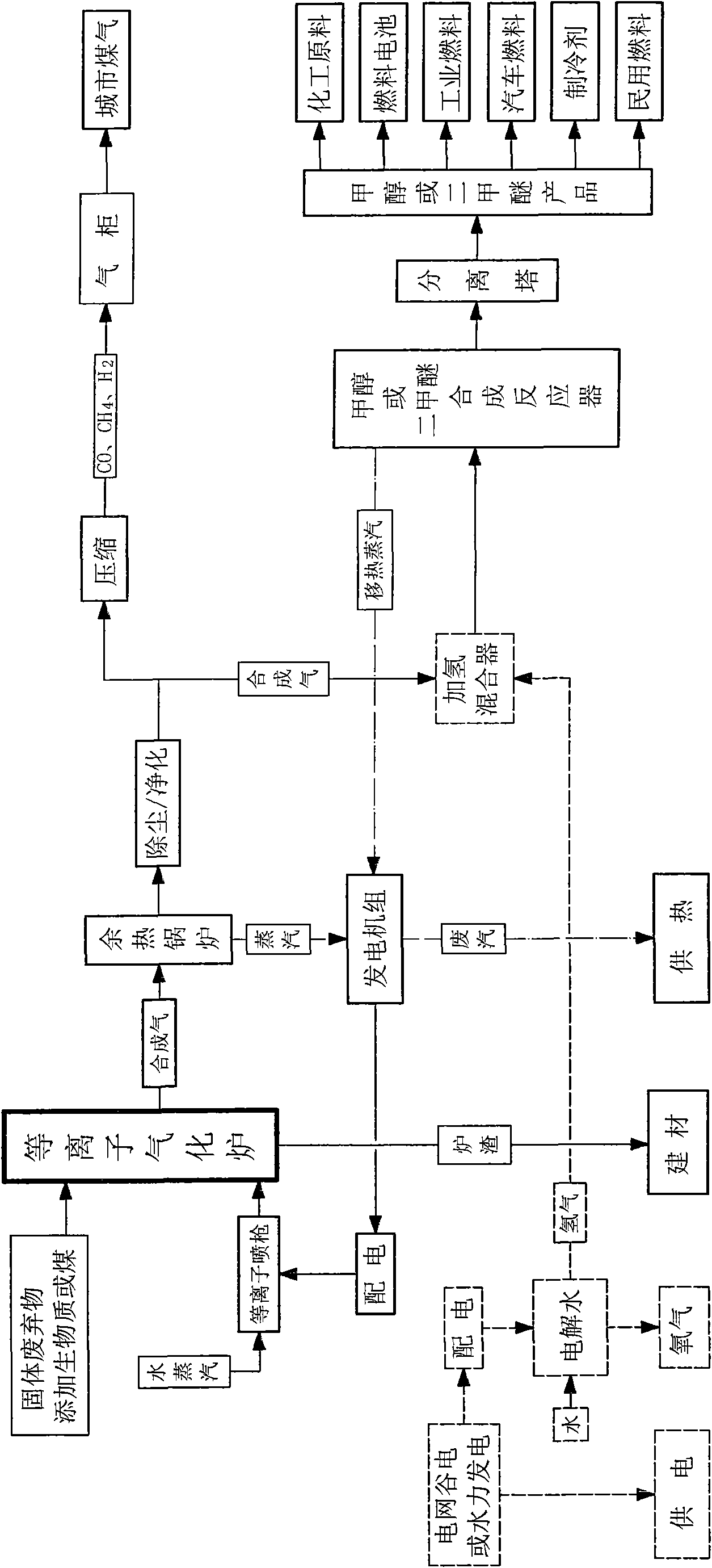

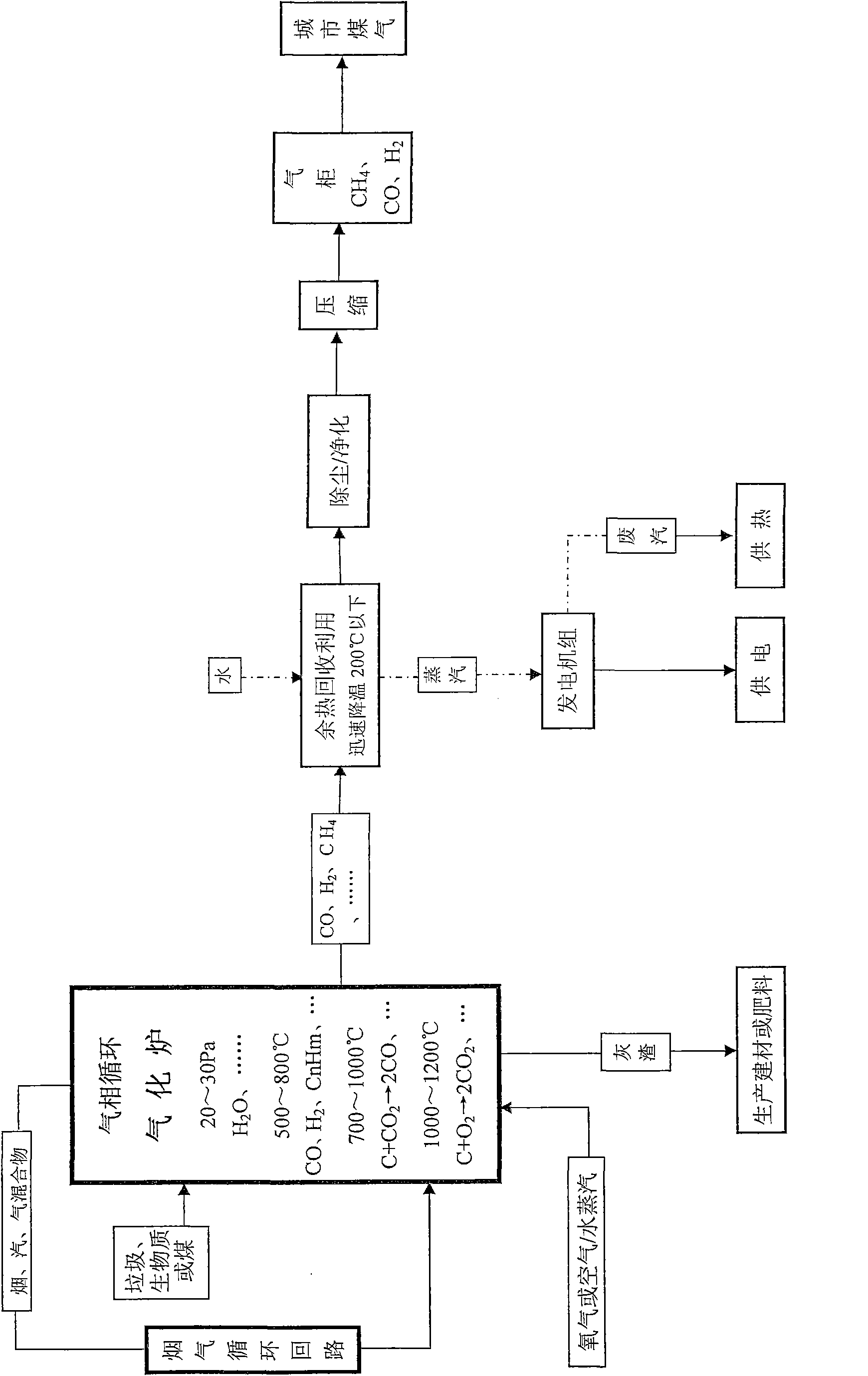

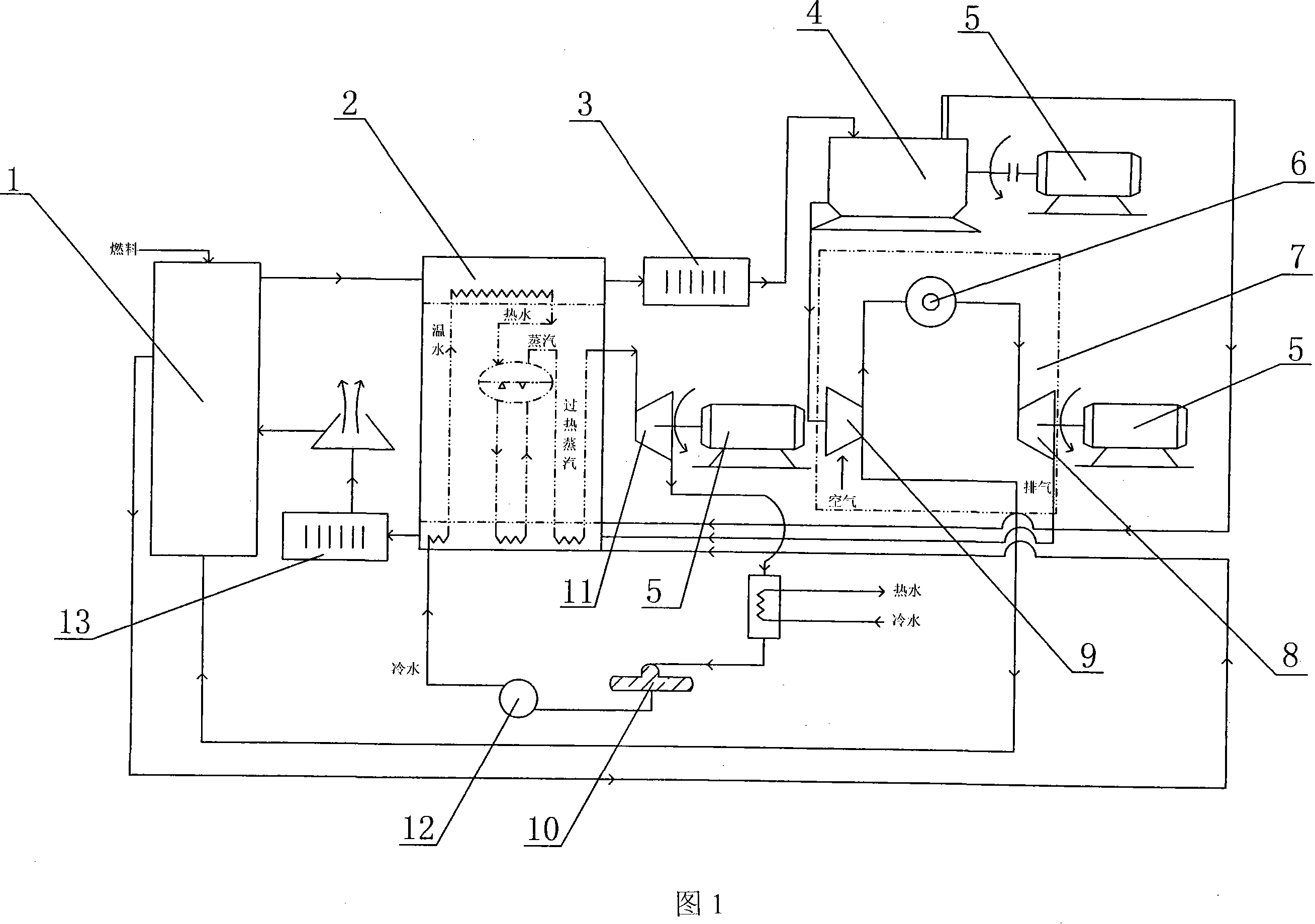

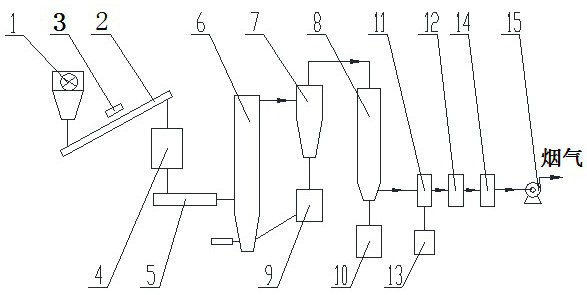

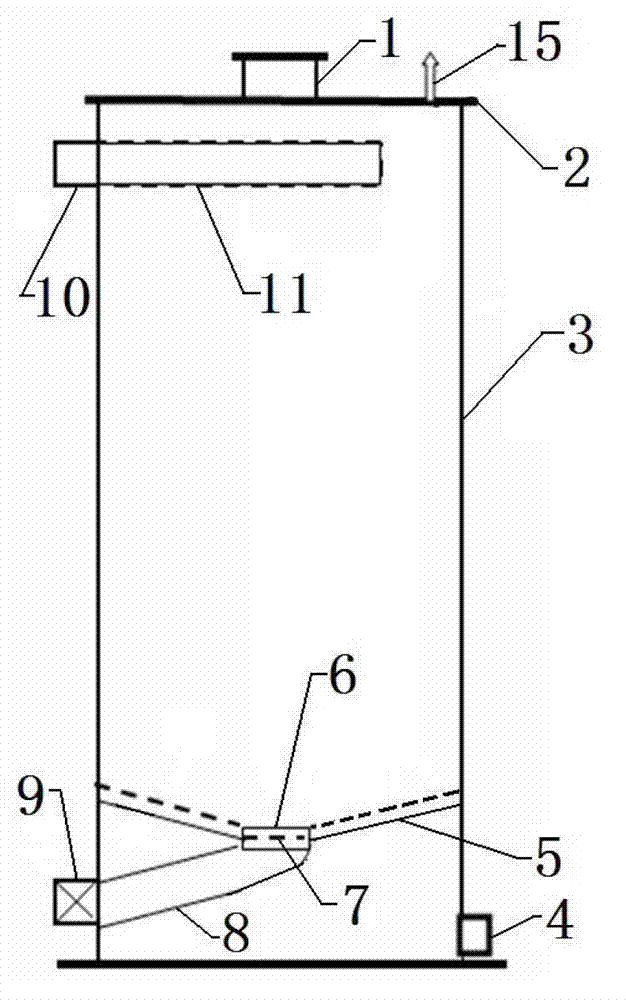

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

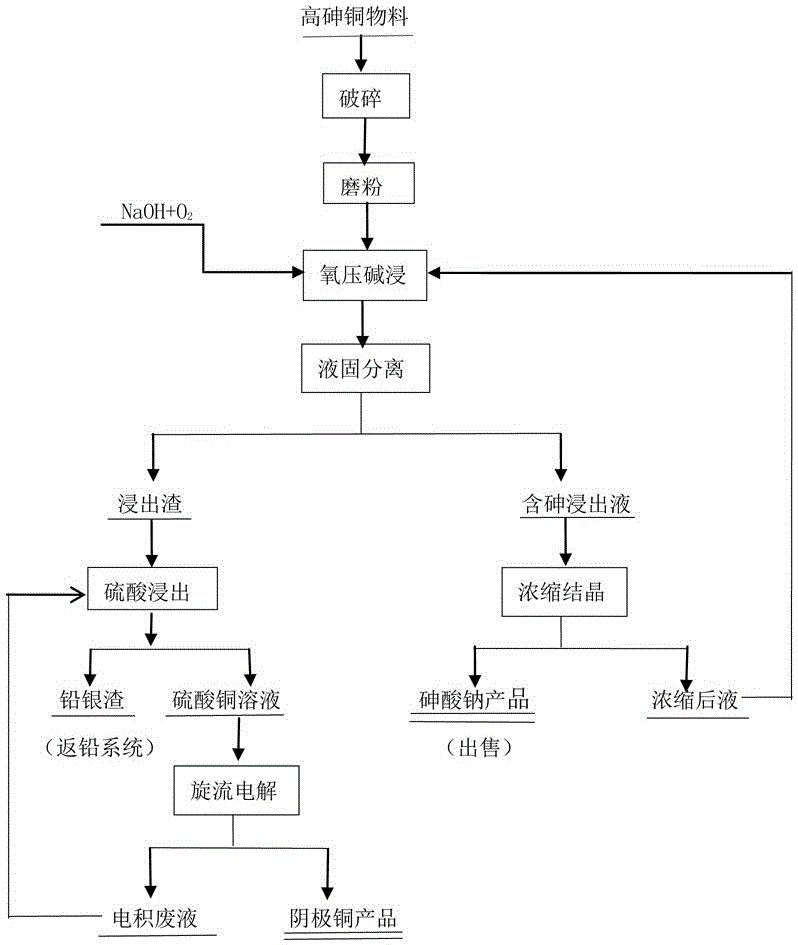

Technology for treating high-arsenic copper material

ActiveCN106555058AEnvironmental pollutionNo pollution to the environmentPhotography auxillary processesProcess efficiency improvementElectrolysisCopper sulfate

The invention discloses a technology for treating a high-arsenic copper material. The technology comprises the steps that the high-arsenic copper material is subjected to crushing, grinding, sodium hydroxide mixing and oxidizing leaching, copper in the high-arsenic copper material is oxidized and left in residues in a residual mode along with lead and noble metal of gold, silver and platinum, arsenic enters a solution in a sodium arsenate mode, leachate is subjected to concentration and crystallization, a sodium arsenate product is obtained, and a concentrated solution returns to be subject to oxygen-pressure alkali leaching; leached residues are subjected to sulfuric-acid atmospheric pressure leaching, copper enters the solution in a copper sulfate mode, acid adjustment is conducted, and vortex electrolysis is directly conducted for extracting copper; electrodeposited waste liquid is recycled; and lead and the noble metal enter lead and silver residues, and valuable elements of Pb, Ag and Au are comprehensively recycled. The technology belongs to a clean metallurgy process, is low in equipment corrosion-resistant requirement, free of pollution to environment, easy to operate and high in comprehensive recycling degree of metal and has the advantages of being higher in practicability and adaptability to raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for comprehensive utilization of fragrans by using special flavour improvement enzyme

A method for comprehensively utilizing the sweet osmanthus flower by use of flavouring enzyme includes such steps as picking up sweet osmanthus flower, deactivating enzyme by microwave, microwave drying, hydrolyzing by flavouring enzyme, extracting coarse extract by petroleum ether, refining to obtain refined oil and wax by-product, extracting oleanolic acid from said wax by-product, and extracting flavone from flower dregs. Its advantage is high output rates for all products.

Owner:JIANGNAN UNIV

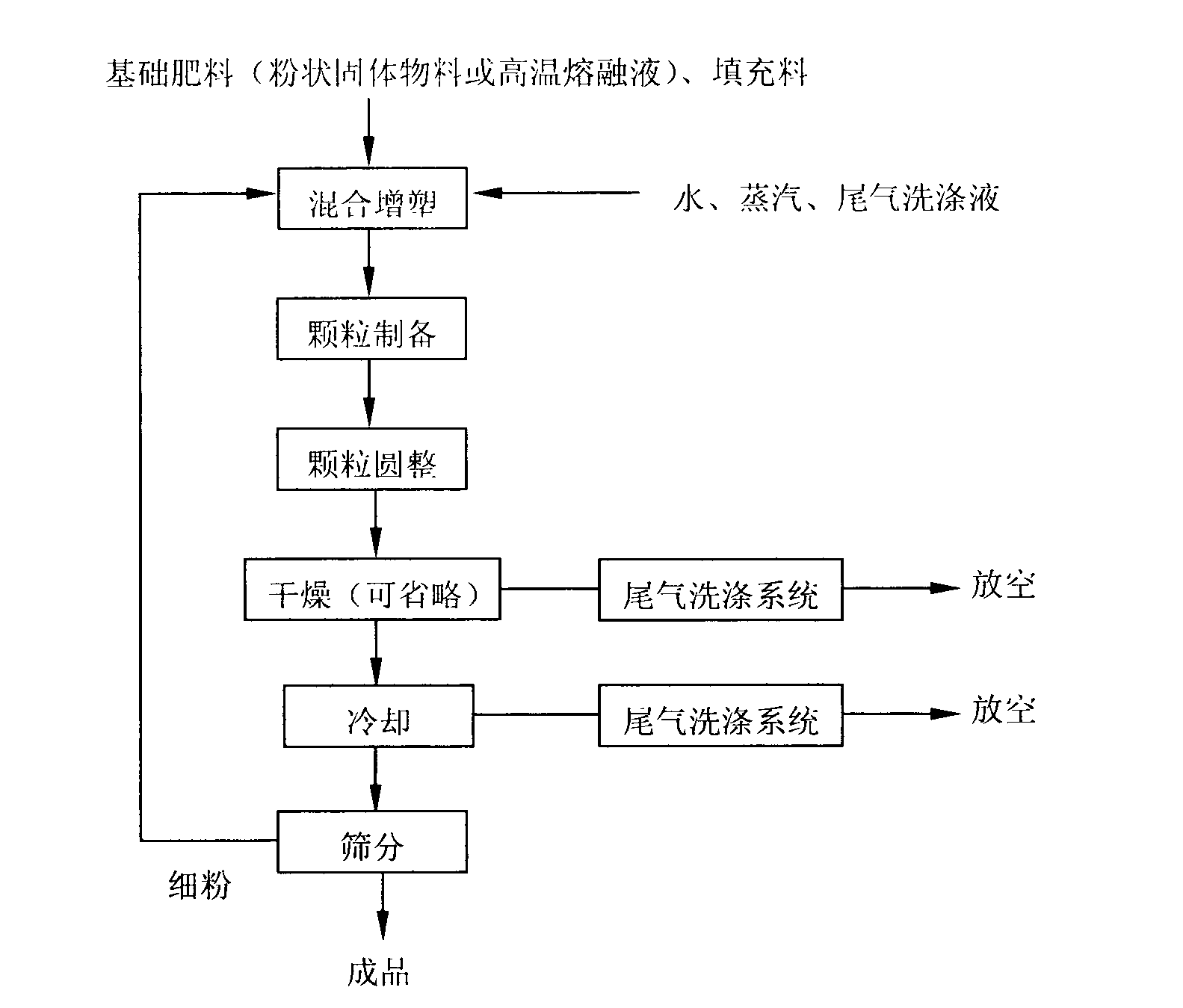

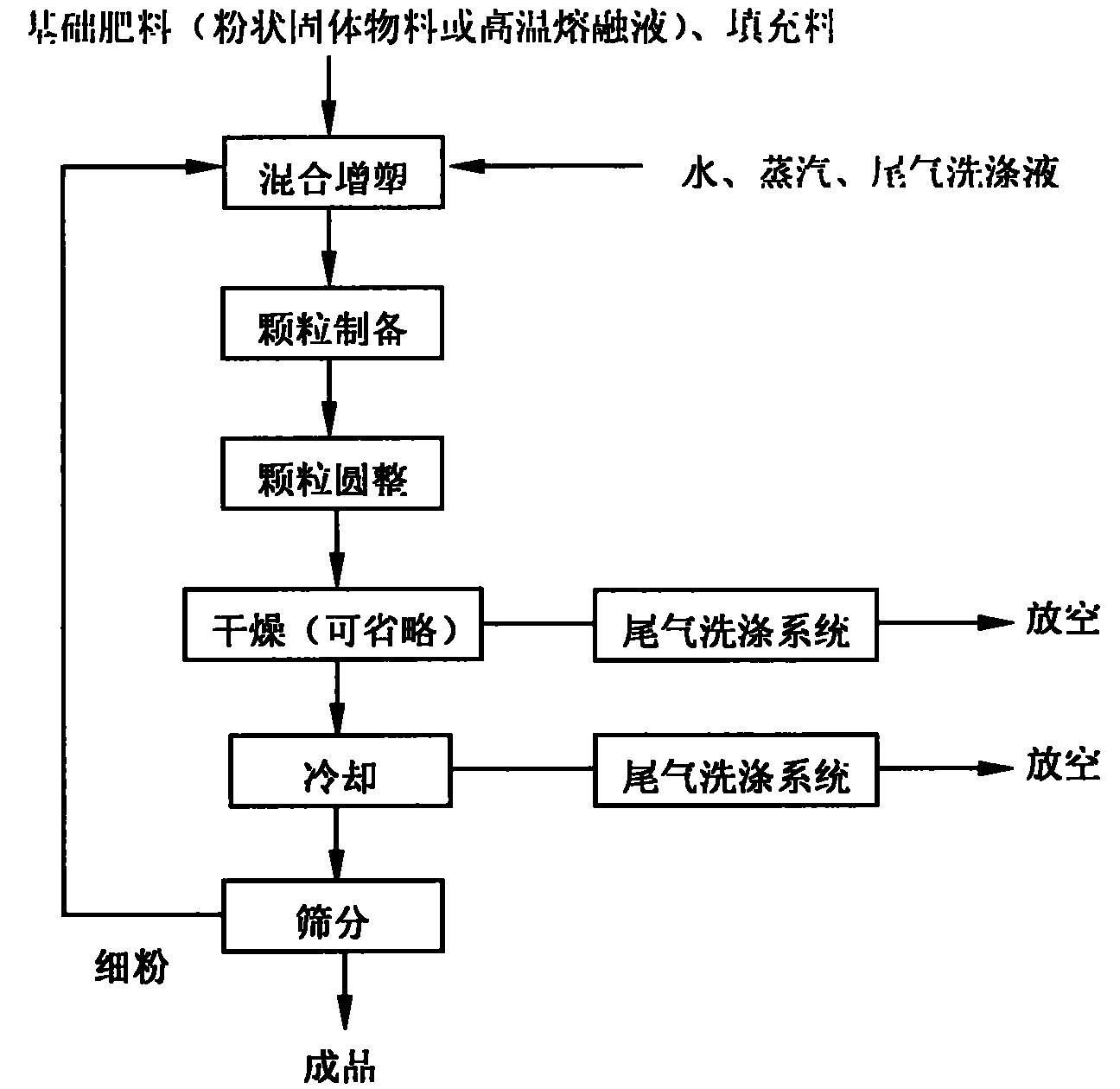

Preparation method for particle compound fertilizer

The invention relates to a preparation method for a particle compound fertilizer. The method comprises the following steps of: wetting or heating and mixing a basic fertilizer and a filler to obtain a plastically-enhanced material with high moisture content or high temperature; preparing a mixed material into uniform particles through extruding machinery; rounding the surfaces of particle materials; drying (e.g., the step can be eliminated when the temperature for preparing the particle materials is high); and cooling and sieving to obtain the particle compound fertilizer. Compared with the conventional extruding method, the method has the advantage that: abrasion on extruding equipment is reduced. Compared with the conventional agglomerating method, the method has the advantages that: material returning multiple in a production process can be reduced, and production energy consumption and production cost are lowered. Product particles are uniform, are round in appearance, and have high pressure resistance and agglomeration resistance. In production process, waste emission is reduced, and the field operation environment is remarkably improved.

Owner:SHANGHAI RES INST OF CHEM IND

Preparation method of concentrated culture solution of nitzschia closterium minutissima allen et nelson and plastic barrel cultural method

ActiveCN103834568ANot easy to scratchBig errorUnicellular algaeMicroorganism based processesGrowth plantNitzschia closterium

The invention discloses a preparation method of a concentrated culture solution of nitzschia closterium minutissima allen et nelson and a plastic barrel cultural mode. The conventional preparation method of the culture solution is immediate preparation; the culture solution is prepared once for use at one time according to the use level, so that the conventional method is time-, work- and labor-consuming, troublesome to weigh and great in error. According to the invention, the concentrated liquor is adopted by the inventor for use for many times, so that the culture solution is simple to operate, convenient to store and convey, suitable for scaled, industrialized, commercialized and professional production, and very convenient. The inventor optimizes the conventional formula and supplements NaHCO3, 920 plant growth stimulin, human urine, sea mud extracting liquor, cow dung and sheep manure lixivia and the like, so that the culture solution is more complete, balanced and abundant in nutrition. As for the cultural mode, the inventor adopts a household mineral water barrel cultural mode to replace conventional open cement pit culture, so that the cultural method is easy to operate, difficult to be polluted, easy to master, agile and diverse, difficult to scratch, safe and reliable, good in transmission of light, low in cost and fast in growth, and the output is improved by 150%.

Owner:山东中科绿碳科技有限公司

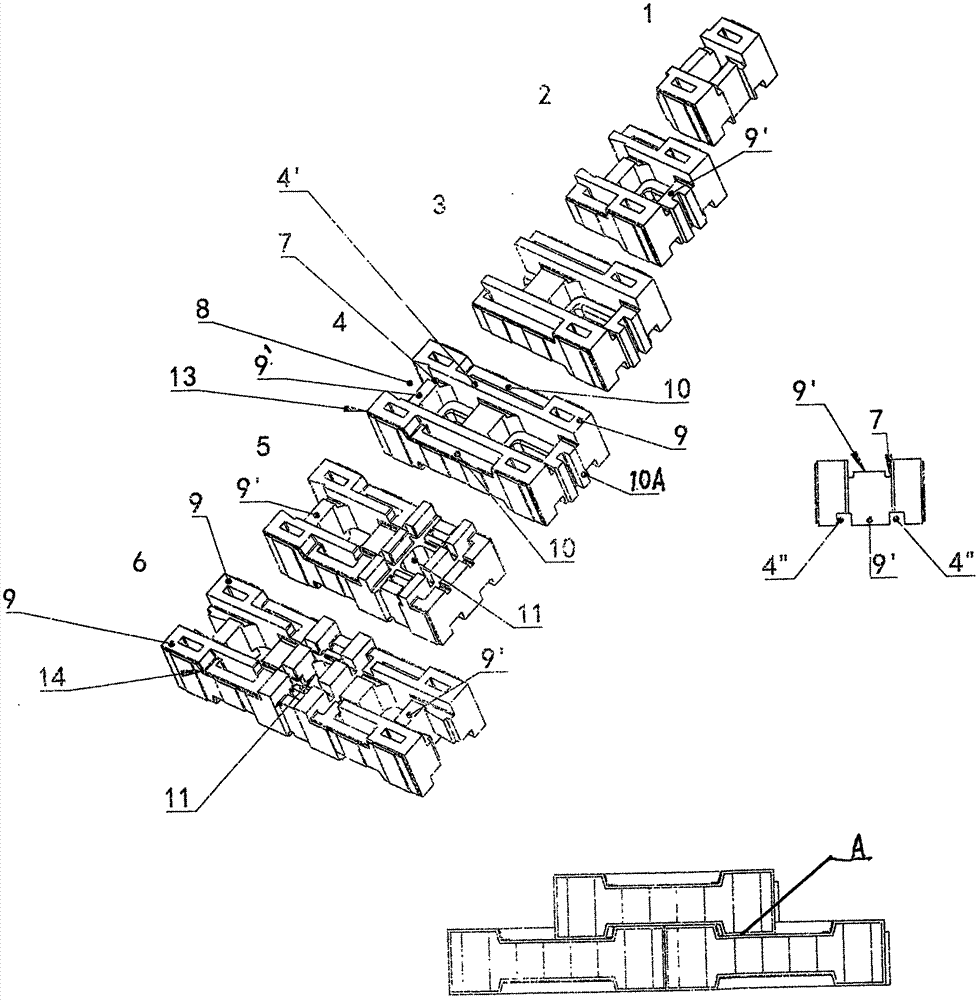

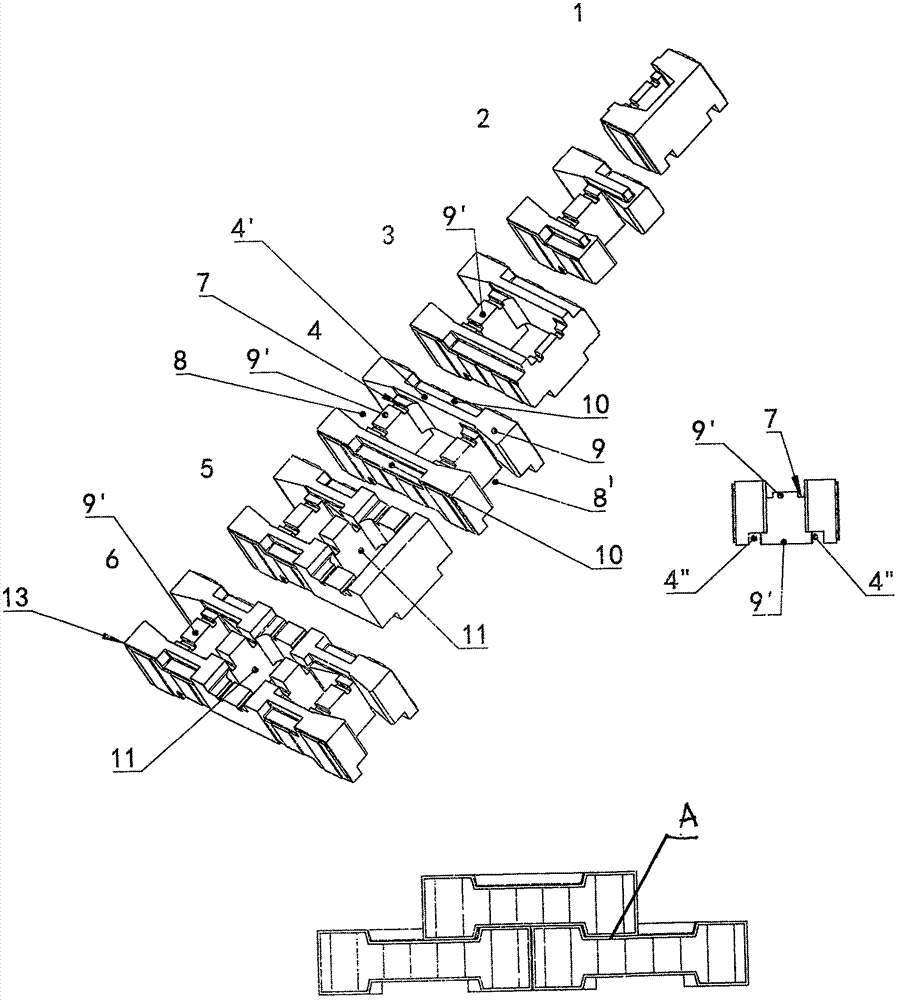

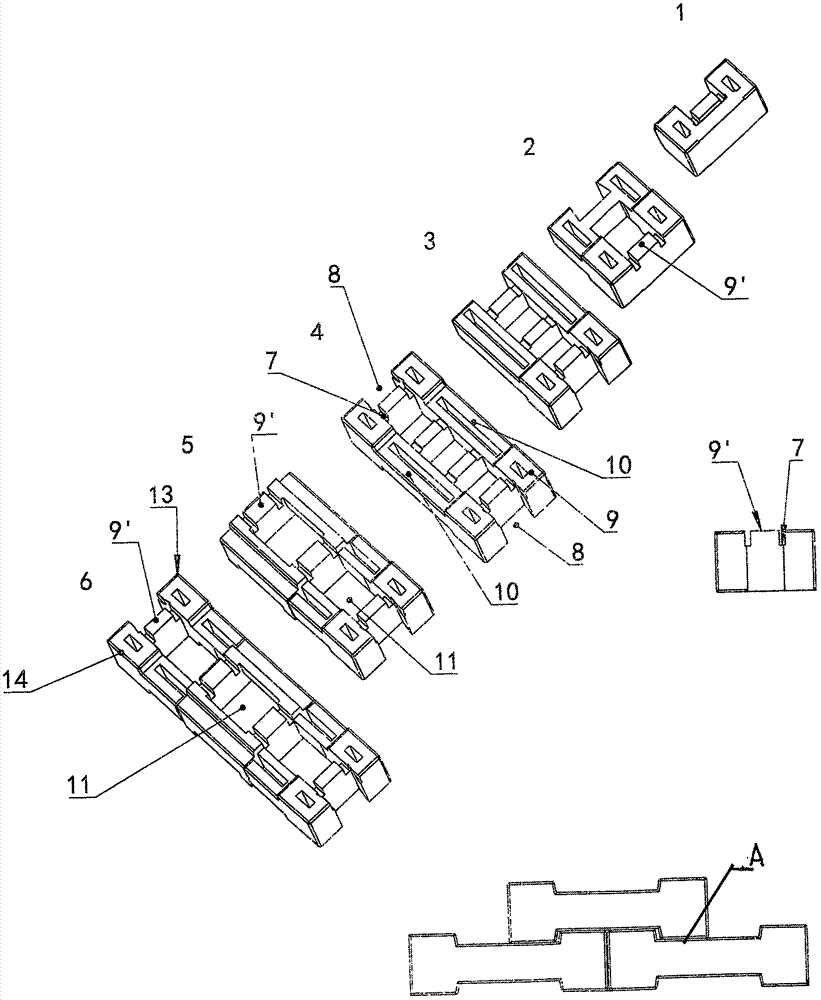

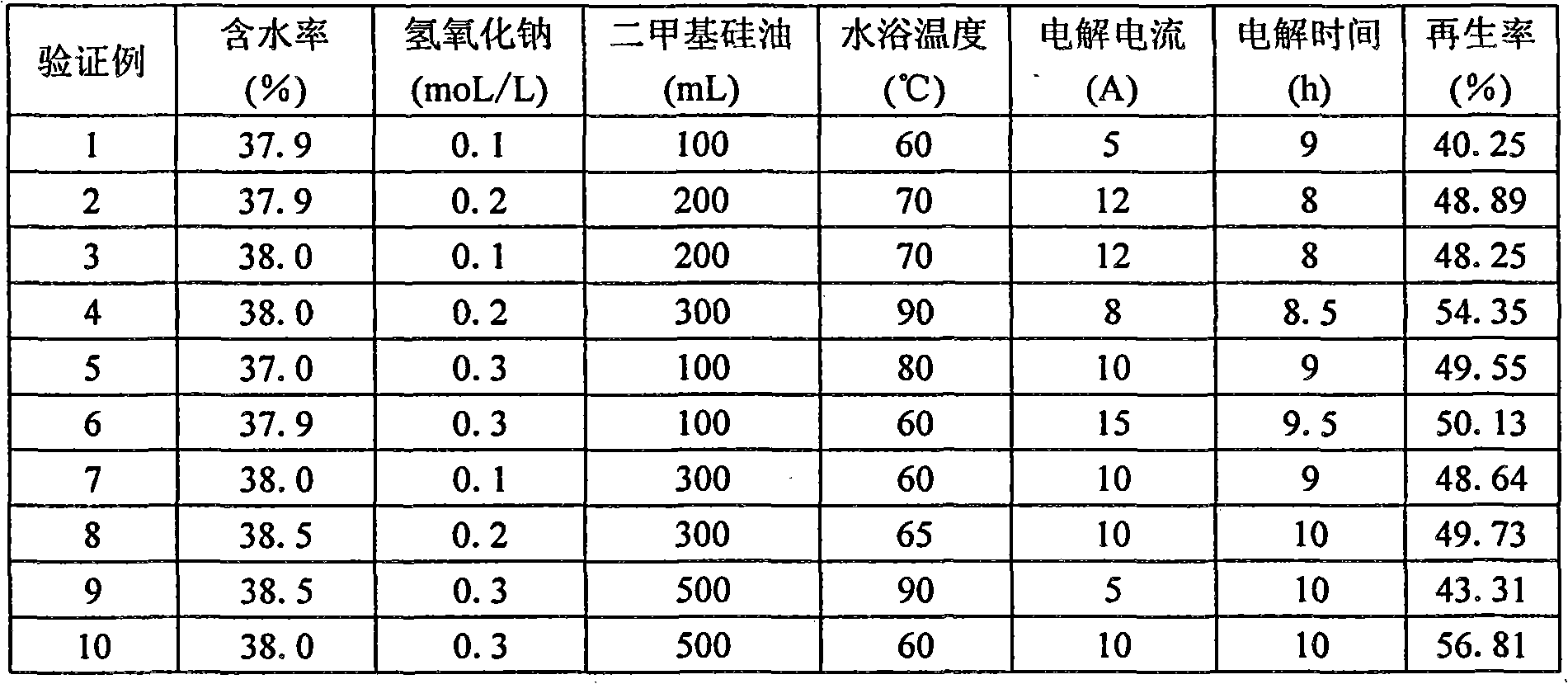

Method for fabricating house through members assembled by interlocking combined building blocks

ActiveCN107060071AReduce the risk of manpower working at heightsEasy to implement finelyWallsEngineeringHigh rise

The invention relates to a method for fabricating a house through members assembled by interlocking combined building blocks. The combined building blocks with different thicknesses, different interlocking types and functional block shapes are assembled to be the independent members such as inner-outer-wall equal thickness and unequal thickness hollow or solid square, L-shaped, T-shaped and cross structural column window beams, door beams, cantilevering beams, ring beams, wallboards and floors, and the independent members are fabricated to be the house meeting the current standard quality requirements. The products are not only suitable for small scattered living house man-made buildings, but also suitable for whole mechanical low-rise, multi-rise and high-rise full-fabricated buildings, the effect of improving seismic performance of the house is achieved, the aerial working safety risk under layer-by-layer erecting is avoided, lots of formworks are saved, the building construction speed is increased, and compared with all other domestic and oversea current building structure systems, the products have the more significant cost performance advantage.

Owner:段志祥

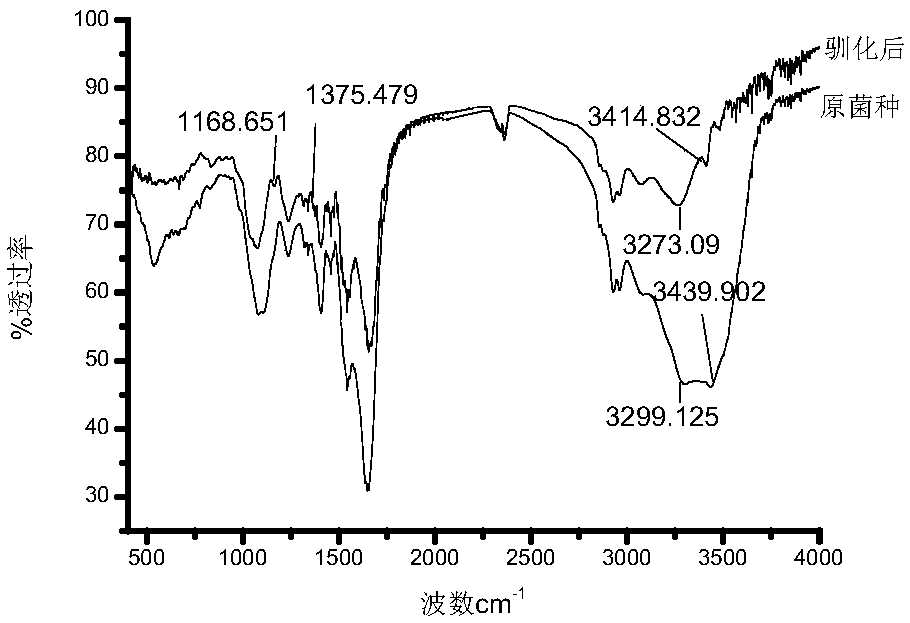

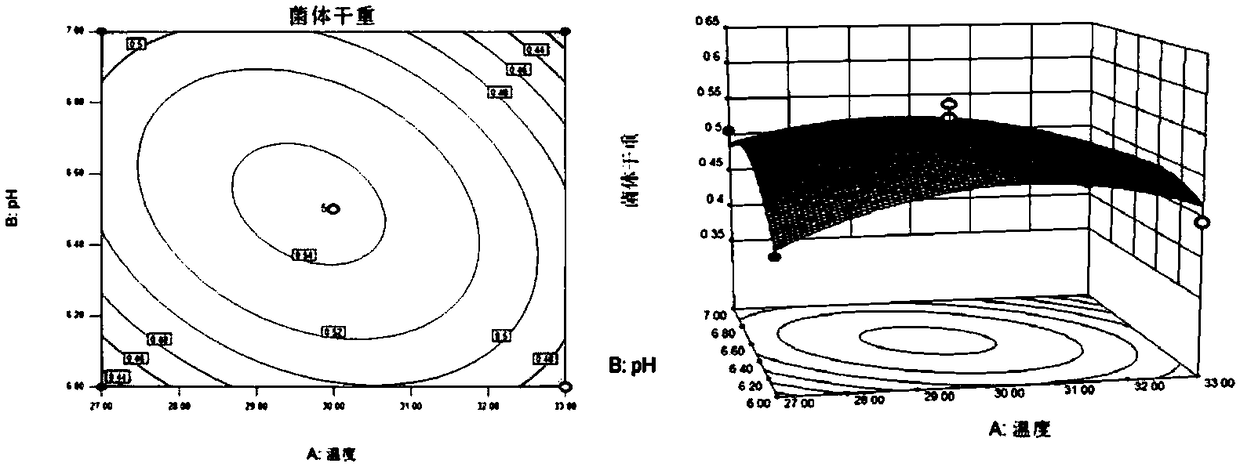

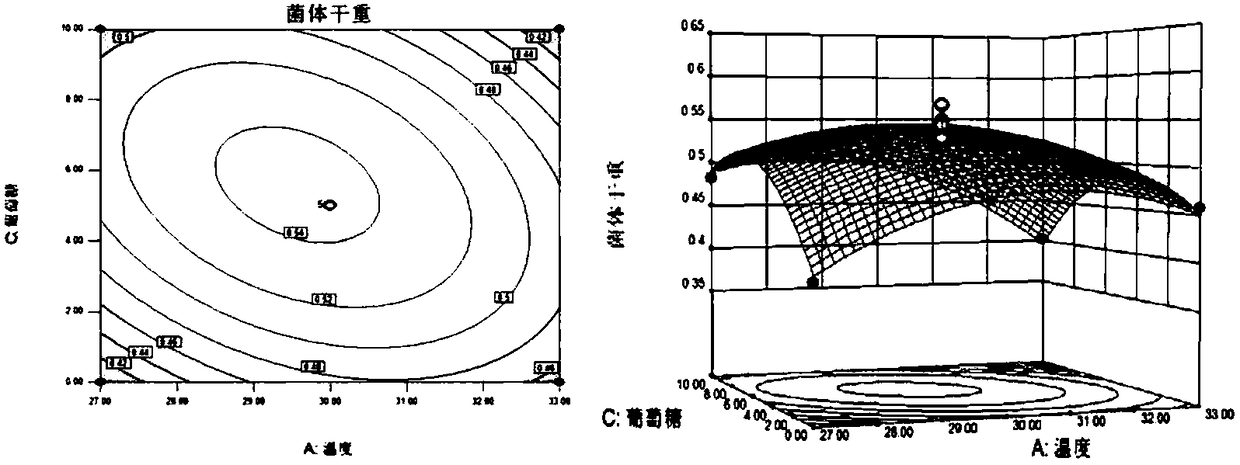

Copper-rich bacillus subtilis and cultivating method thereof

ActiveCN108342342AImprove feed utilizationImprove animal immunityBacteriaAnimal feeding stuffEnzymeSmall peptide

The invention relates to copper-rich bacillus subtilis and a cultivating method thereof. Bacillus subtilis of probiotics and Cu<2+> are fermented together, and the bacillus subtilis is domesticated bygradually increasing the concentration of CuSO4 to obtain a target bacillus subtilis strain NT66. By domestication of the bacillus subtilis by adopting a method of gradually increasing the concentration of Cu<2+>, the tolerance of the bacillus subtilis can be remarkably improved, and the copper content of thalli is increased. Through the optimization of a culture medium and the fermentation condition, a bacillus subtilis copper product is obtained, so that not only are active substances, such as enzyme, amino acid and small peptides, generated in the thallus fermentation process improved, butalso the copper enrichment amount of bacillus subtilis is increased. The prepared bacillus subtilis copper not only has the advantages of bacillus subtilis, inorganic copper is converted into thallusorganic copper, the utilization rate of animals on trace metal elements is greatly improved, and the biological function of organic copper is exerted well.

Owner:山东德信生物科技有限公司

Blue crab battery rearing and fattening method

InactiveCN101185422AQuality improvementImprove product qualityClimate change adaptationAnimal feeding stuffShrimpAquatic product

The invention provides a cage rearing and fattening method of a blue crab, relating to an aquiculture method, providing a cage rearing and fattening method of the blue crab without land occupancy, with non-deteriorating culture substrate, various scale, convenient operation and harvesting ways, high survival ratio and rate of live weight growth and improvement of culture quality and goods grade. A rope is taken as a large rope for the structure of cage rearing, floaters are arranged every 3 to 5m, and both ends of the large rope are fixed down the bottom of a sea, with a line spacing between 4 to 6m; the crab cage is cylinder-shaped, with a height of 80 to 120cm and a diameter of 30 to 40cm, and separated into 4 to 6 layers; a small door is arranged for every layer to cast bait, and the crab cage is fixed on the large rope by a thin rope with a diameter ranging from 0.6 to 1cm. The fattening measures are that: fattening objects are female or male crabs with complete appendages and insufficient fatness or those mated female crabs with immature ovary, and a single cage is used for cage rearing for every crab and sunk to the seawater; the daily feeding quantity of low value shellfishes is controlled between 20 to 30 percent of the total weight of the blue crab, and that of small fishes and shrimps is controlled between 5 to 12 percent of the total weight of the blue crab.

Owner:XIAMEN UNIV

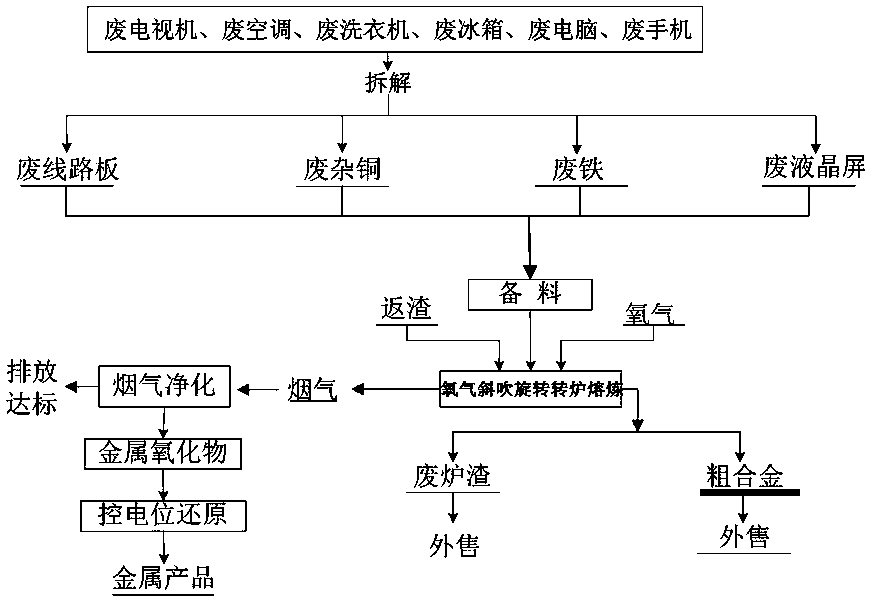

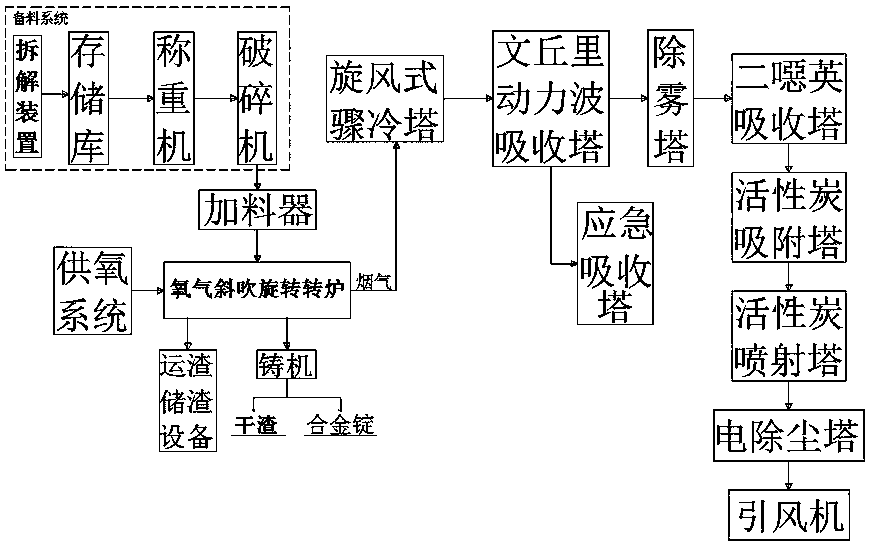

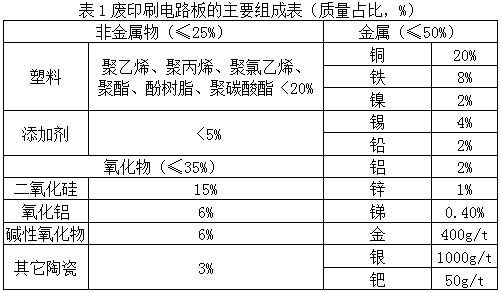

Hazard-free treatment system and method for electronic waste

PendingCN108224433AGood economic benefitsCompact structureSolid waste disposalIncinerator apparatusScrapPyrolysis

The invention discloses a hazard-free treatment system and method for electronic waste. The system comprises a material preparation system, a pyrolysis system, a casting machine, an oxygen supply system and a flue gas purification system. The material preparation system comprises a disassembling device, a waste storage bank, a weighing device, a conveying device and a physical crusher, wherein waste printed circuit boards and waste liquid crystal display screens are stored in the waste storage bank. The pyrolysis system comprises an oxygen obliquely-blowing revolving furnace and a feeder. Thetreatment method comprises the steps of 1, collecting and storing the waste printed circuit boards, the waste liquid crystal display screens, scrap copper and scrap iron; 2, conducting material preparation, weighing, material compounding, mixing and crushing, and delivering the materials into the feeder; 3, conducting feeding; 4, conducting reductive smelting; 5, conducting slag dumping; 6, conducting blowing; 7, conducting drossing and ingot casting; and 8, discharging a product out of the furnace, and casting an alloy plate. The hazard-free treatment system and method have the beneficial effects that smelting, reduction and refining can be completed in the same furnace, an additional smelting furnace does not need to be added, and inertia slag capable of being piled up is generated; andthe hazard-free treatment system can be completely closed, and the environmental requirement is met.

Owner:甘肃华壹环保技术服务有限公司

Process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste

ActiveCN108435754ALess investmentLow costSolid waste disposalExcrement fertilisersLiquid wasteSludge

The invention discloses a process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste. The process comprises the steps of step one, waste leachate treatment and foul smell deodorization; step two, waste screening, sorting and coarse crushing; step three, non-organic matter magnetic separation, winnowing and fine crushing; step four, agricultural and forestry waste crushing and screening; step five, stirring of waste combustible materials, agricultural and forestry waste, sludge and water, compression molding, airing and biomass fuel obtaining; andstep six, waste organic matter adding of livestock and poultry manure, and organic fertilizer obtaining. According to the process, the biomass fuel can be directly used in a boiler, and the problem that the livestock and poultry manure pollutes the environment in a livestock farm is solved through the organic fertilizer; for the construction of waste treatment plants, the investment is small, thecost is low, and implementation is easy; the agricultural and forestry waste is collected with paying performed, so that the income of farmers is increased, and the pollution is reduced; the profit rate is high, and operating can last without government subsidy; the waste gas, the waste liquid and the waste residue are subjected to the environmental protection treatment so that new pollution can be avoided.

Owner:于继林

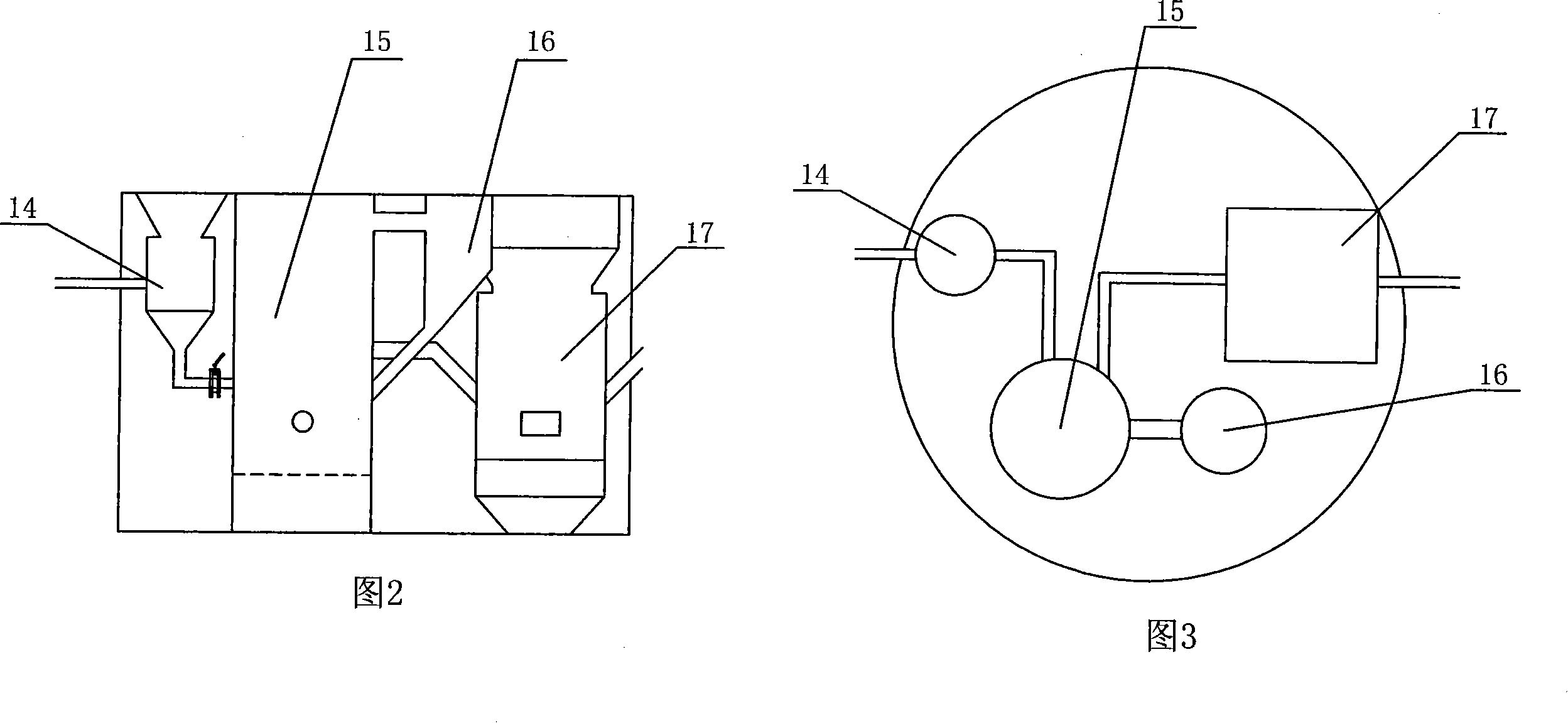

Modularized 5000KW multi-fuel generator set

InactiveCN101131119AEasy maintenance and operationHave diversityInternal combustion piston enginesEnergy inputGas compressorFixed bed

The 5000 KW modular multiple fuel generator set includes one fixed bed, one fluidized bed, one directly burning furnace, one separator and one afterheat boiler communicated through pipeline; one internal combustion engine communicated through one fume purifier to the afterheat boiler and with power output shaft connected to one first generator; one gas turbine communicated through one gas compressor to the internal combustion engine and with power output shaft connected to one second generator; and one steam turbine communicated to the directly burning furnace and with power output shaft connected to one third generator. The three generators can reach one total power output of 5000 KW.

Owner:YUNNAN BLUE OCEAN NEW ENERGY INVESTMENT

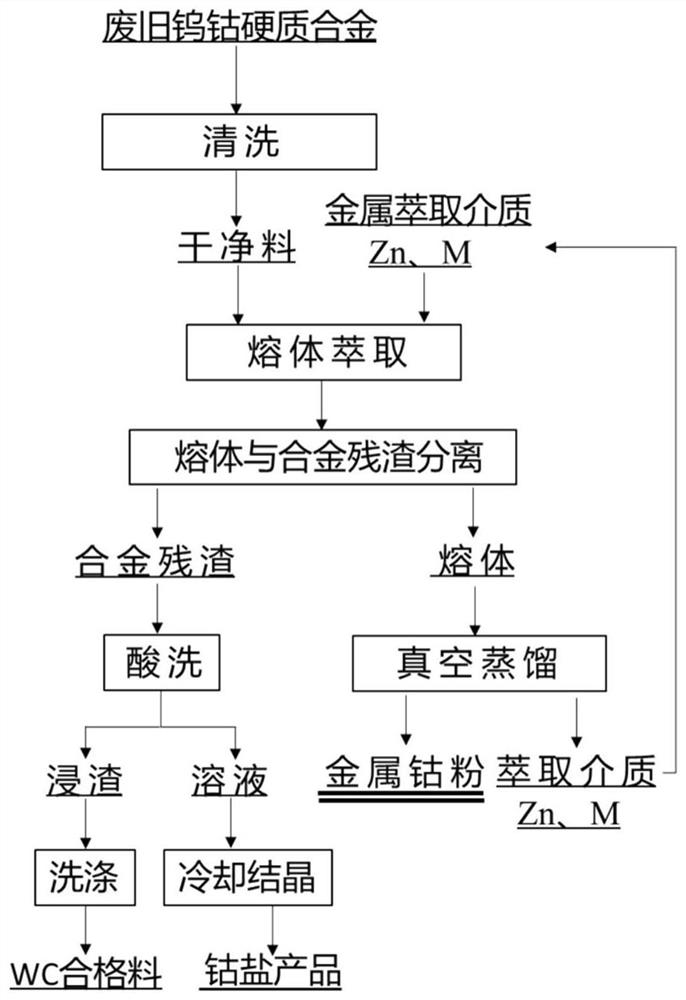

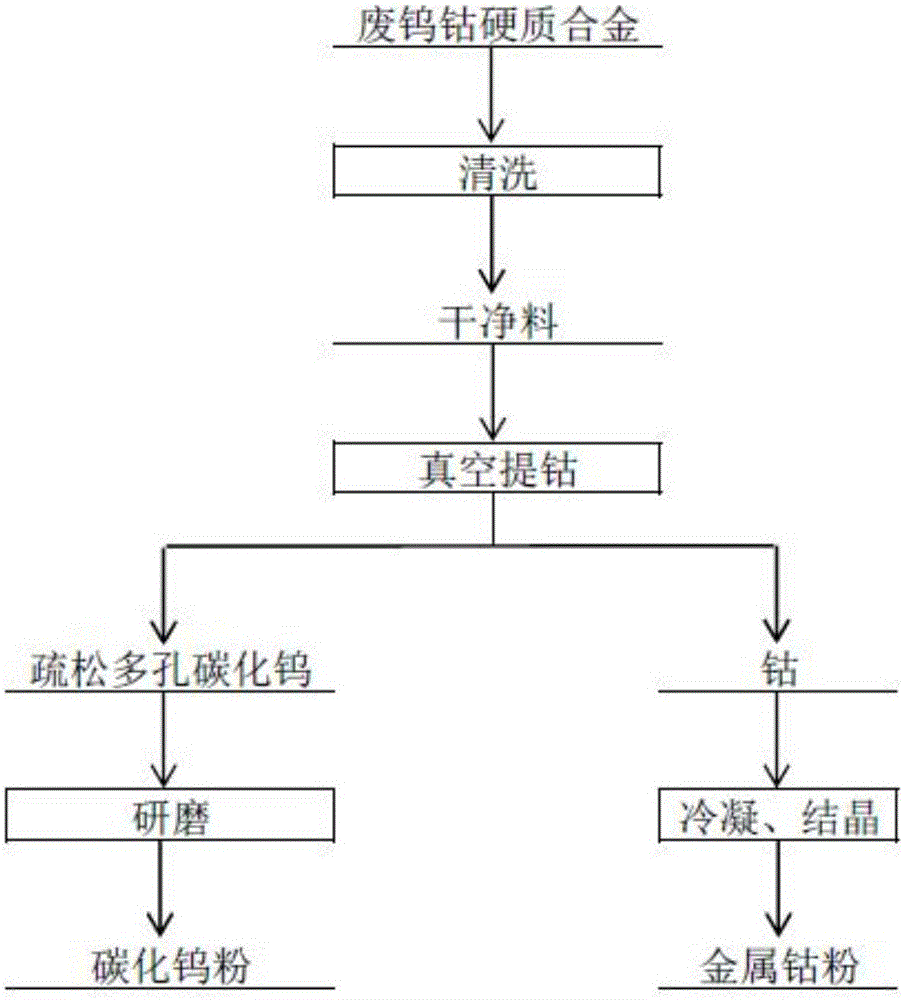

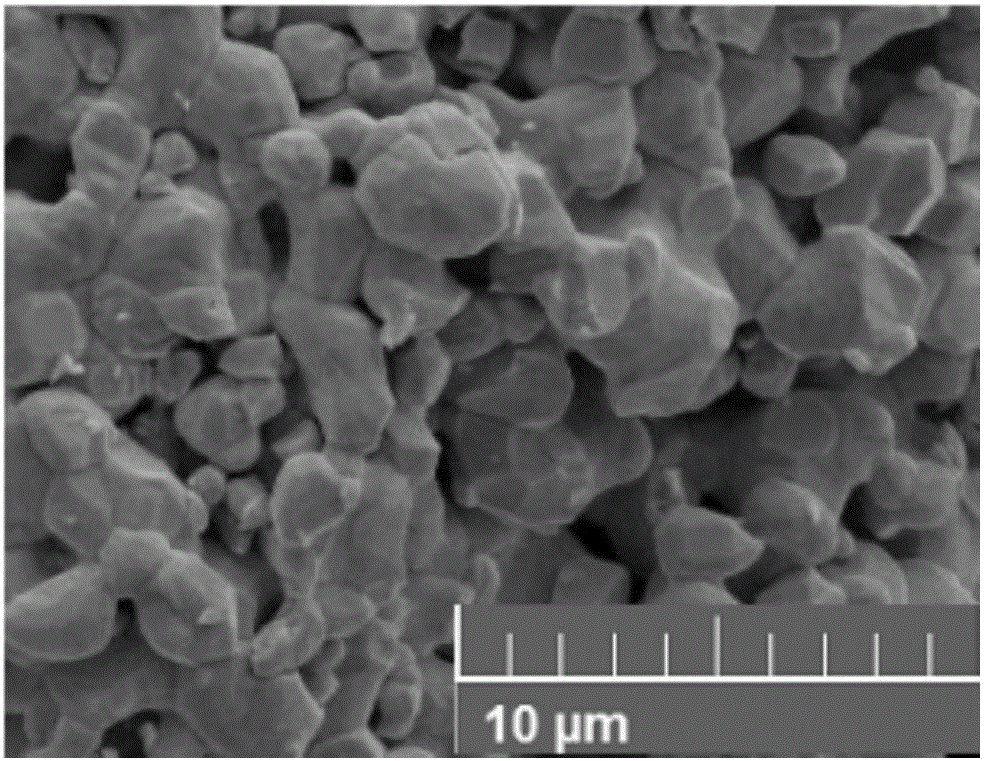

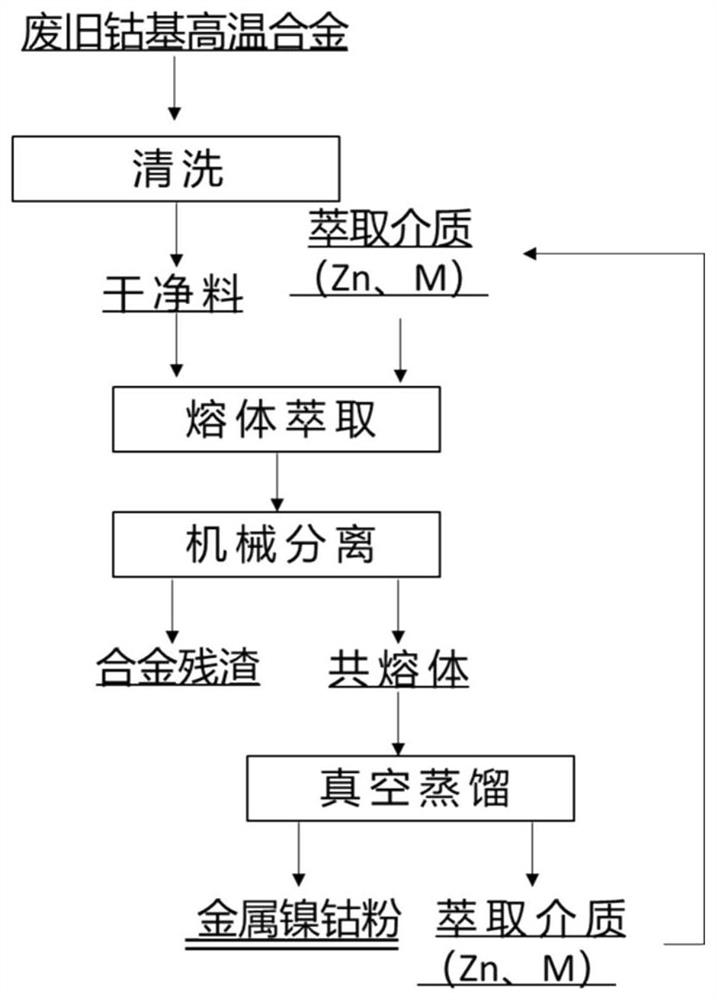

Method for extracting, separating and recycling tungsten carbide and cobalt in waste hard alloy by melt

ActiveCN111778400AHigh purityHigh recovery rate of cobaltTungsten/molybdenum carbideProcess efficiency improvementCemented carbideCobalt

The invention discloses a method for extracting, separating and recovering tungsten carbide and cobalt in waste hard alloy by melt. The method comprises the following steps that S1, extracting treatment is carried out by using molten Zn-M alloy as an extraction medium and waste tungsten-cobalt hard alloy as a to-be-extracted substance to obtain eutectic melt and alloy residue, Zn in the Zn-M alloyis a base metal, m is one or more of Mg, Pb, Bi or Sn; and S2, the eutectic obtained in the S1 is subjected to vacuum distillation, and metal cobalt powder and a condensed extraction medium are obtained. The method for separating and recycling tungsten carbide and metal cobalt in the waste tungsten-cobalt hard alloy is clean and efficient, and the method has the advantages of short process flow,simple equipment, high cobalt recovery rate, low cost, recyclable extraction medium and clean and environment-friendly process.

Owner:CENT SOUTH UNIV

Photosynthetic bacteria fermentation technology under natural ecological condition

InactiveCN102140429ALow costEasy to operateBacteriaMicroorganism based processesDisinfectantChemistry

The invention relates to a photosynthetic bacteria fermentation technology under the natural ecological condition, which comprises the following steps of: preparing a disinfectant from high test hypochlorite, aluminum potassium sulfate and sodium carbonate in a weight ratio of 2:5:0.5; making a weight ratio of components of a photosynthetic bacteria culture medium, namely sodium acetate to sodiumthiosulfate to sodium bicarbonate to monopotassium phosphate, calcium chloride and magnesium sulfate 7:3:1.3:0.1:(0.04-0.05):(0.01-0.02); adding water for culture into a transparent container, adding0.1 weight percent of disinfectant, stirring, standing and filtering to obtain sterilizing clear liquid; adding the photosynthetic bacteria culture medium in an amount which is 1 weight percent basedon the water for culture into the sterilizing clear liquid to prepare culture solution, adding photosynthetic bacteria strain liquid into the culture solution, ensuring a weight ratio of the culture solution to the photosynthetic bacteria strain liquid 3:(0.9-1.1), and uniformly stirring; and filling in a fermentation container, reserving a gas chamber, arranging in a light place outdoors, and culturing at the temperature of between 15 and 40 DEG C for 2 to 5 days until the color is deep red. The method is low in cost, easy to operate, adjustable in scale, and high in success rate, does not require a fixed production field, and is particularly suitable for agriculture and independent culture of cultivators.

Owner:QINGDAO ZHONGREN PHARMA

Method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide

ActiveCN106145114AWide applicabilitySolve the long process processProcess efficiency improvementCemented carbideCobalt

The invention relates to the technical field of recycling of waste tungsten alloy, and provides a method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide. The technological process comprises the steps that waste tungsten-cobalt cemented carbide is cleaned and dried, vacuum cobalt extraction is conducted in a graphite crucible, tungsten carbide with a loose and porous structure is obtained in the crucible, loose and porous tungsten carbide is subjected to crushing and grinding to obtain tungsten carbide power, cooling crystallization is conducted in a cobalt crystallizer, and metallic cobalt powder is obtained. According to the method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide, the cobalt extraction process is conducted in a high vacuum closed environment, smudging does not exist, impurities are removed through volatilization, a product is subjected to purification, and high-quality tungsten carbide can be obtained; the purity of cobalt powder extracted through a vacuum method is high, the condition of extracting cobalt is adjusted, and the cobalt powder with different particle sizes can be obtained. The method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide is wide in applicability, simple in equipment, low in energy consumption, not prone to smudge, free of pollution, high in recovery rate, low in cost and flexible in scale, and a new way for recycling waste tungsten-cobalt cemented carbide in an efficient and green mode is opened up.

Owner:GANZHOU HUAXIN METAL MATERIAL CO LTD

Method and equipment for fluidized bed gasification and melting treatment of solid waste and hazardous waste

PendingCN112283715AGood practicalityImprove practicalityEmission preventionIncinerator apparatusProcess engineeringFluidized bed gasifier

The invention discloses a method and equipment for fluidized bed gasification and melting treatment of solid waste and hazardous waste. The equipment comprises a shredder, wherein a discharge port ofthe shredder is connected to a conveyor, a discharge port of the conveyor is communicated with a feed port of a stokehole stock bin, and the stokehole stock bin is connected to a fluidized bed gasification furnace through a sealed feeder; an exhaust port of the fluidized bed gasification furnace is connected to a separator and a melting furnace, and an ash discharge port of the separator is communicated with a return feeder; an ash discharge port of the return feeder is connected to the fluidized bed gasification furnace; and a slag hole of a melting fire grate is connected to a water quenching slag box. According to the method, the solid waste and the hazardous waste are subjected to gasification reaction firstly, organic matter and carbon in the solid waste and the hazardous waste are changed into combustible gas, and ash fusion is achieved through the characteristics that gas-gas reaction is violent and high temperature is likely to be generated. Only furnace slag and vitreous bodies which are burnt at high temperature are generated in the whole process, so that harmless treatment of the solid waste and the hazardous waste is realized.

Owner:深圳市泽源环境科技有限公司

Closed circulation active carbon adsorption system

InactiveCN102732721AHigh recovery rateIncrease gold loading capacityProcess efficiency improvementActivated carbonEconomic benefits

The present invention discloses a closed circulation active carbon adsorption system, wherein a closed active carbon adsorption column is adopted as a basic adsorption unit, and a plurality of the basic adsorption units are connected in series to form a closed circulation, which is provided for recovery of gold from a gold-containing solution. According to the system, the system can not be affected by landform and is especially suitable for a flatland layout, and no adsorption cascade table is required to be specially arranged, such that the cascade preparation manner of the traditional adsorption column is completely changed; the counter current carbon series connection manner is changed, and change of inlet and outlet manners of the extracted gold pregnant solution can be achieved only by adopting adjustment of control of valve opening and valve closing in a system pipeline. With application of the system of the present invention, quality and adsorption rate of gold loaded carbon in gold production can be completely improved, the cascade counter current carbon series connection manner in production can be changed, the adsorption operation manner without carbon series connection can be achieved, the labor intensity of workers can be effectively reduced, the process can be simplified, the gold recovery rate can be improved, the whole economic benefits of the mine can be improved, and the production cost can be reduced. In addition, the system has characteristics of safety, reliability, easy preparation, flexible operation and variable scale.

Owner:广西地博矿业集团股份有限公司

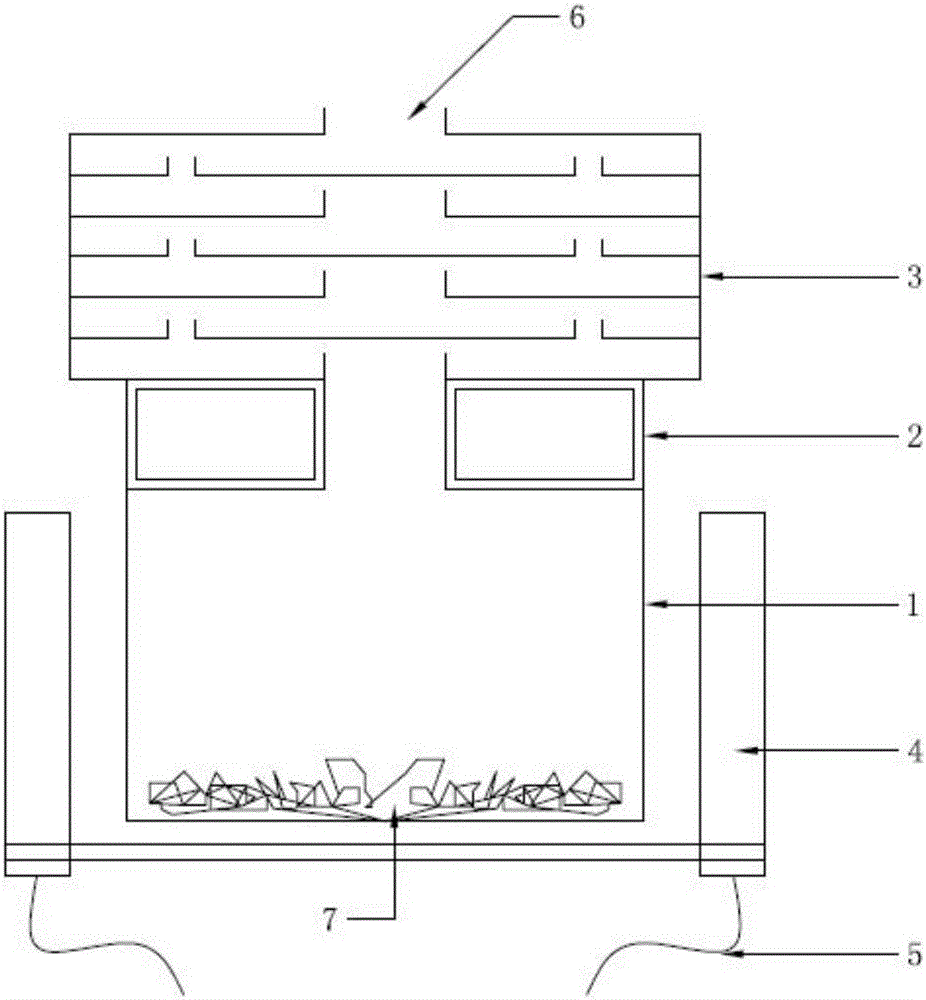

Method for producing germinated brown rice tea through low-temperature kilning

InactiveCN104397296ASimple production processSimple and fast operationTea substituesFlavorNutritive values

The invention discloses a method for producing germinated brown rice tea through low-temperature kilning and belongs to the technical field of food processing. The method comprises steps as follows: (1) evenly laying germinated brown rice in a drying container provided with a bottom air hole plate; (2) pressing clean hot air into the container to perform programmed temperature-rise kilning on the germinated brown rice; (3) cooling the kilned germinated brown rice with clean air to the normal temperature to obtain the germinated brown rice tea. The method has the advantages that the palatability of the germinated brown rice is improved, and the nutrition of the germinated brown rice is better kept; the tea can be directly made for drinking and can also be compounded with tartary-buckwheat tea, buckwheat tea, tea leaves and the like, and germinated brown rice compounded tea with the better flavor and the higher nutritive value is obtained; the method is simple in technology and high in operability.

Owner:四川谷黄金集团有限公司 +3

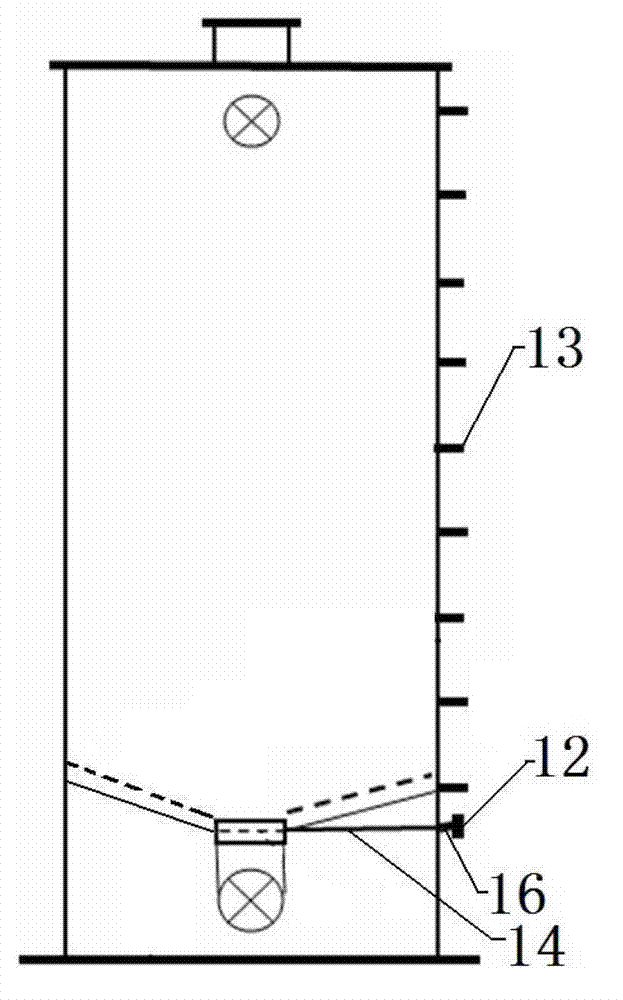

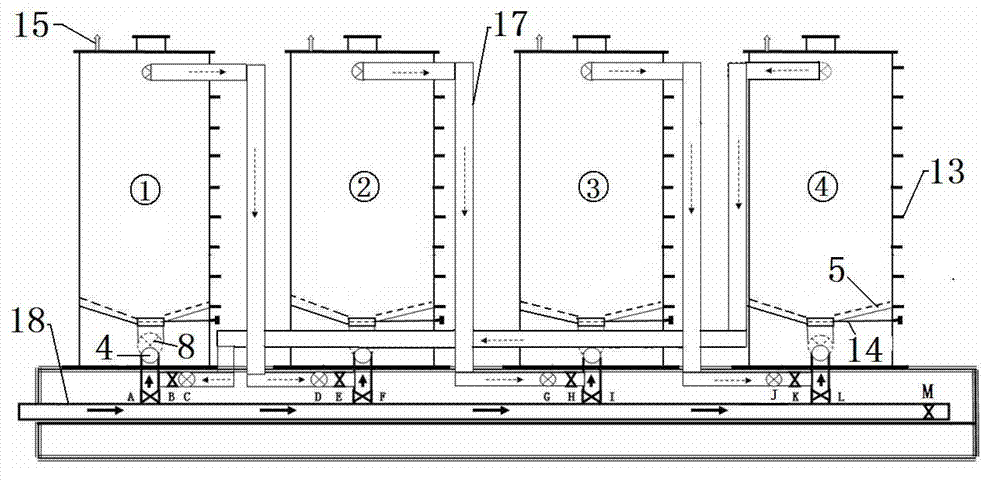

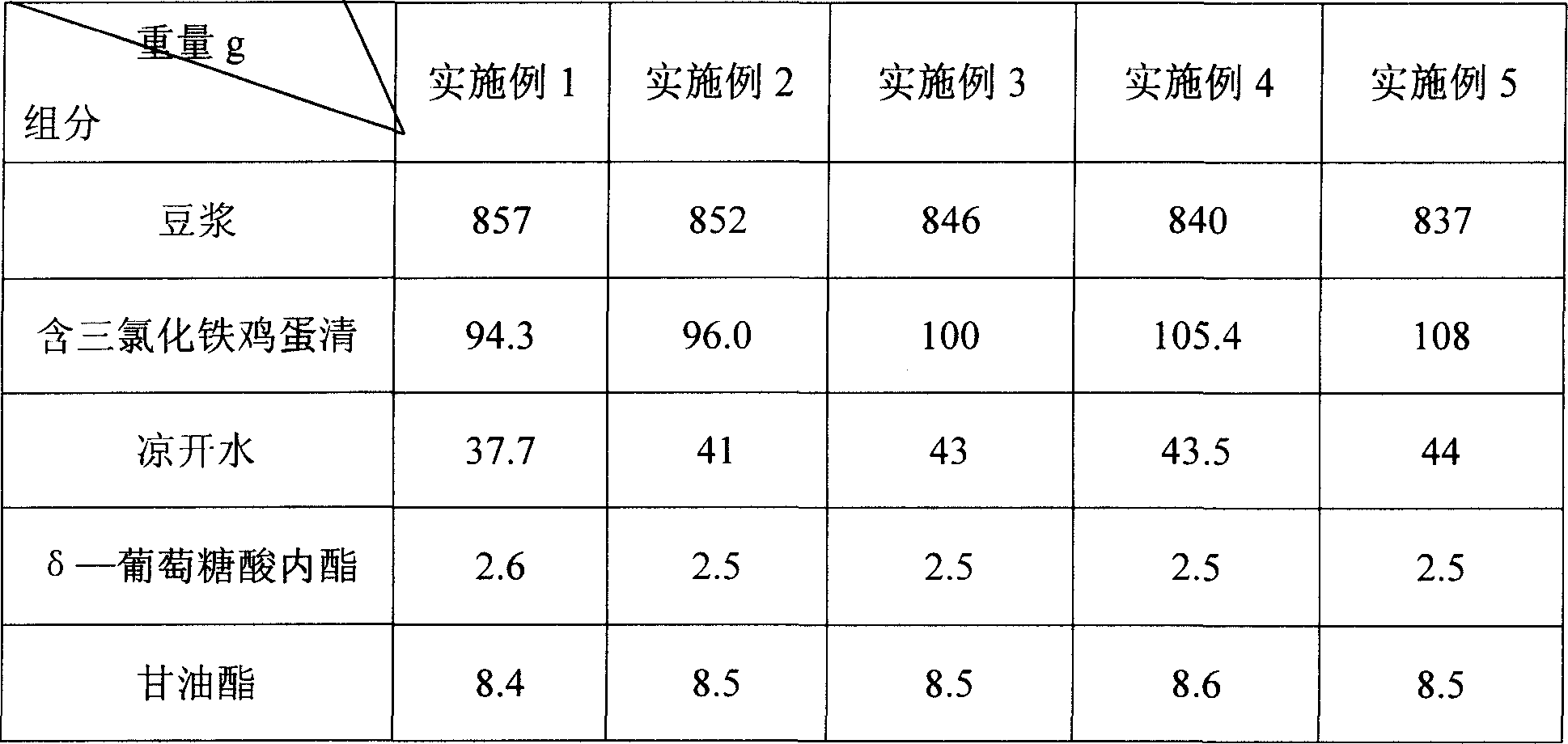

Lactone bean curd having iron supplementing function and its preparation method

InactiveCN1830303ANo side effectsSuitable for public nutrition improvement requirementsFood preparationGlycerol ester of wood rosinGluconic acid

Owner:SHANXI UNIV

Desulfurization method for acid leaching process of manganese-rich slag

InactiveCN102251120AIncrease reaction rateAvoid it happening againProcess efficiency improvementElectricityPyrolusite

The invention relates to a desulfurization method for an acid leaching process of manganese-rich slag. In the desulfurization method, a sulfuric acid solution is used as a leaching agent and the mass percentage of sulfur in the manganese-rich slag is 0.55-2.0%. In the steps of the desulfurization method provided by the invention, three measures that pyrolusite is added and used as an oxidant, electrocatalytic oxidation is carried out by virtue of electrifying and the manganese-rich slag is added gradually in a small amount are utilized. By utilizing the three measures, the oxidation on negative divalent sulfur in the manganese-rich slag is enhanced and the oxidation reaction rate of the negative divalent sulfur is greatly increased, thus effectively inhibiting the hydrogen sulfide generation during the acid leaching process of the manganese-rich slag and reducing the environmental pollution. Meanwhile, in the desulfurization method provided by the invention, used pyrolusite powder is natural pyrolusite without any treatment, the raw materials have wide sources and low cost, the whole process is simple and convenient to operate, the reaction conditions are easy to control, the scale can be large or small and the desulfurization method has better economic and environmental benefits.

Owner:CHONGQING UNIV

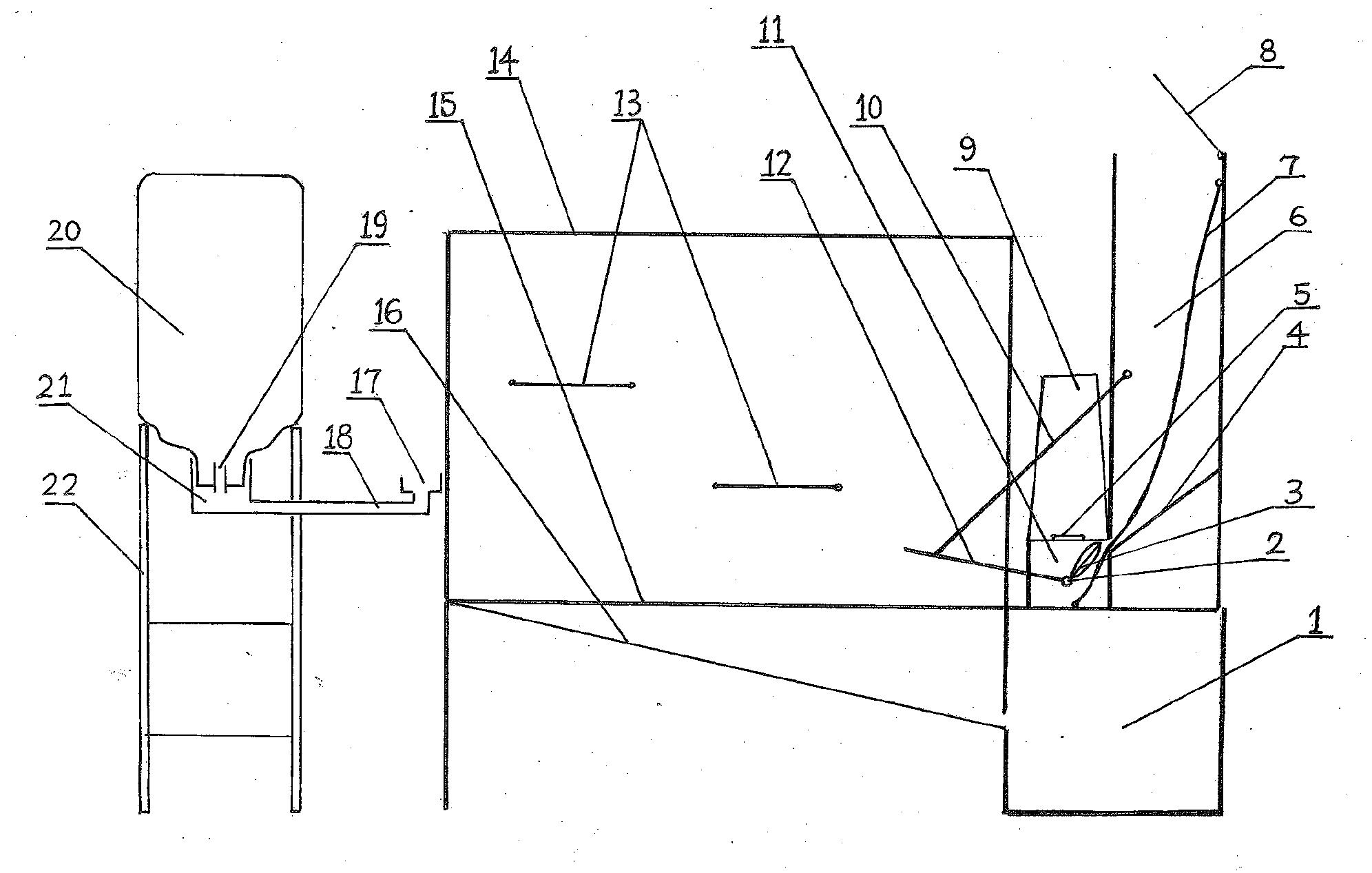

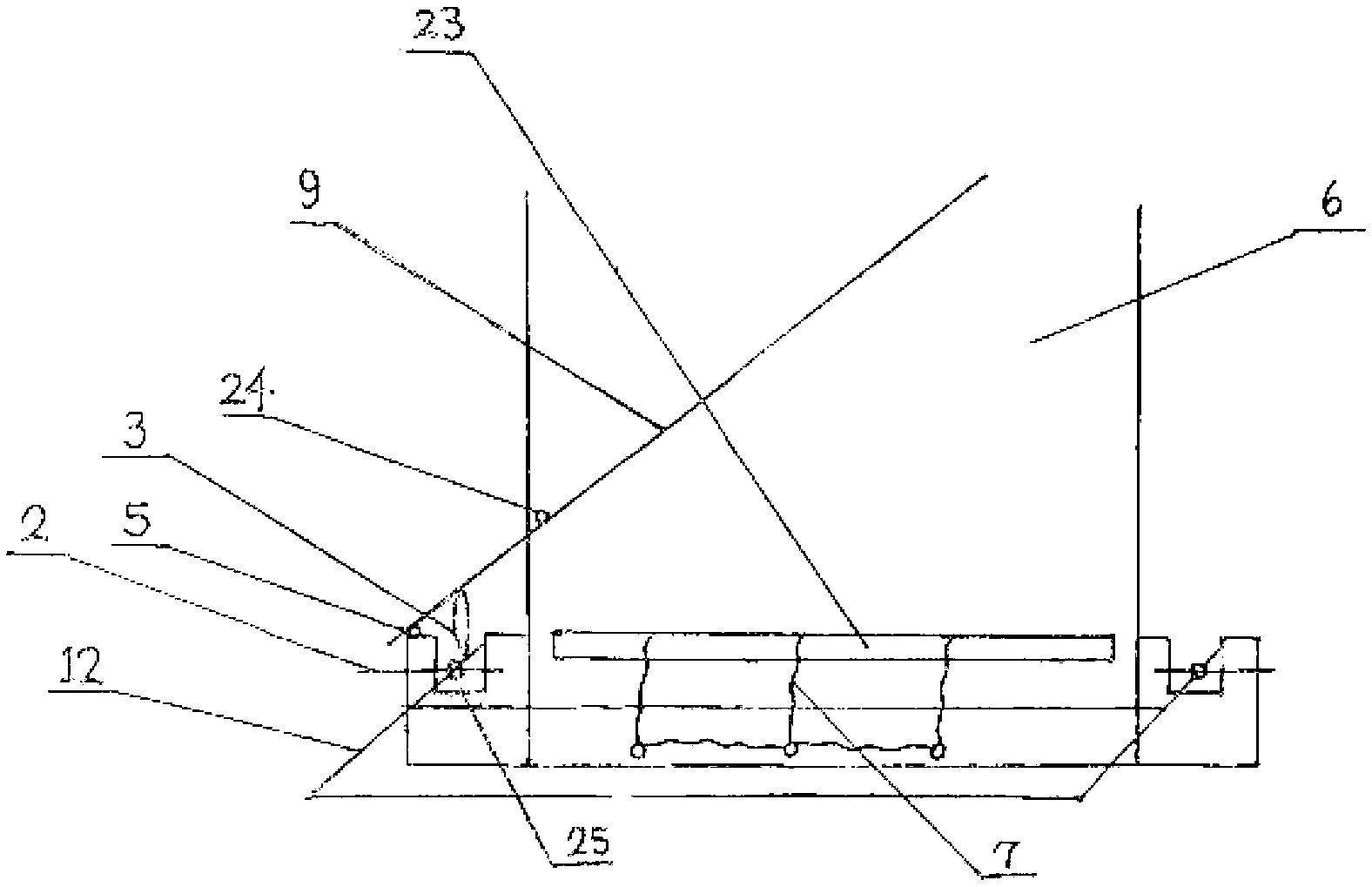

Automatic odorless chicken-raising device

An automatic odorless chicken-raising device is characterized in that a fodder bin (6) and a covered feeding trough (11) are arranged at right front of a hencoop; an aluminium sloping plate (16) communicated with a hen dung collecting box (1) is arranged at the bottom of the hencoop; an sloping plate (4) is arranged at the bottom of the fodder bin (6) and is provided with a lower end right facing towards a discharging outlet (23) of the feeding trough; one end of a feeding pedal (12) is fixedly connected with an ejector rod (3)of a cover plate of the feeding trough, and the other end thereof is movably connected with a spring (3); the other end of the ejector rod (3)of the cover plate of the feeding trough is a free end, and the other end of the spring is arranged on the fodder bin; one end of a steel wire rope is arranged on the fodder bin, and the other end thereof is movably connected with the bottom of the feeding trough; a drinking water device is arranged behind the hencoop. The device provided by the invention utilizes the self-characteristics of the hencoop, realizes the functions of automatic water supply, automatic fodder feeding and automatic dung collection, is simple and practical, is flexible in size, low-carbon, environment-friendly, wide in adaptability, and low in cost, and has a strong popularization value.

Owner:沈天德

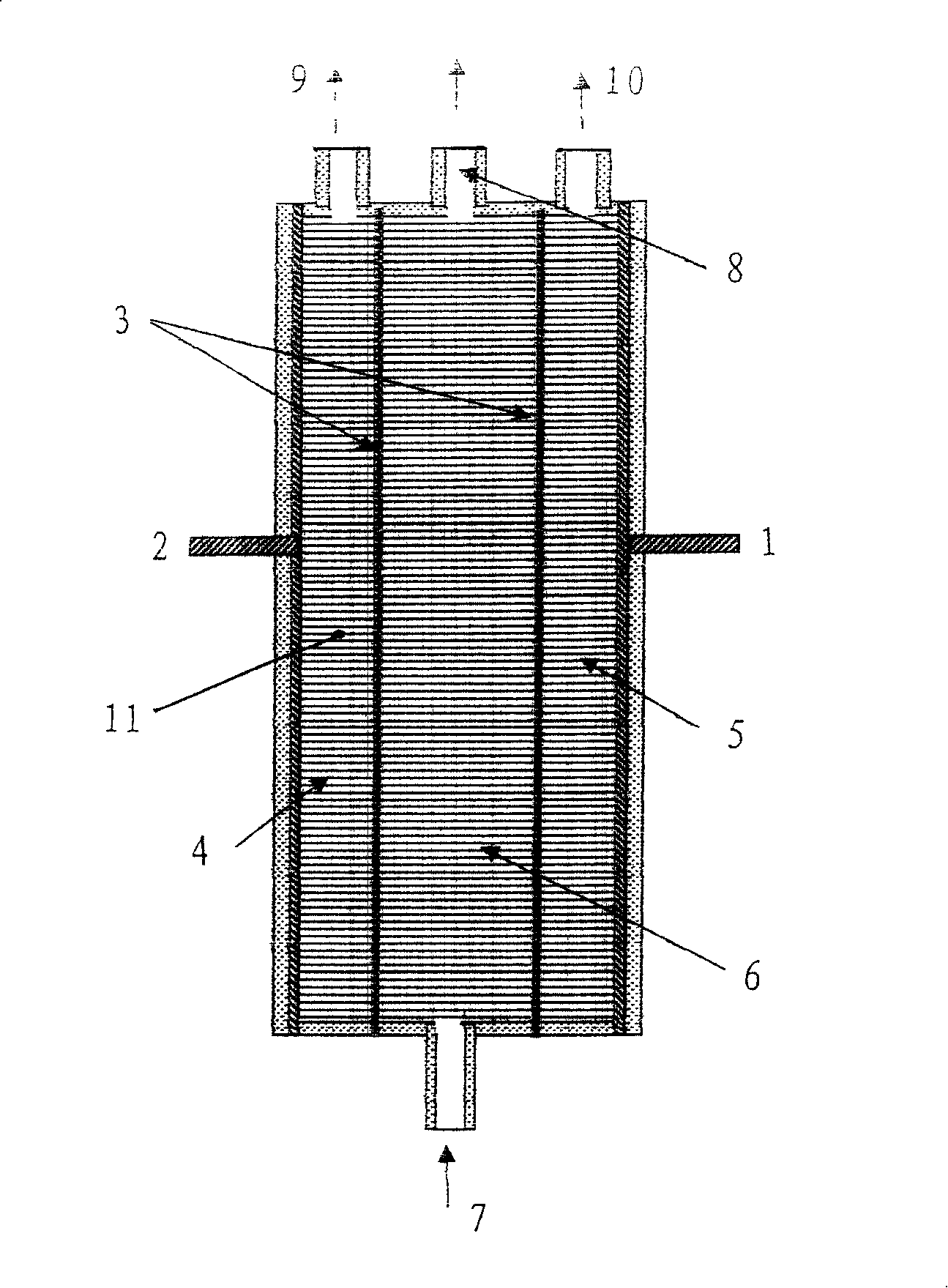

High-voltage electrodialysis water purifier

InactiveCN101239746AExtended service life without disassemblyLow running costDispersed particle separationElectrodialysisElectrical field strengthWater source

The present invention provides a high voltage electrodialysis water purifier, belonging to water processing field, the barrier of the present electrodialysis unit is made of multiple ionic membrane, and the present electrodialysis unit changes frequently, has a lower purification efficiency, not suitable for purification of groundwater with high hardness, and has a high cost, the invnetion is made of acrylic braided fabric, neutral semipermeable membrane or pylome foam plastic plate etc, a supporter is made of insulating material, voltage between anode and cathode is 100-200V, electrical field strength is 5-100V / cm, the invention has effect of high purification efficiency, simple technology, large or small purifying scale, suitable for water purification having higher pollution degree, and lower operating cost.

Owner:北京索能技术有限公司

Environment protection modified pitch

The environment protecting modified pitch has material comprising 10#-60# petroleum pitch 45-70 wt%, waste tyre rubber 12-35 wt%, waste lubricating oil 10-25 wt%, raw lacquer 0.5-3 wt%, tung oil 0.5-3 wt% and turpentine 1-5 wt%. The modified pitch may be used as filleting material for road and cement and concrete structures, waterproof material in roof, underground engineering, warehouse, etc. With partial waste in its material, the present invention has lowered cost and is environment friendly.

Owner:黄振钧

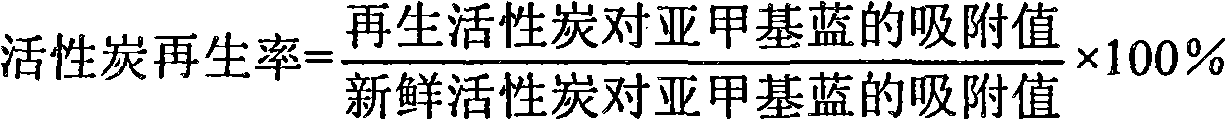

Method for regenerating active carbon after decoloration of glycin mother liquid

InactiveCN101884912AImprove the effectEasy to operateOther chemical processesOrganic compound preparationActivated carbonChemistry

The invention discloses a method for regenerating active carbon after decoloration of glycin mother liquid, which is an electrochemical regeneration method. The method comprises the following steps of: mixing waste active carbon not dried, NaOH solution and simethicone in an electrolytic cell, putting the electrolytic cell into a water bath, and inserting two graphite plate electrodes and a bubbling airpipe into mixed slurry; performing electrolysis, and simultaneously blowing and bubbling; standing, precipitating, and scraping simethicone floating on the upper layer; and filtering for separation, and drying a filter cake to obtain the regenerated active carbon. The method has the advantages of simple and convenient operation, easily controlled reaction conditions, small loss of the active carbon, small or large scale, and relative low overall cost.

Owner:CHONGQING UNIV

Rotary fork tooth type stereo garage

InactiveCN106481123AEasy to park and pick upSafe and reliable parkingParkingsParking spaceLift system

The invention provides a rotary fork tooth type stereo garage. The rotary fork tooth type stereo garage mainly comprises a stereo garage body with a plurality of fixed fork tooth type vehicle loading trays, a garage carrying lifting system and the like. The fixed fork tooth type vehicle loading trays and the movable fork tooth type vehicle loading trays are directly exchanged vertically to park and take vehicles. The problem that parking spaces of an existing comb tooth type stereo garage cannot be directly exchanged to park and take the vehicles is solved. The garage is simple in structure; vehicles are parked and taken conveniently and quickly; and the stereo garage is safe and reliable, and is simple to mount and repair and scientific and reasonable in structure. The cost of the stereo garage is lower than that of an existing garage. In addition, a plurality of stereo garages can be established together according to the occupied area. Sizes of construction molds can be large or small. The rotary fork tooth type stereo garage has quite large market competitive superiority and quite large development potential; and the problem that the vehicles park difficultly can be solved well.

Owner:靳文勇

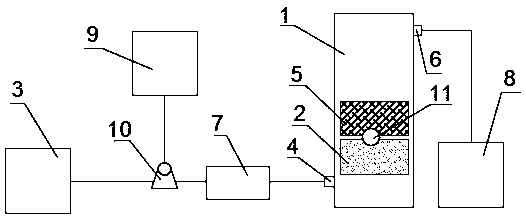

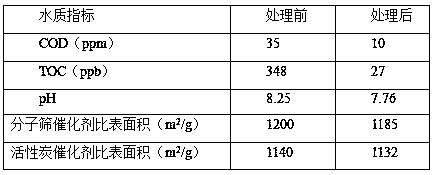

Composite catalyst bed layer based efficient catalytic sodium hypochlorite reclaimed water treatment system and process thereof

ActiveCN107915310AGood catalytic activityExcellent oxidation resistance, stabilityWater/sewage treatment by oxidationActivated carbonMolecular sieve

The invention discloses a composite catalyst bed layer based efficient catalytic sodium hypochlorite reclaimed water treatment system. The system comprises an oxidation tower internally provided withan activated carbon catalyst bed layer and a molecular sieve catalyst bed layer. The invention further discloses a composite catalyst bed layer based efficient catalytic sodium hypochlorite reclaimedwater treatment process. A sodium hypochlorite activating effect of a catalyst bed layer is realized, the content of refractory organics in reclaimed water is effectively decreased, and deep treatmentof reclaimed water is realized. Catalyst utilization efficiency is greatly improved, sodium hypochlorite oxidation effects are remarkably improved, mechanical strength and surface antifouling performance are both improved effectively, catalyst loss in a utilization process is avoided, and stability of the process is effectively improved. By adoption of the process, catalyst utilization efficiencyis completely guaranteed, the catalyst bed layer can be used for treatment of various types of urban reclaimed water, a catalyst utilization period is prolonged, and applicability of the process is greatly improved.

Owner:HUANENG JIAXIANG POWER GENERATION CO LTD

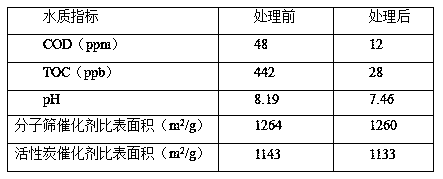

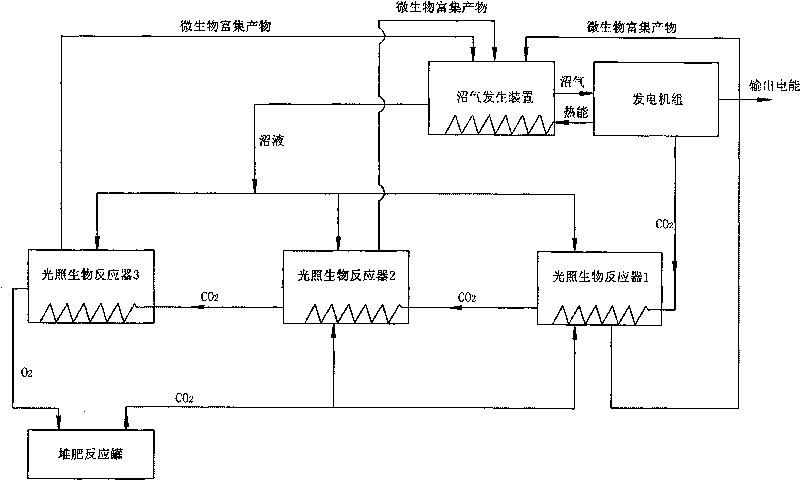

Microorganism power generating method by utilizing carbon source in a recycling way

InactiveCN101749106AGood breeding conditionsFull of nutritionInternal combustion piston enginesWaste based fuelNutrient solutionInternal combustion engine

The invention discloses a microorganism power generating method by utilizing carbon source in a recycling way, comprising the following steps: a) nutritional type microorganisms of light are placed in an illumination bioreactor, liquid nutrient solution is added, carbon dioxide gas is introduced, the microorganism enrichment products at the upper part of the floating illumination bioreactor are output; b) the microorganism enrichment products are input in a methane generator, the generated methane liquid is input in the illumination bioreactor, and the generated methane is input in a combustion motor in a generator set for burning; c) the output carbon dioxide gas is input to the illumination bioreactor. In the method, the luminous energy nutritional type microorganisms are used as primary material for marsh gas power generation, non-renewable resources are not consumed, and harmful gas is not exhausted. By adopting the way of circulating utilization, all products in the process flow can be used.

Owner:刘爱平

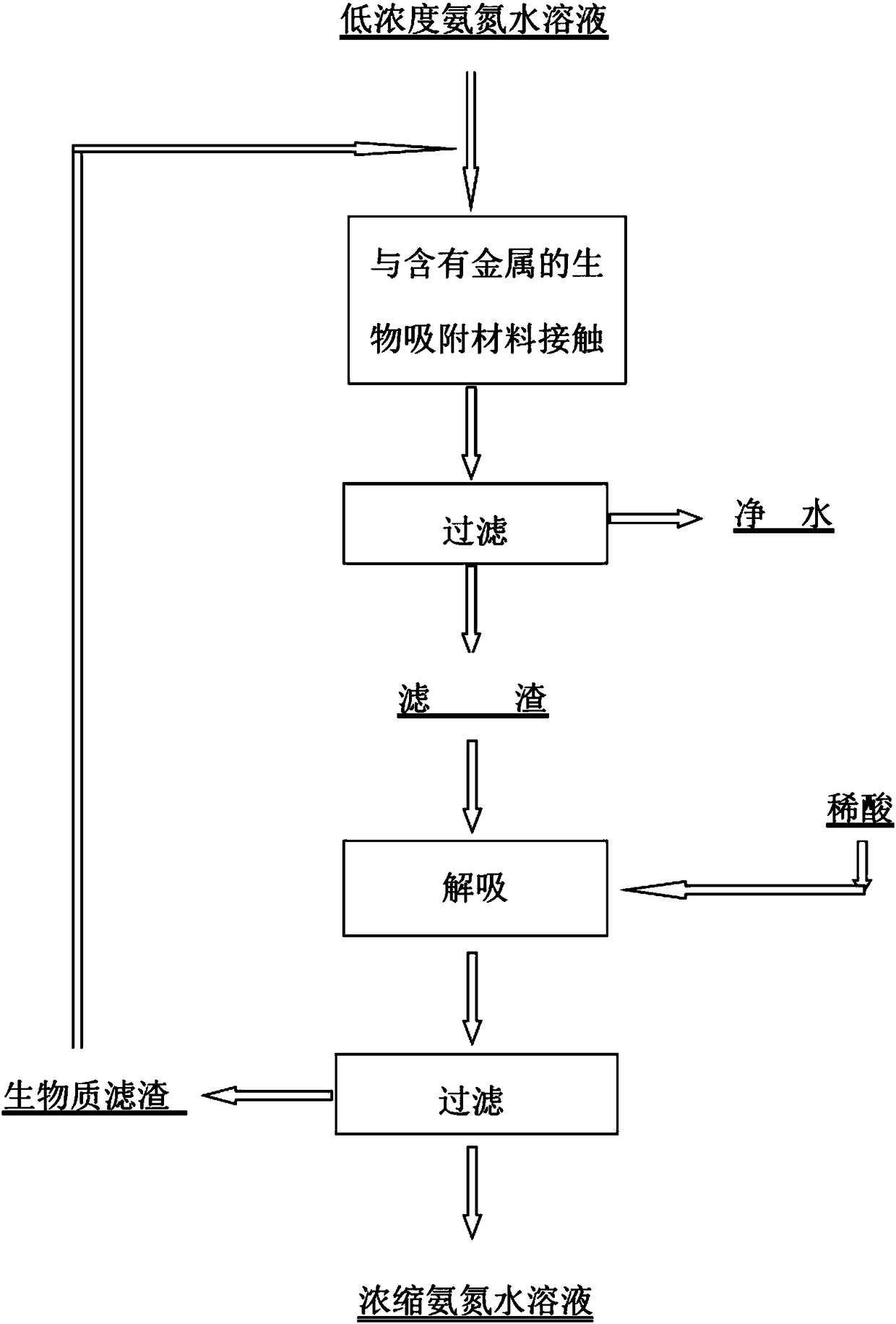

Method for removing low-concentration ammonia nitrogen in water body through biological adsorption

InactiveCN108970586ASimple and fast operationSimple processOther chemical processesWater/sewage treatment by sorptionSorbentDesorption

The invention particularly relates to a method for removing low-concentration ammonia nitrogen in a water body through biological adsorption. The method comprises: preparing a biomass adsorbent material; loading metal ions on the biomass adsorbent material; and pouring the adsorbent material in wastewater or water body containing ammonia nitrogen components to immobilize the ammonia molecules in the aqueous medium onto the metal ion-loaded biomass adsorbent particle material so as to achieve the adsorption removal purification of the ammonia nitrogen components in the water body, wherein the adsorbed ammonia nitrogen molecules can be subjected to dilute acid desorption, concentration and recovery, and the adsorbent material can be repeatedly used multiple times. According to the present invention, the method has characteristics of simple operation, easy performing and no secondary pollution, the used raw and auxiliary materials are inexpensive and easy to obtain, the scale can be largeor small, the adsorbent material can be used in large-watershed water bodies, and can further be used in specially-designed reactors, and the method is the advanced technology used for treating low-concentration ammonia nitrogen water medium and having the application prospects due to the characteristics of high efficiency, economy, strong adaptability and the like.

Owner:南京博络金环保科技有限公司

Method for recovering nickel and cobalt in waste cobalt-based high-temperature alloy through melt extraction separation

ActiveCN111778399AHigh recovery rateShort processProcess efficiency improvementGas emission reductionSuperalloyCobalt

The invention discloses a method for recovering nickel and cobalt in a waste cobalt-based high-temperature alloy through melt extraction separation. The method comprises the following steps: 1, extraction treatment is carried out with a molten Zn-M alloy as an extraction medium, and a waste and old cobalt-based high-temperature alloy as an extract to obtain eutectoid and alloy residues, wherein inthe Zn-M alloy, Zn is a main metal and M is one or more of Pb, Bi or Sn; and 2, vacuum distillation is carried out on the eutectoid obtained in step 1 to obtain metal nickel cobalt powder and a condensed extraction medium. According to the method for recovering nickel and cobalt in the waste cobalt-based high-temperature alloy through melt extraction separation, the process is clean and efficient. The method has the advantages of short process flow, simple equipment, high nickel-cobalt recovery rate, low cost, recyclable extraction medium, and clean and environment-friendly process.

Owner:CENT SOUTH UNIV

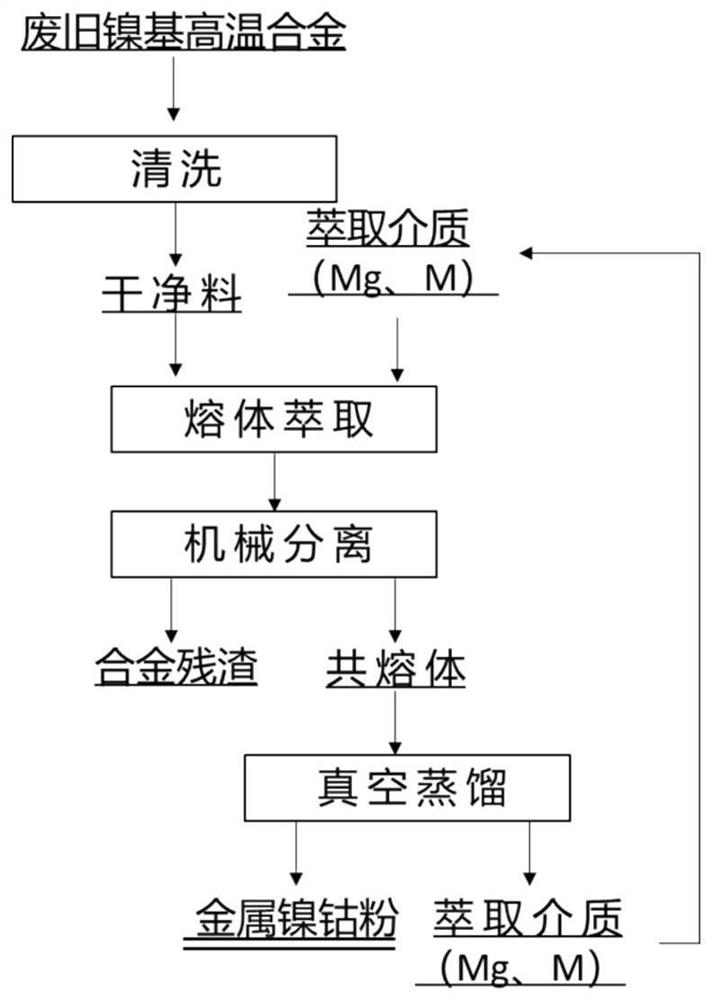

Method for extracting, separating and recycling nickel and cobalt in waste nickel-based high-temperature alloy by using melt

ActiveCN111778411AHigh recovery rateShort processProcess efficiency improvementGas emission reductionCobaltMetal metal

The invention discloses a method for extracting, separating and recycling nickel and cobalt in waste nickel-based high-temperature alloy by using a melt. The method comprises the following steps thatS1, molten Mg-M alloy is taken as an extraction medium and the waste nickel-based high-temperature alloy is taken as a to-be-extracted substance, extraction treatment is carried out, and eutectic meltand alloy residues are obtained, wherein Mg is used as a main metal in the Mg-M alloy, and M metal is one or more of Pb, Bi and Sn; and S2, the eutectic obtained in the step 1 is subjected to vacuumdistillation to obtain metal nickel-cobalt powder and the condensed extraction medium. The invention provides a clean and efficient method for separating and recycling the metal nickel and cobalt in the waste nickel-based high-temperature alloy. The method is short in technological process, simple in equipment, high in nickel-cobalt recycling rate and low in cost, the extraction medium can be recycled, and the process is clean and environmentally friendly.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com