Desulfurization method for acid leaching process of manganese-rich slag

A manganese-rich slag and acid leaching technology, applied in the field of acid leaching manganese-rich slag, can solve problems such as affecting health, polluting the environment, hydrogen sulfide gas escape, etc., and achieves the suppression of hydrogen sulfide production, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

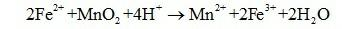

[0013] A desulfurization method in the process of acid leaching manganese-rich slag, the leaching agent in the method is sulfuric acid solution, and the mass percentage of sulfur in the manganese-rich slag is 0.55-2.0%. In the inventive method, comprise the steps:

[0014] (1) Put pyrolusite with a manganese dioxide content of 30% to 40% into the leaching tank, add sulfuric acid solution, and stir at a constant speed at room temperature; wherein, the concentration of sulfuric acid solution is 2 to 4mol / L, pyrolusite: sulfuric acid Solution=1kg: 30~40L (clear to those skilled in the art, the manganese dioxide content refers to the mass percent of manganese dioxide in pyrolusite);

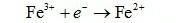

[0015] (2) Then, insert two graphite electrode plates into the leaching tank, turn on the power to carry out the electrocatalytic oxidation reaction; among them, the voltage is 3-4.5V, and the anode current density is 100-300A / m 2 ;

[0016] (3) Then, in the stirring state, add manganese-rich slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com