Method for removing low-concentration ammonia nitrogen in water body through biological adsorption

A low-concentration ammonia nitrogen and biological adsorption technology, applied in the field of low-concentration ammonia nitrogen, can solve the problems of large reactor, long process, difficult regeneration, etc., and achieve the effect of no secondary pollution, simple process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

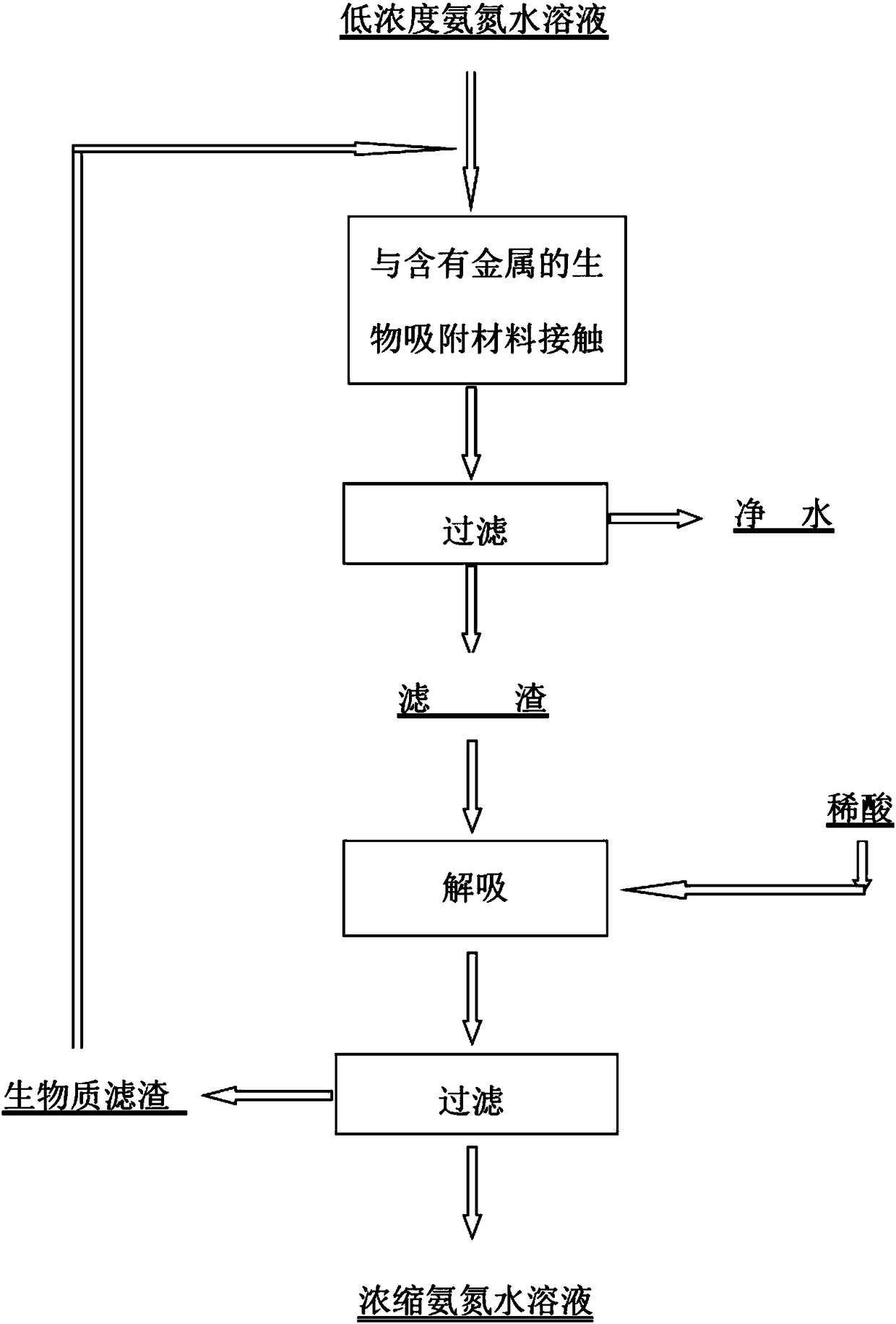

Image

Examples

Embodiment 1

[0021] Prepare 10 liters of copper nitrate ion solution with a concentration of 0.1M, adjust the pH of the metal ion solution to 6 with 0.1M hydrochloric acid and sodium hydroxide solution, put in 200 grams of apple peel adsorbent, stir and react for 30 minutes, and filter the adsorbent , after washing with distilled water for 3 times, put it into an oven at 60°C and dry it with hot air for 6 hours; further grind, sieve, and classify to obtain a negative copper biosorption powder product with a particle size below 200 mesh. Take 10 liters of water samples containing 50mg / L ammonia nitrogen, measure its pH value to 7.2, directly put 50 grams of the negative copper biosorption powder product prepared above, stir and react for 5 hours, filter, and measure the ammonia nitrogen content in the water samples is less than 1mg / L.

[0022] The adsorbent particles are stirred and reacted with 200 ml of dilute hydrochloric acid with a pH value of 3 for 1 hour, and an appropriate amount o...

Embodiment 2

[0024] Prepare 10 liters of nickel nitrate ion solution with a concentration of 0.1M, adjust the pH of the metal ion solution to 6 with 0.1M hydrochloric acid and sodium hydroxide solution, put in 100 grams of garlic peel adsorbent, stir and react for 300 minutes, then filter the adsorbent , after washing with distilled water for 3 times, put it into an oven at 60°C and dry it with hot air for 6 hours; further grind, sieve, and classify to obtain a negative nickel biosorption powder product with a particle size below 200 mesh. Take 10 liters of water samples containing 50mg / L ammonia nitrogen, measure its pH value to 7.2, directly put 50 grams of the negative nickel biosorption powder product prepared above, stir and react for 5 hours, filter, and measure the ammonia nitrogen content in the water samples is less than 3mg / L.

[0025] The adsorbent particles are stirred and reacted with 200 ml of dilute hydrochloric acid with a pH value of 3 for 1 hour, and an appropriate amoun...

Embodiment 3

[0027] Prepare 10 liters of silver nitrate ion solution with a concentration of 0.1M, adjust the pH of the metal ion solution to 4 with 0.1M nitric acid and sodium hydroxide solution, then drop in 300 grams of beer malt distiller's grains adsorbent, stir and react for 500 minutes, and then absorb After washing with distilled water for 3 times, put it into an oven at 60°C and dry it with hot air for 6 hours; further grind, sieve, and classify to obtain a negative silver biosorption powder product with a particle size below 200 mesh. Get 10 liters of water samples containing 50 mg / L ammonia nitrogen, measure its pH value to 7.2, directly drop into 50 grams of the negative silver biosorption powder product prepared above, stir and react for 5 hours, filter, and measure the ammonia nitrogen content in the water samples to be less than 0.5 mg / L.

[0028] The adsorbent particles are stirred and reacted with 200 ml of dilute citric acid with a pH value of 4 for 1 hour, and then filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com