Closed circulation active carbon adsorption system

A technology of activated carbon adsorption and closed-circuit circulation, applied in the direction of improving process efficiency, etc., can solve the problems of further improvement of gold recovery rate, inflexible and convenient operation, and high labor intensity of workers, so as to improve the overall economic benefits and reduce the labor intensity of workers , Improve the effect of grade and adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

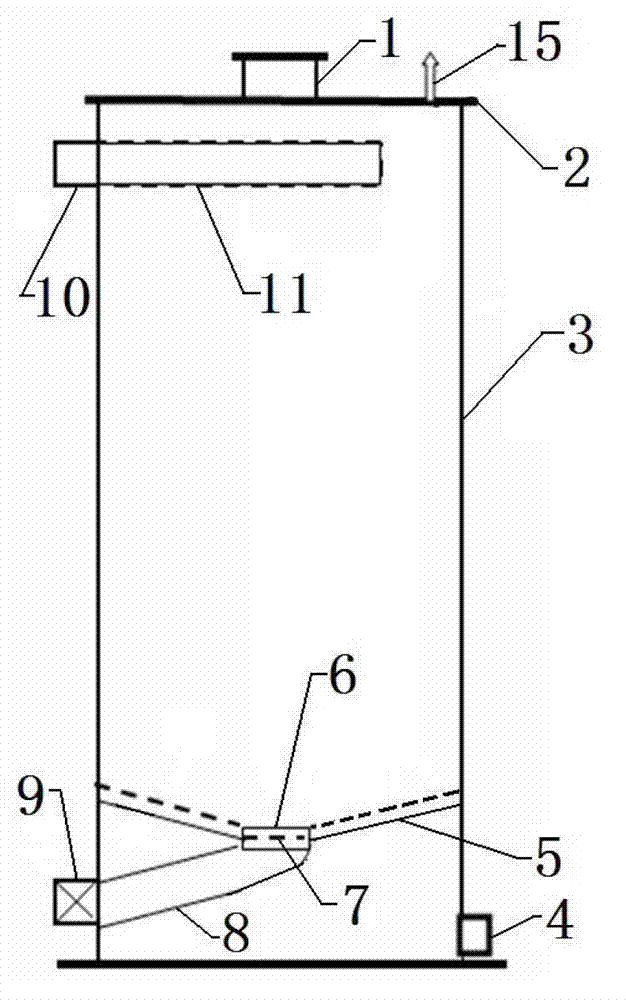

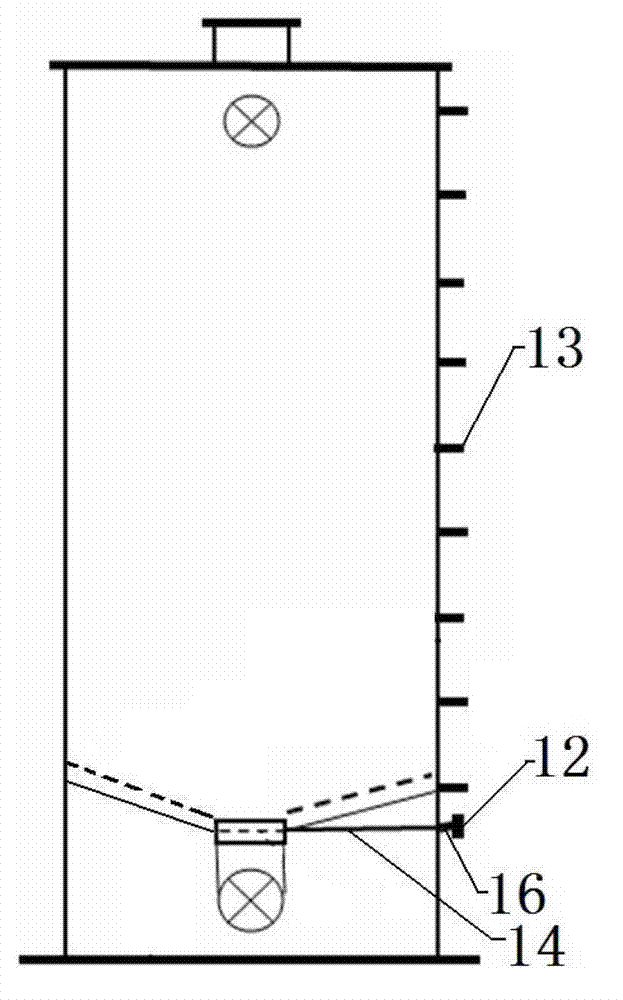

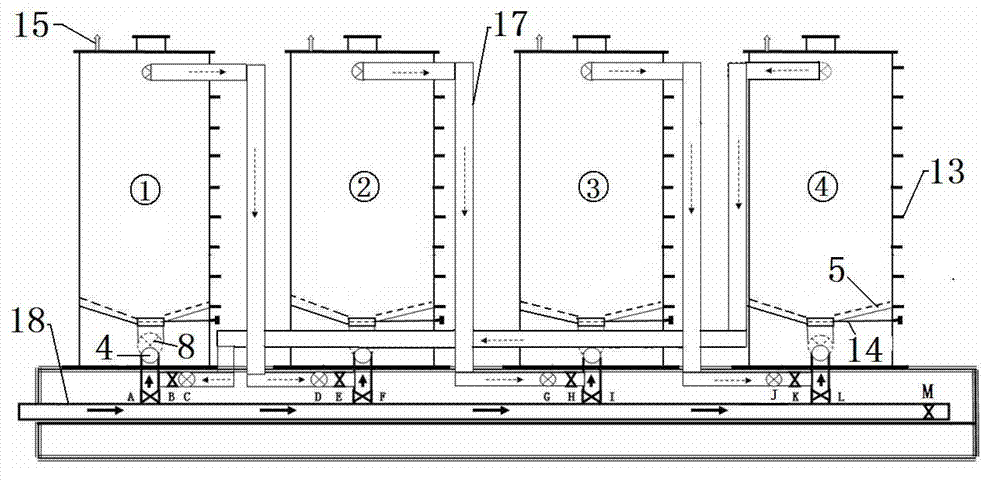

[0021] Such as Figure 1 to Figure 4 As shown, the closed-loop activated carbon adsorption system of the present invention is connected in series by four closed activated carbon adsorption columns of No. 1, No. 2, No. 3 and No. 4 to form a closed-circuit cycle; the closed activated carbon adsorption column mainly includes the adsorption column body 3 ( The diameter-to-height ratio of the column is 1:2~3) and the detachable sealed top cover 2, a ladder 13 is installed outside the adsorption column body 3, the upper part of the adsorption column body 3 is provided with a barren liquid discharge conduit 10, and the lower part is provided with a charcoal discharge conduit 8 Hegui liquid inlet 4, a sealable carbon filling port 1 is installed on the detachable sealing top cover 2, and an automatic exhaust sealing device 15 is installed on the detachable sealing top cover 2, which is composed of a guide rod, a tapered sealing sleeve, and a floating ball; The length of the poor liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com