Method for extracting, separating and recycling nickel and cobalt in waste nickel-based high-temperature alloy by using melt

A nickel-based superalloy, separation and recovery technology, applied in the direction of reducing gas emissions, improving process efficiency, etc., can solve the problems of low product purity, uncompetitiveness, and low added value, and achieve short process flow, wide use, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The Ni-based superalloy waste to be recovered and separated in this embodiment includes Ni, Co, Fe, Mo, and Ta elements, wherein the mass percentage of Ni is 52.6%, and the mass percentage of Co is 9.5%.

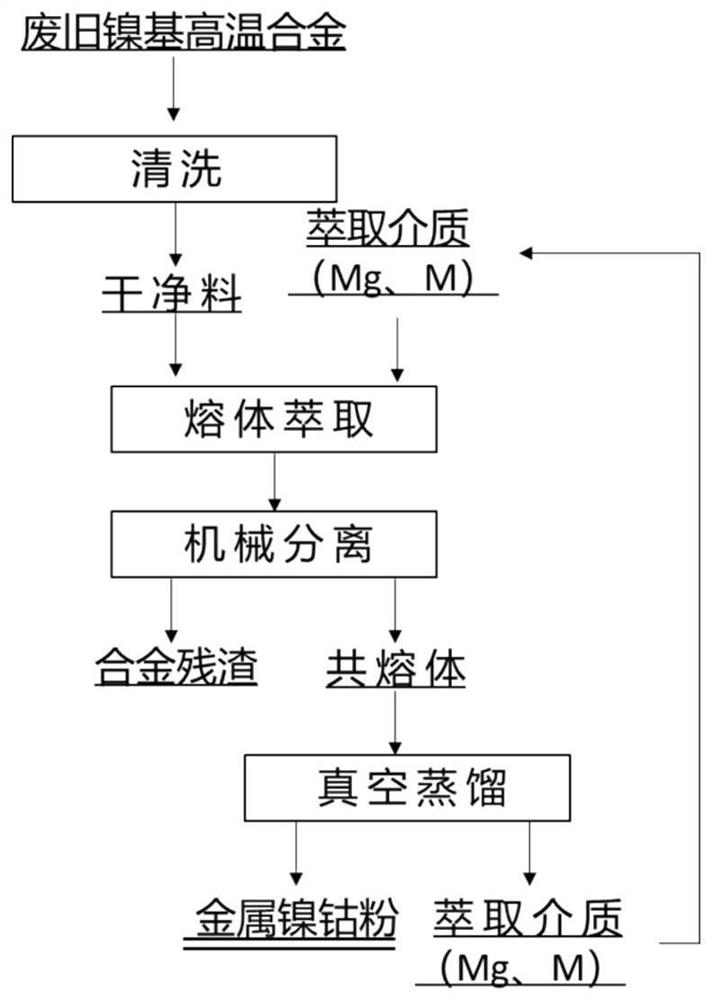

[0047] combine figure 1 , The method for separating and recovering nickel and cobalt from nickel-based superalloy waste in this embodiment includes the following steps.

[0048] (1) Treat the surface of the nickel-based superalloy waste to remove the refractory material on the surface of the nickel-based superalloy waste, and then clean and dry the waste nickel-based superalloy to obtain clean raw materials.

[0049] (2) Take 1000g of clean nickel-based superalloy material, 5000.0g of Mg-Bi binary alloy as the extraction medium, and the molar percentages of Mg and Bi in the Mg-Bi binary alloy are 90% and 10% respectively. The clean nickel-based superalloy is placed in a porous and liftable titanium mesh, the extraction medium is placed in a graphite crucible, and the...

Embodiment 2

[0052] The Ni-based superalloy waste to be recovered and separated in this embodiment includes Ni, Co, Fe, Mo, and Ta elements, wherein the mass percentage of Ni is 54.6%, and the mass percentage of Co is 9.3%.

[0053] combine figure 1 , The method for separating and recovering nickel and cobalt from nickel-based superalloy waste in this embodiment includes the following steps.

[0054] (1) Treat the surface of the nickel-based superalloy waste to remove the refractory material on the surface of the nickel-based superalloy waste, and then clean and dry the waste nickel-based superalloy to obtain clean raw materials.

[0055] (2) Take 900g of clean nickel-based superalloy material, 7200.0g of Mg-Sn binary alloy as the extraction medium, and the molar percentages of Mg and Sn in the Mg-Sn binary alloy are 70% and 30% respectively. The clean nickel-based superalloy is placed in a porous and liftable titanium mesh, the extraction medium is placed in a graphite crucible, and then...

Embodiment 3

[0058] The Ni-based superalloy waste to be recovered and separated in this embodiment includes Ni, Co, Fe, Mo, and Ta elements, wherein the mass percentage of Ni is 58.7%, and the mass percentage of Co is 10.4%.

[0059] combine figure 1 , The method for separating and recovering nickel and cobalt from nickel-based superalloy waste in this embodiment includes the following steps.

[0060] (1) Treat the surface of the nickel-based superalloy waste to remove the refractory material on the surface of the nickel-based superalloy waste, and then clean and dry the waste nickel-based superalloy to obtain clean raw materials.

[0061] (2) Take 800g of clean nickel-based superalloy material, 2400.0g of Mg-Pb binary alloy as the extraction medium, and the molar percentages of Mg and Pb in the Mg-Pb binary alloy are 80% and 20% respectively. Put the clean nickel-based superalloy in a porous and liftable titanium mesh, place the extraction medium in a magnesia crucible, then put the magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com