Method for regenerating active carbon after decoloration of glycin mother liquid

A technology of glycine mother and activated carbon, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of high cost of reaction devices, large amount of concentrated sulfuric acid, difficult recycling and other problems, and achieves low secondary pollution and high efficiency. Economic benefits and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

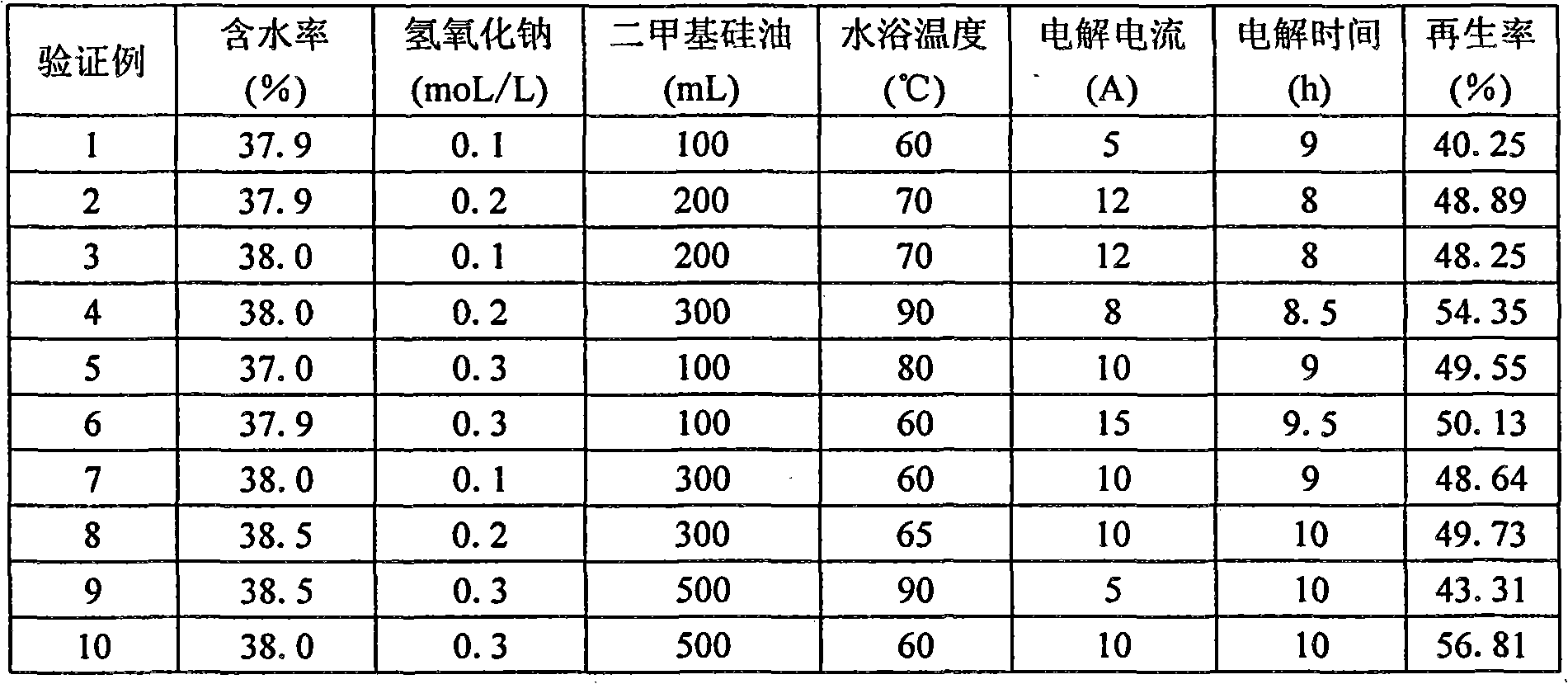

[0012] A method of activated carbon after regeneration glycine mother liquor decolorization, this method is electrochemical regeneration method, and it comprises the steps:

[0013] ①Put the undried waste activated carbon into the electrolytic cell, add NaOH solution and dimethyl silicone oil in sequence, part of the untreated waste activated carbon exists in the form of agglomerates, but the structure is loose, and it is easy to disperse when encountering liquid, so it can be Mix with added solution successively to form mixed slurry, wherein, the water content of waste activated carbon is 37.0~38.5%, the concentration of NaOH solution is 0.1~0.3mol / L, waste activated carbon: NaOH solution: simethicone=1kg: 10L: 100~500mL;

[0014] ②Then, put the electrolyzer into the water bath, insert two graphite electrode plates into the mixed slurry, the two plates face to face, and insert the bubbling air tube connected with the bubbler into the mixed slurry; wherein, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com