Hazard-free treatment system and method for electronic waste

A technology for electronic waste and treatment system, which is applied in the direction of electronic waste recycling, solid waste removal, combustion methods, etc. The effect of meeting environmental requirements and preventing spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

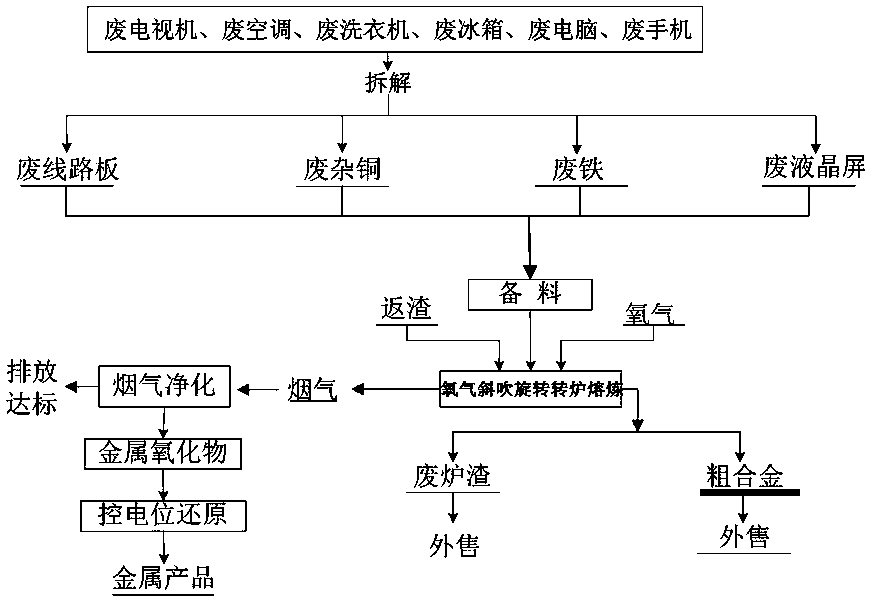

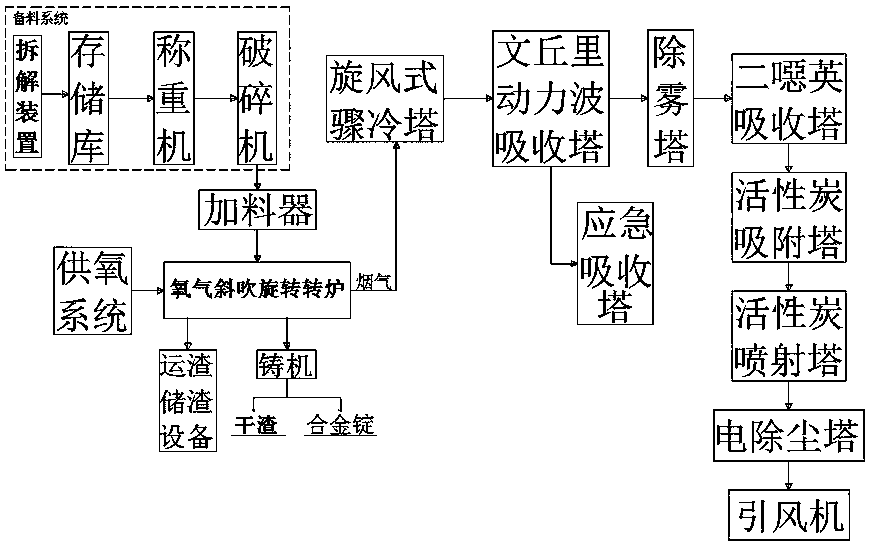

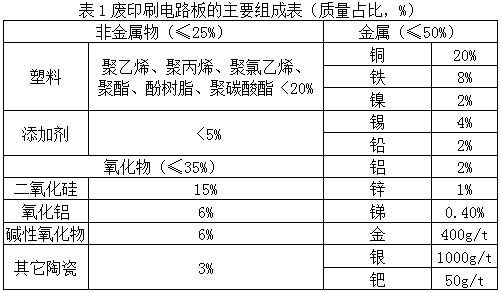

[0039] Example 1 of the treatment method: a treatment method for the harmless utilization of electronic waste. Electronic waste includes waste printed circuit boards, waste liquid crystal screens, waste miscellaneous copper, and scrap iron. , waste washing machines, waste air conditioners, waste computers, waste mobile phones, and waste MP3 players are dismantled, and the waste printed circuit boards, waste LCD screens, waste miscellaneous copper, and scrap iron obtained from dismantling are stored separately;

[0040] 2) Prepare materials

[0041] According to the mass ratio, waste printed circuit boards, waste liquid crystal screens, waste miscellaneous copper, and scrap iron are weighed and mixed according to the ratio of 56:4:35:5, and then crushed. In the feeder supporting the converter (a boat type feeder can be used);

[0042] 3) Feeding

[0043] Before the start of a production cycle, the oxygen oblique blowing rotary converter furnace is preheated to 950-1050°C. At ...

Embodiment 2

[0058] Example 2 of the treatment method: a treatment method for harmless utilization of electronic waste. Electronic waste includes waste printed circuit boards, waste liquid crystal screens, waste miscellaneous copper, and scrap iron. , waste washing machines, waste air conditioners, waste computers, waste mobile phones, and waste MP3 players are dismantled, and the waste printed circuit boards, waste LCD screens, waste miscellaneous copper, and scrap iron obtained from dismantling are stored separately;

[0059] 2) Prepare materials

[0060] According to the mass ratio, waste printed circuit boards, waste LCD screens, waste miscellaneous copper, and scrap iron are weighed and mixed according to the ratio of 55:3.5:34:4.5, and then crushed, and the crushed fragments are sent to the oxygen oblique blowing rotation In the feeder supporting the converter (a boat type feeder can be used);

[0061] 3) Feeding

[0062] Before the start of a production cycle, the oxygen oblique blo...

Embodiment 3

[0077] Example 3 of the treatment method: a treatment method for the harmless utilization of electronic waste. Electronic waste includes waste printed circuit boards, waste liquid crystal screens, waste miscellaneous copper, and scrap iron. , waste washing machines, waste air conditioners, waste computers, waste mobile phones, and waste MP3 players are disassembled, and the waste printed circuit boards, waste LCD screens, waste miscellaneous copper, and waste iron obtained from dismantling are stored separately

[0078] 2) Prepare materials

[0079] According to the mass ratio, waste printed circuit boards, waste LCD screens, waste miscellaneous copper, and scrap iron are weighed and mixed according to the ratio of 57:4.5:36:5.5, and then crushed, and the crushed scraps are sent to the oxygen oblique blowing rotation In the feeder supporting the converter (a boat type feeder can be used);

[0080] 3) Feeding

[0081] Before the start of a production cycle, the oxygen oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com