Acidification device and method of high-solid content dry livestock and poultry manure

A high solid content, pig manure technology, applied in the field of acidification equipment for livestock and poultry manure, can solve the problems of high solid content, poor fluidity, dry cleaning pig manure, etc., and achieve the effect of improving speed, improving capacity and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

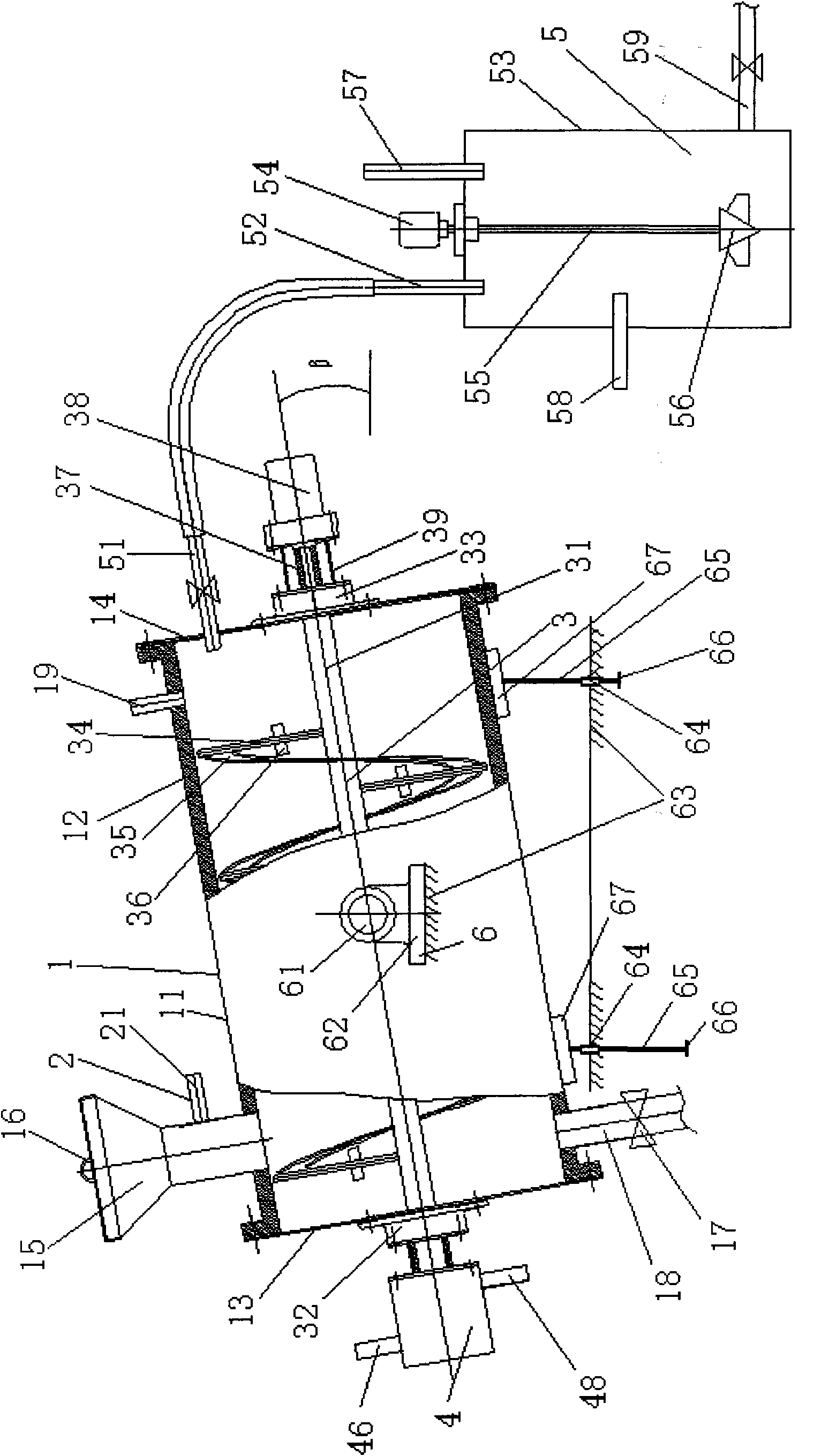

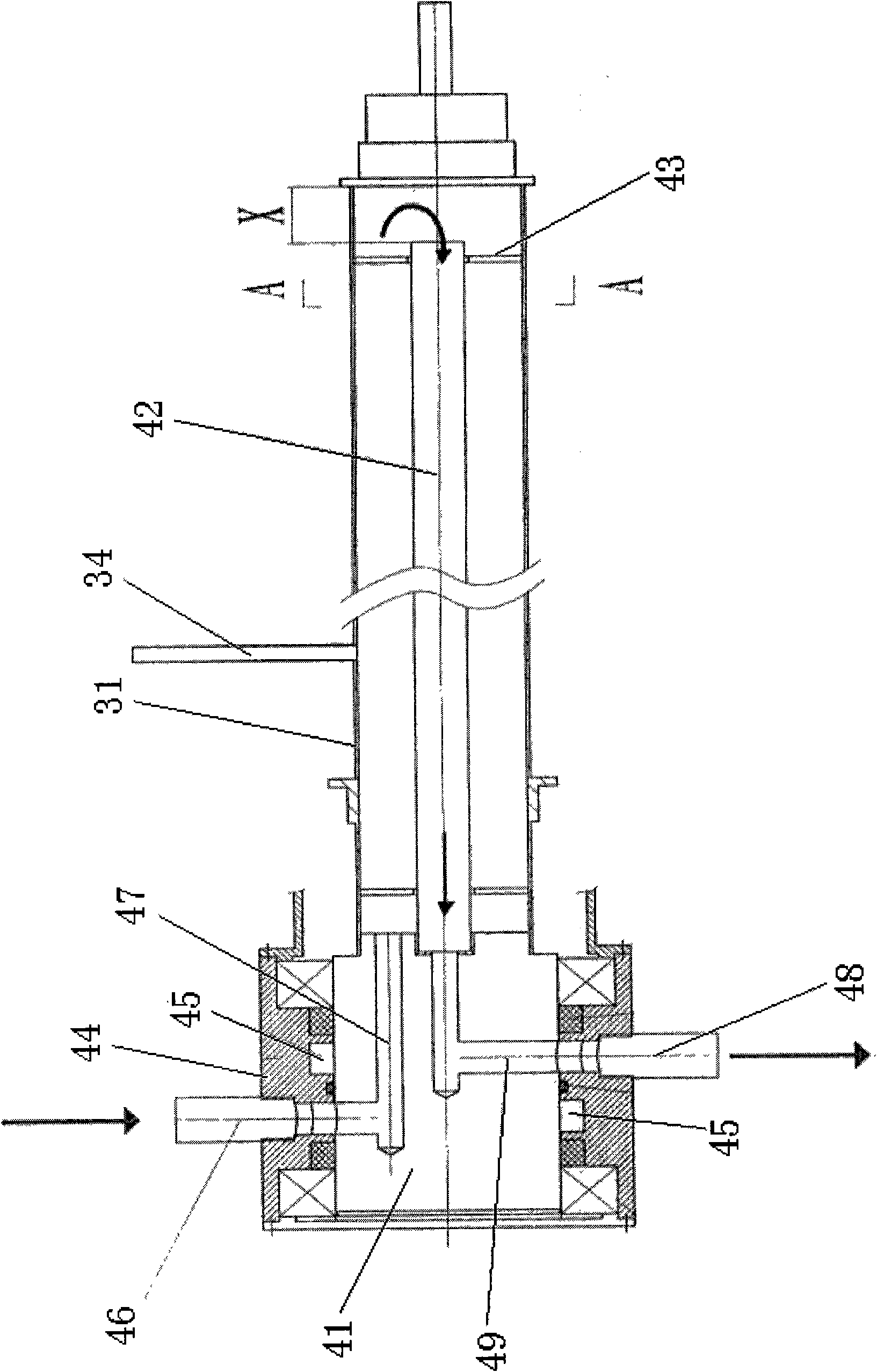

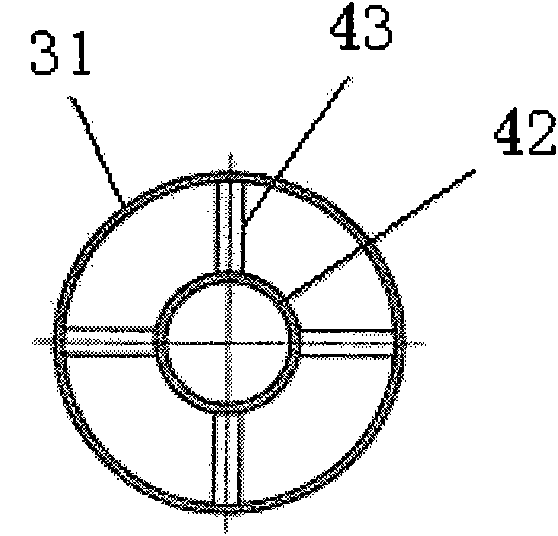

[0016] Such as figure 1 As shown, the device of the present invention includes a hydrolysis acidification reactor 1, a biogas slurry reflux flushing organic acid solution device 2, a stirring and squeezing mechanism 3, a hot water circulation heat transfer system 4, an acid solution collection and deployment system 5 and an acidification tank angle adjustment mechanism 6 .

[0017] The hydrolysis acidification reactor 1 of the present invention comprises a cylindrical acidification tank 11, on which an insulation layer 12 is arranged, one end of the acidification tank 11 is a feed end, and the other end is an acid discharge end. A flange 13 and a flange 14 are respectively provided at the feed end and the acid discharge end. A feed hopper 15 is arranged on the top of the acidification tank 11 near the feed end, and a sealing cover 16 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com