Device for preparing biogas by continuous treatment of straw and livestock and poultry feces and biogas preparation method

A biogas device, livestock and poultry manure technology, applied in biochemical equipment and methods, biological material sampling methods, biomass post-processing, etc., can solve problems such as water pollution, air pollution, uncleanness, etc., and achieve low equipment investment , organic fertilizer with high fertilizer efficiency and low processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

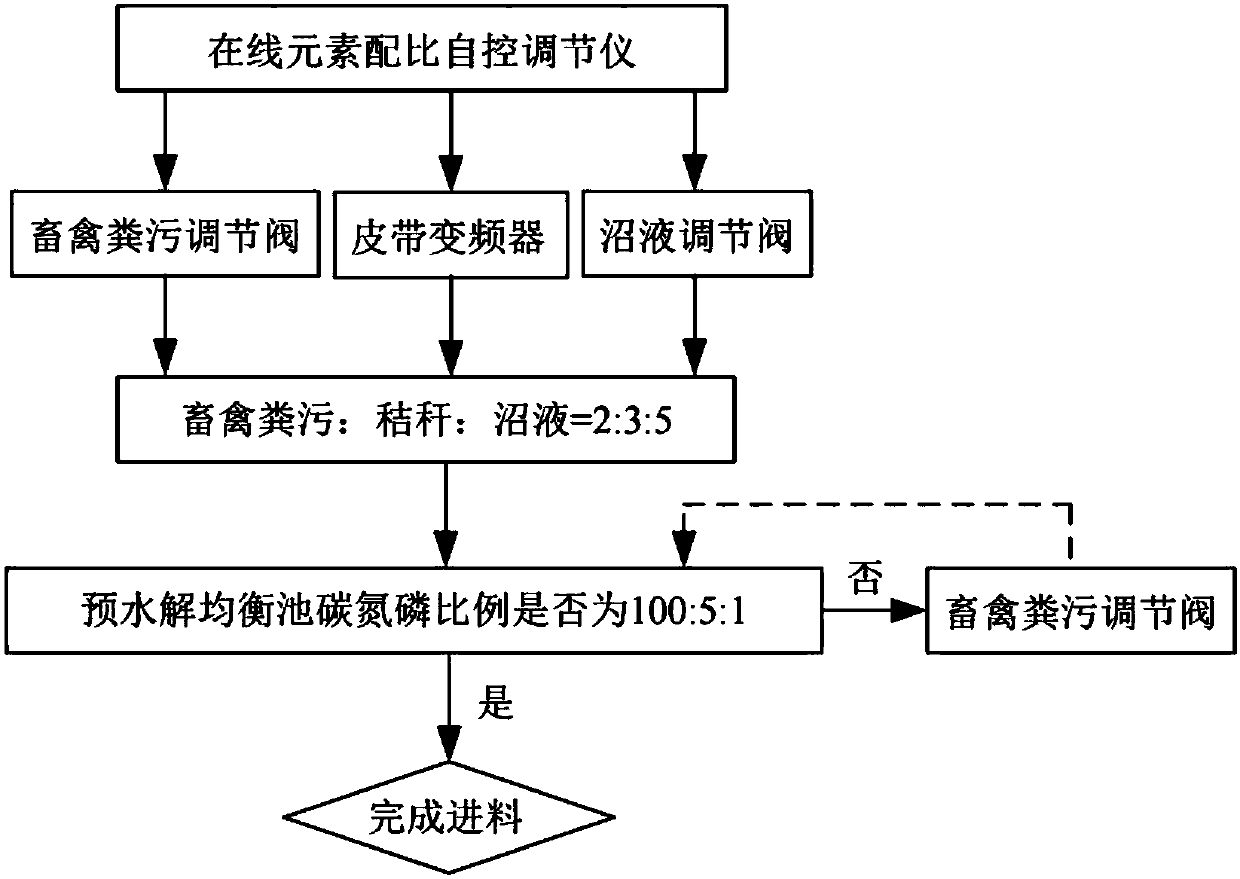

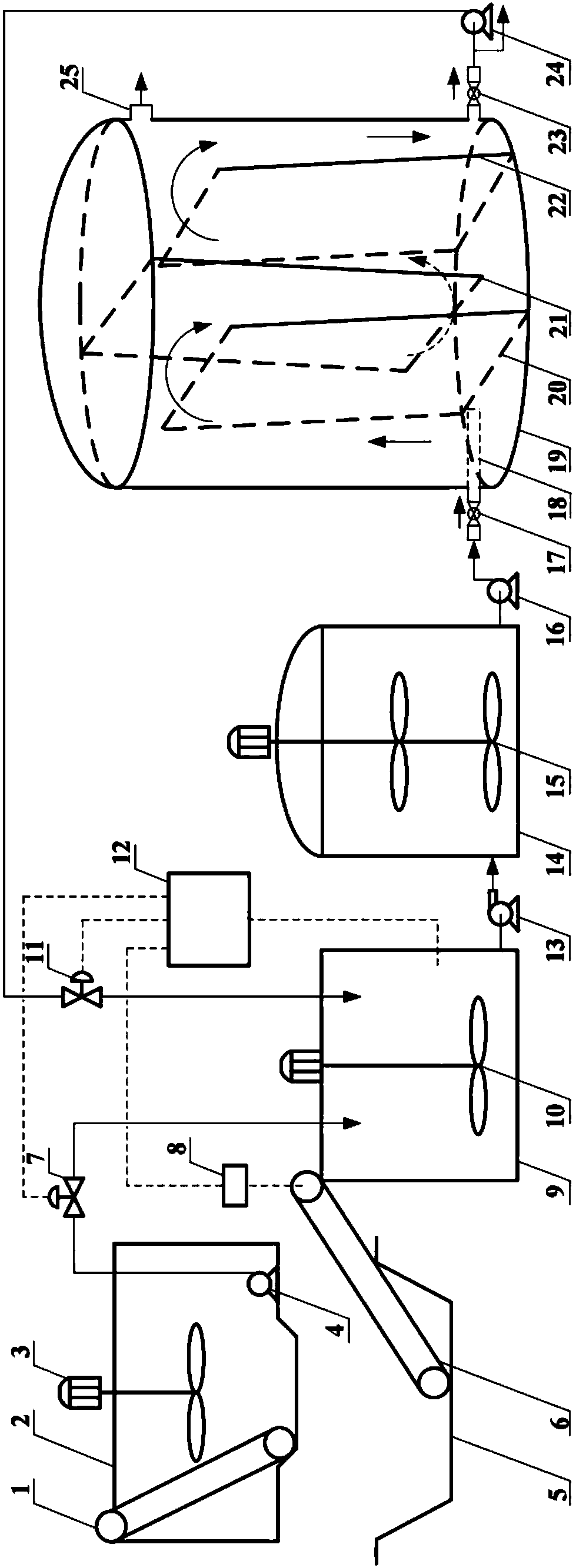

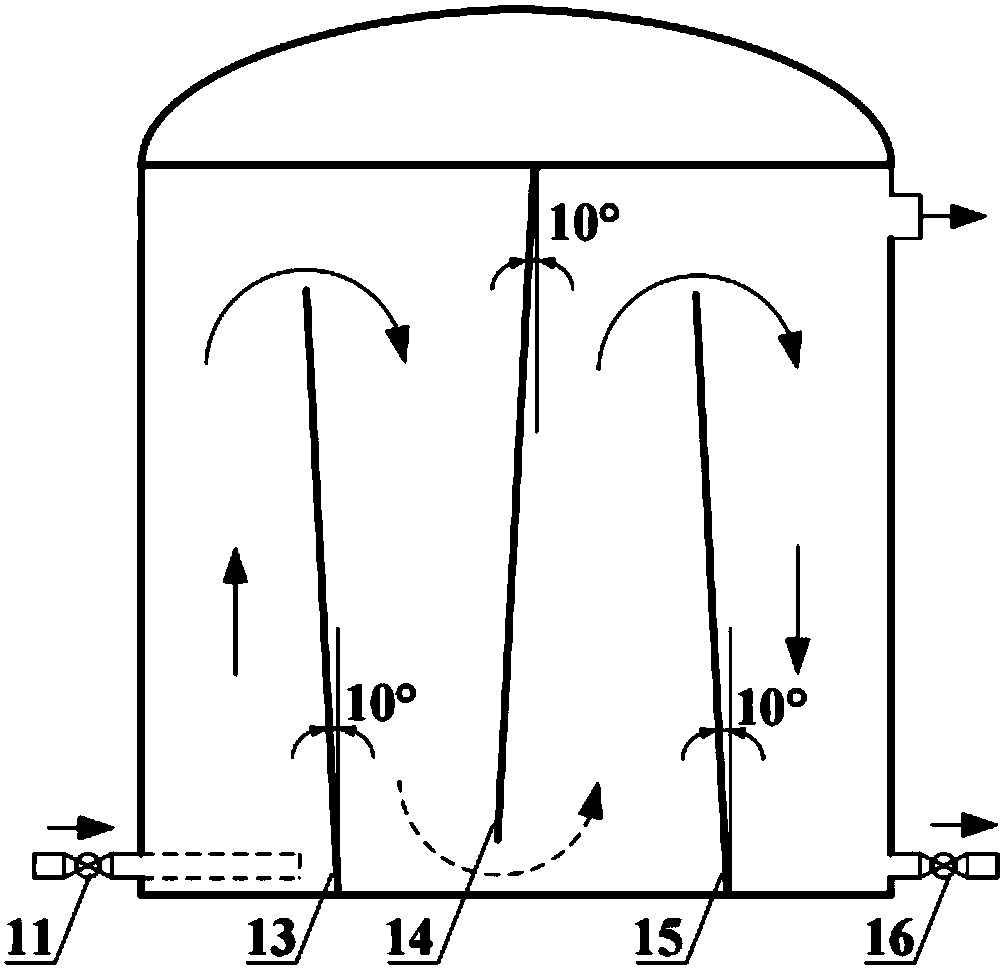

[0044] combined with Figures 1 to 5 The specific embodiments of the present invention are further described:

[0045] Continuous processing of straw and livestock and poultry manure to prepare biogas device, including sedimentation sand removal tank 2, straw silage tank 5, pre-hydrolysis equalization tank 9, feed buffer tank 14, anaerobic fermentation tank 19, the sedimentation sand removal tank, straw The silage tanks are respectively connected to the pre-hydrolysis equalization tank, the pre-hydrolysis equalization tank is connected to the feed buffer tank, the feed buffer tank is connected to the feed port of the anaerobic fermentation tank, and the outlet at the bottom of the anaerobic fermentation tank is connected to the pre-hydrolysis balance tank. A biogas outlet 25 is provided on the top of the fermenter.

[0046] The anaerobic fermentation tank is provided with a first inclined accelerating deflector 20, a second inclined accelerating deflector 21, and a third incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com