Method and device for producing bio-gas by organic waste

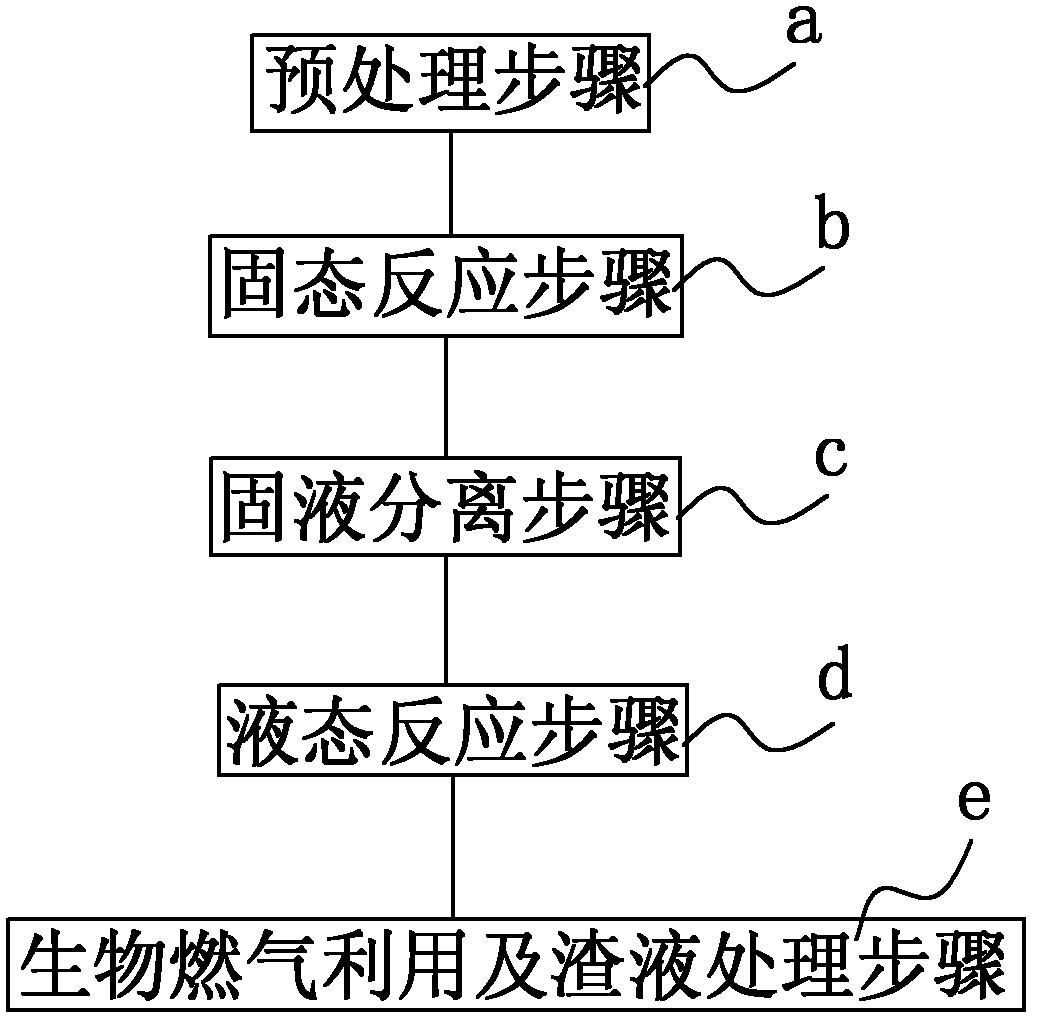

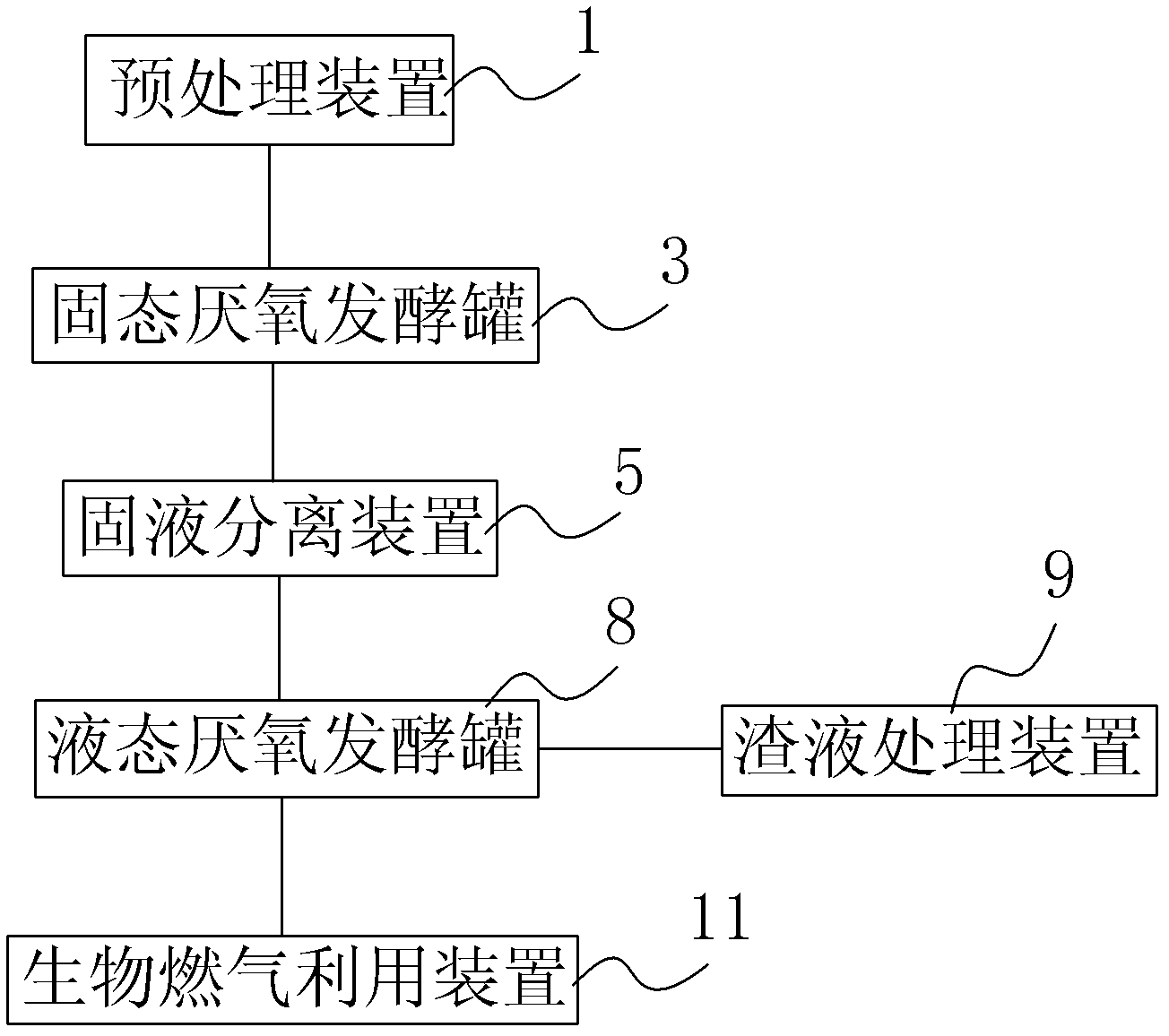

A technology of organic waste and biogas, applied in biochemical equipment and methods, gas production bioreactors, liquid production bioreactors, etc., can solve the problems of low pollution load, complex system composition, high pollution load, etc., and achieve biogas The liquid production is small, the system adaptability is good, and the effect of energy saving and emission reduction can be met

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

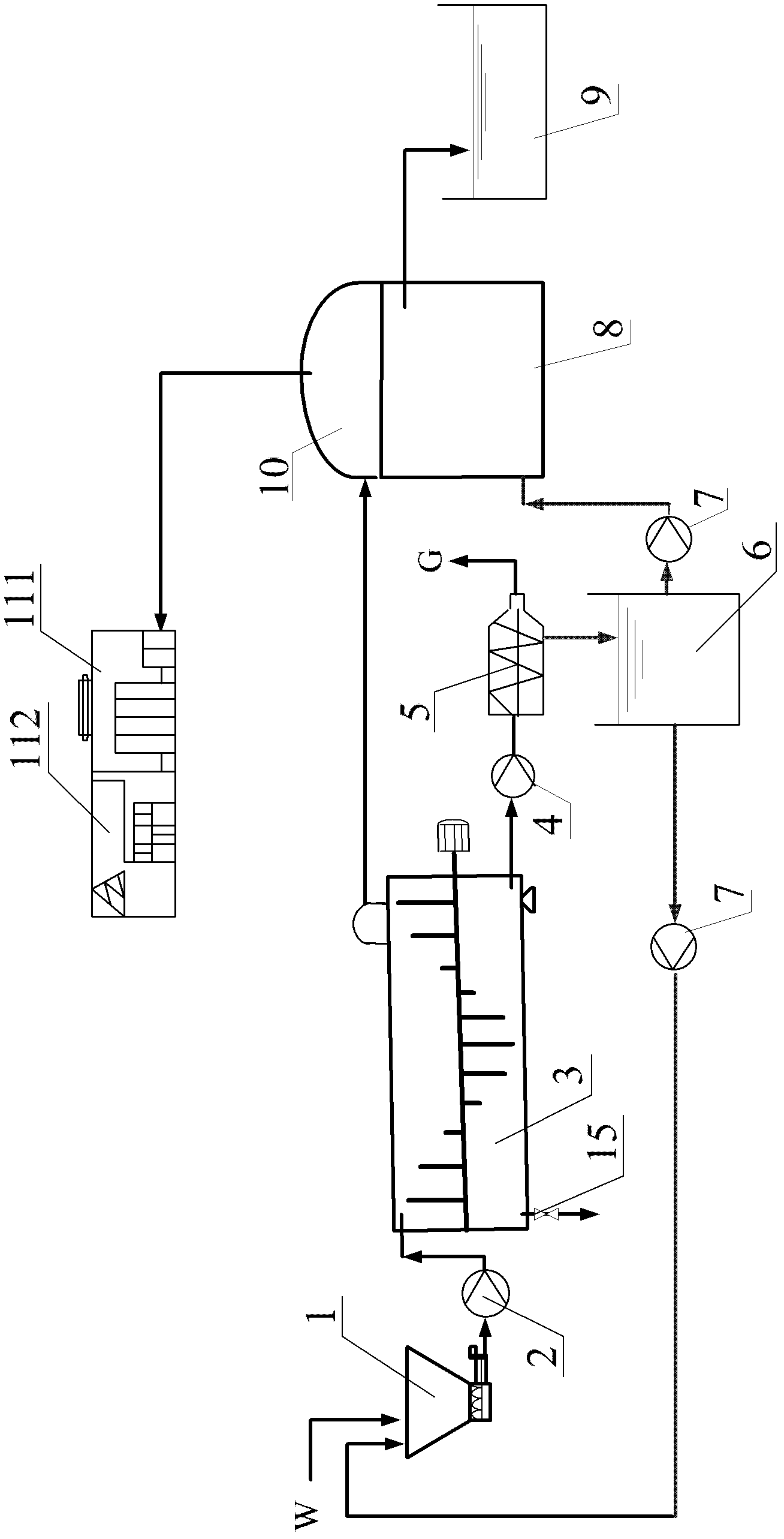

[0078] The raw material is dried cow manure collected from dairy farms, and the dry matter content is 18% to 23%.

[0079] (1) After the raw material is properly heated by aerobic retting, it is sent to the pretreatment device 1, and after preheating, inoculation and mixing, it is sent to the first-stage solid-state anaerobic fermentation tank 3 by the rotor cam pump 2 . The inoculum is the leachate from the leachate buffer tank 6, and the mass ratio of the inoculum to the incoming material is 1:2.

[0080] (2) The first-stage solid-state fermenter 3 is an anaerobic fermenter with horizontal propeller shaft mechanical stirring. The material enters the tank body 23 from the feed port 13, is stirred and pushed by the propeller blade shaft 19, and gradually advances to the reactor discharge port 14 as time goes by. The blades 20 on the propeller blade shaft 19 are arranged in a helical line, and the radial angle α is 90°. The first-stage solid-state fermentation adopts medium-t...

Embodiment 2

[0087] The raw material is municipal waste.

[0088] (1) Mechanically sort municipal waste, recycle metals, plastics, etc., and remove inert substances such as glass and stones as much as possible to obtain organic municipal waste.

[0089] (2) Crushing the organic municipal waste to crush the material particles to within 40 mm; adding the biogas slurry in the liquid storage tank of the slag liquid treatment device 9 to adjust the moisture content of the material to 65%-70%.

[0090] (3) After being preheated, inoculated and mixed in the pretreatment device 1, the material is sent to the first-stage solid anaerobic fermentation tank 3 by the rotor cam pump 2. The inoculum is the leachate from the leachate buffer tank 6, and the mass ratio of the inoculum to the incoming material is 1:1.

[0091] (4) The first-stage solid-state fermenter 3 is an anaerobic fermenter with horizontal propeller blade shaft mechanical stirring. The material enters the fermenter tank body 23 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com