Method for efficiently and cleanly disposing solid organic wastes

A solid waste and clean treatment technology, which is applied in the preparation of organic fertilizers, organic fertilizers, waste fuels, etc., can solve the problems of nitrogen nutrient loss and other problems, achieve growth and reproduction, high volumetric gas production rate, and improve recycling The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The equipment used in this embodiment includes a photobioreactor, a composting reaction tank, a biogas generator, and a boiler.

[0029] There are 6 composting reaction tanks used, which are connected in series with photobioreactors, each 10m 3 , can load 6m 3 . The photobioreactor used is a light-transmitting, airtight glass container, and three photobioreactors are connected in series as a group. A biogas generator and a combustion device (boiler) are connected in series between the light bioreactor and the composting reaction tank.

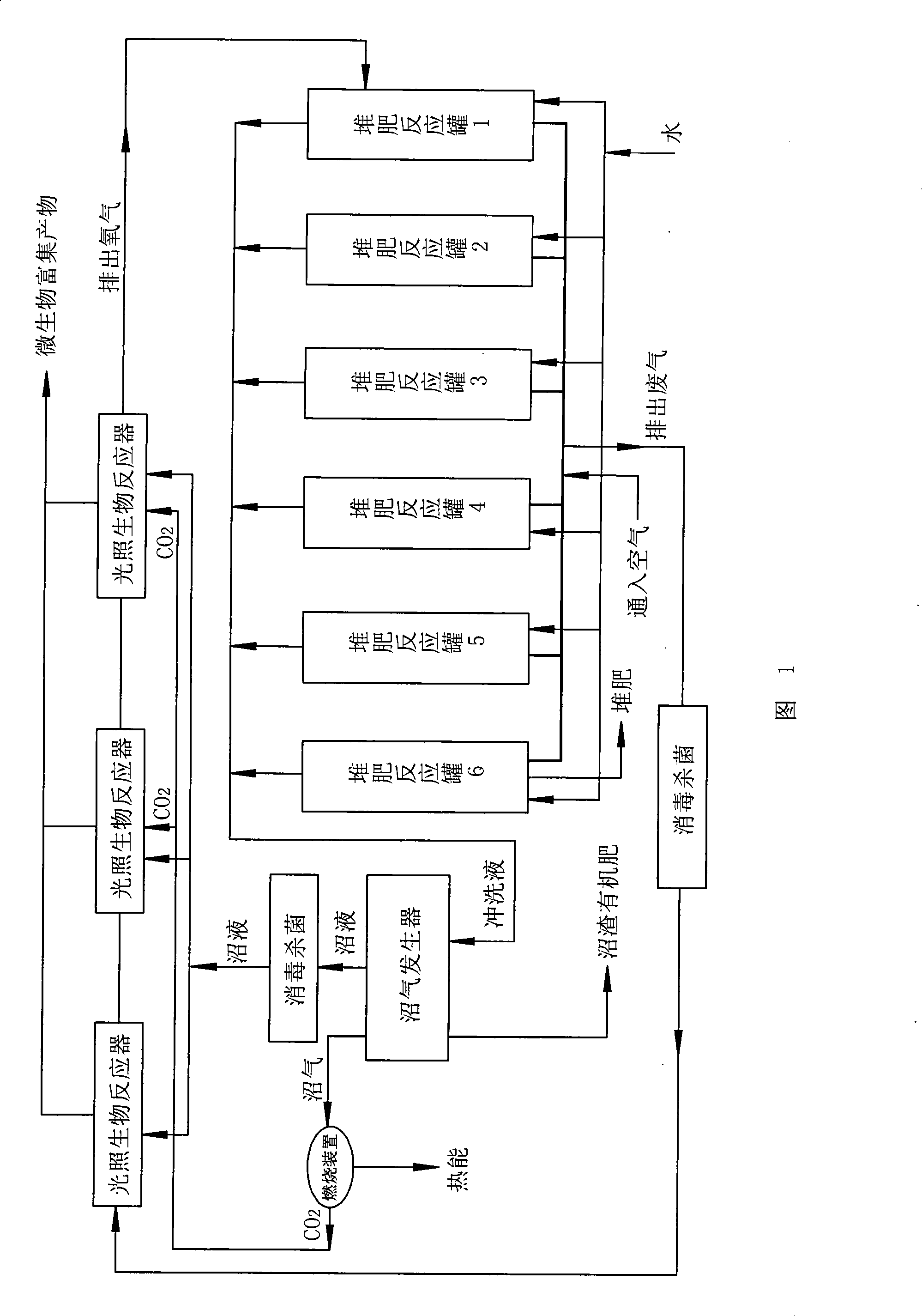

[0030] The process flow is shown in Figure 1, and the specific method is as follows:

[0031]a> Crush the straw into granules of about 10mm, add pig manure according to the weight ratio of 1:1, adjust the carbon-nitrogen ratio (to control the carbon-nitrogen ratio within 20-40:1), add compost after mixing In the reaction tank, air is passed into the composting reaction tank for 1 hour at an interval of 1 hour, and the ventilation rat...

Embodiment 2

[0034] The equipment used in this embodiment includes a photobioreactor and a composting reaction tank.

[0035] The three photobioreactors in this embodiment are connected in series as one group. The carbon dioxide gas produced by the composting reactor is passed into three photobioreactors respectively through the diversion pipe to provide carbon sources for the growth and reproduction of phototrophic microorganisms. Oxygen produced during the photobiological reaction is returned to the composting tank to provide the composting reaction. Process flow with reference to Fig. 1.

[0036] Concrete process steps are:

[0037] a> Crush the straw into granular matter of about 20mm, add cow dung to adjust the carbon-nitrogen ratio according to the weight ratio of 1:1.2 (to keep the carbon-nitrogen ratio within 20-40:1), add compost after mixing In the reaction tank, the air is fed into the reaction tank for 1.5 hours at intervals of 2 hours, the ventilation rate is 100 liters per...

Embodiment 3

[0042] There is one photobioreactor and one composting reaction tank in this embodiment. The process flow can refer to Figure 1.

[0043] Concrete process steps are:

[0044] a> Crush the bean cake into granular substances of about 10 mm, add rice straw to adjust the carbon-nitrogen ratio (to keep the carbon-nitrogen ratio within 20-40:1), mix it and put it into the composting reaction tank, and pass it continuously at the initial stage of operation Air, ventilation volume controlled at 1.0g O 2 / g organic matter——4.0g O 2 g between organic matter. Ferment for 10 days to form compost.

[0045] b> put chlorella and macroalgae in photobioreactor, add anaerobic sludge leaching solution (this solution can be purchased from the market), control the water temperature at 25-30°C, and let it stand for 36-40 hours.

[0046] c> The gas (mainly carbon dioxide) discharged from the composting tank is sterilized and transported to the photobioreactor; when the dry matter concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com