Automatic stacking device of iron core shearing production line

A production line and automatic technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of difficult to realize large-scale pick and place of sheet materials, high labor intensity of workers, low degree of automation, etc., to achieve structural Simple, small footprint and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

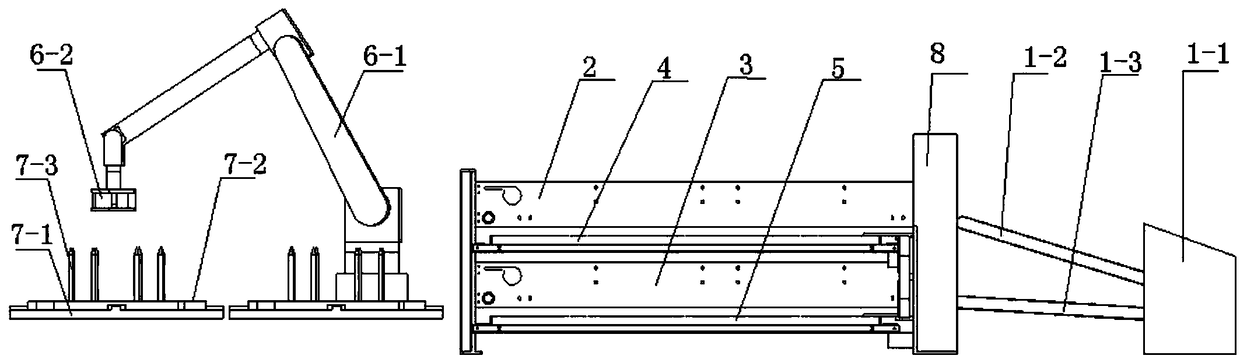

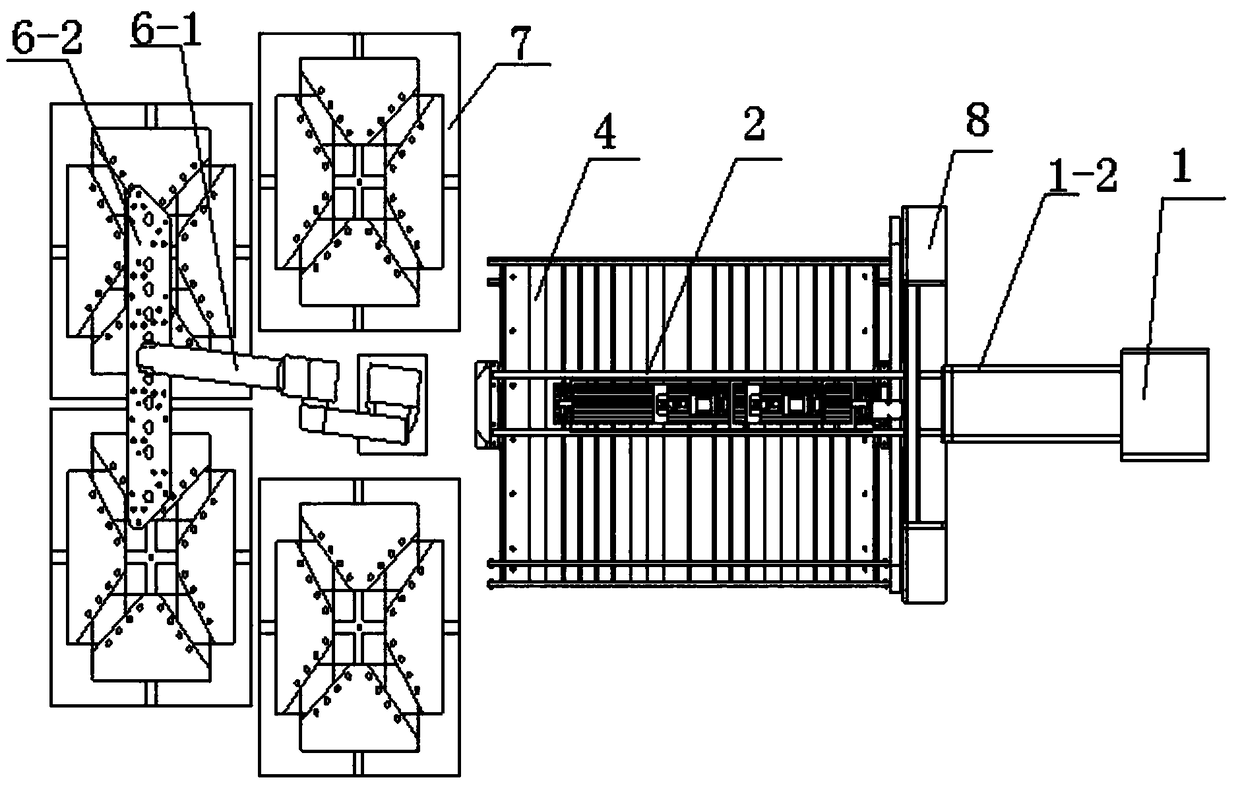

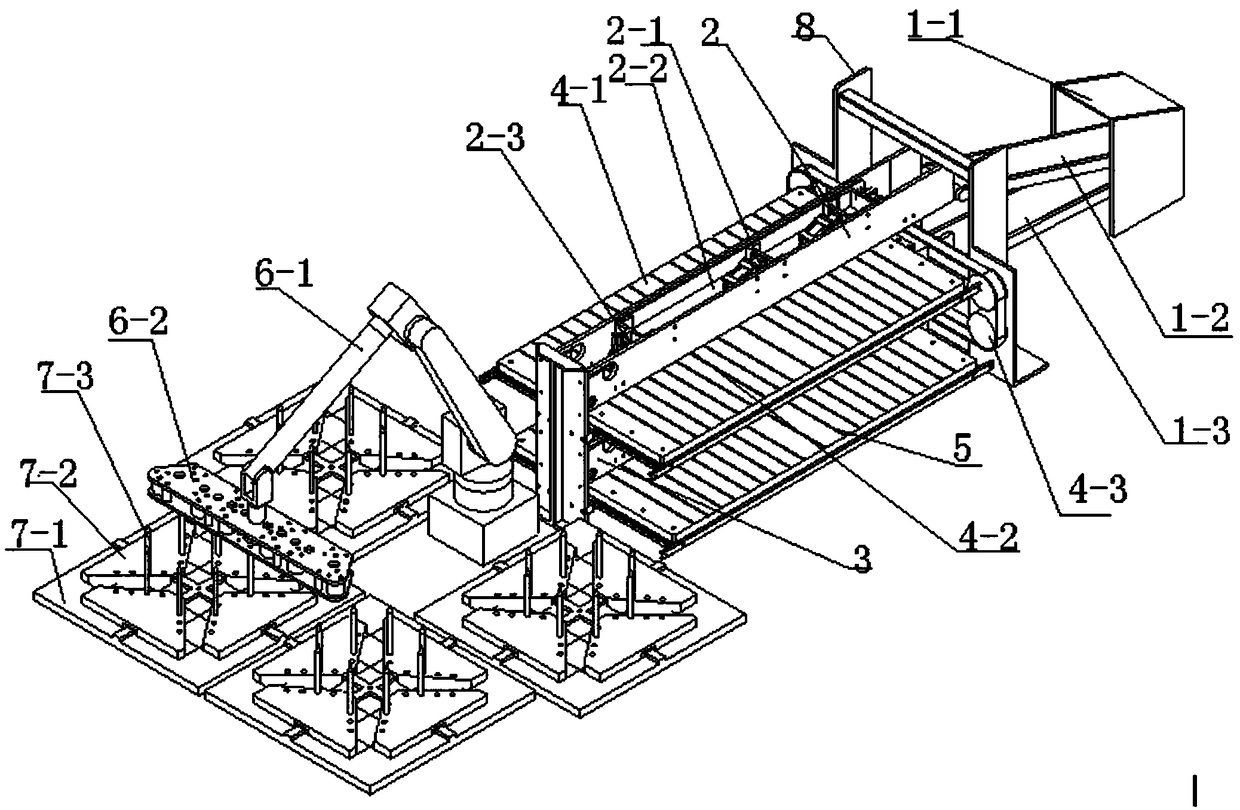

[0020] An automatic stacking device for an iron core shearing production line, including a frame body 8, and at least a material distribution device 1, an upper layer conveying device 2, a lower layer conveying device 3, an upper layer receiving platform 4, a lower layer receiving platform 5, a stacking The robot hand 6 and the multi-station stacking platform 7, the upper conveying device 2, the upper material receiving platform 4, the lower conveying device 3 and the lower material receiving platform 5 are sequentially connected to the frame body 8 from top to bottom, and the right side of the frame body 8 The side is connected to the material distribution device 1 and the output end of the material distribution device 1 is respectively connected to the input end of the upper layer conveying device 2 and the input end of the lower layer conveying device 3. The left side of the frame body 8 is provided with a stacking robot 6 and a multi-station stacking machine. The platform 7...

Embodiment 2

[0022] like Figure 1-3 As shown, an automatic stacking device for an iron core shearing production line includes a frame body 8, and at least includes a material distribution device 1, an upper layer conveying device 2, a lower layer conveying device 3, an upper layer receiving platform 4, and a lower layer receiving platform 5 , the stacking robot arm 6 and the multi-station stacking table 7, the upper conveying device 2, the upper material receiving platform 4, the lower conveying device 3 and the lower material receiving platform 5 are sequentially connected on the frame body 8 from top to bottom, and the frame body The right side of 8 is connected to the material distribution device 1 and the output end of the material distribution device 1 is respectively connected to the input end of the upper layer conveying device 2 and the input end of the lower layer conveying device 3, and the left side of the frame body 8 is provided with a stacking robot arm 6 and a multiplexer. ...

Embodiment 3

[0025] The material distribution device 1 at least includes a material distribution flap 1-1, an upper belt conveyor 1-2 and a lower belt conveyor 1-3, and the material distribution flap 1-1 is respectively connected to the input of the upper belt conveyor 1-2. and the input end of the lower belt conveyor 1-3, the output end of the upper belt conveyor 1-2 is connected to the input end of the upper conveyor 2, and the output end of the lower belt conveyor 1-3 is connected to the input end of the lower conveyor 3 . The material distribution flap 1-1 of the material distribution device 1 divides the sheet material into upper and lower layers according to the sheet shape. The belt conveyor 1-3 transports the sheet material to the lower conveying device 3, which has a high degree of automation.

[0026] Described upper conveying device 2 and lower conveying device 3 all at least comprise conveying belt conveyor 2-1, movable magnetic plate 2-2 and positioning signaling switch 2-3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com